Patents

Literature

38results about How to "Effective online monitoring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cigarette factory superspeed carton packaging machine multi-condition process online monitoring and fault diagnosis method

ActiveCN105573290AImprove monitoring resultsEffective online monitoringProgramme controlElectric testing/monitoringSliding time windowUltra high speed

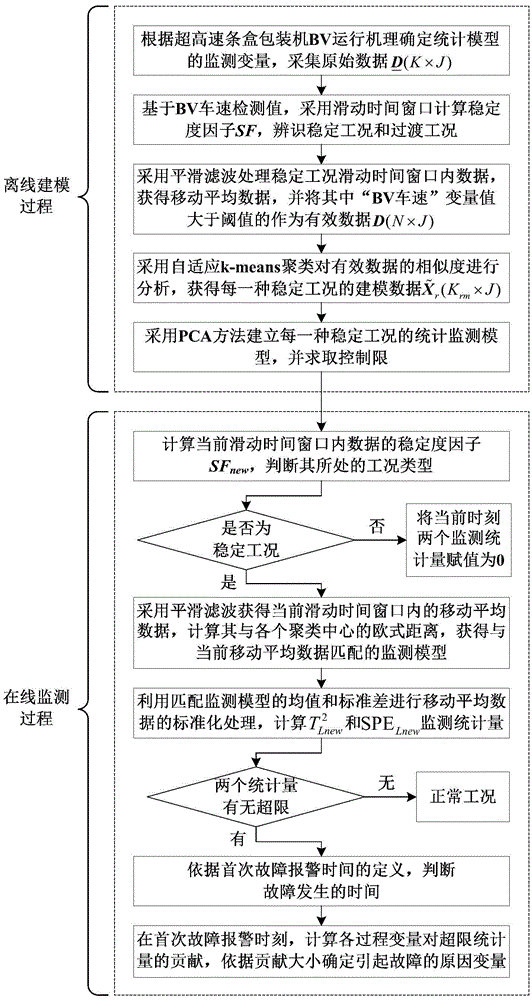

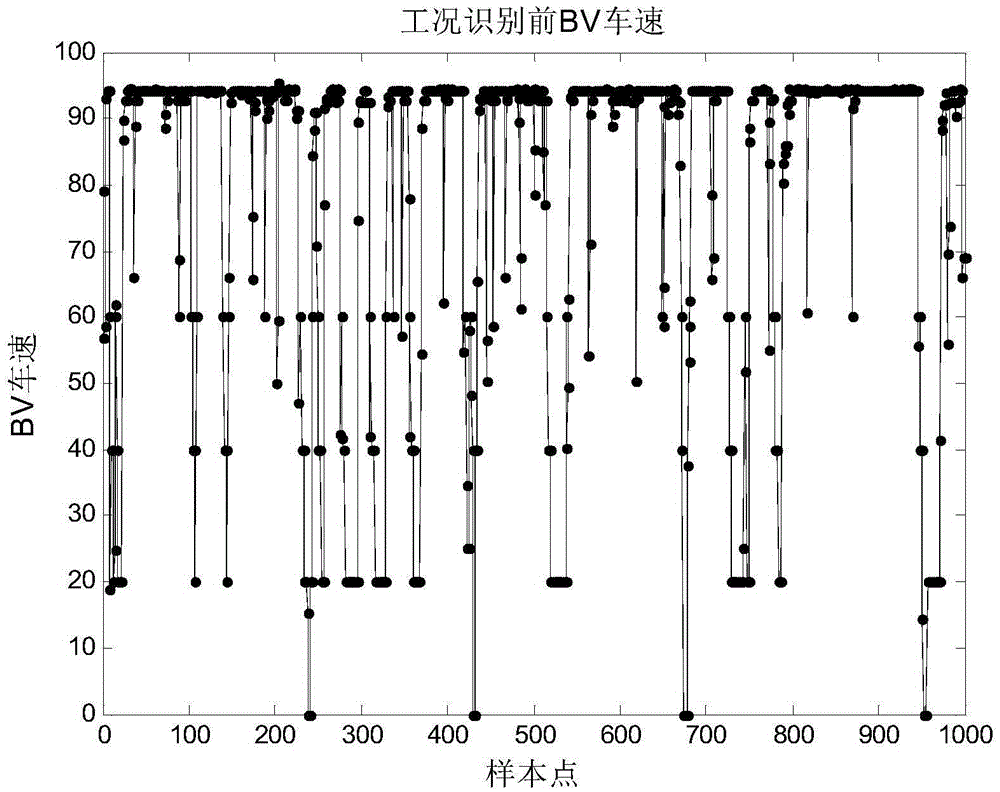

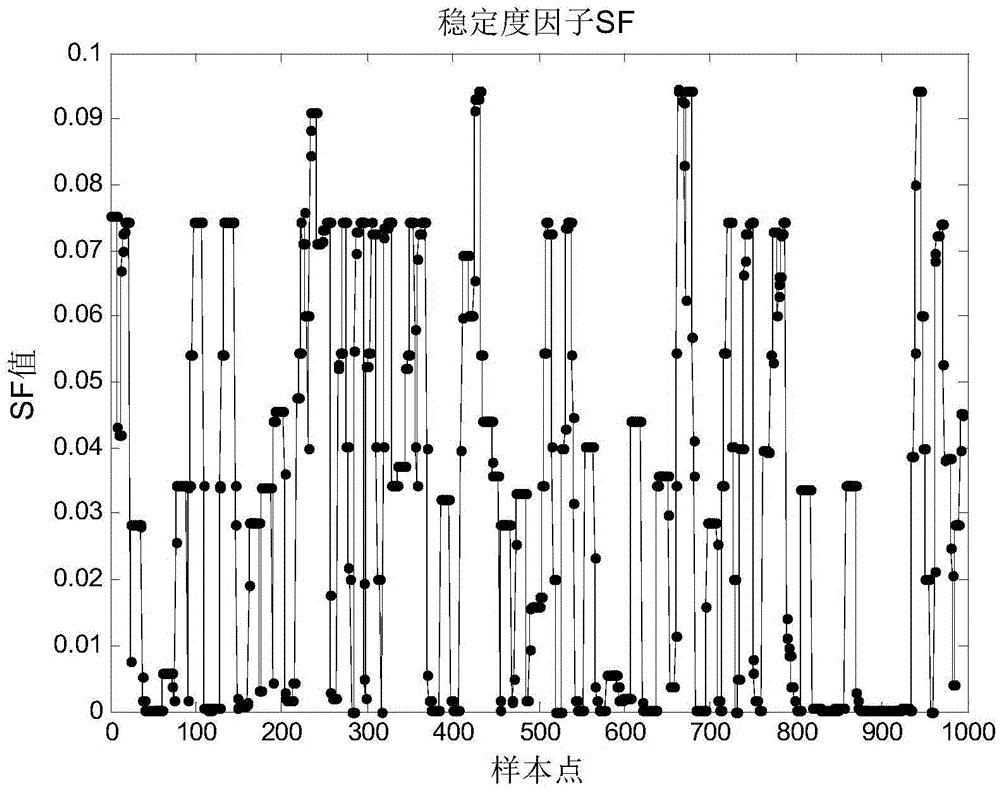

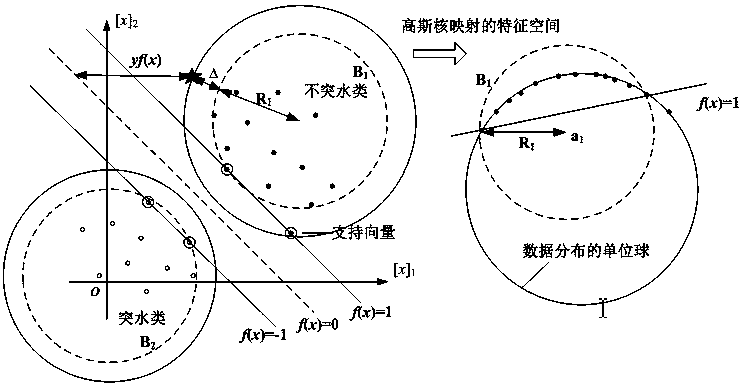

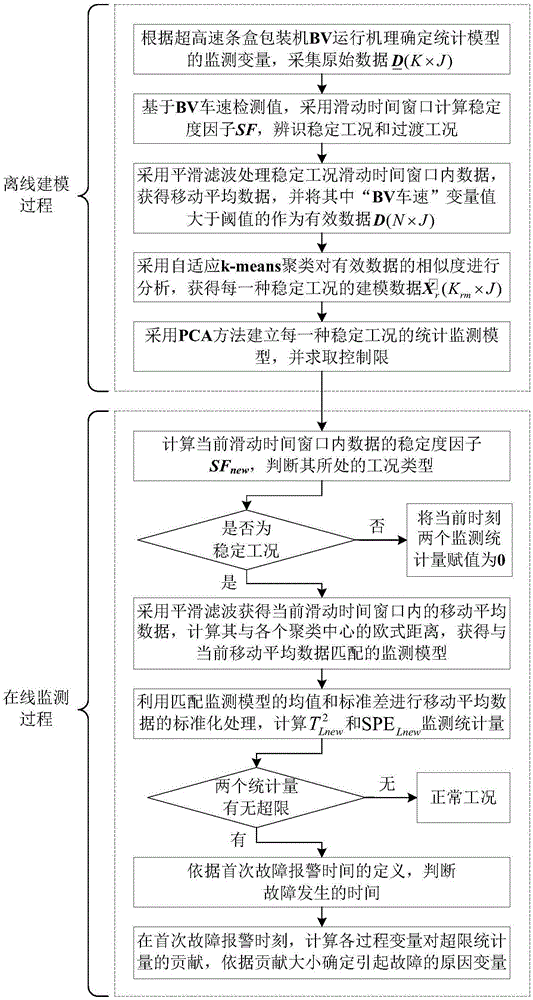

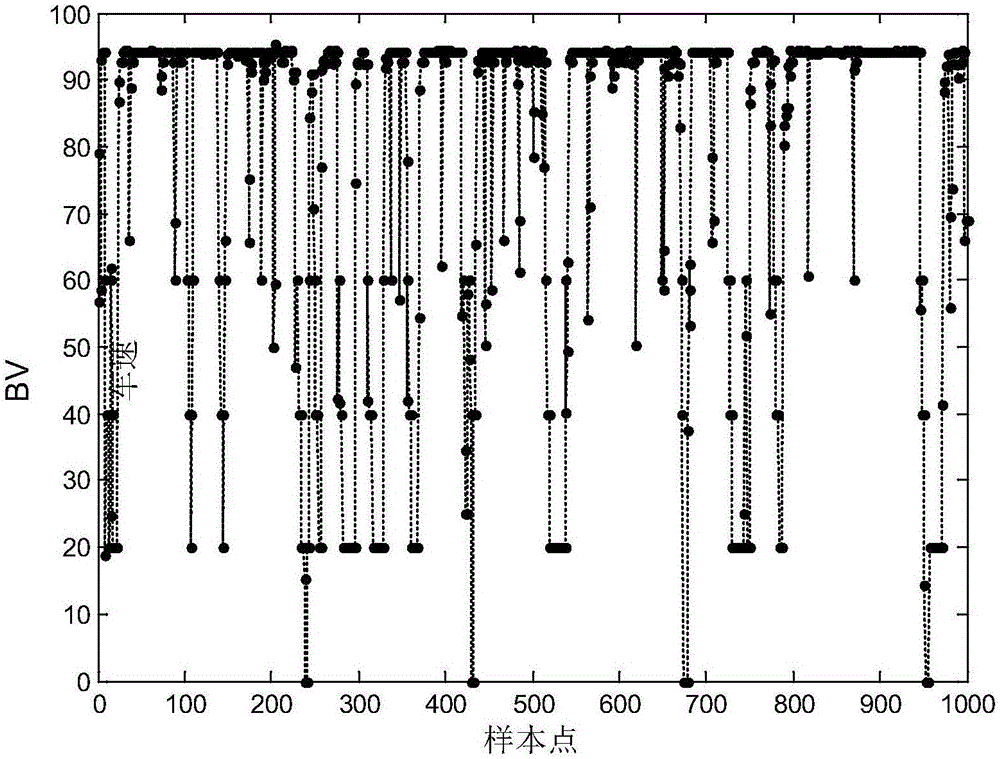

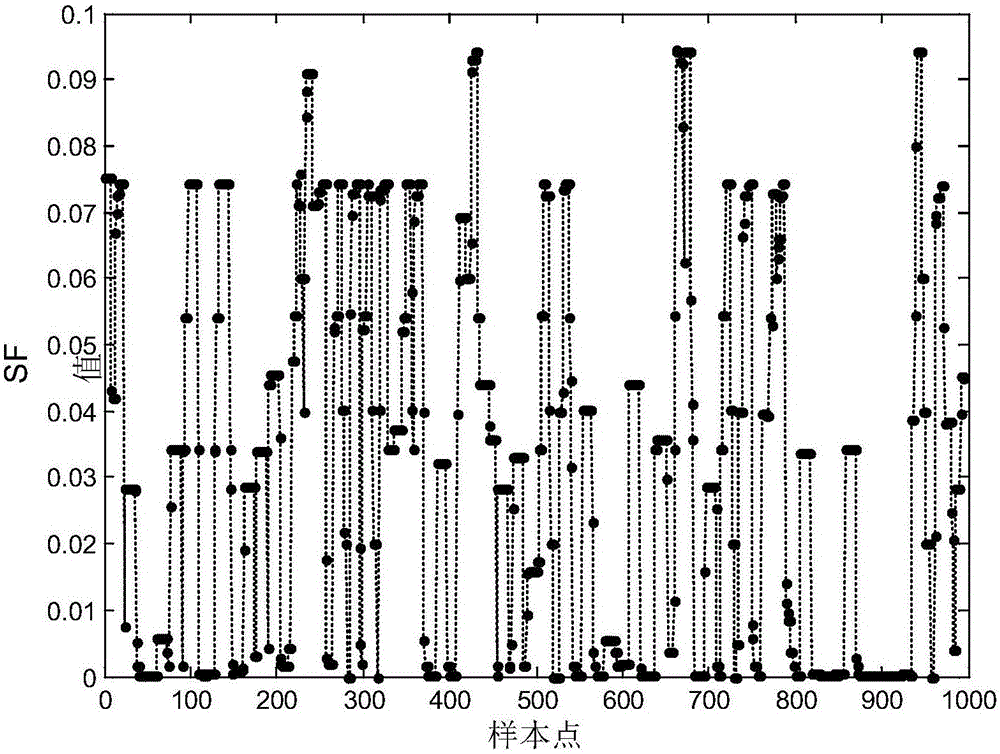

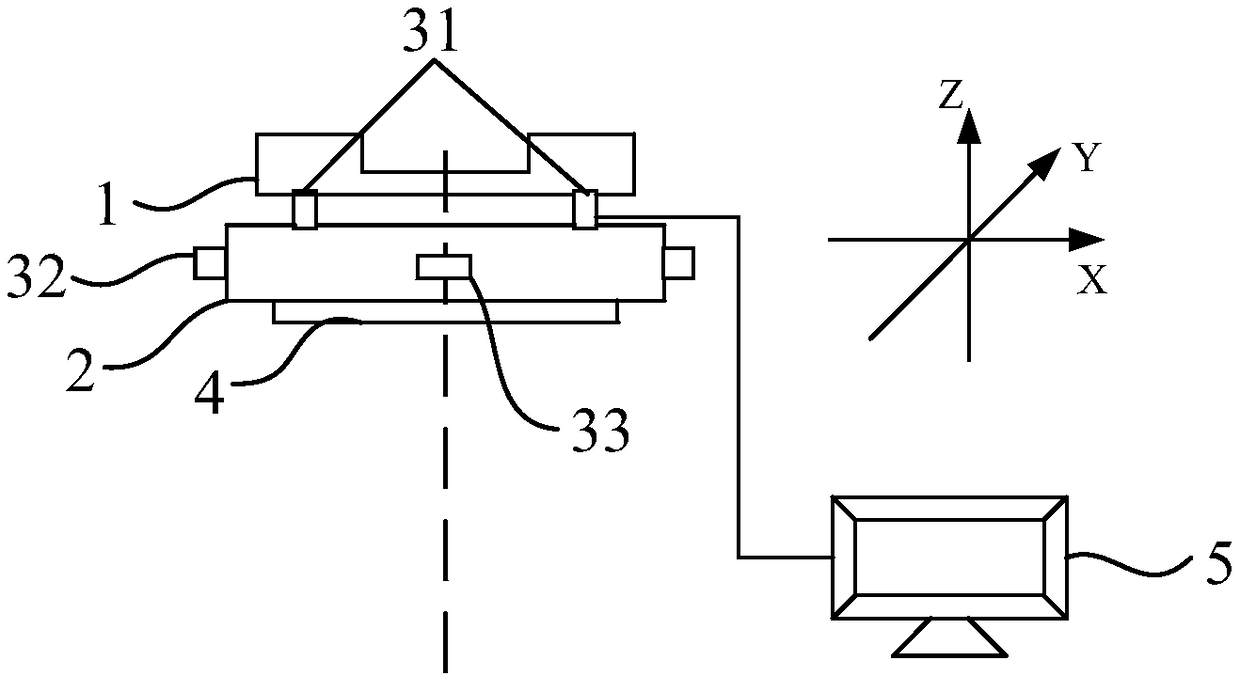

The invention relates to a statistical modeling, online monitoring and fault diagnosis technology of a superspeed carton packaging machine BV of the Italian G.D company and discloses a cigarette factory superspeed carton packaging machine multi-condition process online monitoring and fault diagnosis method. According to the method, a stable condition and a transition condition of stability factor identification are calculated based on a slide time window in an offline mode, the stable condition is divided to form a plurality of stable condition data clusters by use of an adaptive k-means cluster method, and then a statistical monitoring model is established independently for each stable condition data cluster by use of a PCA method. During online monitoring, a condition type is determined according to a stability factor of data in a current slide time window, under the stable condition, real-time monitoring is carried out by use of one PCA monitoring model corresponding to a cluster with a minimum distance, when any one statistical amount exceeds a limit, a major process variable causing a fault is determined by use of a contribution graph method, and finally, an effective feasible method is provided for online monitoring and fault diagnosis of the superspeed carton packaging machine BV.

Owner:CHINA TOBACCO ZHEJIANG IND

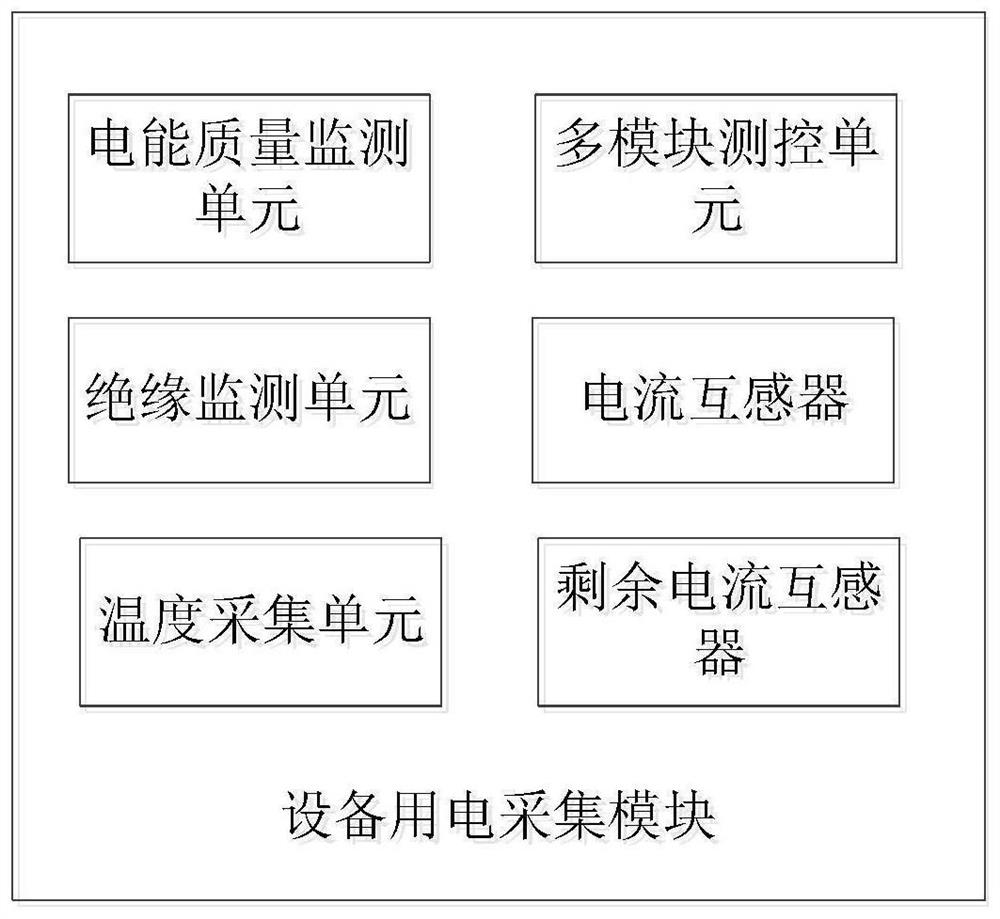

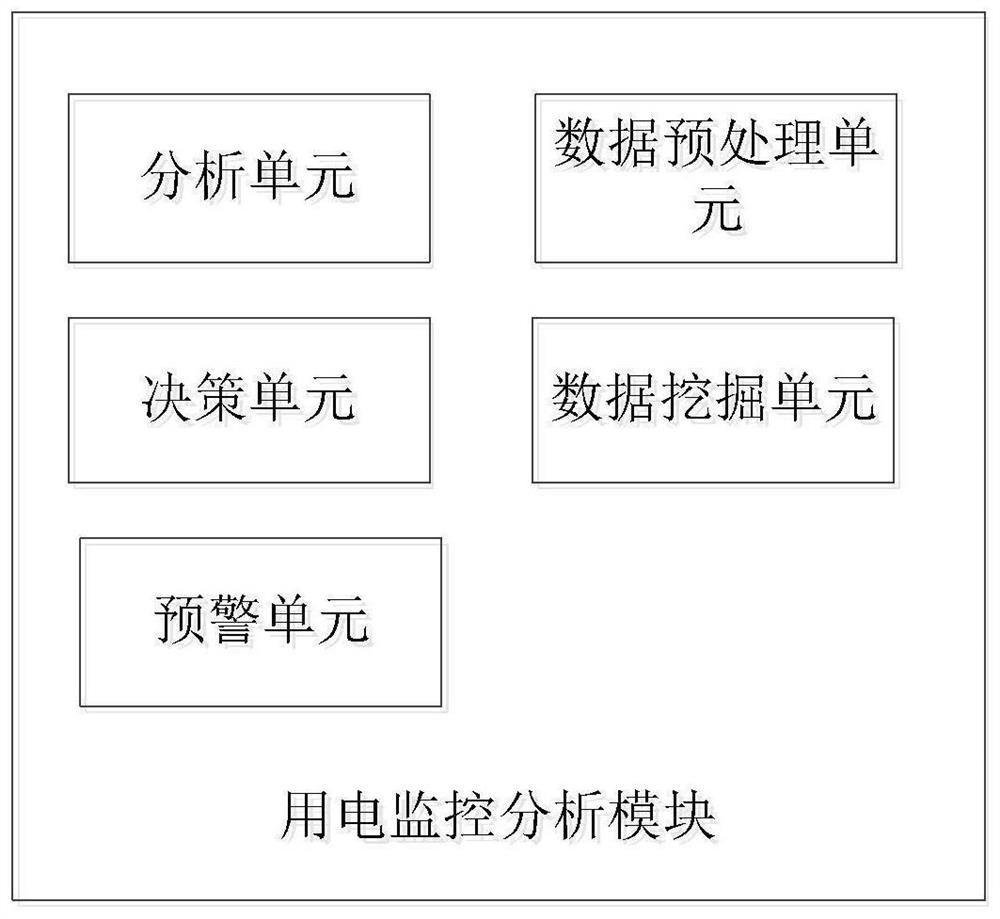

Intelligent and safe electricity utilization monitoring system integrated with Internet-of-Things technology

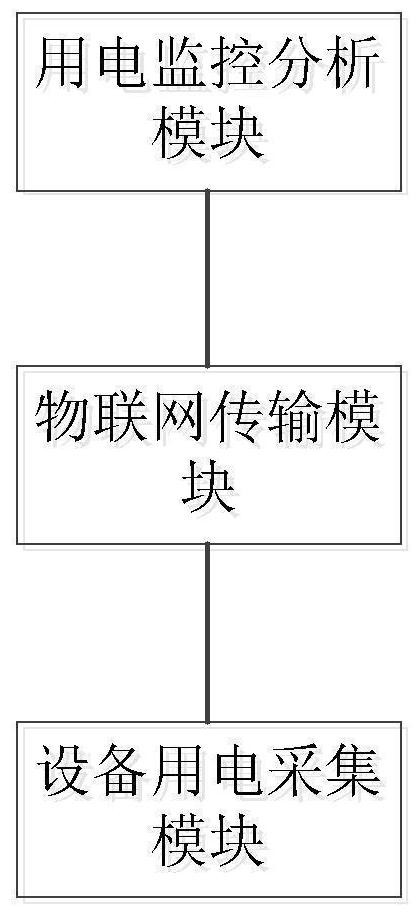

InactiveCN113467350AEffective Online MonitoringTimely forecastProgramme controlComputer controlThe InternetData transport

The invention discloses an intelligent and safe electricity utilization monitoring system fused with the Internet-of-Things technology. The system is characterized in that an equipment electricity utilization acquisition module sends acquired data to an Internet-of-Things transmission module; the Internet-of-Things transmission module transmits the received data to the monitoring analysis module; the power utilization monitoring analysis module is used for storing, analyzing and deciding the data acquired by the equipment power utilization acquisition module to obtain whether the operation condition of the to-be-monitored equipment is normal or not, carrying out power-off or shutdown processing on abnormal equipment, and carrying out early warning or prompting on abnormal data; according to the data acquired by the equipment electricity utilization acquisition module and the historical abnormal condition, the cause of the electrical fire is analyzed, the factor data of the electrical fire is tracked and statistically analyzed in real time, whether the electrical circuit and the to-be-monitored equipment have potential safety hazards is found, and the information of the potential safety hazards is sent to the user terminal. The system can discover abnormal electric equipment in time, predict and warn the potential safety hazard of electricity utilization, and reduce the occurrence of electricity utilization safety accidents of the equipment.

