Embedded type scraping plate corner detecting device and detecting method of scraping plate conveyor

A scraper conveyor and detection device technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of lack of scraper corner detection technology, etc., to achieve convenient and easy signal detection and processing, wide practicability, The effect of small amount of processing and transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

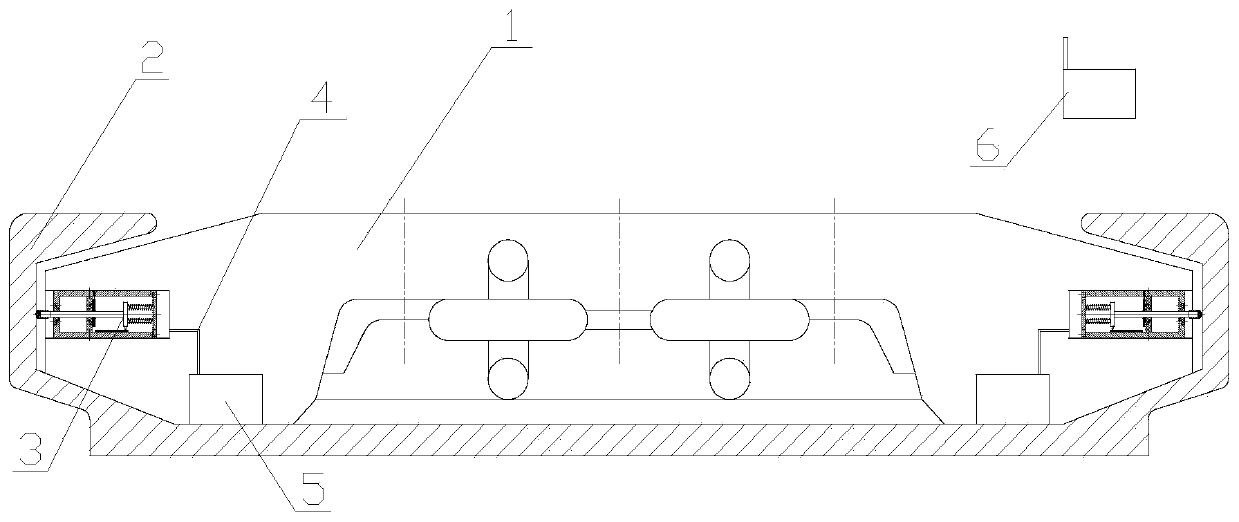

[0031] Such as figure 1 As shown, a built-in scraper angle detection device for a scraper conveyor includes a telescopic detection device 3, a signal detection unit 5 and a remote processing unit 6. The telescopic detection device 3 is connected to the signal detection device through a connection cable 4. The unit 5 is connected, and the telescopic detection device 3 and the signal detection unit 5 are provided with two sets, which are respectively arranged at both ends of the scraper 1 .

