Welding quality control system and method for arc temperature difference before and after plasma arc piercing

A plasma welding and control system technology, applied in plasma welding equipment, welding equipment, welding equipment, etc., can solve the problems that there is no standard for measuring the stability of the perforated molten pool, and there is no definite standard for evaluation, so as to improve welding efficiency, Good control and optimization of the results of the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

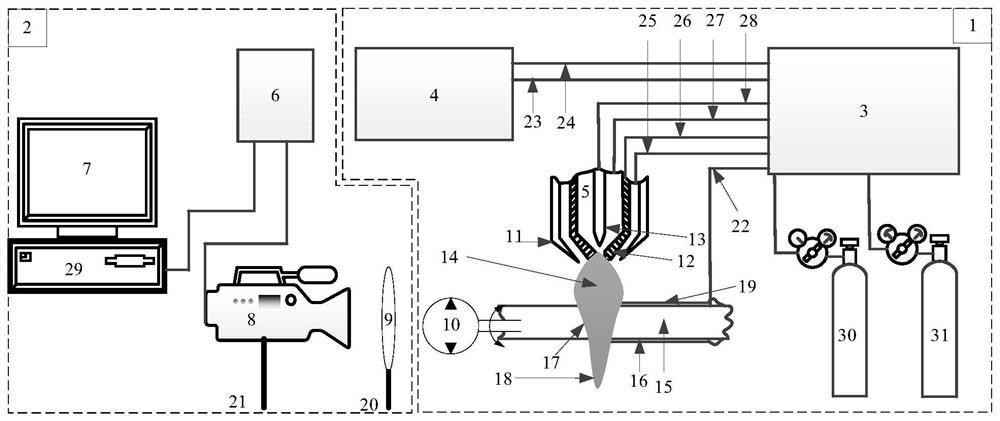

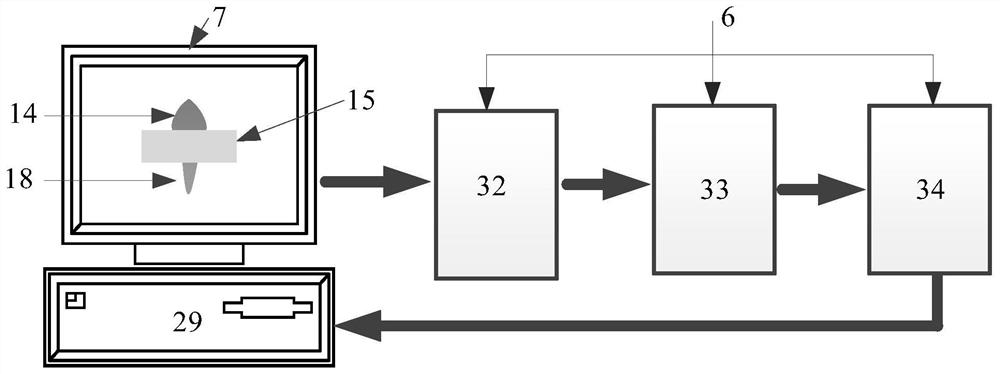

Embodiment 1

[0041] At first, the pre-welding work is ready, adjust the optical filter 9, the high-speed camera 8 and the welding plane to be on the same axis, and adjust the focal length, which remains unchanged during the welding process; after opening the ion gas cylinder 31 and the shielding gas cylinder Before switching 30 and cooling water tank 4, ensure that the welding torch and other necessary gas and water circuits are correctly connected during welding. According to requirements, various switches of the variable polarity plasma welding system 1 are turned on, and the acquisition window of the image processing unit 6 is opened at the same time. And in strict accordance with the requirements of variable polarity perforation plasma welding, the ion gas 26 is sent out in advance, and then the DC maintenance arc is started by high frequency; after the maintenance arc is stable, the shielding gas 25 is sent out, and the DC arc is started to preheat the workpiece; and then the variable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com