Owner:郑州易能科技有限公司

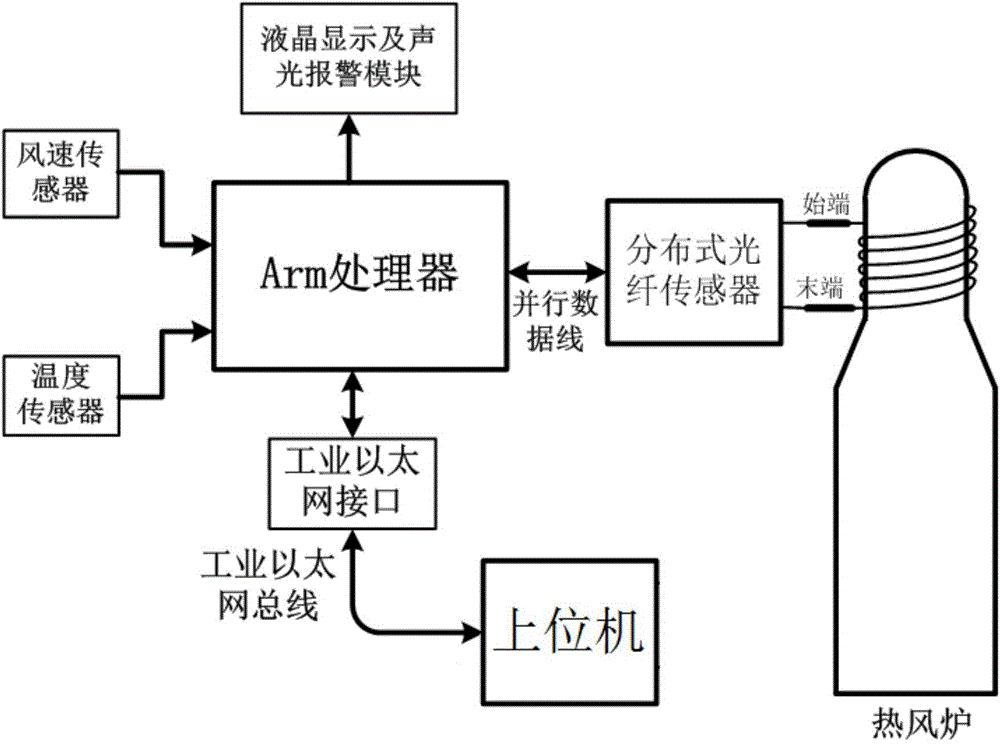

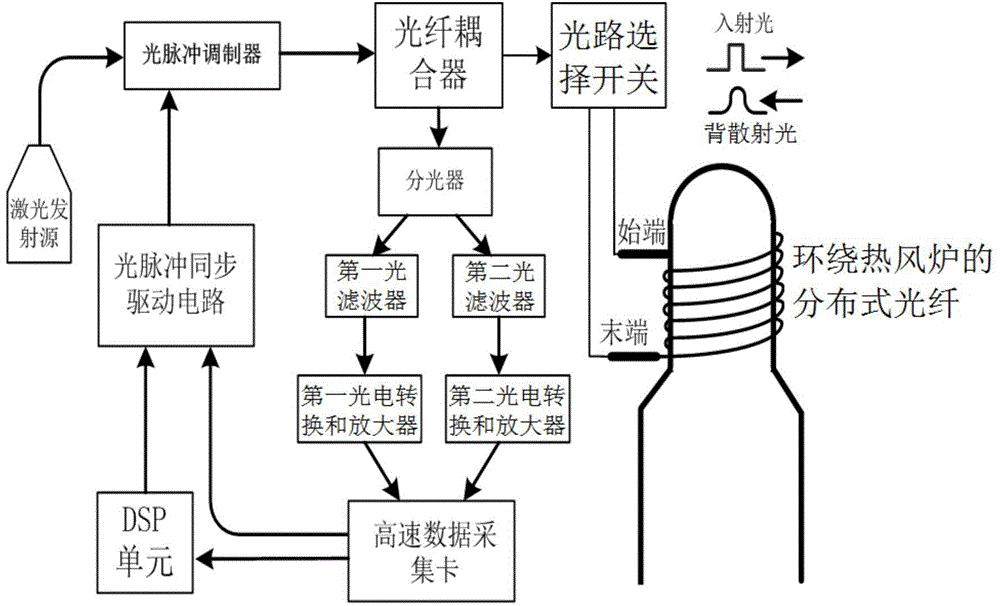

Distributed optical fiber-based blast furnace hot blast stove temperature monitoring system and method

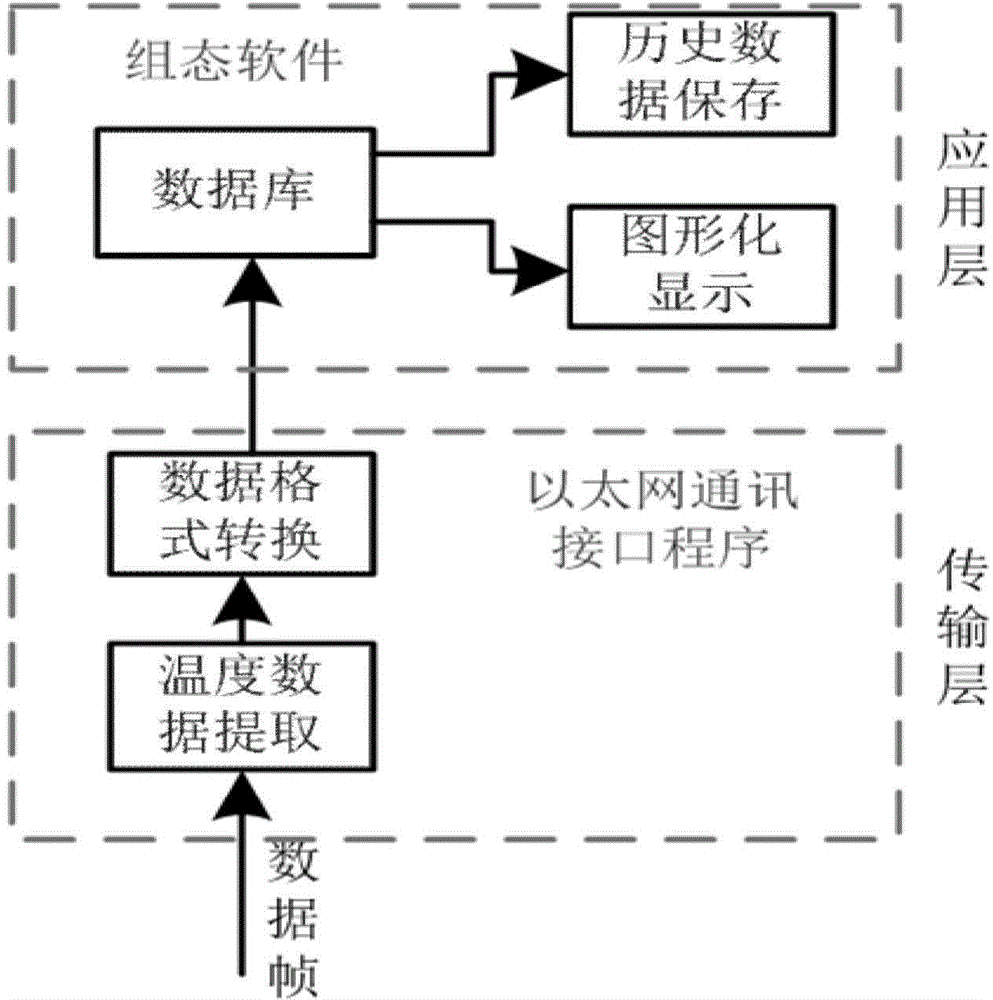

ActiveCN104697665AImprove insulation performancePrecise positioningThermometers using physical/chemical changesProduction rateIndustrial Ethernet

The invention discloses a distributed optical fiber-based blast furnace hot blast stove temperature monitoring system and method and belongs to the technical field of hot blast stove temperature detection. According to the distributed optical fiber-based blast furnace hot blast stove temperature monitoring system and method, a distributed optical fiber transversely winds the top part of a hot blast stove, both the starting end and end of the distributed optical fiber are connected with a distributed optical fiber sensor, the distributed optical fiber sensor is connected with an ARM processor, the distributed optical fiber sensor receives back scattering signals generated by the optical fiber, a novel temperature signal demodulation method is used, the temperature value of each measuring point on the optical fiber is extracted through a double-end single-way demodulation method, and the temperature value of each measuring point is sent to the ARM processor; the ARM processor is connected with an upper computer through an industrial Ethernet interface. According to the distributed optical fiber-based blast furnace hot blast stove temperature monitoring system and method, the surface temperature of the hot blast stove is performed with multi-point measurement through the distributed optical fiber, because the optical fiber directly and firmly contacts with a hot blast stove shell, the temperature measurement result is capable of reflecting the real temperature of the hot blast stove body; the distributed optical fiber-based blast furnace hot blast stove temperature monitoring system and method are convenient for early forecasting the stove shell damage situation and good for improving the service life of the hot blast stove, lowering the coke ratio and improving the blast furnace production rate.

Owner:马鞍山博新高科产业服务有限公司

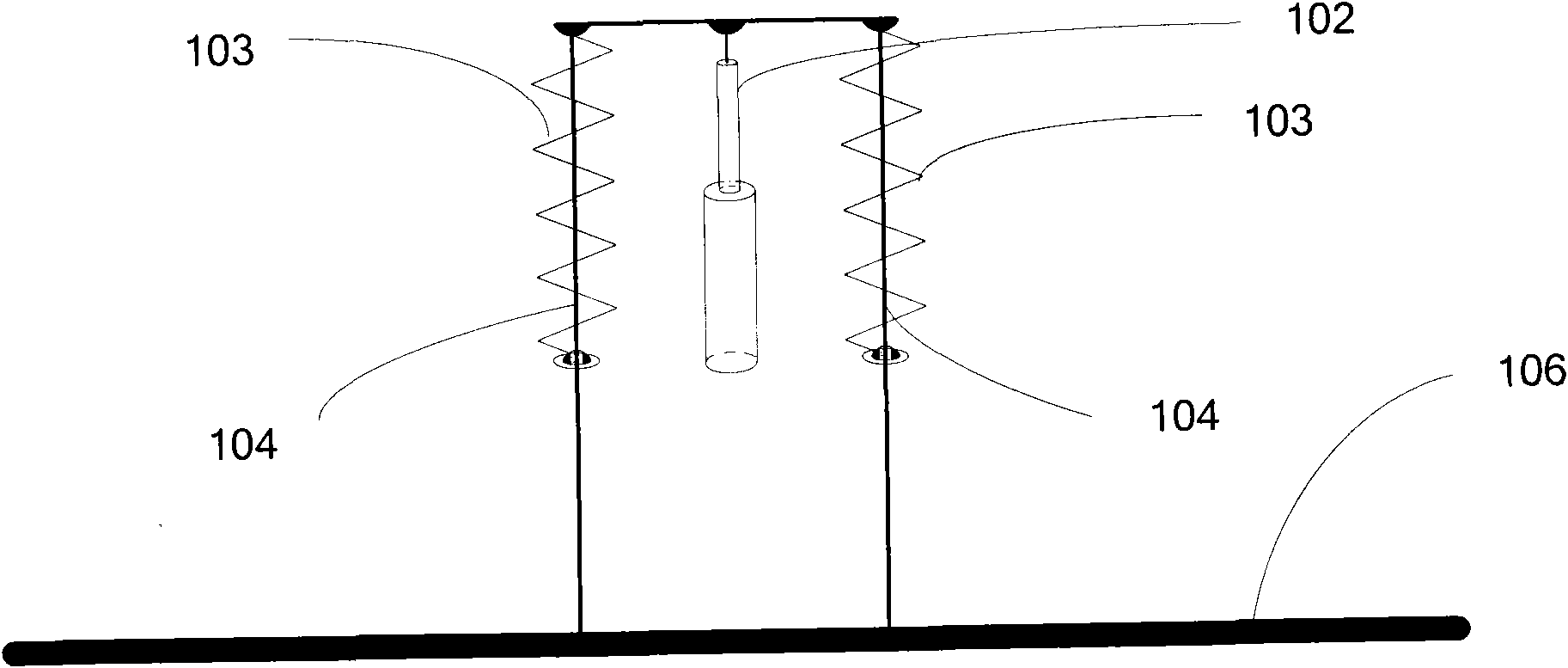

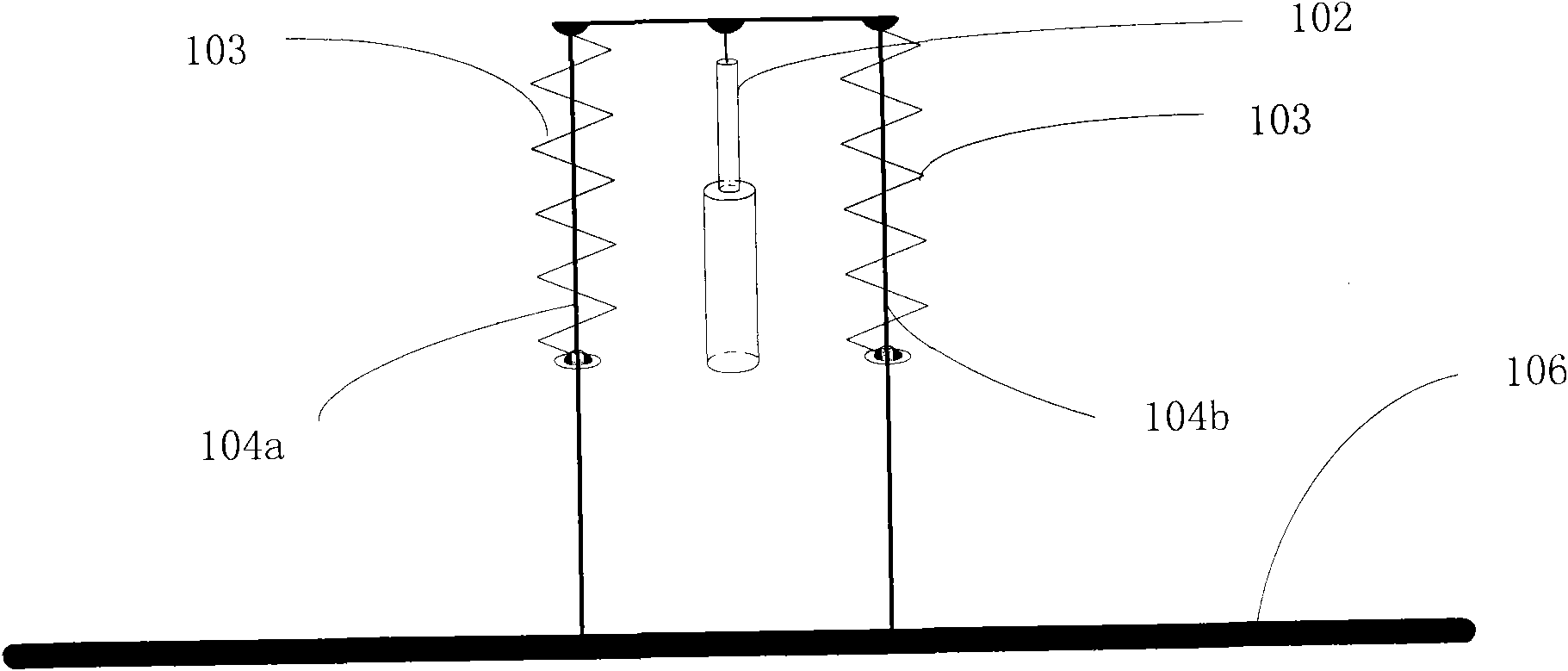

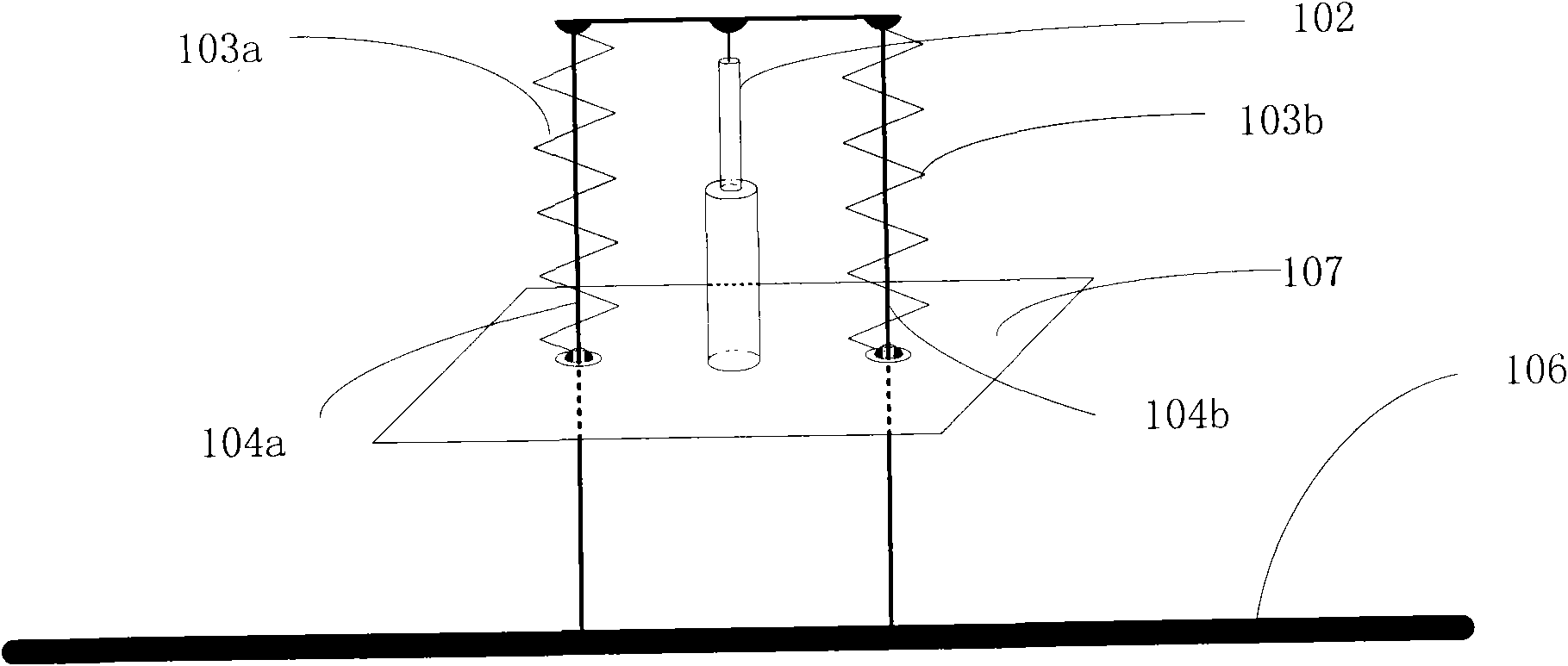

Wire ice cover monitoring device

ActiveCN102338625AEffective online monitoringSimple structureForce measurement using counterbalancing forcesEngineeringElastic component

The invention provides a wire ice cover monitoring device, solving the problems that the existing wire ice cover monitoring device is difficult to manufacture and has low safety factor. The wire ice cover monitoring device comprises a tested wire, two vertical connecting rods, a vertical elastic component and a displacement sensor, wherein the two vertical connecting rods are in parallel and are vertically and fixedly connected with the tested wire; the upper end of the vertical elastic component is fixed with the upper ends of the vertical connecting rods, the lower end of the vertical elastic component is fixed, the vertical elastic component is used for receiving vertical pressure applied by the vertical connecting rods when the vertical connecting rods move down followed by the tested wire which is under the ice cover pressure so as to generate a deformation variable; and the displacement sensor is used for measuring the deformation variable. Through the technical scheme, the ice covering on the running wire can be subjected to effective on-line monitoring, and the wire ice cover monitoring device has the advantages of simple structure and high safety factor and is convenient to use and easy to maintain.

Owner:STATE GRID CORP OF CHINA +2

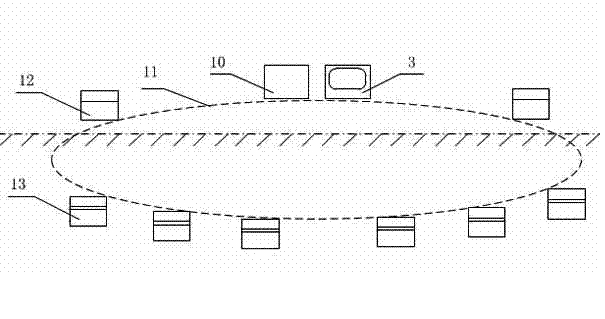

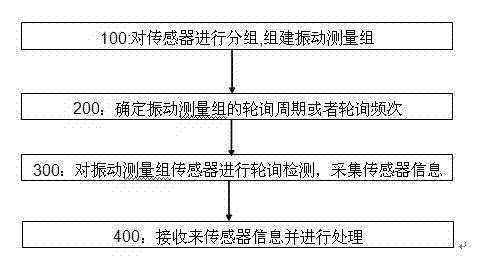

Vibration monitoring method based on sensors

ActiveCN103162816AHandle online monitoringReduce monitoring costsSubsonic/sonic/ultrasonic wave measurementMonitoring systemVibration detection

The invention relates to a vibration monitoring method based on sensors. The vibration monitoring method comprises following steps: a step 100: the sensors are distributed on a vibration measuring group, and the vibration measuring group is constructed; a step 200: a poll period or a poll frequency of the vibration measuring group is confirmed; and a step 300: the sensors of the vibration measuring group conduct poll detection, and information of the sensors of an interactive vibration measuring group is collected. A time-share detection strategy is adopted by the technical scheme, vibration detection device allocation is small, the vibration sensor grouping arrangement is optimized, application range of a vibration monitoring system is expanded, on-line vibration detection of low-cost equipment failure is achieved, and the designed system is low in cost, high in efficiency, safe, reliable, open-ended and capable of being maintained.