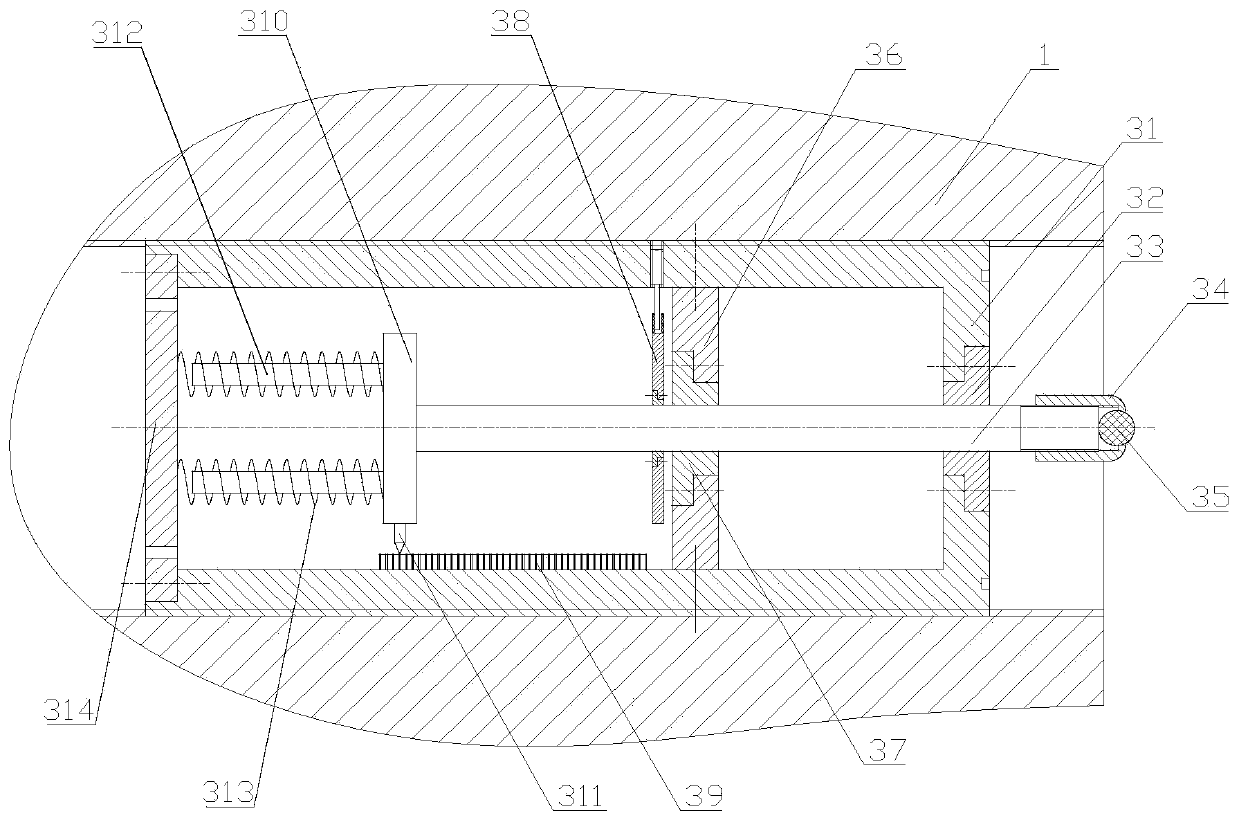

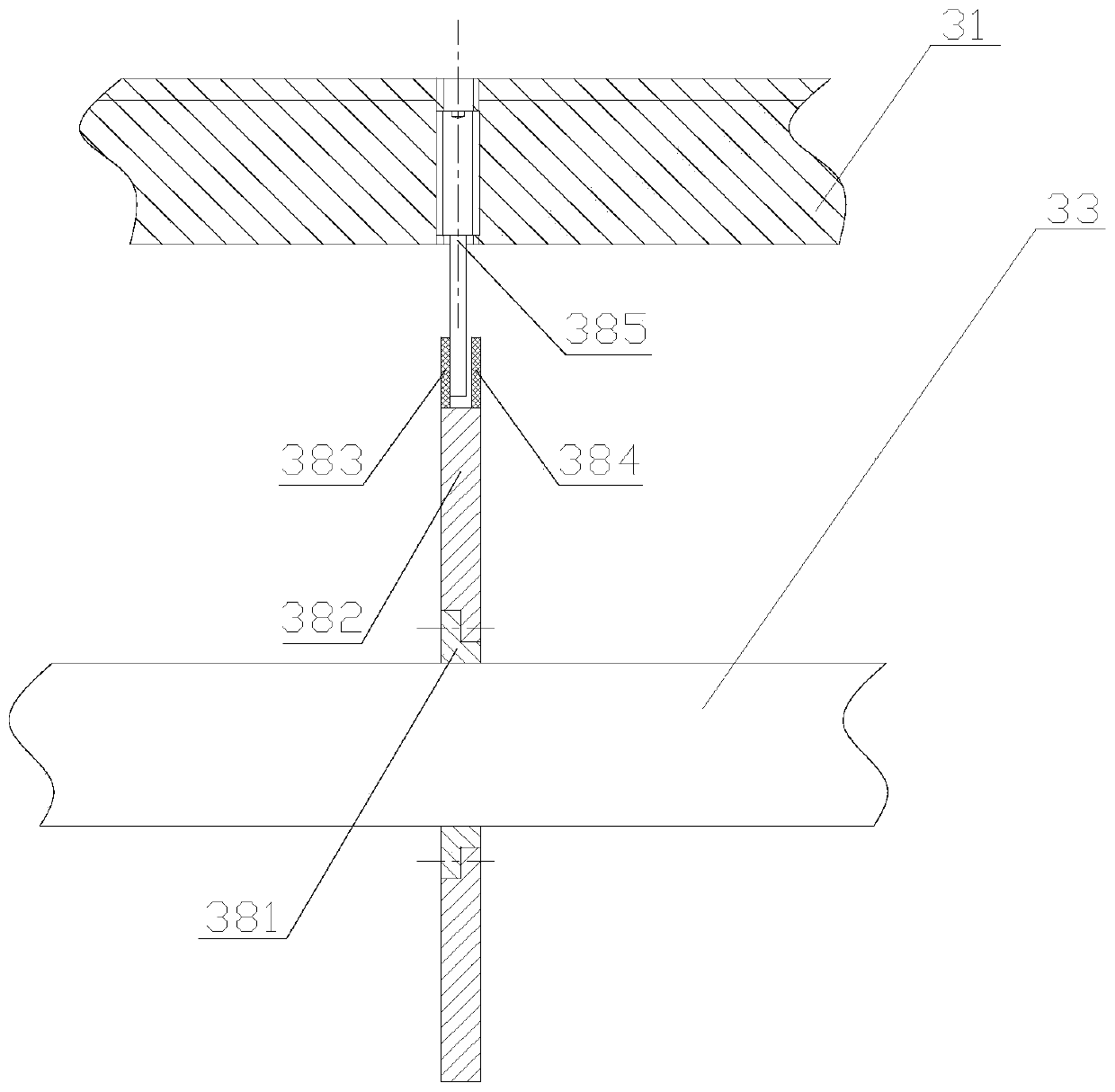

[0032] Such as figure 1 , figure 2As shown, the telescopic detection device 3 includes an outer cylinder 31, a guide ring I 32, a mandrel 33, a measuring end 34, a support ring 36, a guide ring II 37, a direction measuring device 38, a measuring slip ring 39, a measuring probe 311 and Bottom cover 314; the outer surface of the outer cylinder 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com