Distributed optical fiber-based blast furnace hot blast stove temperature monitoring system and method

A distributed optical fiber and monitoring system technology, applied in the direction of physical/chemical changes in thermometers, thermometers, measuring devices, etc., can solve the problems of unfavorable promotion of infrared thermal imaging temperature measurement technology, expensive movement, and high air dust concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

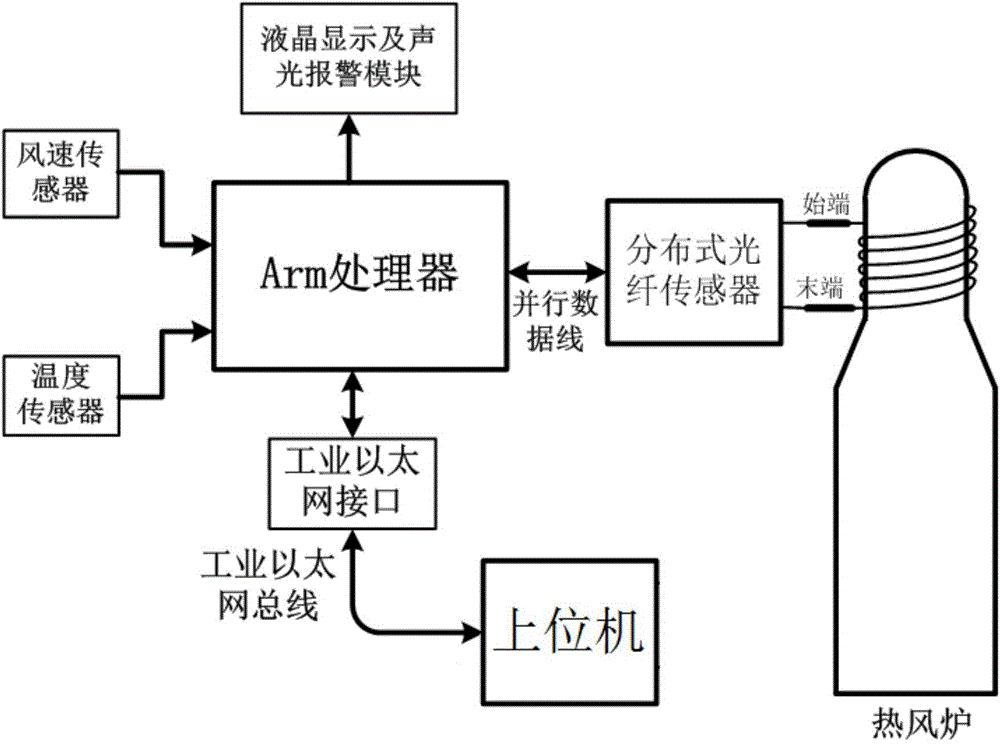

[0045] see figure 1 , a kind of blast furnace hot stove temperature monitoring system based on distributed optical fiber of the present embodiment, comprises host computer, ARM processor, display and alarm module (ie figure 1 liquid crystal display and sound and light alarm module), wind speed sensor, temperature sensor, distributed optical fiber sensor and distributed optical fiber. The ends are all connected to the distributed optical fiber sensor, the distributed optical fiber sensor is connected to the ARM processor through the parallel data line, and the ARM processor is connected to the upper computer through the industrial Ethernet interface, and the ARM processor is also connected to the wind speed sensor, temperature The sensor, display and alarm module are electrically connected. The wind speed sensor is used to detect the wind speed (air convection velocity) outside the hot blast stove. The temperature sensor is used to detect the ambient temperature outside the hot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com