Owner:CITIC HIC KAICHENG INTELLIGENT EQUIP CO LTD

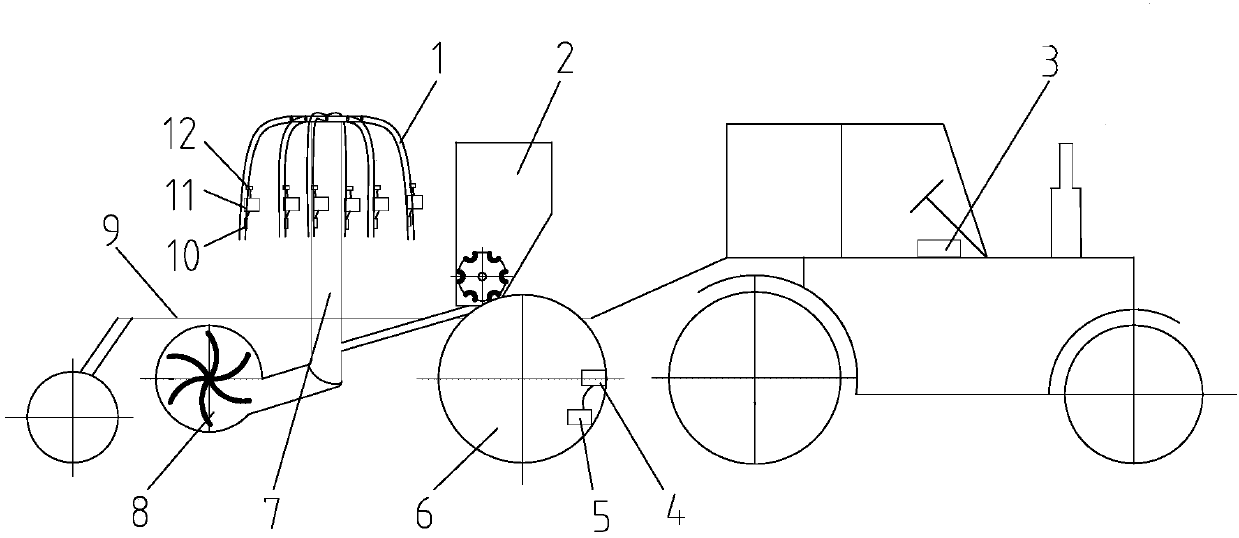

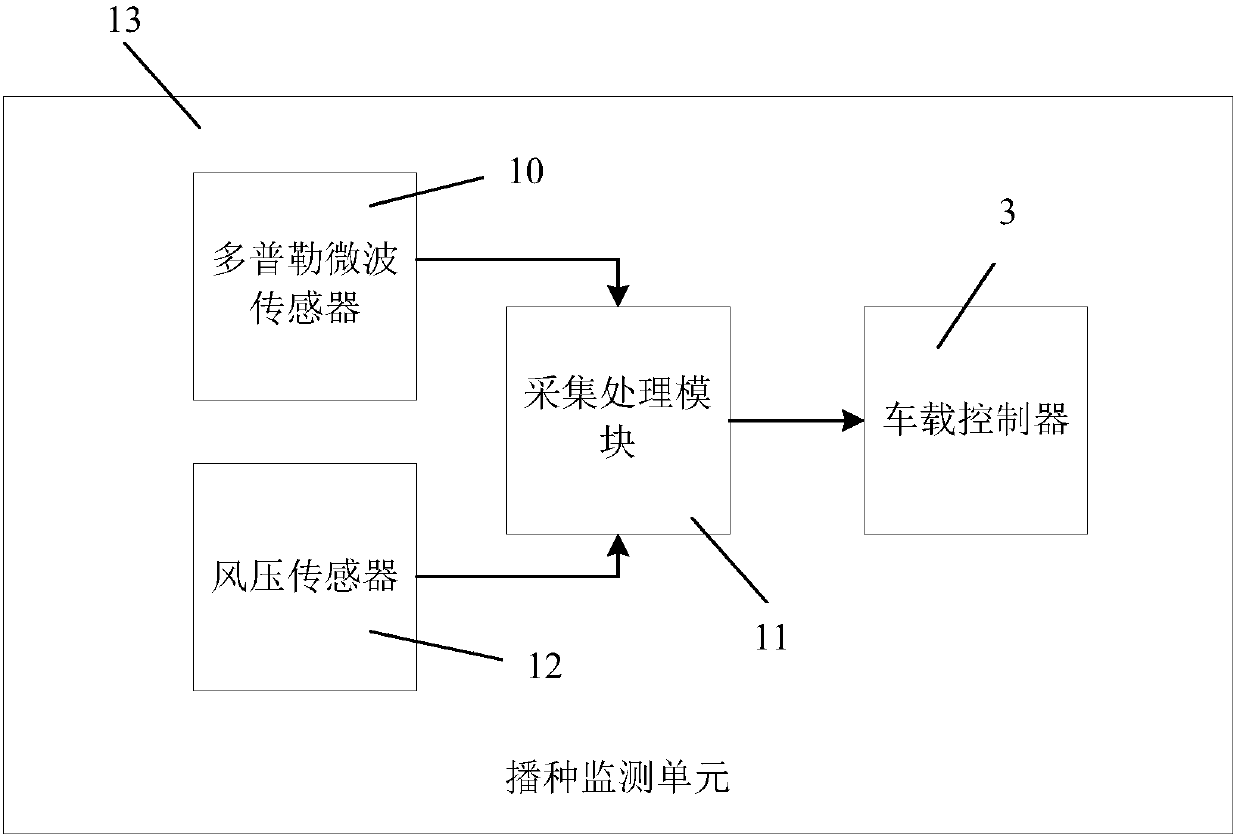

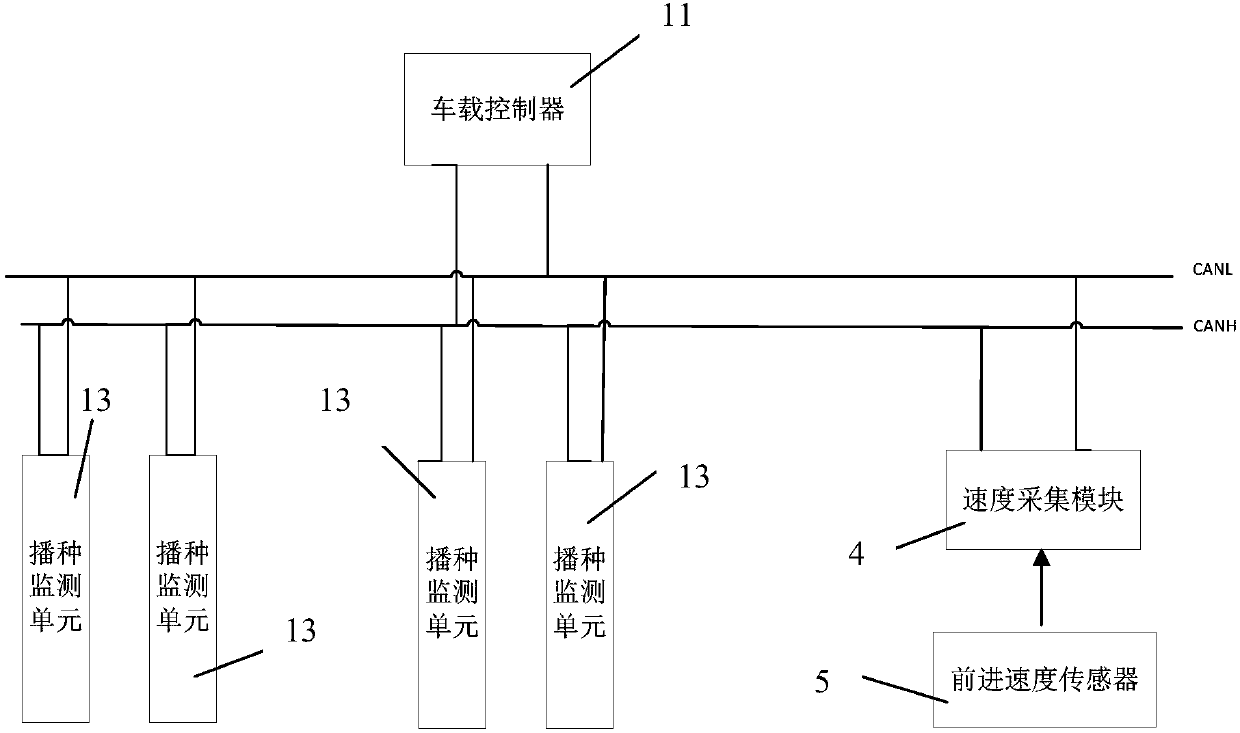

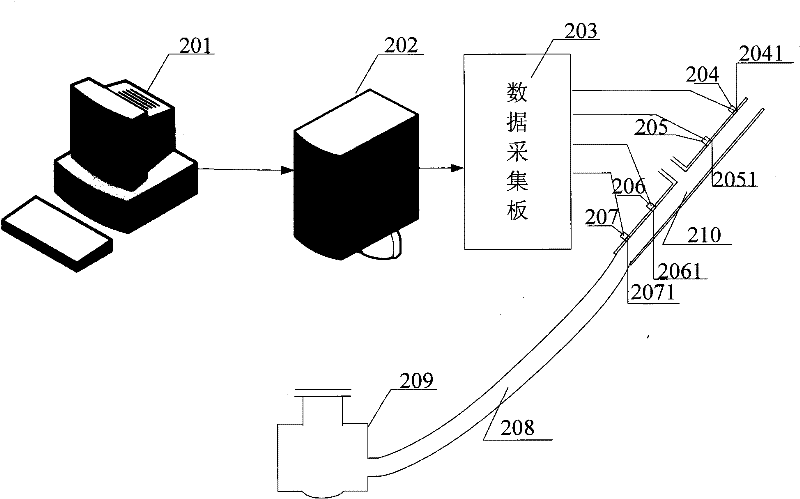

Pneumatic conveying type precision combined seed and fertilizer drill, and miss-seeding and blocking detection method and device thereof

ActiveCN109831979AEffective online monitoringEffective alarmMeasurement devicesSeed depositing seeder partsElectricityComputer module

The invention discloses a pneumatic conveying type precision combined seed and fertilizer drill, and a miss-seeding and blocking detection method and device thereof. The miss-seeding and blocking detection device includes sowing monitoring units, a forward speed sensor, a speed collecting module and a vehicle controller; the sowing monitoring units are installed on seed metering pipes and includeDoppler microwave sensors, wind pressure sensors and collection processing modules, and the Doppler microwave sensors and the wind pressure sensors are respectively connected to the collection processing modules; the forward speed sensor is installed on a land wheel; the speed collecting module is installed on the land wheel and adjacent to the forward speed sensor; and the vehicle controller is fixed in a driving cab, is connected to a vehicle storage battery to take electricity, and is connected to the sowing monitoring units, the forward speed sensor and the speed collecting module. The miss-seeding and blocking detection method includes collecting a signal of the forward speed sensor to obtain speed information; transmitting the speed information to the vehicle controller in real time;determining, by the vehicle controller, whether the sowing monitoring units enter working states according to the speed information; and performing miss-seeding and blocking detection and alarm sounding during working.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

