Modular assembly type vehicle frame for AGV robot

A modular and assembled technology, applied in manipulators, vehicle parts, transportation and packaging, etc., can solve the problems of low maintenance efficiency, troublesome disassembly and assembly of parts, etc., and achieve the effect of reducing maintenance cost, good practicability and friendly application environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

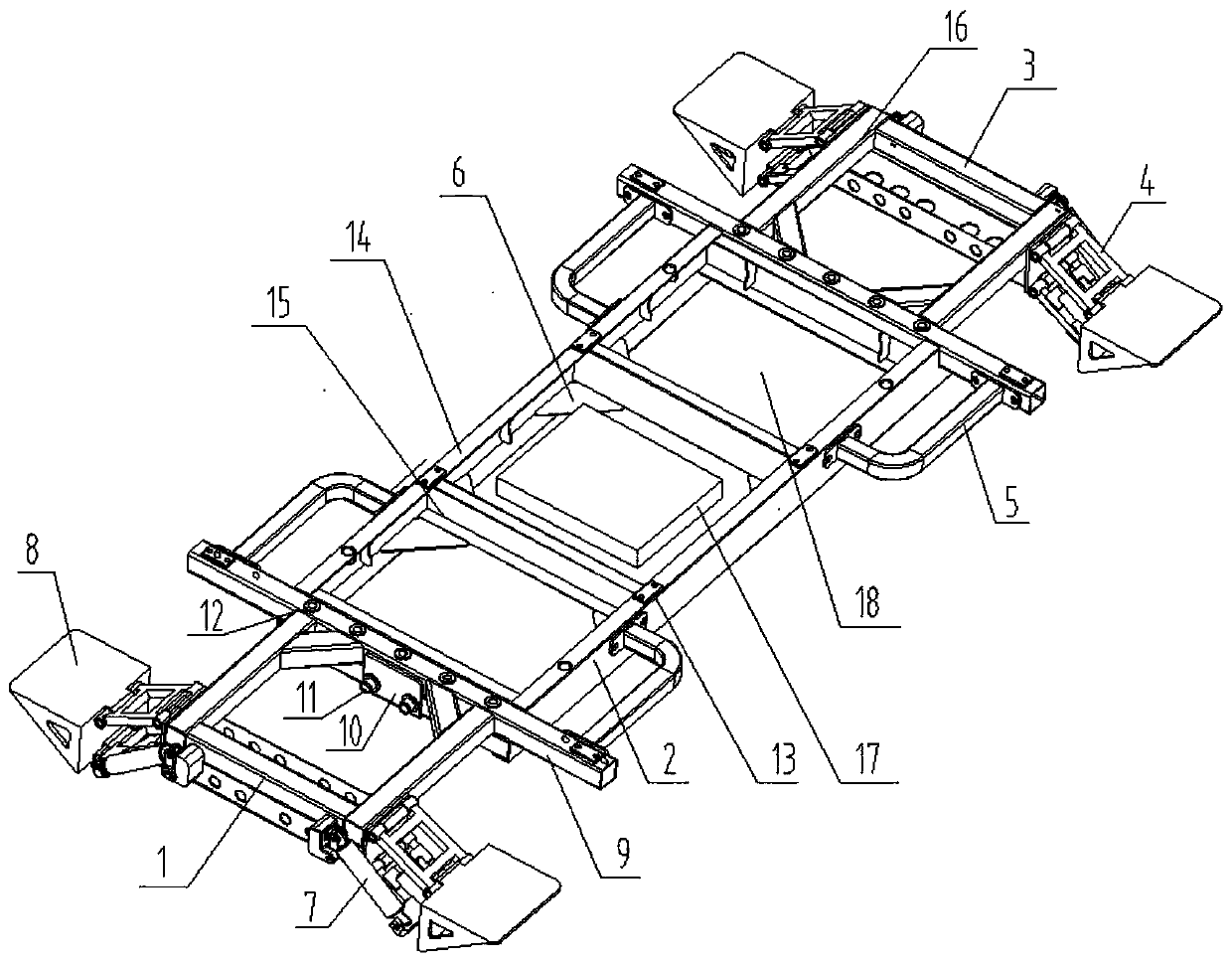

[0011] The modular assembled frame for AGV robots involved in this embodiment includes a body 2 and a front 1 and a rear 3 arranged at the front and rear ends of the body 2. The front 1 and the rear 3 adopt the same structure. The front 1, the body 2 and the rear 3 are connected in a splicing manner. When any part fails, only the faulty part needs to be removed and the spare non-faulty parts are replaced to complete the repair, so that the repair can be completed as soon as possible. The AGV robot is put into use again, and the faulty parts are repaired; the main structure of the body 2 includes: reinforcement beam 5, equipment carrier plate 6, load-bearing pad 13, vertical beam 14 and cross beam 15, attitude control system 17 and power supply 18. ; Four parallel beams 15 and vertical beams 14 on the left and right sides of the beam 15 constitute a mesh-shaped truss structure, used as the main load-bearing structure of the body 2, and the two beams 15 in the middle are in contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com