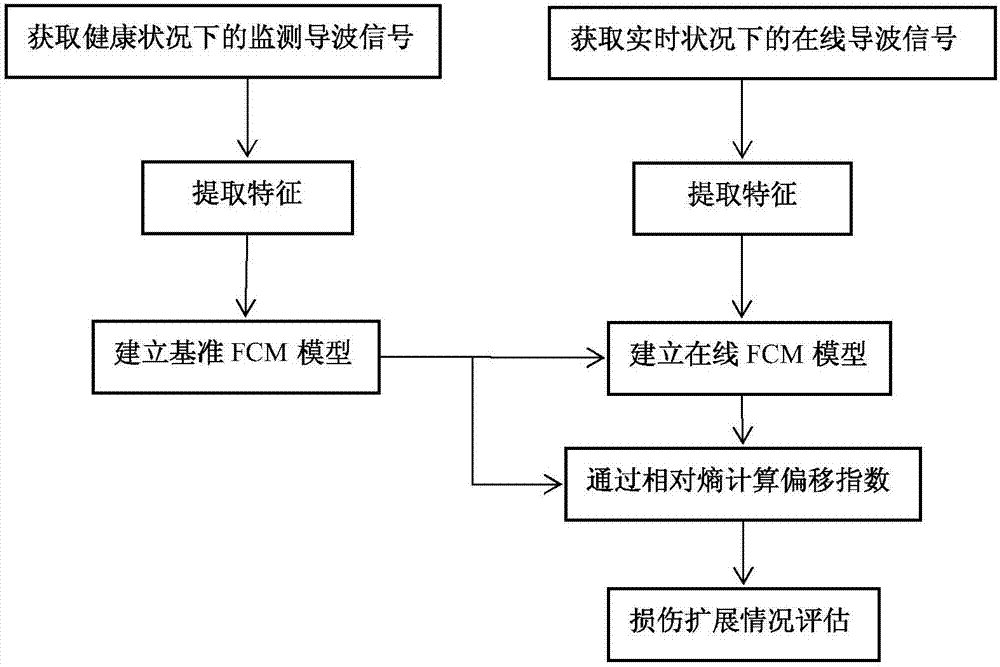

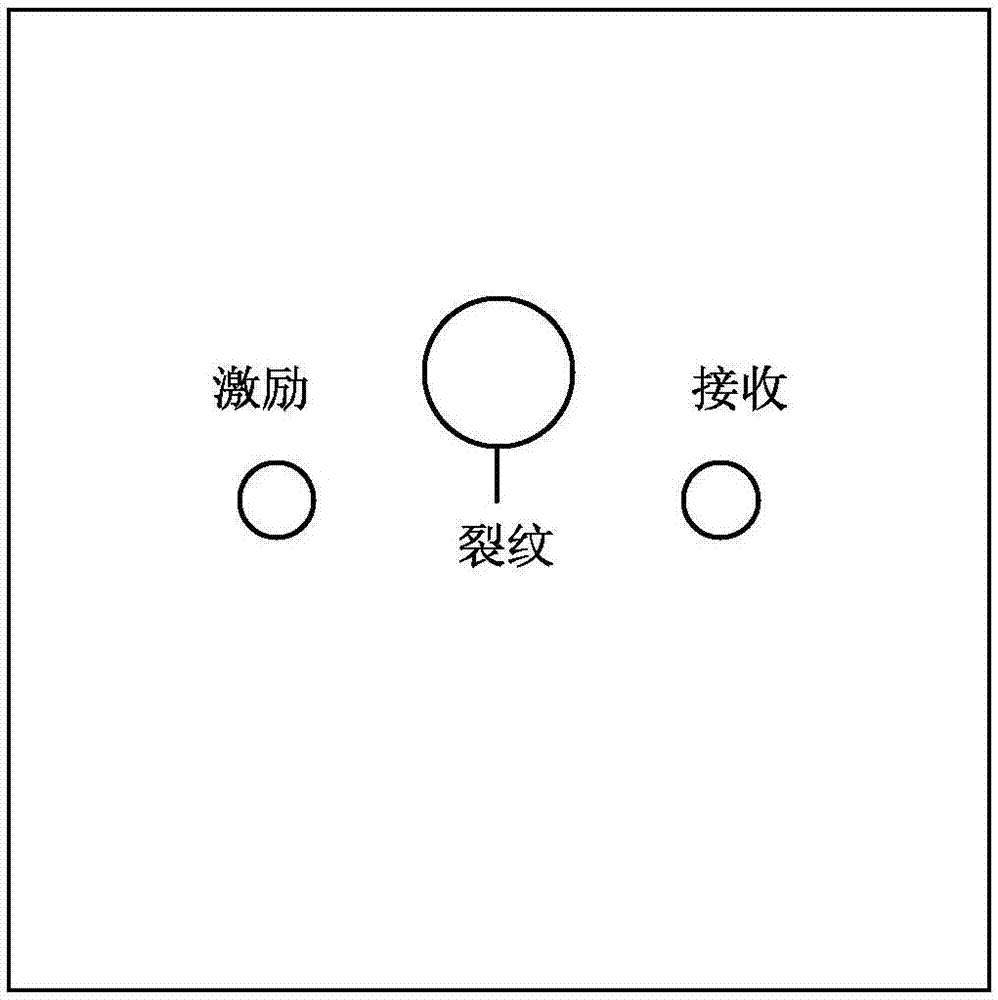

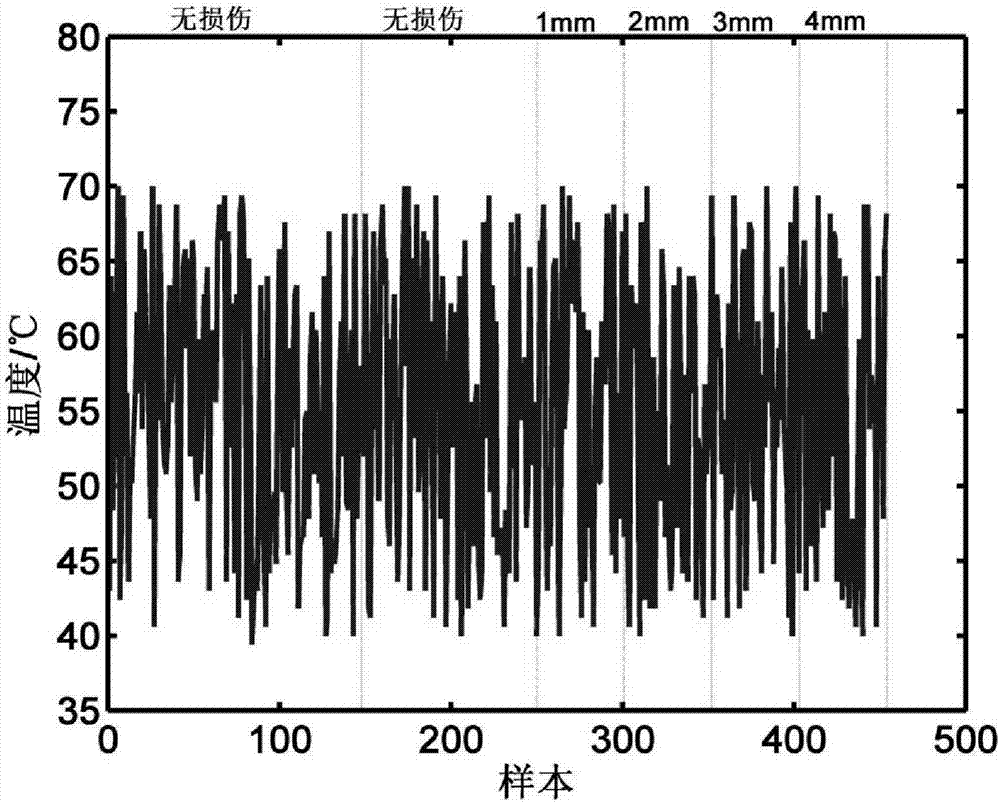

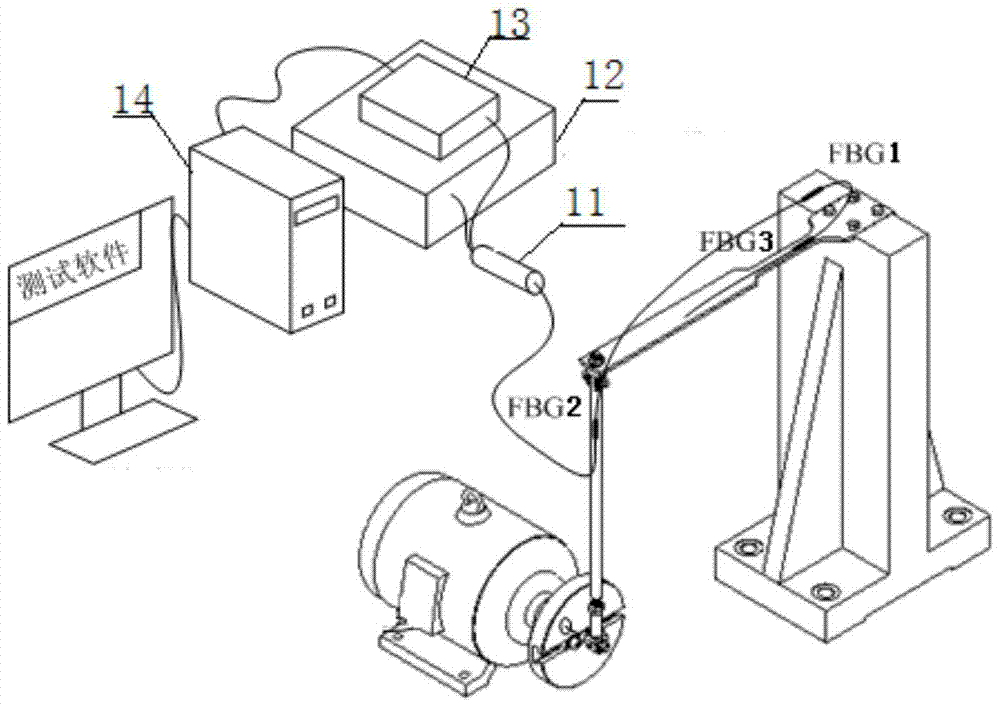

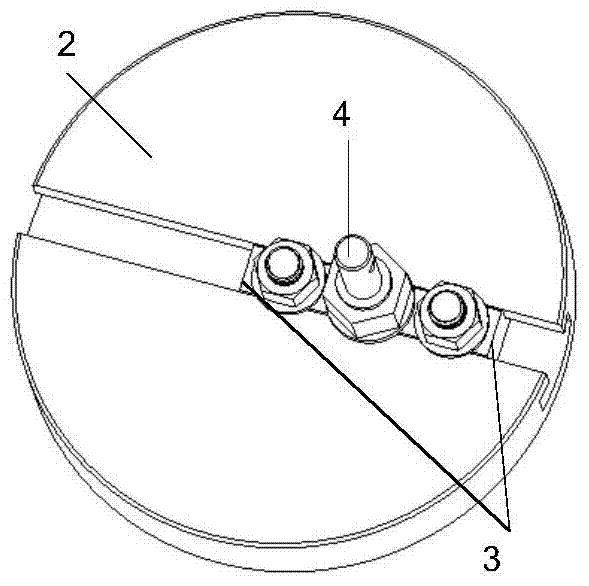

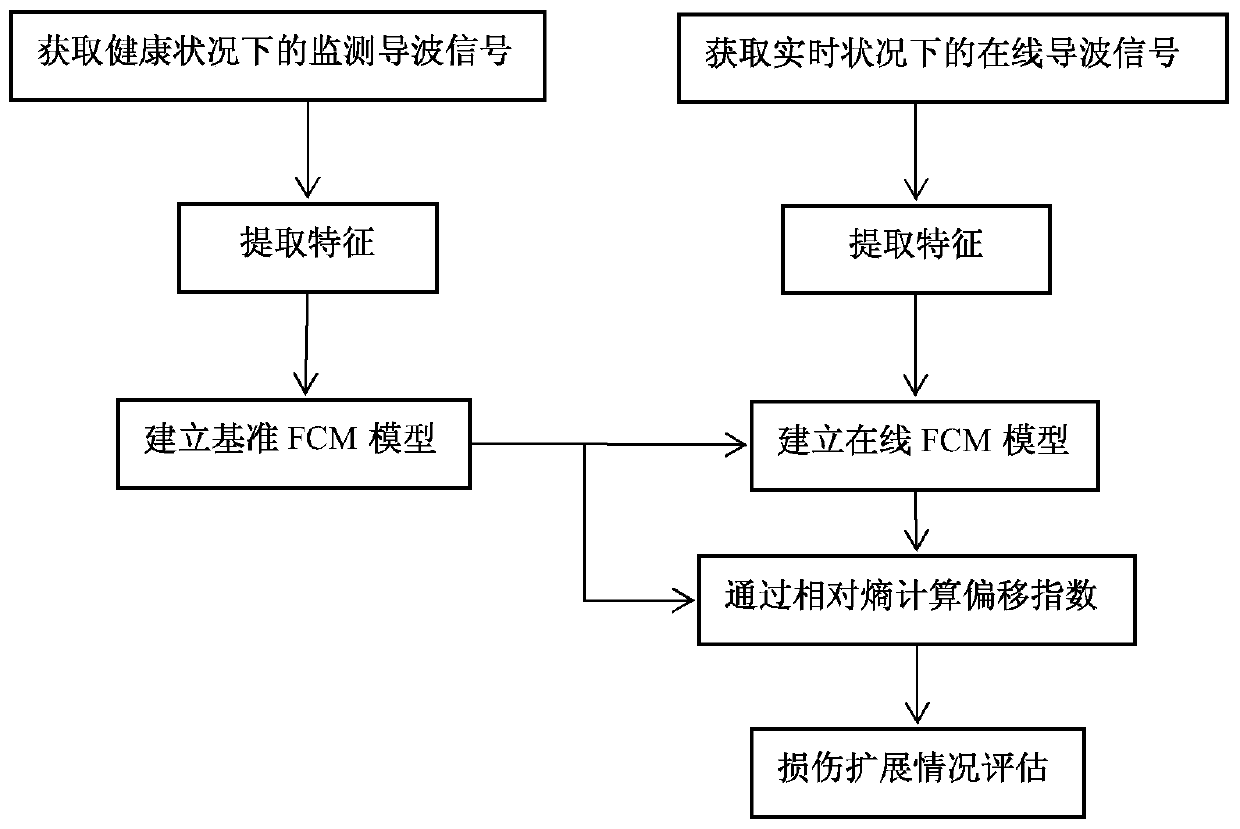

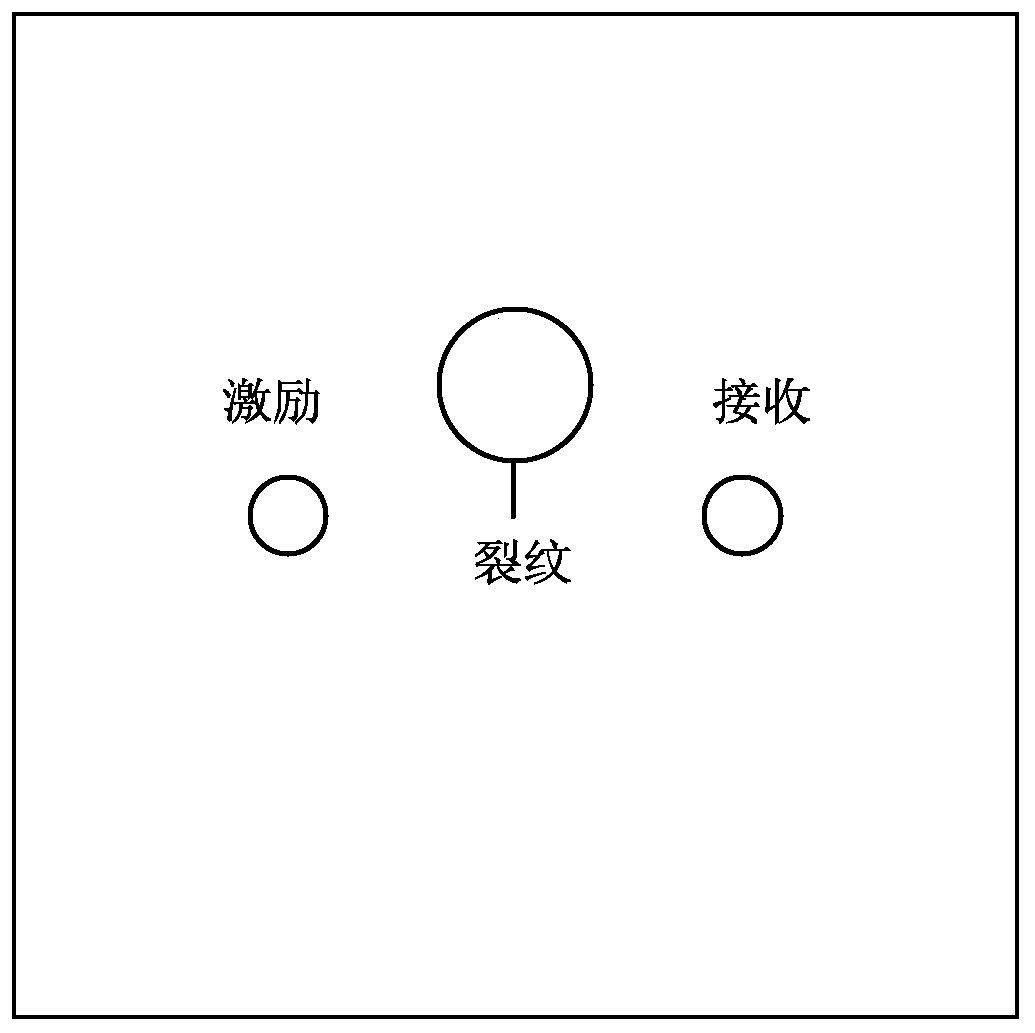

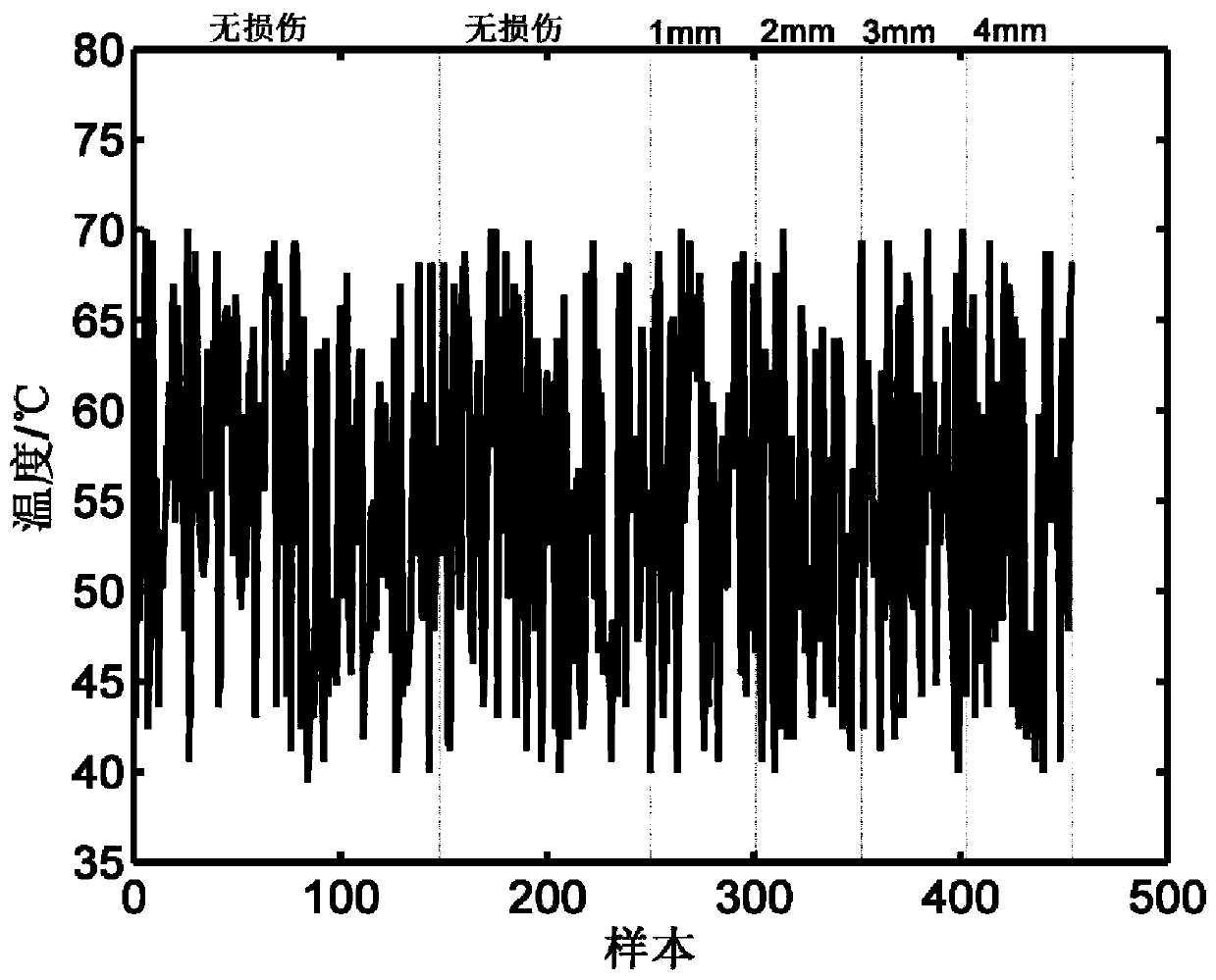

FCM algorithm-based method for real-time monitoring of damage expansion under influence of time-varying temperature

ActiveCN107367552AImprove reliabilityEnsure safetyProcessing detected response signalCharacter and pattern recognitionData setDistribution characteristic

The invention relates to a fuzzy C-means (FCM) algorithm-based method for real-time monitoring of damage expansion under the influence of a time-varying temperature. The method can effectively solve the influences of changing factors only depending on the distribution characteristics of a signal, and can realize effective online monitoring of the change trend of the damage expansion of a structure under the influence of the temperature. The change trend of the damage expansion can be effectively monitored in real time through a shift index, and a certain basis is provided for the quantification of the damage expansion. The method can realize the monitoring through using an existing hardware system without changing or increasing devices and parameters in the realization process, and has the advantages of high feasibility, short algorithm operation time, high accuracy, and easiness in operation. A strategy for waiting the updating of data sets and motion data plays a great role in online real-time damage monitoring, ensures the online updating real-time property, reduces the demand of all historical data, eases the data storage pressure and has very good practical engineering values.

Owner:XIAMEN UNIV

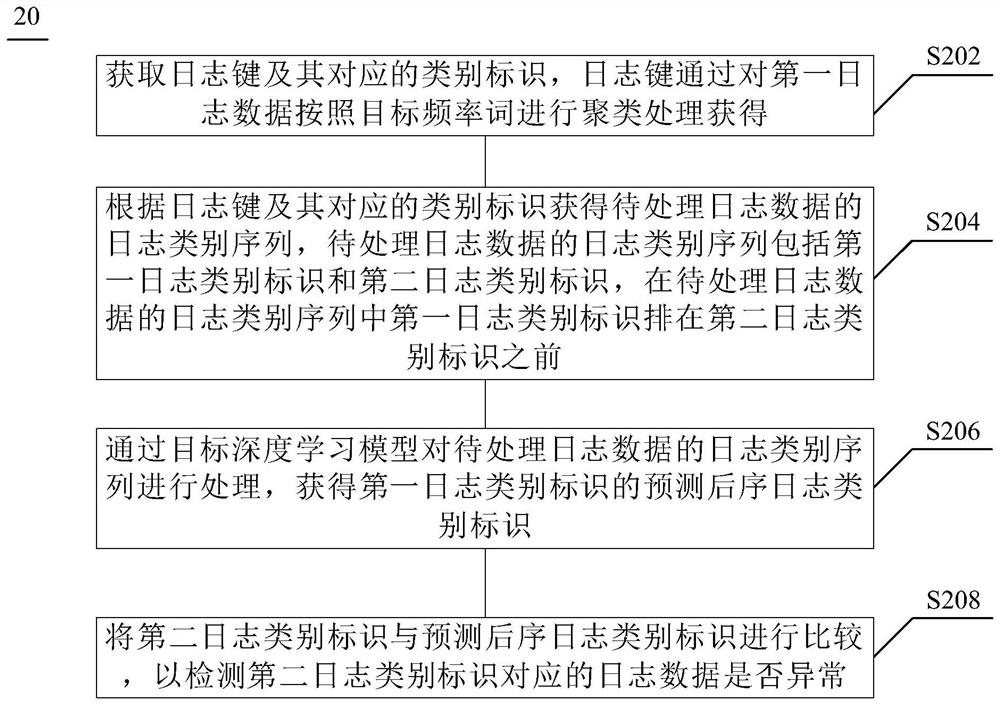

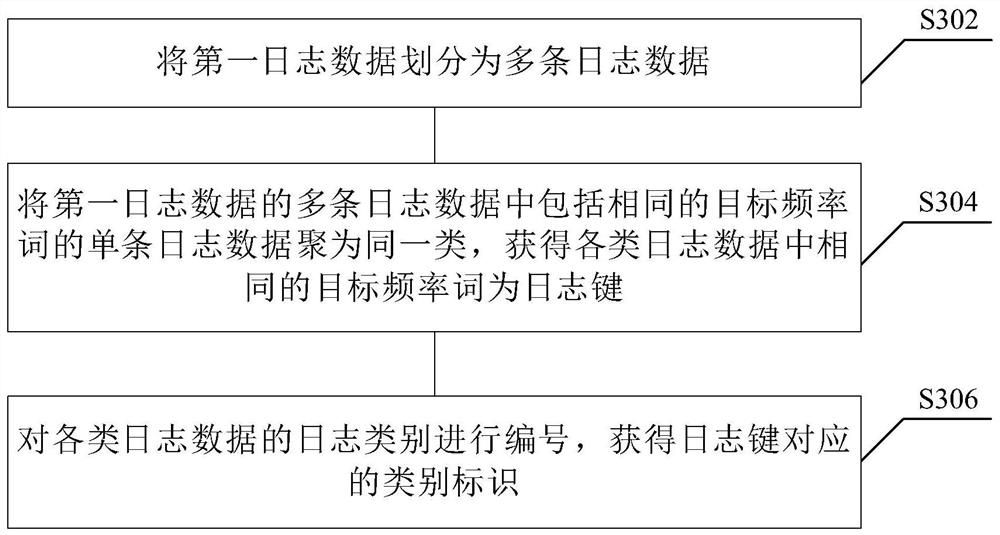

Log data processing method and device, equipment and storage medium

PendingCN114328106AEffective online monitoringEffective detectionHardware monitoringNeural architecturesEngineeringData mining

The invention provides a log data processing method and device, electronic equipment and a storage medium, and relates to the technical field of operation and maintenance. The method comprises the following steps: acquiring log keys obtained by clustering first log data according to a target frequency word and category identifiers corresponding to the log keys; obtaining a log category sequence of the to-be-processed log data comprising a first log category identifier and a second log category identifier according to the log key and the category identifier corresponding to the log key, wherein the first log category identifier in the log category sequence of the to-be-processed log data is ranked before the second log category identifier; processing the log category sequence of the to-be-processed log data through the target deep learning model to obtain a predicted post-order log category identifier of the first log category identifier; and comparing the second log category identifier with the predicted post-order log category identifier to detect whether the log data corresponding to the second log category identifier is abnormal or not. According to the method, the log data exception is efficiently detected.

Owner:CHINA TELECOM CLOUD TECH CO LTD

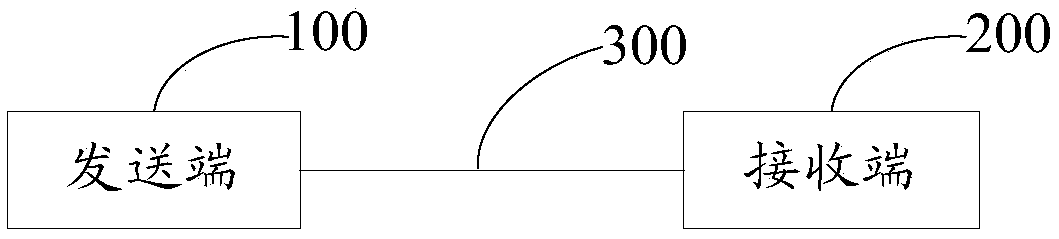

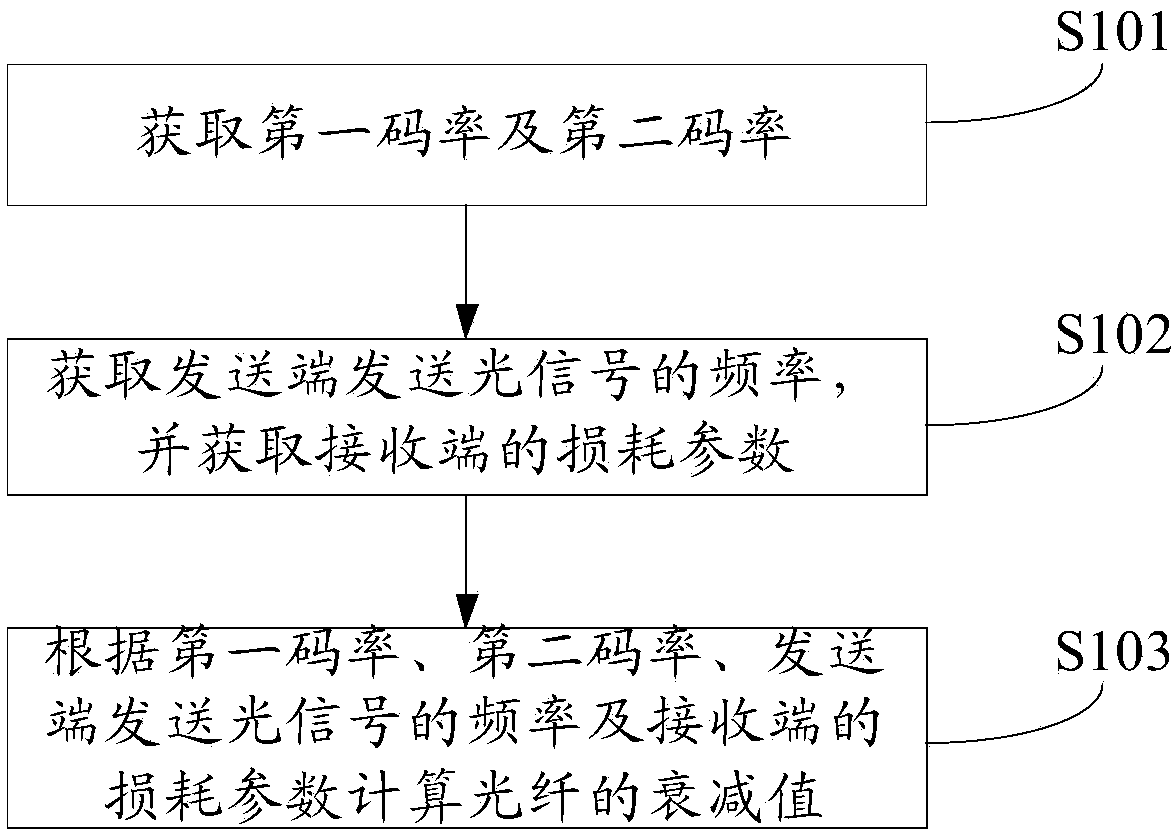

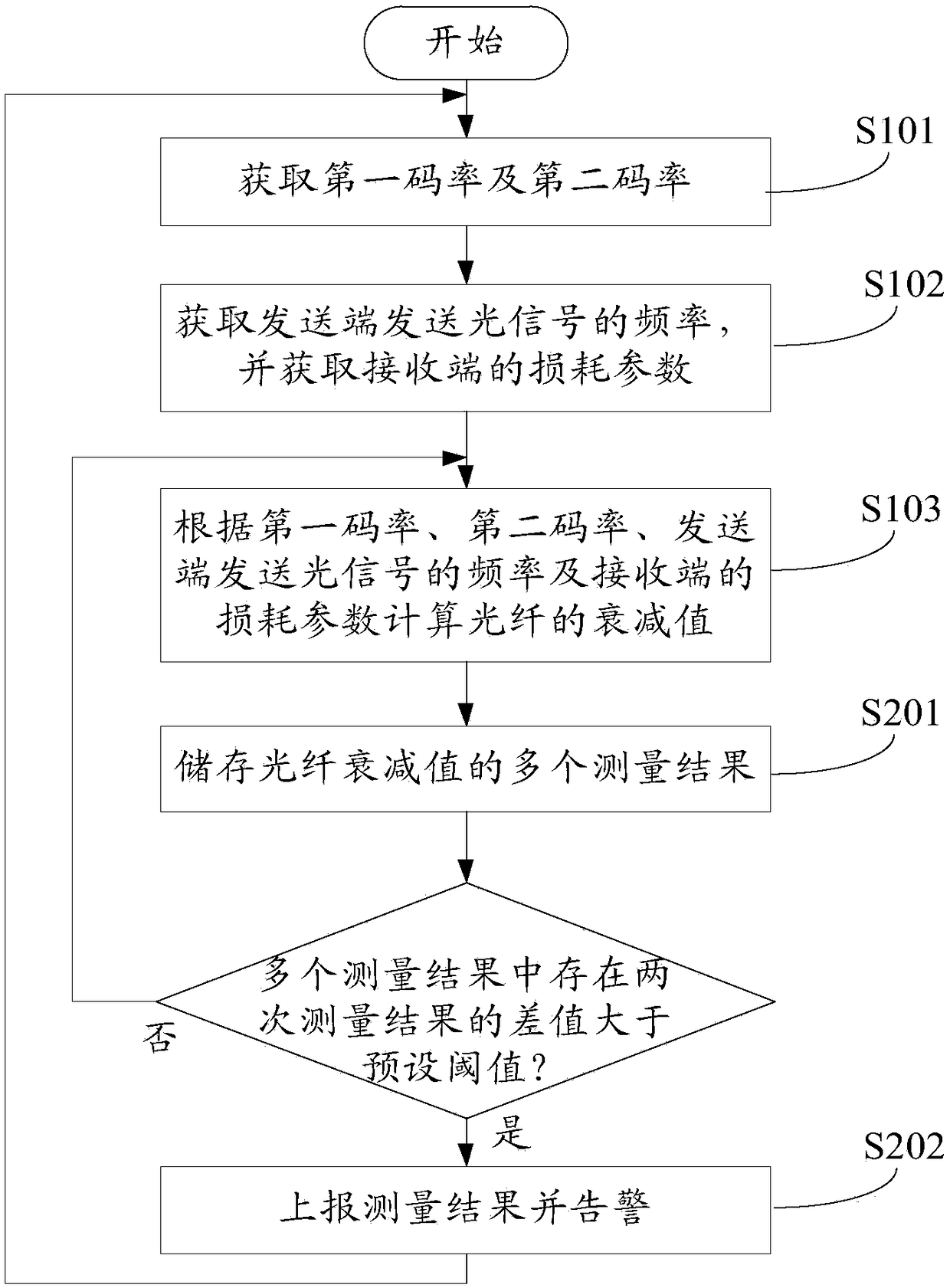

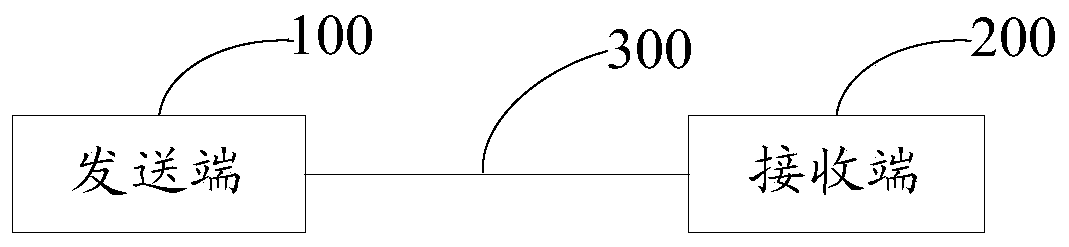

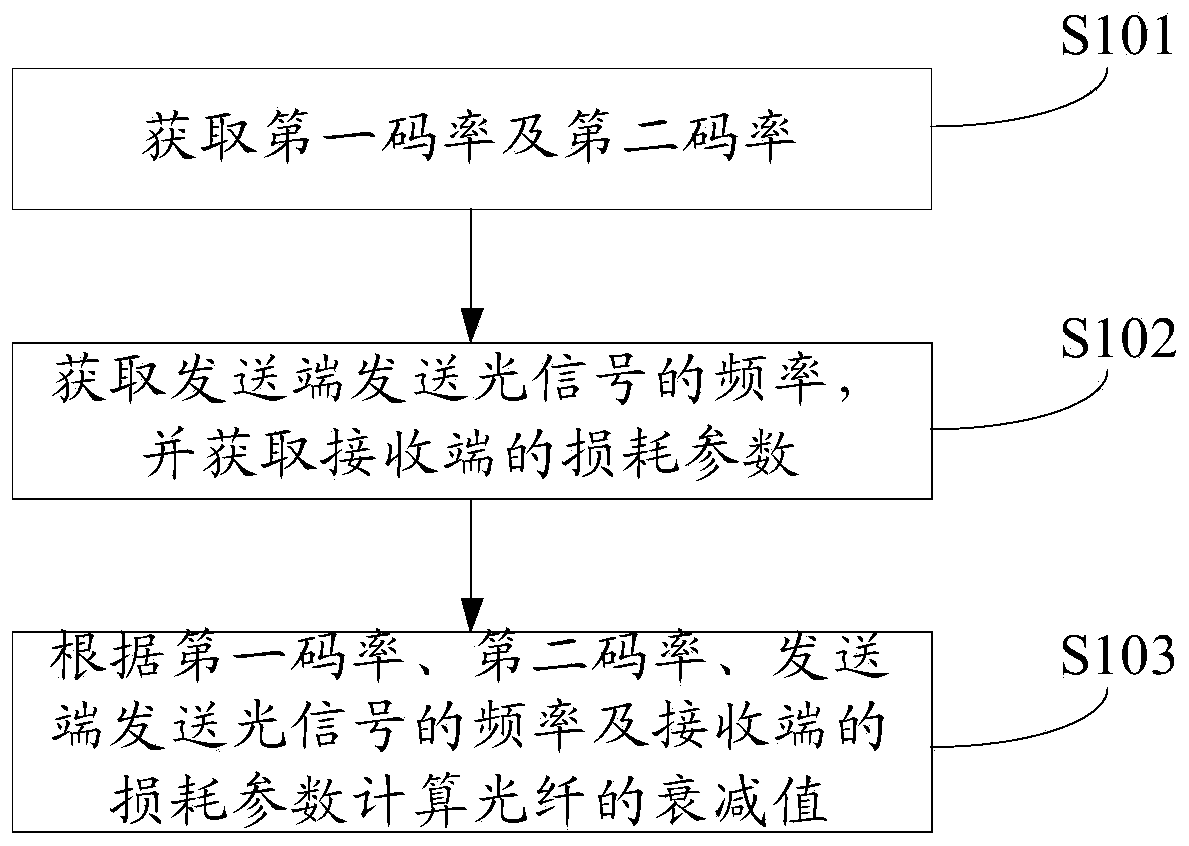

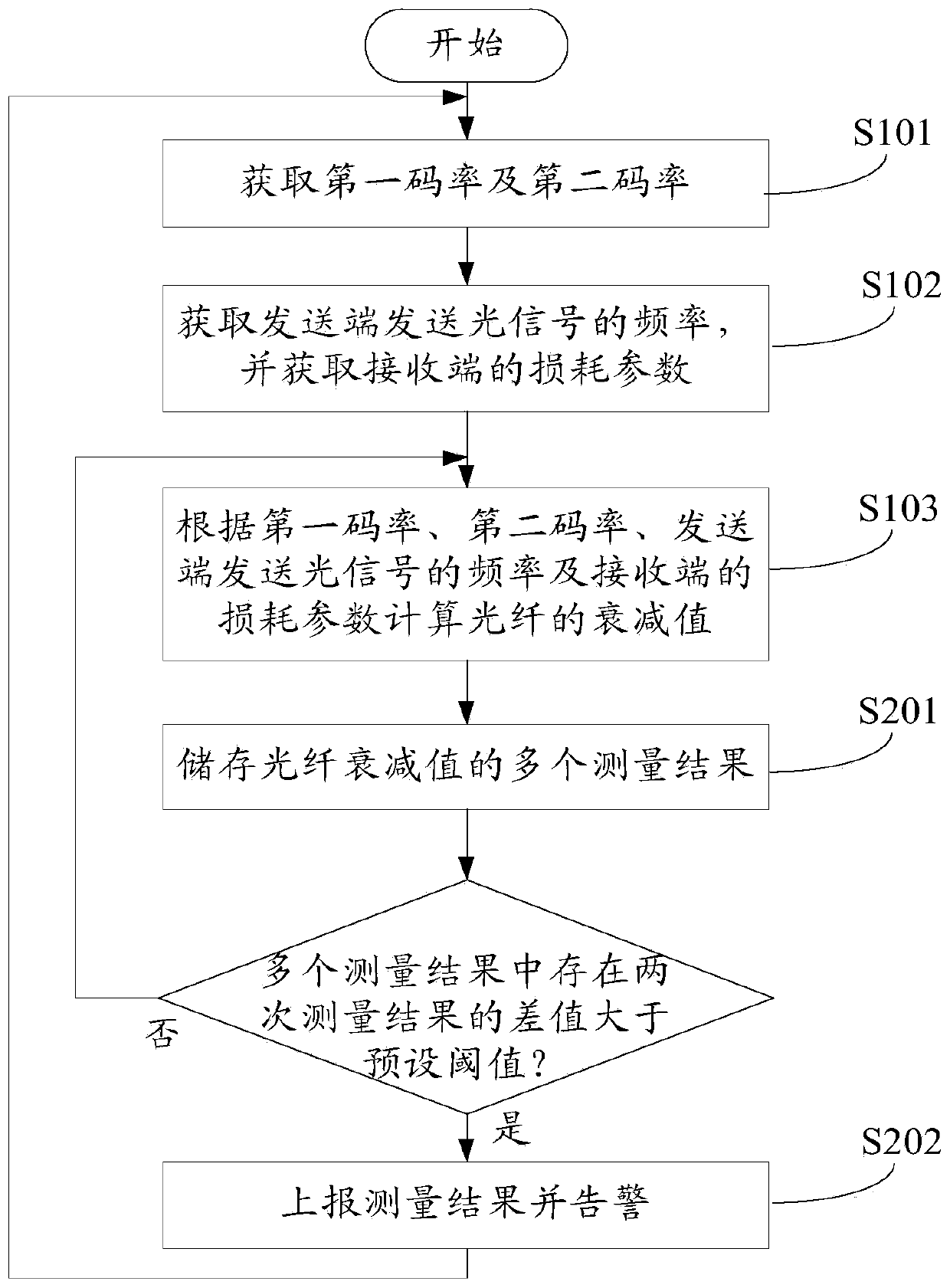

Measurement methods and devices for optical fiber attenuation value

ActiveCN109347553AEffective online monitoringWill not affect performancePhotonic quantum communicationCounting rateUltrasound attenuation

The invention discloses measurement methods and devices for an optical fiber attenuation value, relates to the technical field of quantum communication and is used for monitoring an attenuation valueof an optical fiber online in real time. A method comprises the steps of obtaining a first bit rate and a second bit rate, wherein the first bit rate is a photon counting rate received by a receivingend when a sending end sends optical signals through utilization of the optical fiber, the second bit rate is the photon counting rate received by the receiving end when the sending end stops sendingthe optical signals, and the first bit rate is greater than the second bit rate; obtaining a frequency for the sending end to send the optical signals, and obtaining loss parameters of the receiving end; and computing the attenuation value of the optical fiber according to the first bit rate, the second bit rate, the frequency for the sending end to send the optical signals and the loss parametersof the receiving end. The embodiments of the invention are applied to online measurement of the attenuation value of the optical fiber in a quantum communication network.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

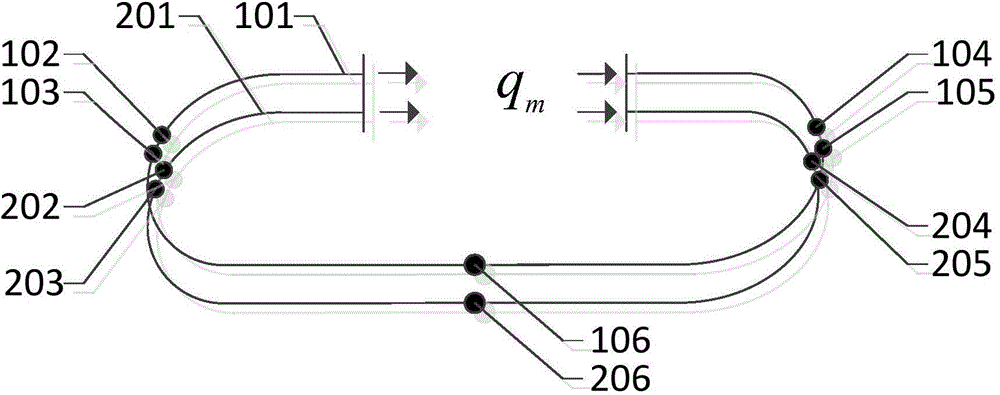

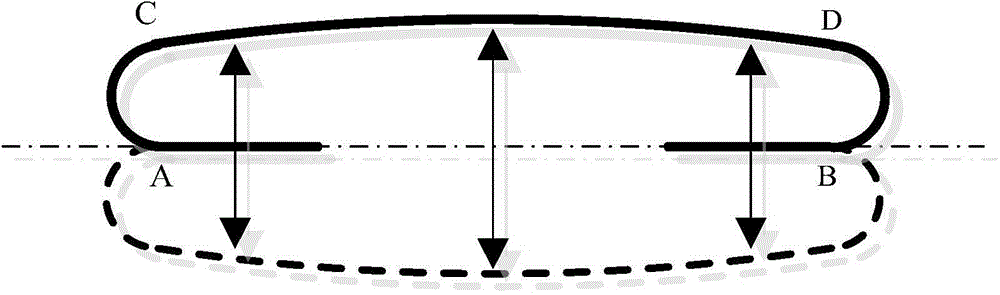

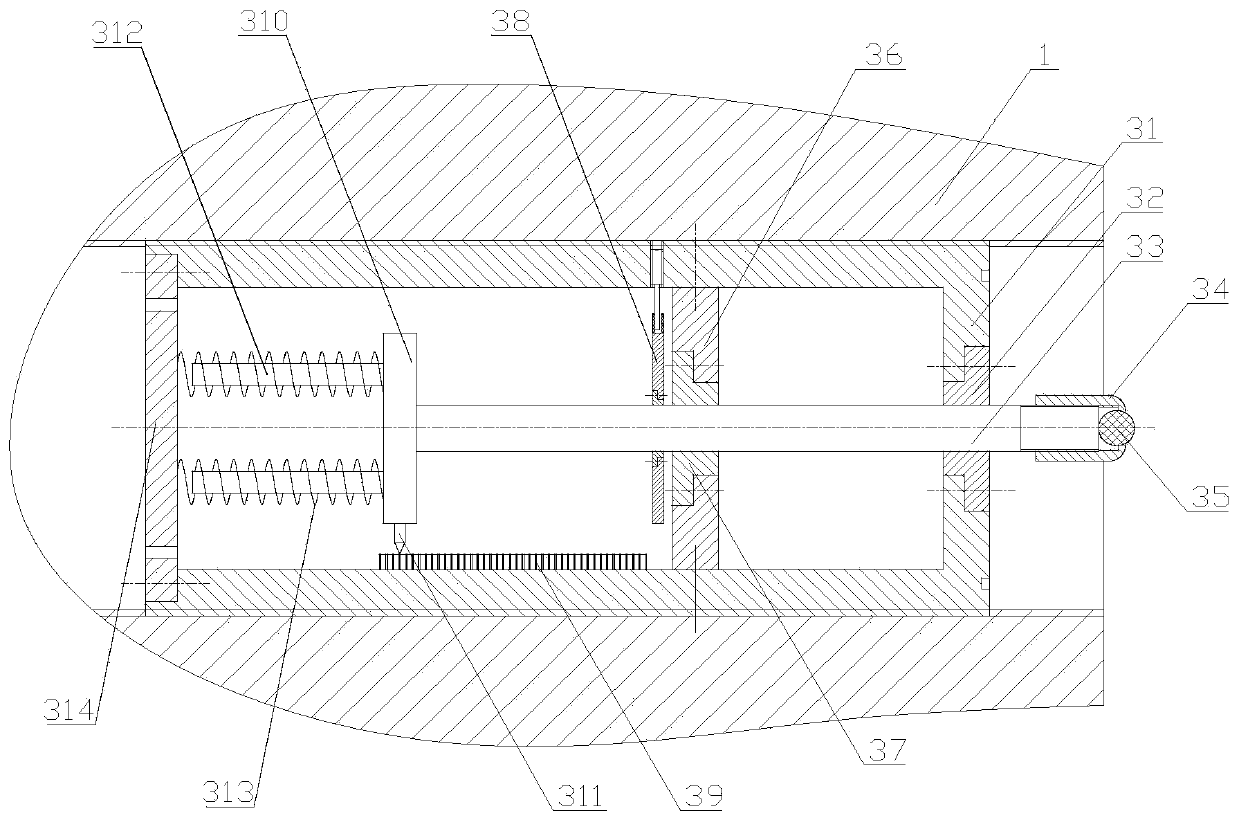

Method and apparatus for monitoring measurement state of coriolis mass flowmeter

ActiveCN104981684AImprove online monitoring efficiencyEffective online monitoringVolume/mass flow measurementTesting/calibration for volume flowPhase differenceClassical mechanics

A method and apparatus for monitoring a measurement state of a Coriolis mass flowmeter. An equivalent driving force F is applied to replace a Coriolis force Fc generated when a liquid passes through a vibration pipeline (101, 201), it is ensured that an acting effect of the equivalent driving force F is the same as an acting effect of the Coriolis force Fc, a phase difference is generated at two sides of the sensor vibration pipeline (101, 201) without circulating the liquid, and a flow transmitter displays, by means of continuous detection and calculation, a mass flow value when the liquid is circulated. By changing the value of the equivalent driving force F, and comparing a flow value qm' displayed by the transmitter and an assumed flow value qm to obtain a difference, the working state of the flowmeter can be monitored without circulating the liquid. The apparatus comprises an apparatus for applying the equivalent driving force F, the acting effect of the equivalent driving force F is the same as the acting effect of the Coriolis force Fc, and the applying position and the value of the equivalent driving force F satisfy a torque condition 2F•d=T.

Owner:XIAN DONGFENG MACHINERY & ELECTRONICS

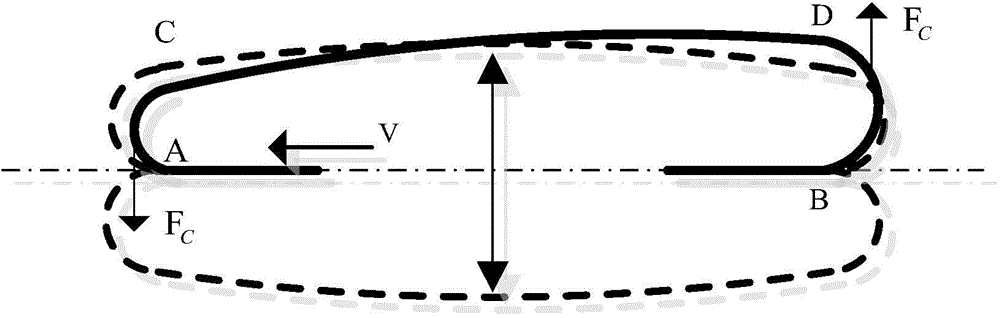

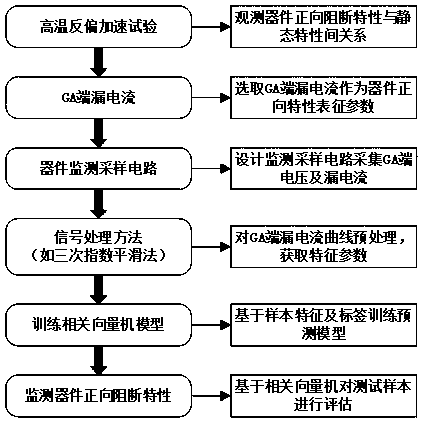

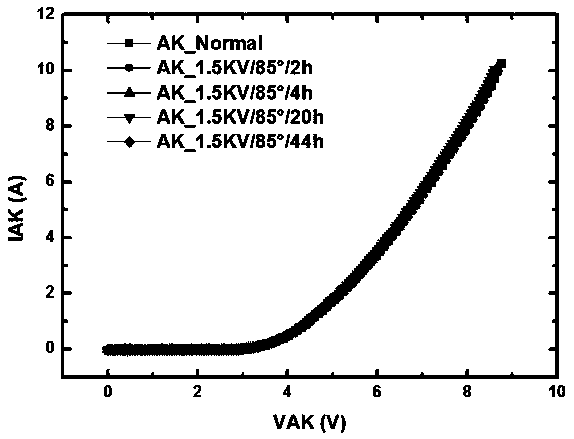

Method for monitoring and diagnosing forward blocking characteristics of embedded SiC-GTO device

ActiveCN109143014AEffective online monitoringAvoid dependencyIndividual semiconductor device testingEmbedded systemRelevance vector machine

The invention discloses a method for monitoring and diagnosing forward blocking characteristics of an embedded SiC-GTO device. According to the method, based on a high temperature reverse bias test, indirect characterization parameters with AG junction electrical characteristic as device blocking voltage is proposed for an SiC-GTO power device, the forward blocking performance of the device is evaluated based on a designed monitoring sampling circuit and a correlation vector machine algorithm, and the forward blocking characteristics of the SiC-GTO device can be effectively monitored online bythe whole method. According to the method, the blank of the research of an embedded monitoring and diagnosis method of SiC-GTO forward blocking characteristics at present is filled, the forward blocking characteristics are indirectly characterized by selecting low-voltage characteristic parameters, the dependence on special high-voltage equipment in a current device blocking characteristic test process is overcome, the forward blocking characteristics of the SiC-GTO device can be monitored online through an embedded monitoring circuit, the high integration of the monitoring circuit and a power circuit is achieved, the applications are flexible, and economic cost and labor cost are saved.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

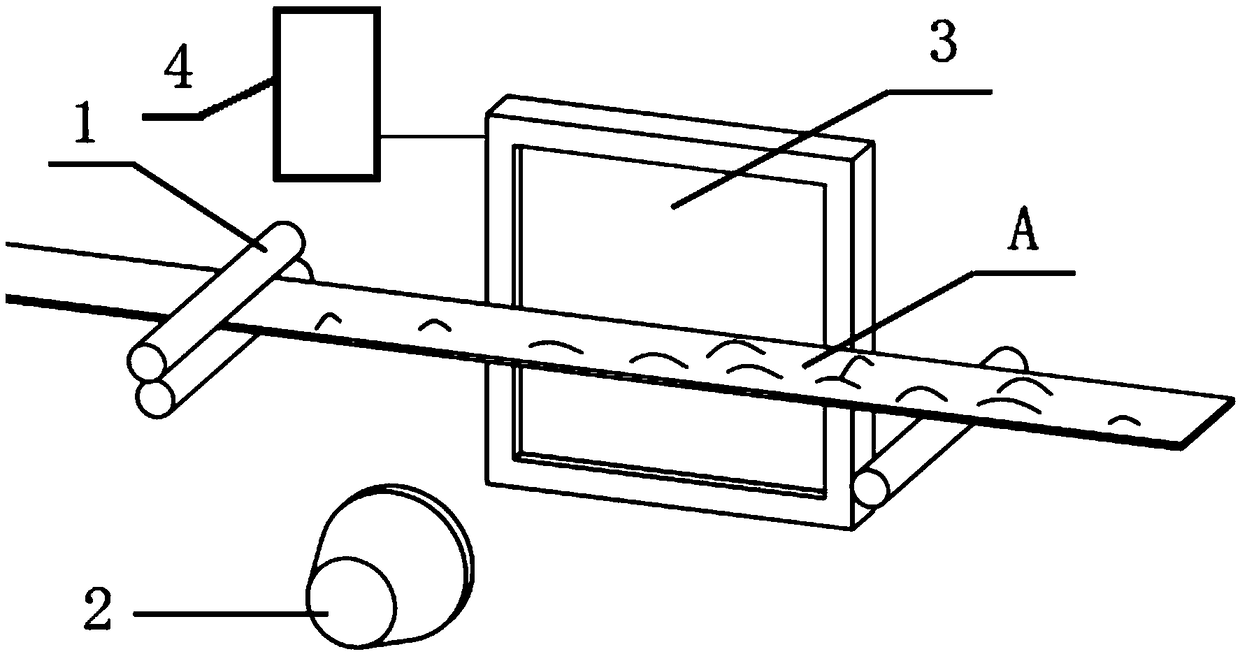

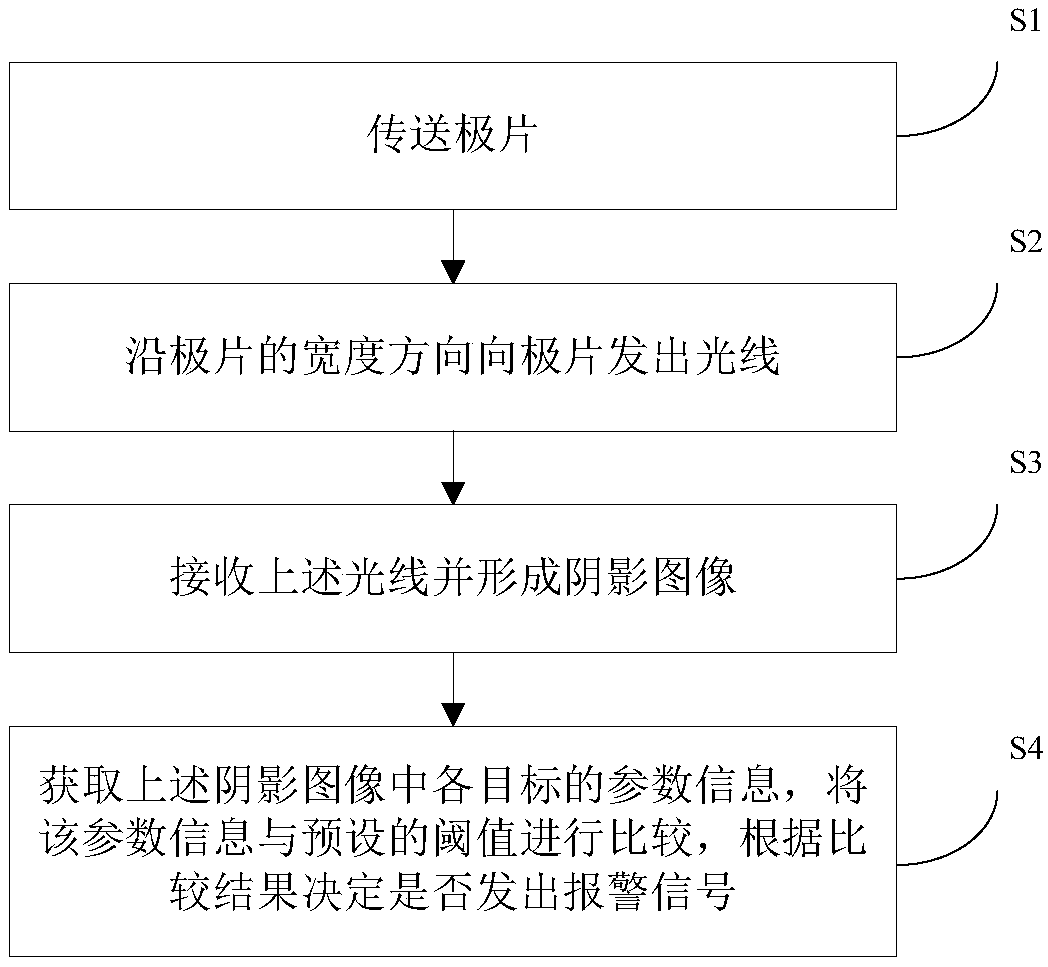

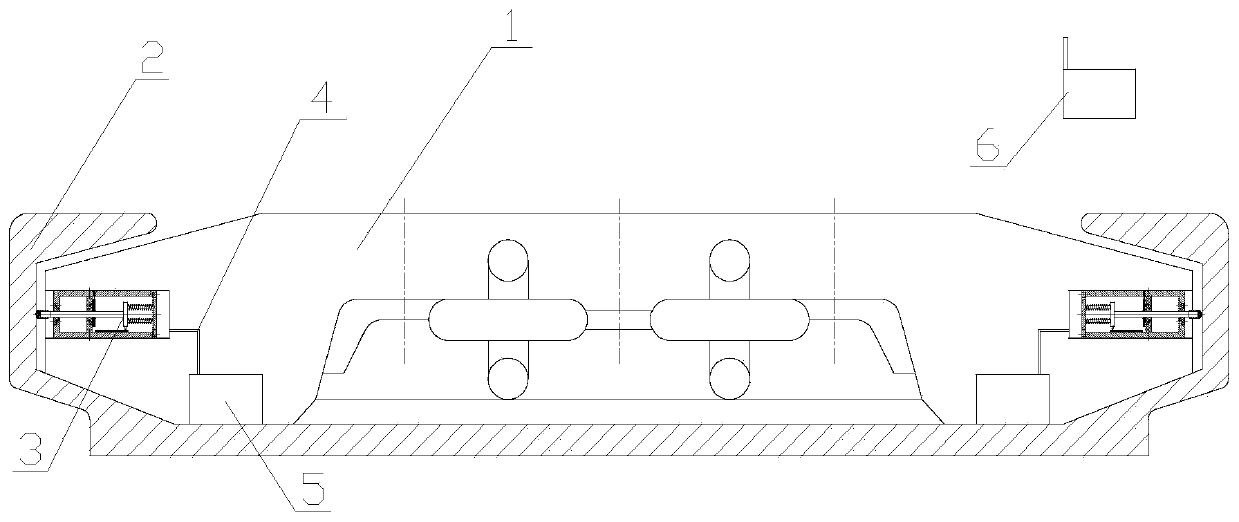

Device and method for monitoring rippled edge of lithium battery pole piece online

InactiveCN108627115AReflect status in real timeEffective online monitoringUsing optical meansEngineeringPole piece

The invention discloses a device for monitoring a rippled edge of a lithium battery pole piece online. The device comprises a conveying mechanism used for conveying a pole piece, a light source whichis arranged at one side of the pole piece and is used for emitting light along the width direction of the pole piece to the pole piece, a receiving screen which is arranged at one side of the pole piece away from the light source and is used for receiving the light and forming a shadow image, and a processor which is used for obtaining the parameter information of each target in the shadow image,comparing the parameter information with the preset threshold and determining whether an alarm signal is emitted according to the comparison result. The device is advantaged in that the structure is simple, operation is convenient, and online monitoring of the rippled edge of the lithium battery pole piece can be effectively carried out.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

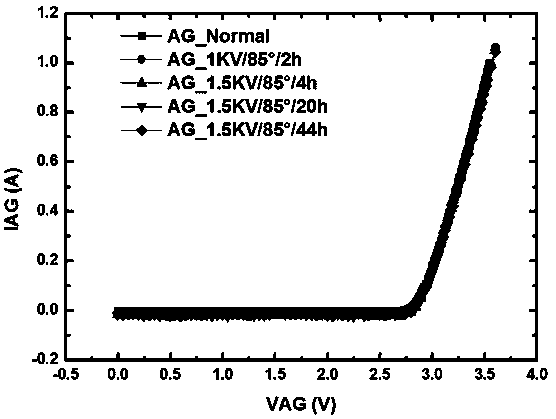

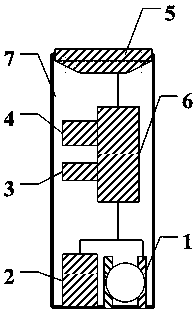

Embedded type scraping plate corner detecting device and detecting method of scraping plate conveyor

ActiveCN110271813ASmall amount of processing and transformationEasy to set upConveyorsControl devices for conveyorsComputer moduleEngineering

The invention discloses an embedded type scraping plate corner detecting device and detecting method of a scraping plate conveyor. The detecting device comprises two telescopic detecting devices, two signal detecting units and a remote processing unit; the telescopic detecting devices and the two signal detecting units are arranged on the two ends of a scraping plate correspondingly, the signal detecting units detect movement displacement of the telescopic detecting devices in real time and send out signals through a wireless transmitting module, the wireless transmitting module and a wireless receiving module are used for data transmission, a signal display processing module is used for calculating the corner value of a scraping plate in real time, meanwhile, the corner value is output and displayed, the real-time measured corner value is compared with the set safety threshold value, and when the value exceeds the safety threshold value, alarm is given out, and prompt is carried out. The device is simple and reliable in structure, low in cost, small in space size, high in adaptation, good in use effect, small in calculation amount in the measuring method, good in real-time performance, high in accuracy and wide in practicability.

Owner:CHINA UNIV OF MINING & TECH +2

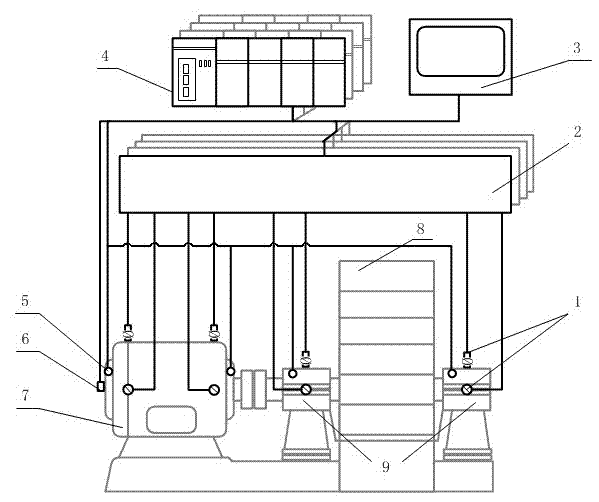

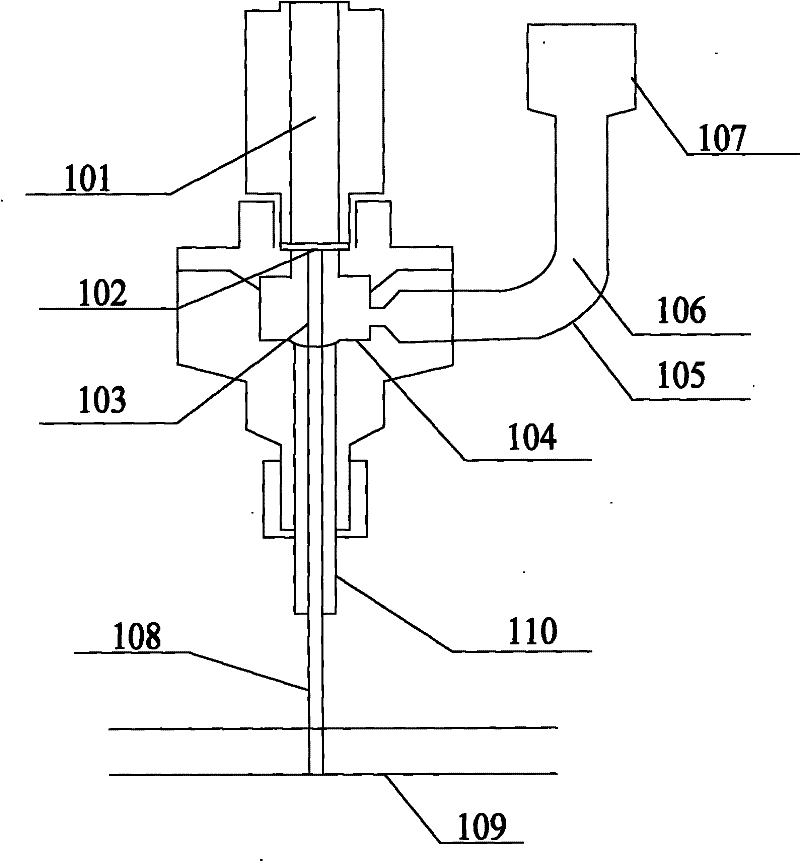

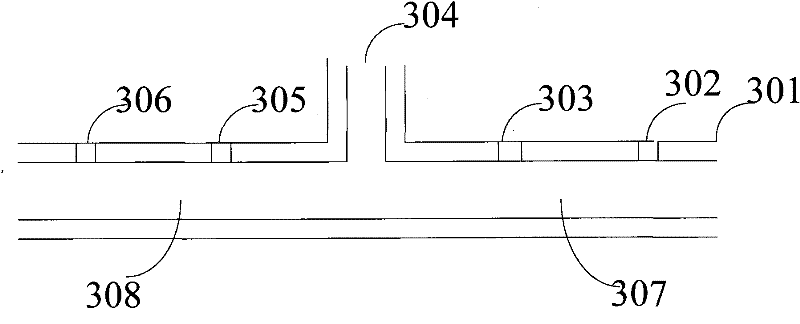

Online monitoring system, device and method of abrasive of high-pressure water-jet cutting machine

InactiveCN101670562BEffective online monitoringAvoid damageAbrasive feedersMonitoring systemData acquisition

The embodiment of the invention discloses an online monitoring system of abrasive of a high-pressure water-jet cutting machine, which comprises a control part, a data collection part and a pressure-measuring adapter, wherein, the pressure-measuring adapter is a pipeline which is connected with an abrasive conveying pipe of the cutting machine, the pressure-measuring adapter is provided with an air flow section and an abrasive flow section which respectively comprise a plurality of partition test small holes, and the abrasive enters into the abrasive conveying pipe through the abrasive flow section; the data collection part comprises a sensor which is arranged in the corresponding position of the partition test small hole and is used for collecting the pressure value of the corresponding position; and the control part is used for carrying out analysis and comparison on data collected by the data collection part and carrying out the corresponding control operation according to the analysis and comparison result, thereby realizing the real-time online monitoring of the cutting process of the high-pressure water-jet cutting machine and avoiding that high-pressure water jet damages a target workpiece caused by depletion or blockage of the abrasive during the conveying process of the abrasive.

Owner:CHONGQING UNIV

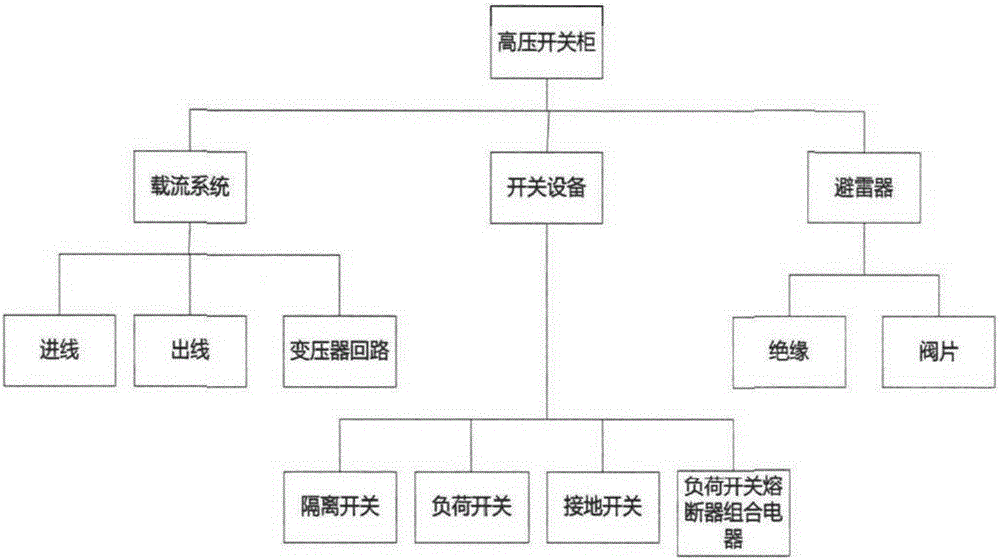

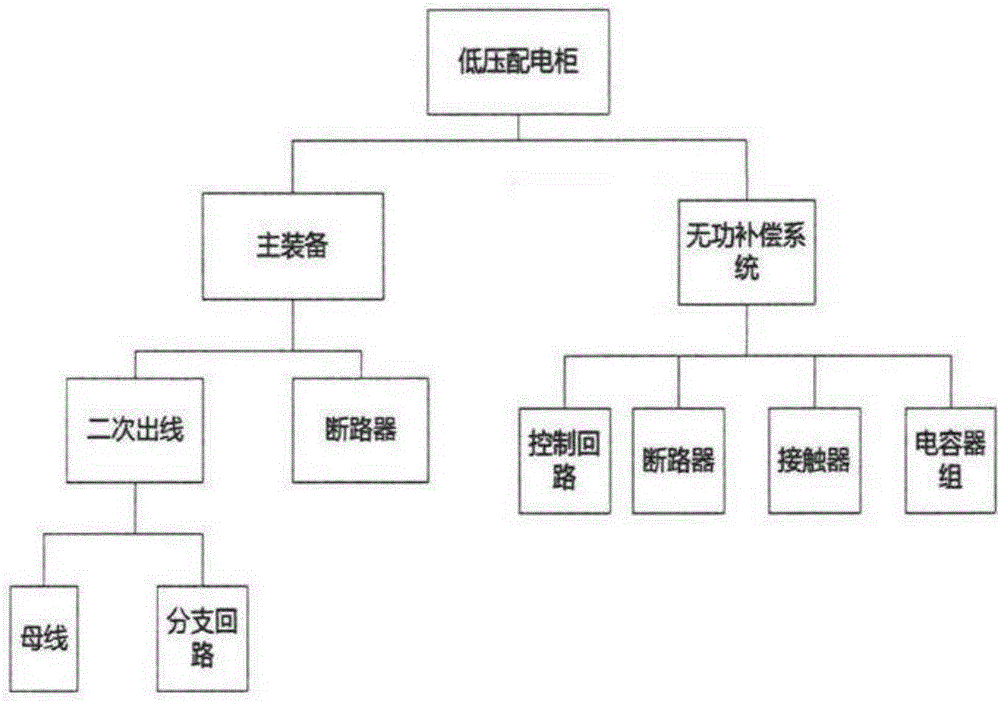

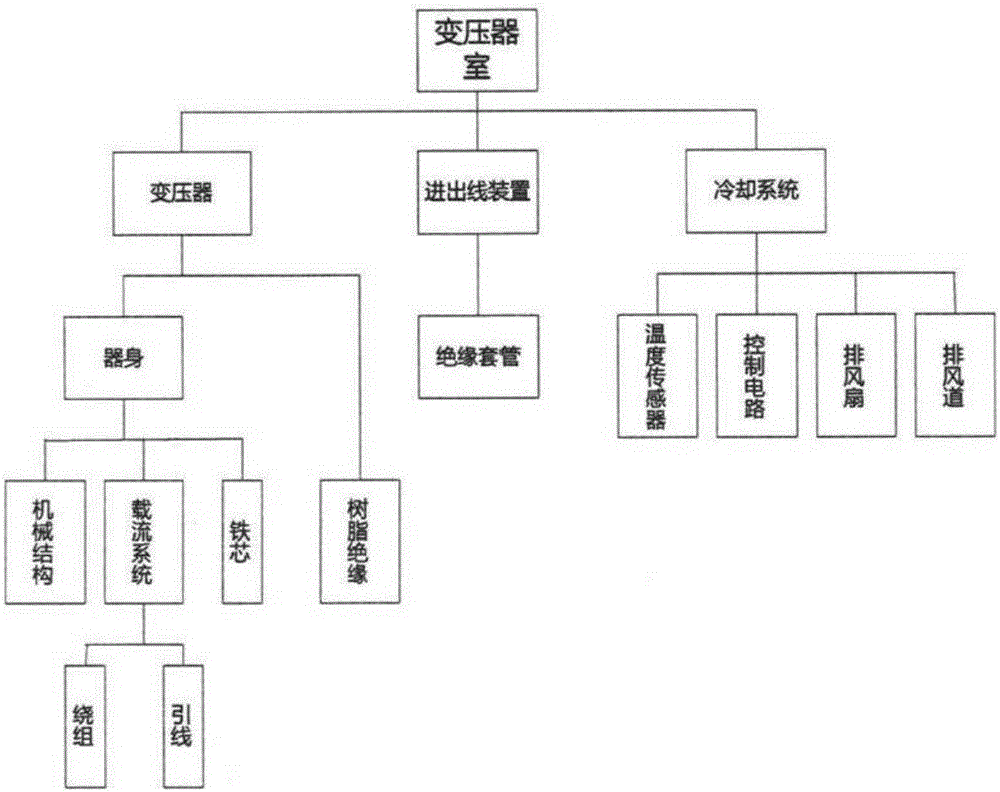

A box transformer substation online detector based on IPV6 intelligent ad hoc network wireless communication

InactiveCN105371890AEffective online monitoringEffective controlMeasurement devicesTransmission systemsEngineeringTransformer

The invention provides a box transformer substation online detector based on IPV6 intelligent ad hoc network wireless communication. The box transformer substation online detector comprises a control system and a cabling system. A box transformer substation comprises a plurality of functional chambers at least including a high voltage chamber, a low voltage chamber, a voltage transformation chamber, an extinguishment bin and a control chamber. The box transformer substation online detector is arranged in the control chamber and can realize wireless communication based on an IPV6 intelligent ad hoc network. The control system of the box transformer substation online detector is used for monitoring and control for box transformer substations.

Owner:BORUI ELECTRIC

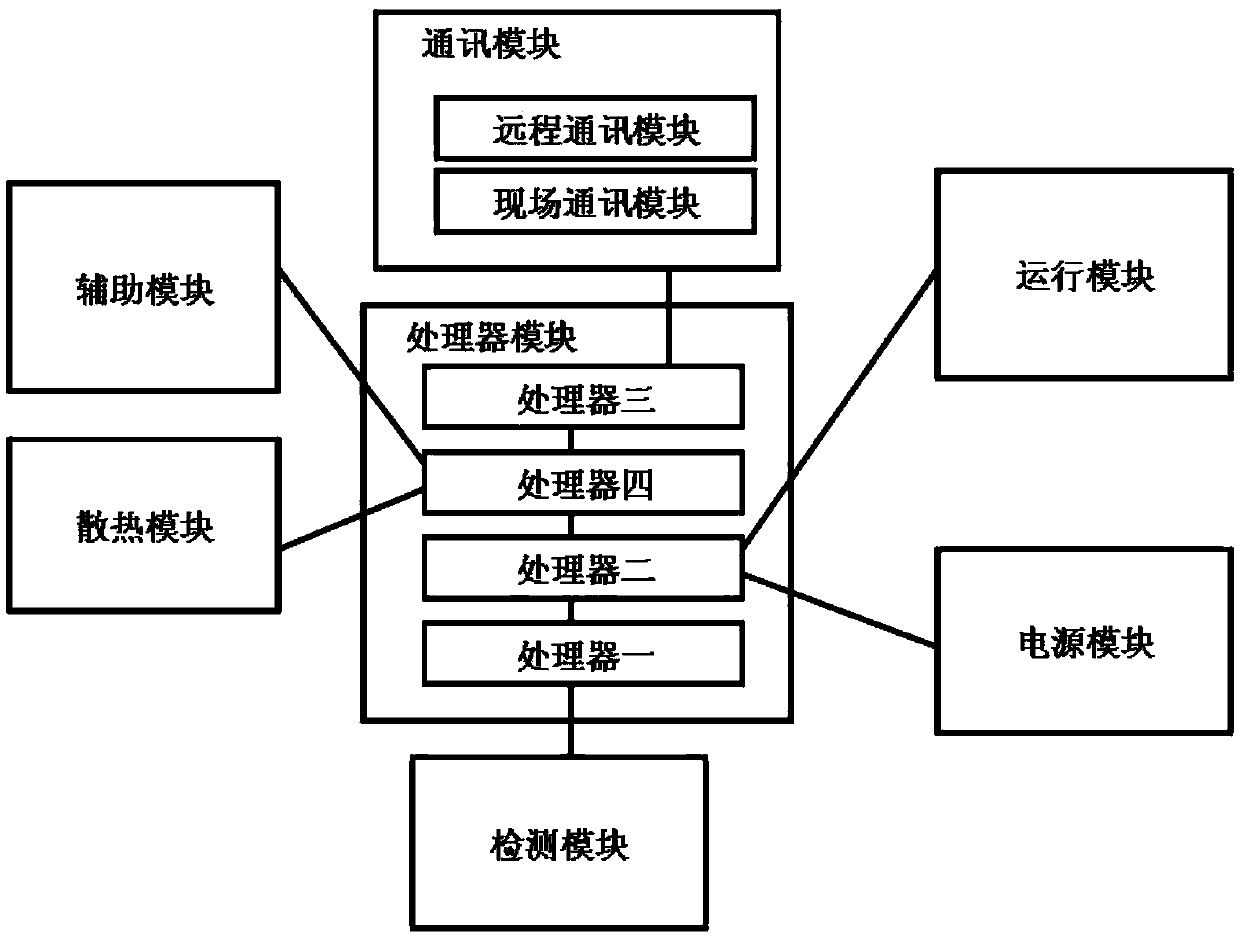

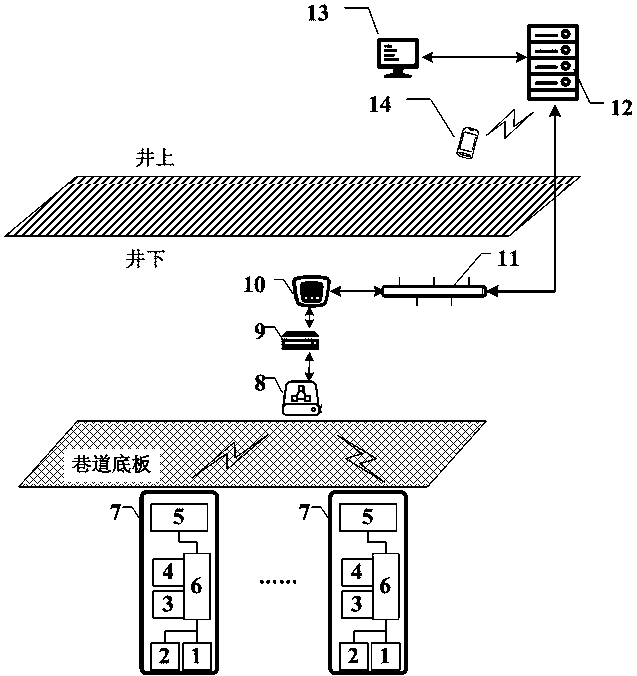

Intelligent early warning system for on-line monitoring of water inrush in austrian limestone on coal mine floor

ActiveCN106194262BImprove transmission efficiencyRealize online intelligent processingMining devicesSensing dataEarly warning system

The invention provides an online intelligent monitoring and early-warning system of ordovician limestone water burst of a coal mine bottom slab. A plurality of multi-parameter sensing subsystems are arranged on the coal mine bottom slab containing ordovician limestone, sensing data obtained through online monitoring are transmitted to a database server through a wireless / wire communication subsystem, and then intelligent early-warning is conducted on the water burst of the coal mine bottom slab through an intelligent water burst early-warning subsystem. By the adoption of the one-hole multi-sense mode, wireless transmission and intelligent early-warning, accurate, convenient, fast and efficient online mine water burst monitoring and early-warning are achieved.

Owner:TAIYUAN UNIV OF TECH

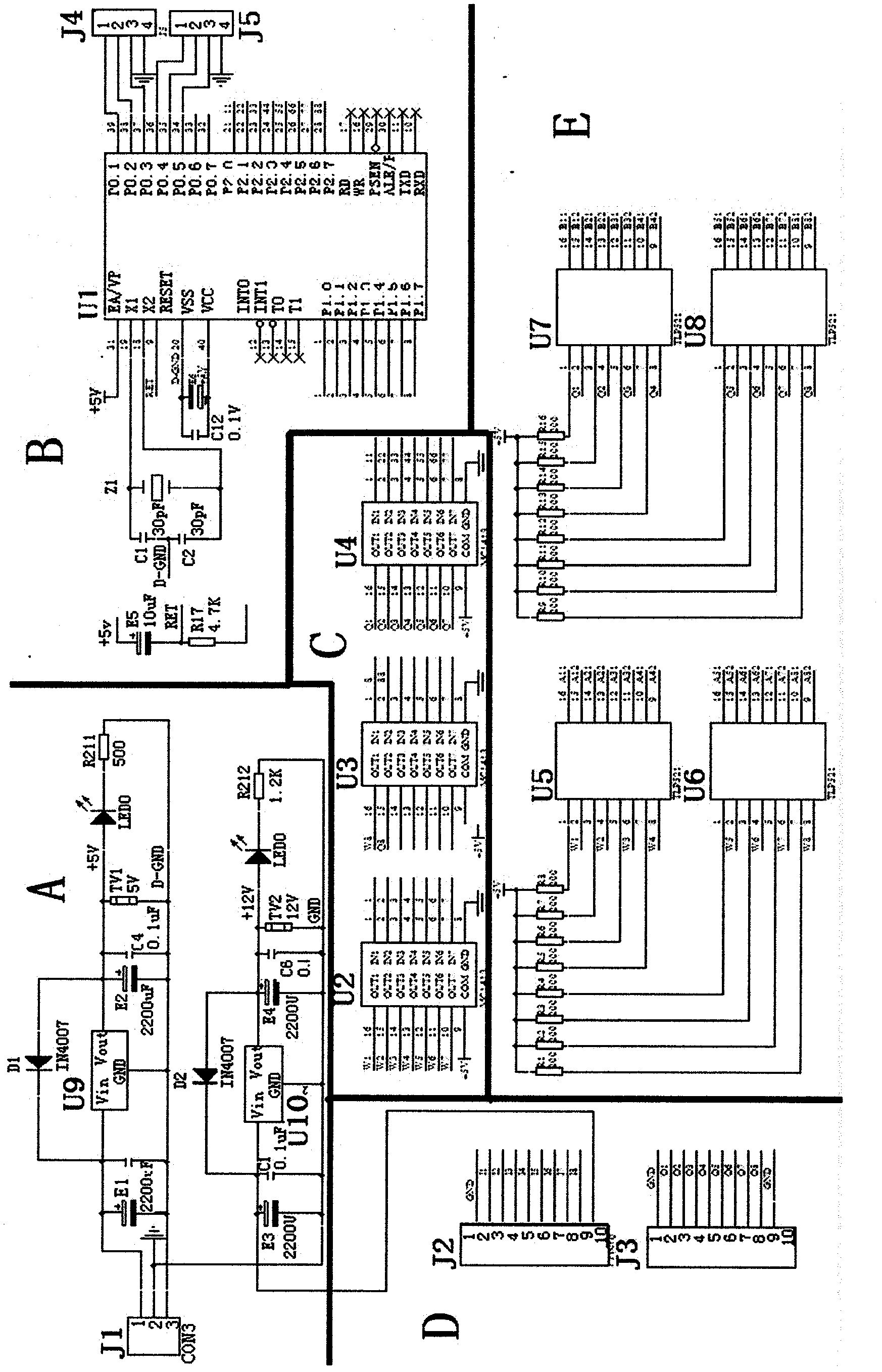

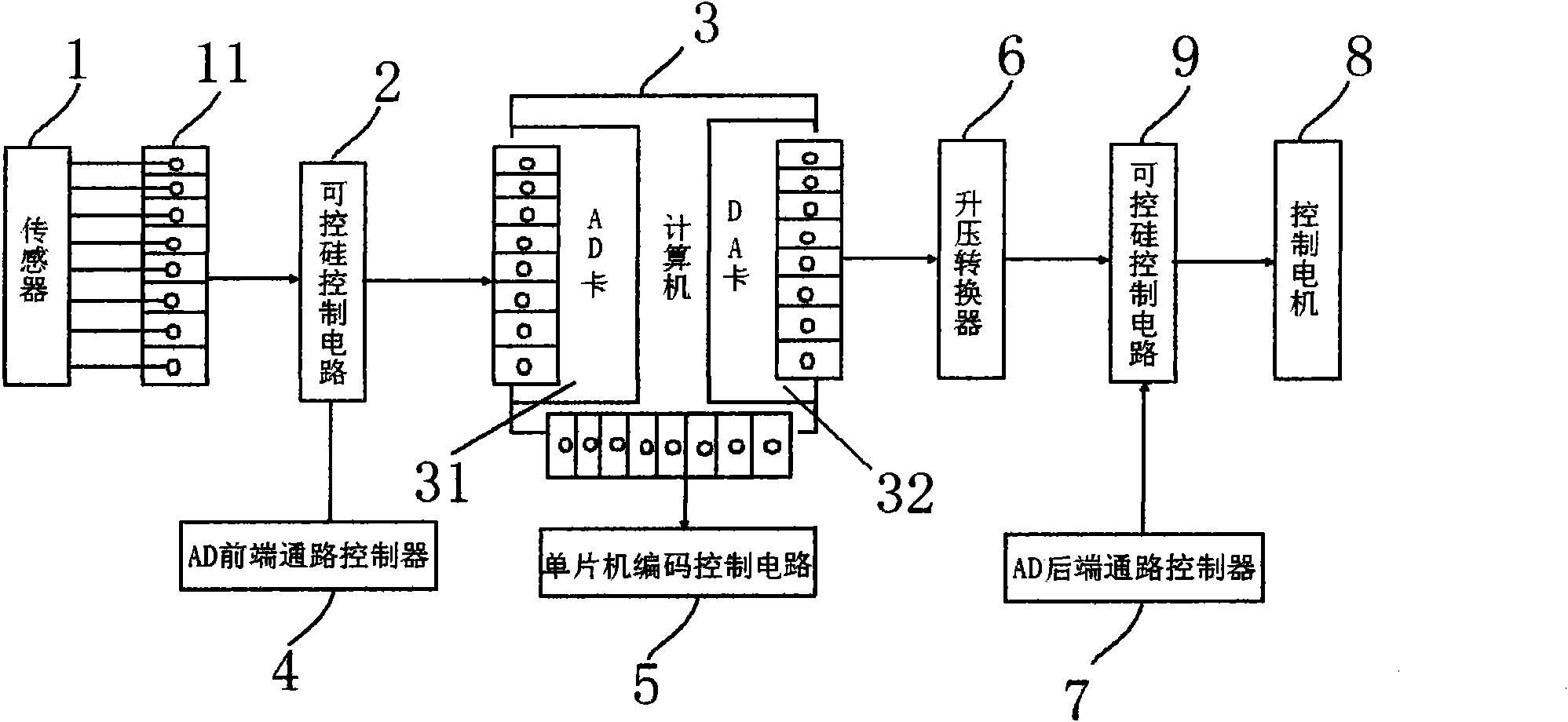

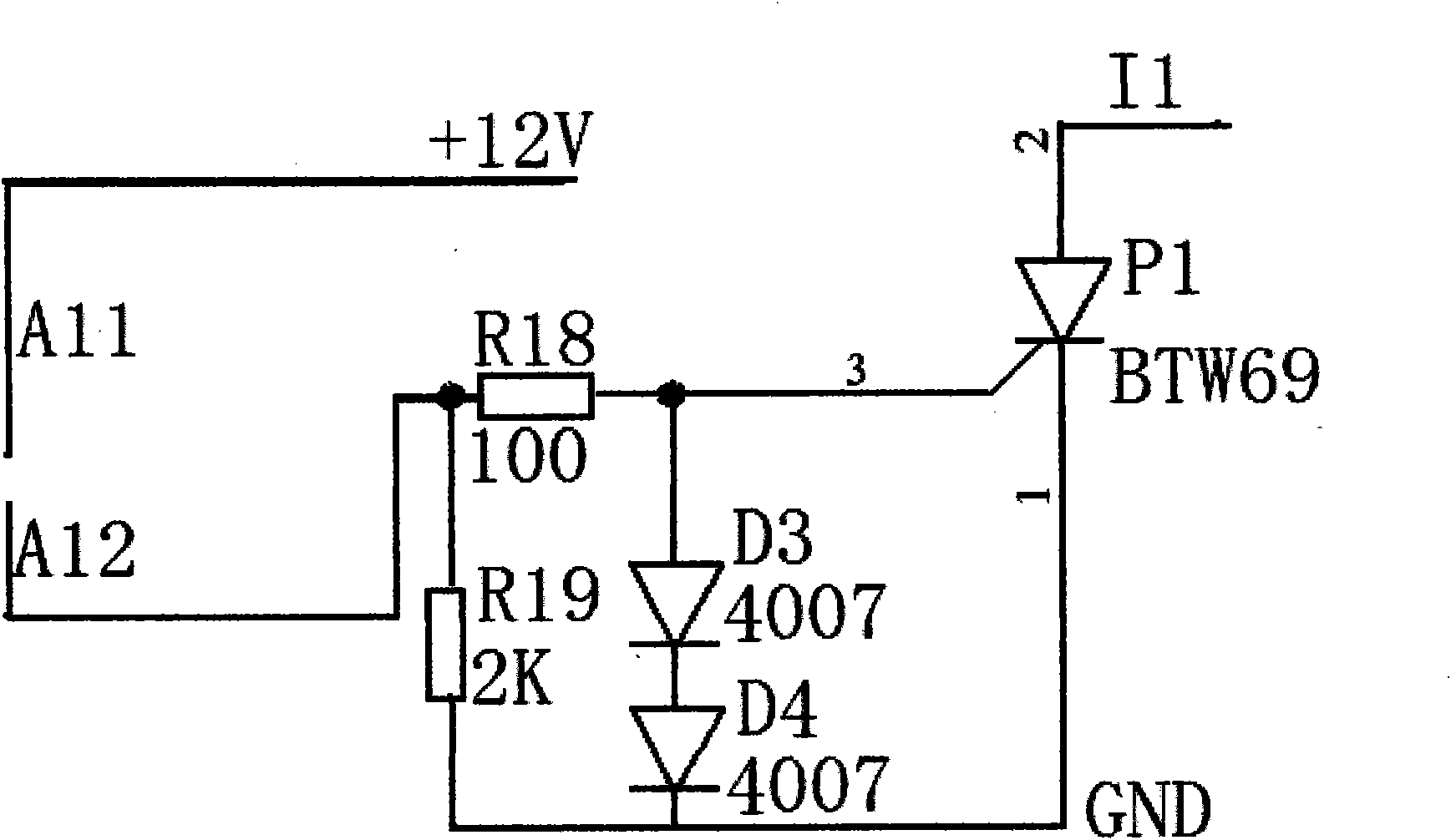

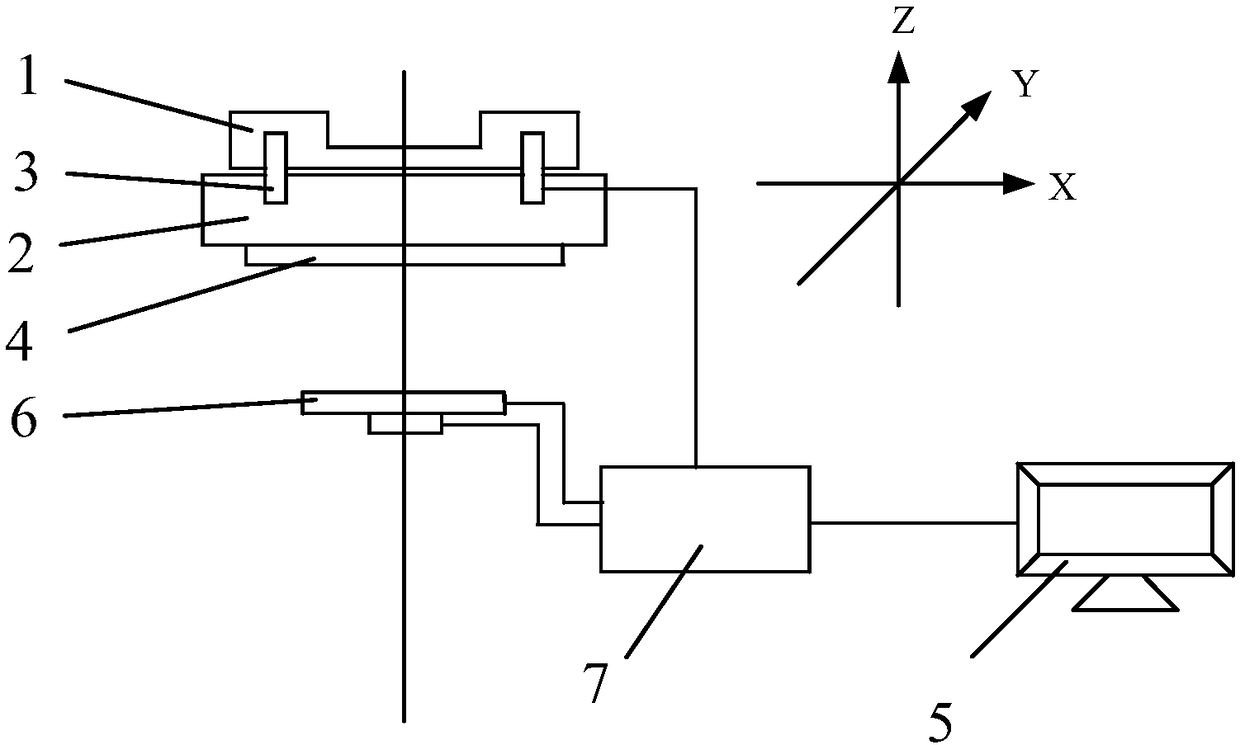

Steel structure performance measurement and control circuit system based on piezoelectric principal element rod piece

InactiveCN102591265AEffective online monitoringEffective real-timeBuilding constructionsTotal factory controlPositive directionBoost converter

The invention discloses a steel structure performance measurement and control circuit system based on a piezoelectric principal element rod piece. An output signal of a sensor is acquired by a controllable silicon control circuit, and the acquiring process is controlled by an AD front end path controller connected with the controllable silicon control circuit; the controllable silicon control circuit is connected with an AD card of a computer, a DA card of the computer is connected with a boost converter, and the computer is connected with a singlechip coding control circuit to process the signal; and the boost converter is connected with one controllable silicon control circuit, and the controllable silicon control circuit is connected to a control motor, and is connected with a DA rear end path controller to control signal output. The system provided by the invention can combine and unify structural steel construction detection and control techniques, can apply forward or backward voltage for control according to the need, can carry out effective on-line monitoring and real-time monitoring, and has high practicability.

Owner:SHAANXI ACAD OF ARCHITECTONICS

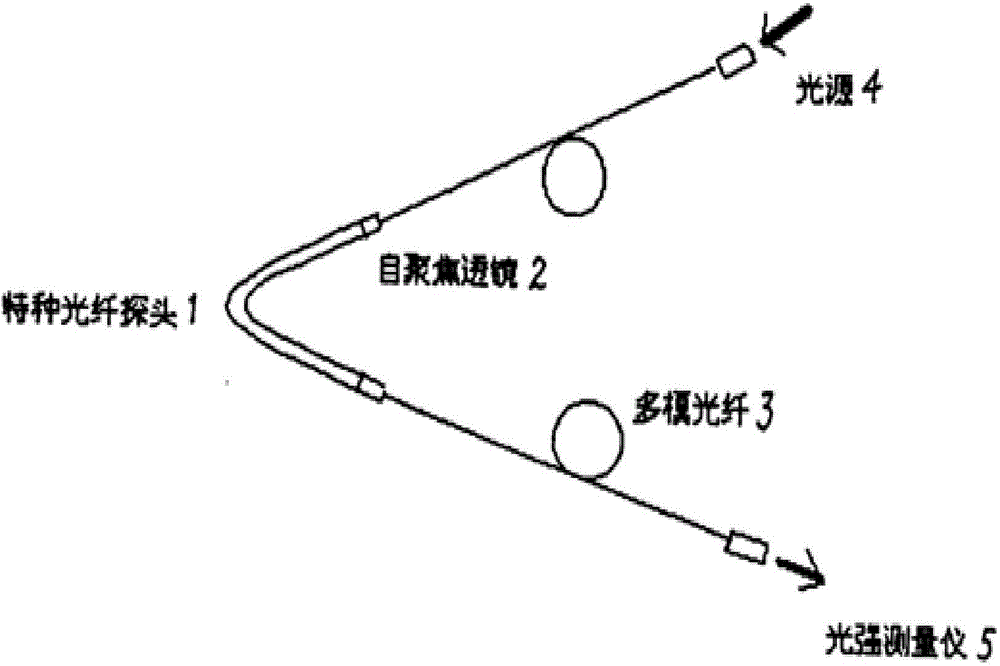

Optical fiber sensor for measuring electrified capacity of transformer oil

InactiveCN104635120AEffective online monitoringSimple structureTesting dielectric strengthPhotometryMeasuring instrumentTransmittance

The invention discloses an optical fiber sensor for measuring electrified capacity of transformer oil. The optical fiber sensor for measuring the electrified capacity of the transformer oil comprises a V-shaped special optical fiber probe and two multi-mode optical fibers coupled to a self-focusing lens. After two fracture surfaces of a special optical fiber rod are ground and polished, the special optical fiber rod is bent into the V-shaped special optical fiber probe; one ends of the two multi-mode optical fibers are respectively coupled to the self-focusing lens; the self-focusing lens is adhered to the optical fiber probe; the optical fiber probe of the optical fiber sensor is directly placed in the transformer oil; and two leading-out ends of the two multi-mode optical fibers are respectively connected with a light source and a light intensity measuring instrument. According to the characteristic that the light gathering capabilities of the optical fibers in media with different dielectric constants are different, change of the electrified capacity of the transformer oil can be monitored by monitoring the change conditions of transmittance of the optical fiber probe in the transformer oil. The optical fiber sensor is simple in structure and high in sensitivity and is convenient and practical.

Owner:DALIAN KANGSAIPU TECH DEV

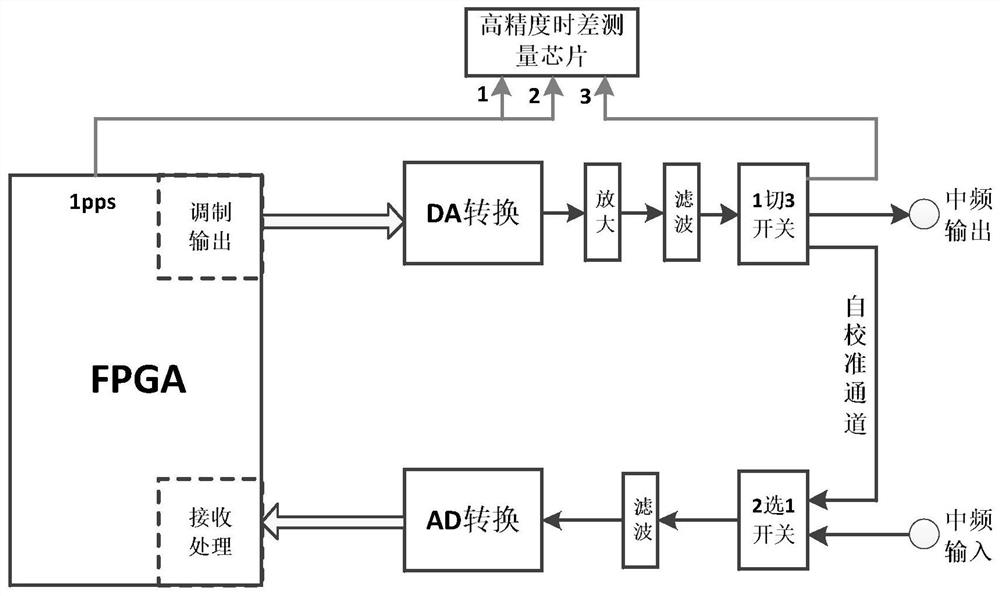

Automatic baseband zero value monitoring method for aircraft measurement and control system

ActiveCN111614407AImprove the accuracy of zero calibrationImprove ranging accuracyTransmitters monitoringReceivers monitoringEngineeringDigital converter

The invention discloses an automatic baseband zero value monitoring method for an aircraft measurement and control system, and aims to provide a baseband zero value automatic monitoring method which is high in monitoring precision, simple and convenient to operate and reliable in monitoring. According to the technical scheme, a modulation output end of an FPGA is sequentially connected with a digital-to-analog converter DA, an amplifier, a filter and a radio frequency self-calibration channel, formed by connecting one-to-three switches, of a one-out-of-two switch; the one-out-of-two switch issequentially connected with the a filter of the FPGA receiving processing interface and an analog-to-digital converter AD in the clockwise direction to form a reception channel; the FPGA sends a 1ppssignal and a baseband output signal to a high-precision time difference measurement chip, and a time difference between a channel 1 and a channel 3 is measured; and a baseband receiving zero value iscompared with a pre-calibrated standard baseband receiving zero value to obtain the variable quantity of the baseband receiving zero value of a measurement and control responder, and zero value of theaircraft measurement and control system is corrected according to the variable quantity.

Owner:10TH RES INST OF CETC

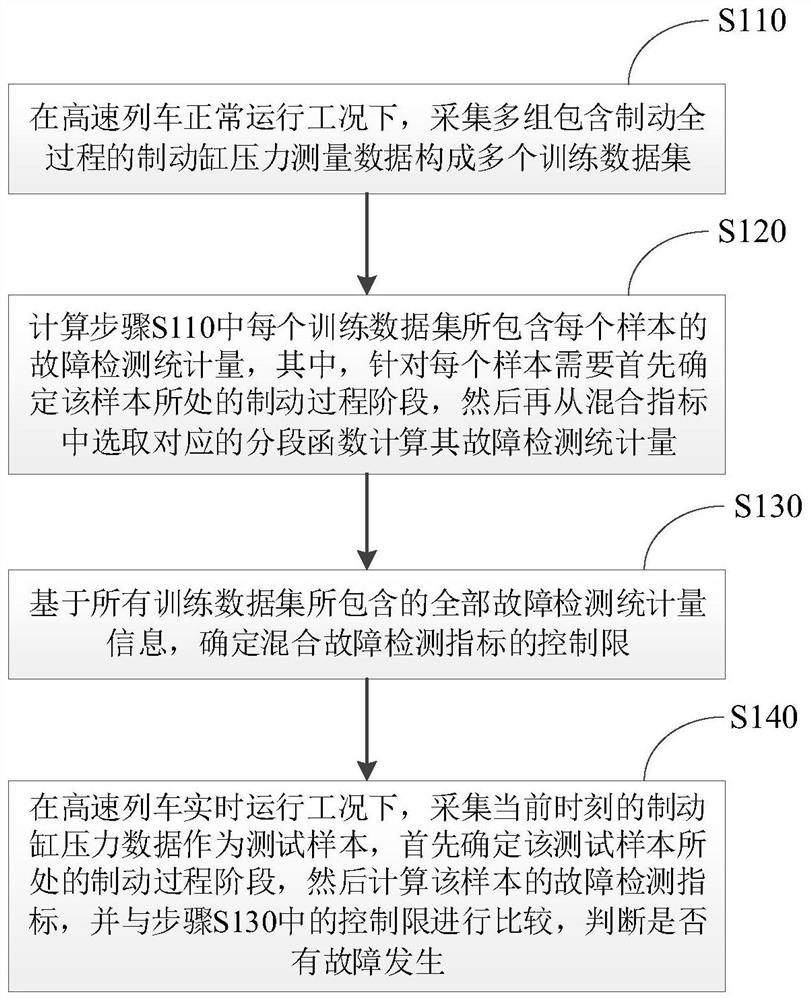

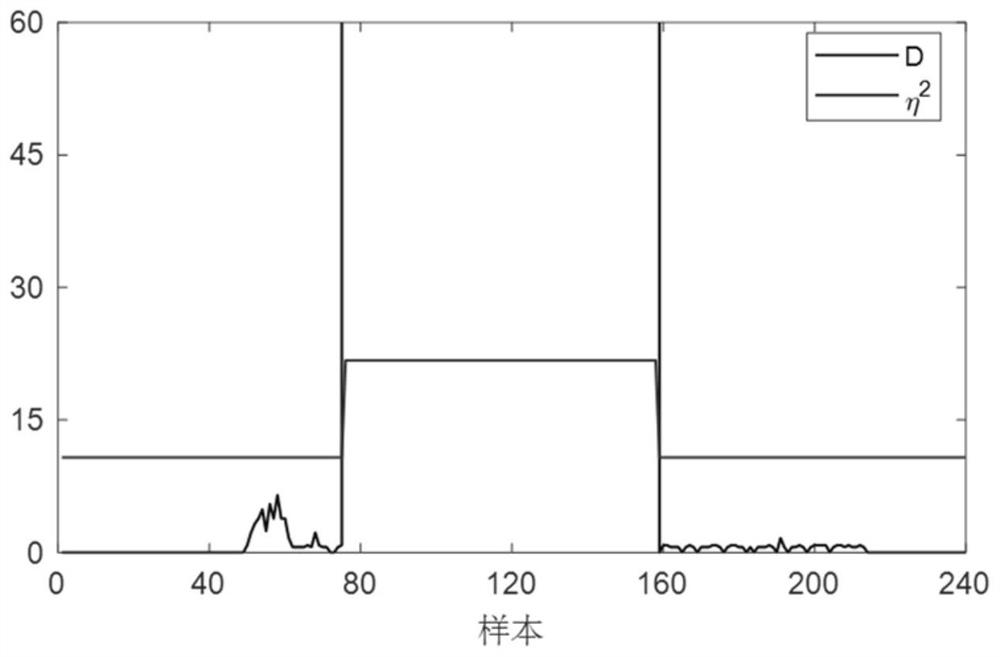

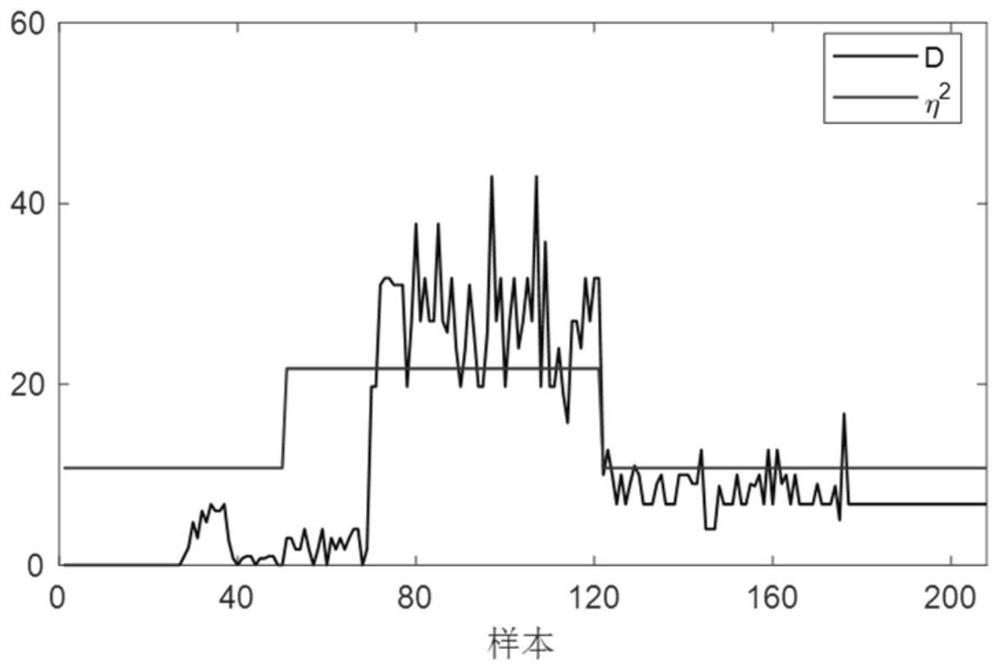

A micro-fault detection method for high-speed train air brake system

ActiveCN110293949BEffective Online MonitoringEasy to implementBrake safety systemsData setData modeling

The invention discloses a micro-fault detection method for an air brake system of a high-speed train, which belongs to the field of fault diagnosis. The method comprises: collecting multiple groups of brake cylinder pressure measurement data including the whole braking process under the normal operation condition of the high-speed train Constitute multiple training data sets; calculate the fault detection statistics of each sample contained in each training data set; determine the control limit of the mixed fault detection statistics based on all the fault detection statistics information contained in all training data sets; Under the real-time operating conditions of high-speed trains, the collected brake cylinder pressure data at the current moment is used as a test sample to determine whether there is a fault. The invention utilizes historical data modeling and online data detection, has no requirements for data distribution, and has a simple algorithm, which is easy for computer implementation and practical application, is applicable to different braking levels and braking stages, and has good detection for several types of micro-faults Effect.

Owner:SHANDONG UNIV OF SCI & TECH

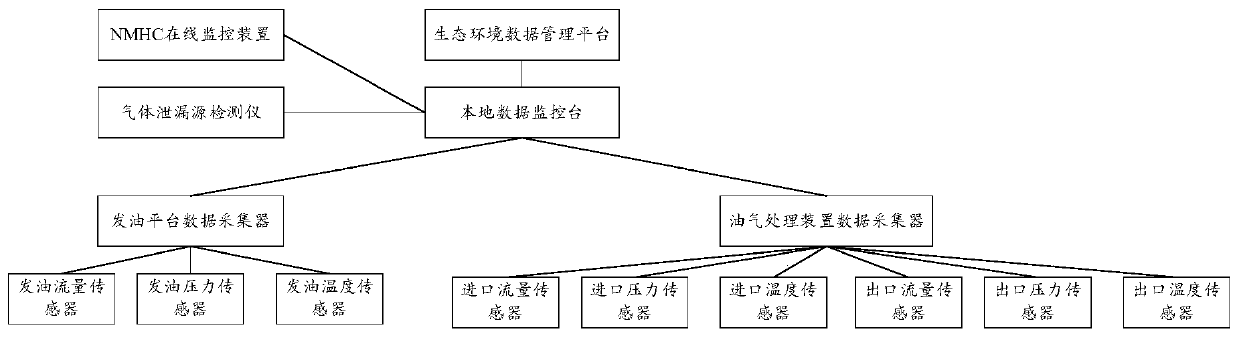

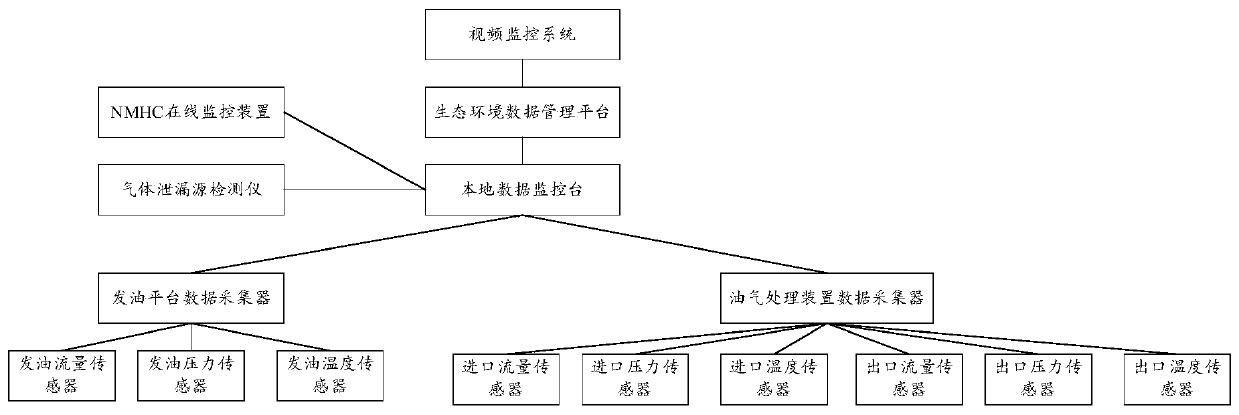

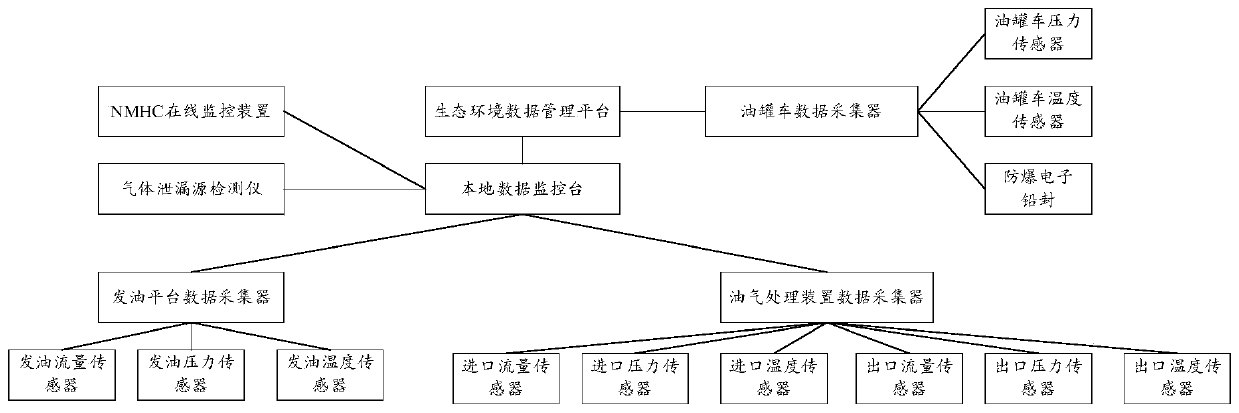

Oil storage oil gas recovery online monitoring system

PendingCN111153063AEffective online monitoringSolve the problem that the recovery of oil and gas in the oil depot cannot be monitoredProtective foundationLarge containersMonitoring systemData acquisition

The invention discloses an oil storage oil gas recovery online monitoring system. An oil delivery platform data collector is correspondingly communicated with an oil delivery oil gas flow sensor, an oil delivery oil gas pressure sensor and an oil delivery oil gas temperature sensor which are mounted on an oil delivery oil gas recovery pipeline; an oil gas processing device data collector is mounted at the end of an oil gas processing device and is correspondingly communicated with an inlet oil gas flow sensor, an inlet oil gas pressure sensor and an inlet oil gas temperature sensor which are arranged at an oil gas inlet of the oil gas processing device and an outlet oil gas flow sensor, an outlet oil gas pressure sensor and an outlet oil gas temperature sensor which are arranged at a discharge port; NMHC online monitoring devices are mounted at the oil gas inlet and the discharge port; a gas leakage source detector is mounted at a leakage point; the oil delivery platform data collector, the oil gas processing device data collector, the NMHC online monitoring devices and the gas leakage source detector are communicated with a local data monitoring station; and the local data monitoring station is communicated with an ecological environment data management platform.

Owner:北京恒合信业技术股份有限公司

Transformation Method of On-Line Monitoring Capacitive Voltage Transformer for Surge Arrester

ActiveCN103645368BAvoid groundingGuaranteed accuracyCurrent/voltage measurementVoltage dividersPower flowFuel tank

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN

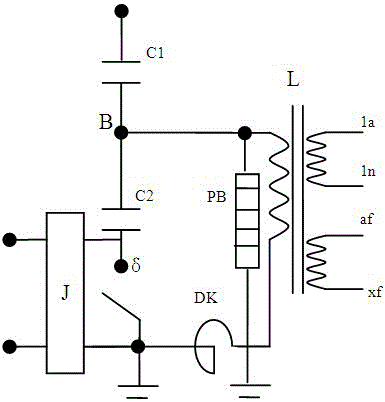

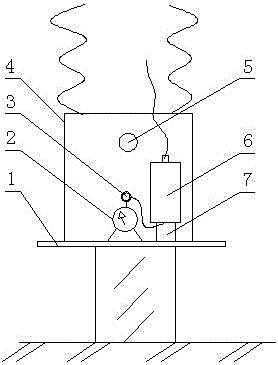

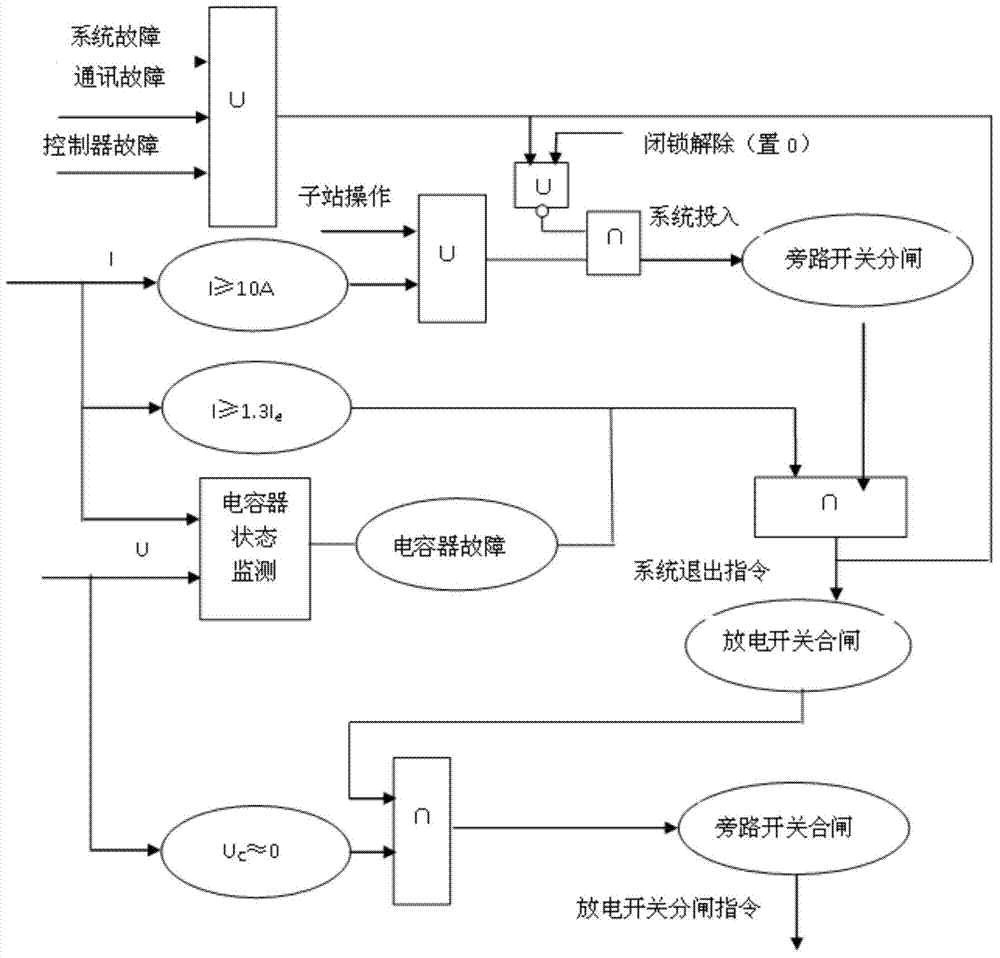

Control method of novel medium and high-voltage power distribution network controller

InactiveCN104753060AEffective online monitoringEffective protectionEmergency protective circuit arrangementsContigency dealing ac circuit arrangementsCapacitanceElectric signal

The invention provides a control method of a novel medium and high-voltage power distribution network controller. The method includes the specific steps of enabling a controller to perform system feedback according to electric signals; receiving discharge switch 15V closing pulse signals transmitted from a fast controller, when a discharge switch is determined to be closed about 10-15 ms later and the voltage at both ends of a capacitor is detected to be zero, issuing a closing instruction to a bypass switch one closing time earlier, and after the bypass switch is determined to be closed, issuing a discharge switch opening instruction; when the line current exceeds 10 A and after a bypass switch energy-storage capacitor is completely charged delayed 2 minutes later, issuing a bypass switch opening instruction; when the instantaneous value of the line current exceeds 1.459 A for 0.4 ms continuously, immediately starting an 'exit system' operation.

Owner:TIANDAQIUSHI ELECTRIC POWER HIGH TECH CO LTD

On-line monitoring and fault diagnosis method of multi-working condition process for ultra-high-speed carton packaging machine in cigarette factory

ActiveCN105573290BImprove monitoring resultsEffective online monitoringProgramme controlElectric testing/monitoringSliding time windowUltra high speed

The invention relates to a statistical modeling, online monitoring and fault diagnosis technology of a superspeed carton packaging machine BV of the Italian G.D company and discloses a cigarette factory superspeed carton packaging machine multi-condition process online monitoring and fault diagnosis method. According to the method, a stable condition and a transition condition of stability factor identification are calculated based on a slide time window in an offline mode, the stable condition is divided to form a plurality of stable condition data clusters by use of an adaptive k-means cluster method, and then a statistical monitoring model is established independently for each stable condition data cluster by use of a PCA method. During online monitoring, a condition type is determined according to a stability factor of data in a current slide time window, under the stable condition, real-time monitoring is carried out by use of one PCA monitoring model corresponding to a cluster with a minimum distance, when any one statistical amount exceeds a limit, a major process variable causing a fault is determined by use of a contribution graph method, and finally, an effective feasible method is provided for online monitoring and fault diagnosis of the superspeed carton packaging machine BV.

Owner:CHINA TOBACCO ZHEJIANG IND

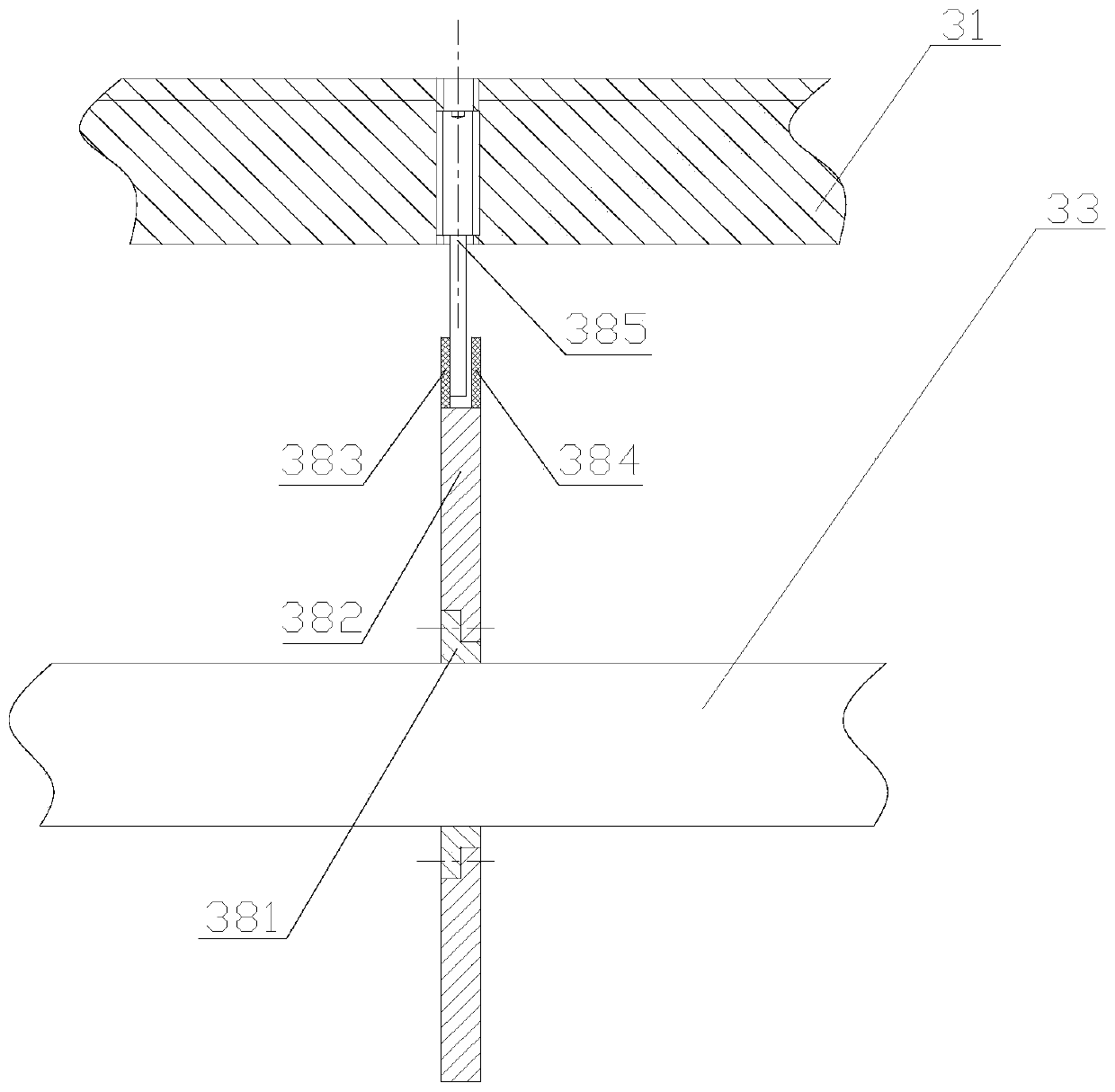

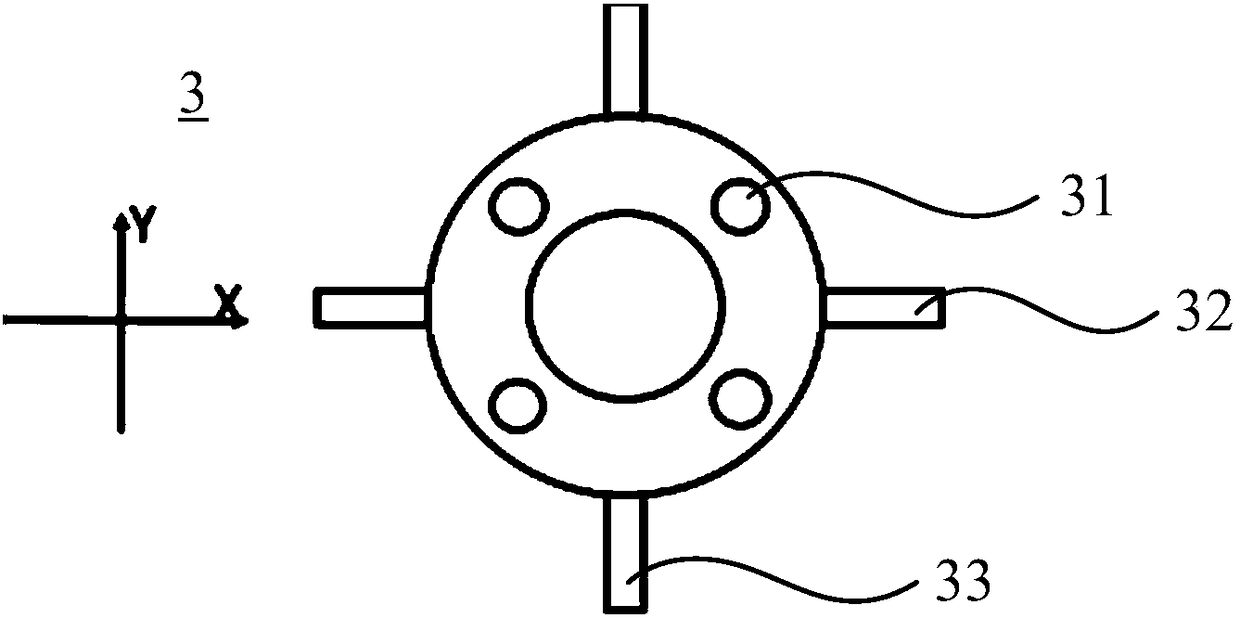

Optical fiber coating concentricity online adjusting device and optical fiber coating concentricity online monitoring and adjusting device

PendingCN109305765AHigh adjustment accuracyOvercoming Inconvenience and Low PrecisionUsing optical meansCeramicElectricity

The invention discloses an optical fiber coating concentricity online adjusting device and an optical fiber coating concentricity online monitoring and adjusting device, and belongs to the technical field of optical fibers. The online adjusting device comprises a piezoelectric ceramic assembly and an assisting part connected with the piezoelectric ceramic assembly. The piezoelectric ceramic assembly comprises at least two first piezoelectric ceramic parts arranged on a base of a coating cup in the Z-axis direction, at least one second piezoelectric ceramic part arranged on the periphery of thecoating cup in the X-axis direction and at least one third piezoelectric ceramic part arranged on the periphery of the coating up in the Y-axis direction. The optical fiber coating concentricity canbe online monitored automatically and conveniently, and the two devices solve the problems of inconvenience and low precision of online monitoring and adjusting in the prior art, can conveniently andeffectively monitor and adjust the optical fiber coating concentricity, has good practicability and can be widely applied to the technical field of optical fiber coating and the like.

Owner:ZHONGTIAN TECH FIBER OPTICS +2

CDMA-communication and local-wireless-ad-hoc-network-communication integrated box transformer substation monitor

InactiveCN105207360AEffective online monitoringEffective controlCircuit arrangementsTransformerControl system

The invention discloses a CDMA-communication and local-wireless-ad-hoc-network-communication integrated box transformer substation monitor. The box transformer substation monitor comprises a control system and a functional system, and CDMA-communication and local-wireless-ad-hoc-network-communication integration can be achieved through the control system. The functional system comprises a high voltage cabin, a low voltage cabin and a variable voltage cabin. The variable voltage cabin is buried underground.

Owner:BORUI ELECTRIC

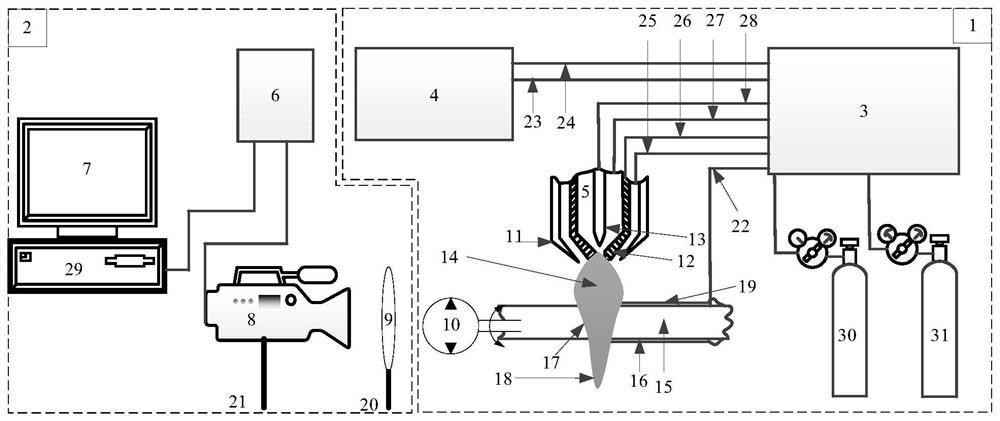

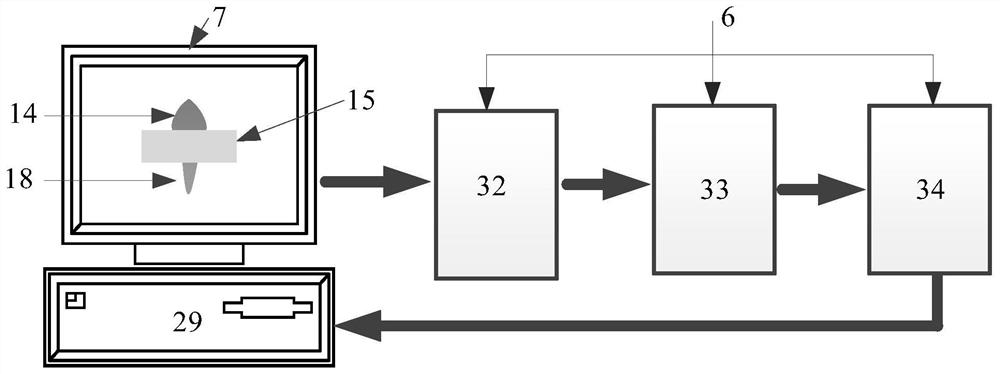

Welding quality control system and method for arc temperature difference before and after plasma arc piercing

ActiveCN108544068BOvercoming the pitfalls of retestingRealize online monitoringWelding/cutting auxillary devicesAuxillary welding devicesControl systemEngineering

The invention discloses a welding quality characterization and control system and method based on the arc temperature difference between the front and back sides of a variable polarity plasma arc. Add a specific narrow-band filter to the arc image. The entire arc image is filtered and symmetrized, and the temperature before and after the arc piercing is obtained by the standard temperature method, and the arc temperature difference between the front and the back is calculated, which is used to characterize the current welding quality. In addition, during the welding process, the temperature difference before and after the arc perforation is collected and calculated in real time and compared with the arc temperature difference of qualified welding quality, and the current welding arc temperature difference is adjusted in real time to within the error range of the qualified welding quality temperature difference, so as to realize plasma arc welding Performance characterization and control of quality.

Owner:BEIJING UNIV OF TECH

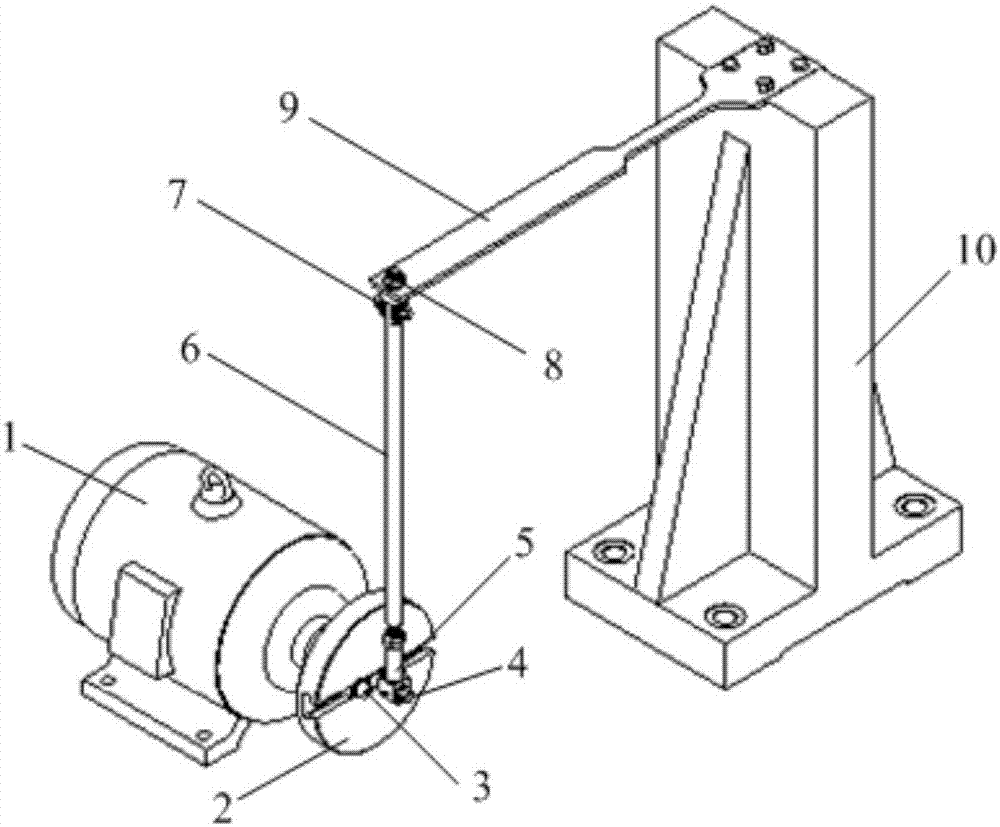

Mechanical structure fatigue damage online monitoring test device

ActiveCN105092397BAvoid superimposed vibrationOnline monitoring of fatigue damage is effectiveMaterial strength using repeated/pulsating forcesFatigue damageCantilevered beam

The invention discloses a mechanical structure fatigue damage online monitoring test device including a cantilever beam specimen with one end fixed; the other end of the cantilever beam specimen is connected with a reciprocating driving mechanism for driving the cantilever beam specimen to swing. The test device also includes a strain transducer for measuring the strain quantity transmitted from the reciprocating driving mechanism to the cantilever beam specimen and a strain transducer for measuring the strain quantity of the cantilever beam specimen in a swinging process. According to the test device, the adopted reciprocating driving mechanism and the adopted cantilever beam specimen are in connection state, and a cantilever beam is suffered from force applied by the driving mechanism in the swinging process, so that the cantilever beam specimen is avoided from being suffered from superposed vibration of the reciprocating driving mechanism in the swinging process, and the driving way is closer to an actual situation; with utilization of the strain transducers, information characterizing a mechanical structure fatigue state can be obtained, and thus the equivalent elasticity modulus of a mechanical structure is obtained, and the fatigue condition of the mechanical structure can be obtained through assessment of a change law of the equivalent elasticity modulus.

Owner:HENAN UNIV OF SCI & TECH

Real-time monitoring method of damage growth based on fcm algorithm under the influence of time-varying temperature

ActiveCN107367552BImprove reliabilityEnsure safetyProcessing detected response signalCharacter and pattern recognitionData setAlgorithm

The invention relates to a real-time monitoring method for damage expansion based on the fuzzy C-means (FCM) algorithm under the influence of time-varying temperature, which can effectively solve the influence of changing factors only by relying on the distribution characteristics of the signal itself, and can effectively detect the damage under the influence of temperature changes. On-line monitoring of the damage expansion trend of the structure. The offset index used in the present invention can effectively monitor the change trend of damage expansion in real time, and can also provide certain basis for the quantification of damage expansion. The invention does not need to change or add equipment and parameters in the realization process, and can be realized by using the existing hardware system, has strong feasibility, short algorithm operation time, high accuracy and easy operation. Other data sets and motion data update strategies have also played a huge role in online real-time damage monitoring, ensuring the real-time performance of online updates and reducing the demand for all historical data, relieving the pressure on data storage, and having good practicality. engineering value.

Owner:XIAMEN UNIV

Method and device for measuring optical fiber attenuation value

ActiveCN109347553BEffective online monitoringWill not affect performancePhotonic quantum communicationEngineeringLight signal

The invention discloses measurement methods and devices for an optical fiber attenuation value, relates to the technical field of quantum communication and is used for monitoring an attenuation valueof an optical fiber online in real time. A method comprises the steps of obtaining a first bit rate and a second bit rate, wherein the first bit rate is a photon counting rate received by a receivingend when a sending end sends optical signals through utilization of the optical fiber, the second bit rate is the photon counting rate received by the receiving end when the sending end stops sendingthe optical signals, and the first bit rate is greater than the second bit rate; obtaining a frequency for the sending end to send the optical signals, and obtaining loss parameters of the receiving end; and computing the attenuation value of the optical fiber according to the first bit rate, the second bit rate, the frequency for the sending end to send the optical signals and the loss parametersof the receiving end. The embodiments of the invention are applied to online measurement of the attenuation value of the optical fiber in a quantum communication network.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com