Vibration monitoring method based on sensors

A sensor and vibration detection technology, which is applied to instruments, measuring devices, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of increasing integration difficulty, consuming huge investment, and hindering universality, so as to reduce vibration measurement module channels and reduce monitoring cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

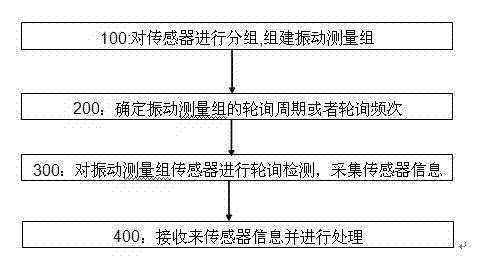

[0018] see first figure 1 , in the first embodiment of the present invention, a sensor-based vibration monitoring method is proposed. The method includes the following steps:

[0019] Step 100: Arranging sensors in groups to form a vibration measurement group.

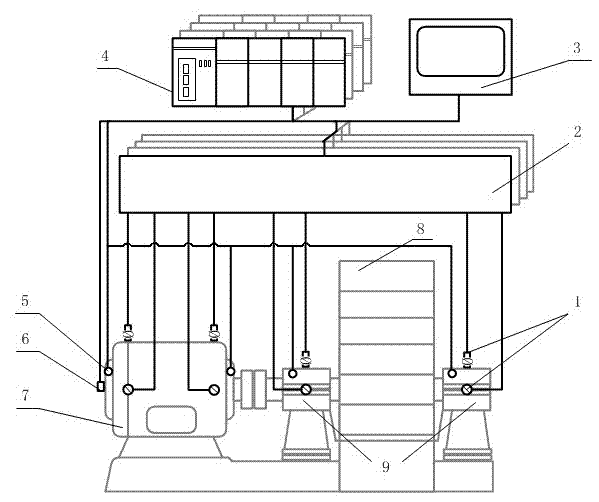

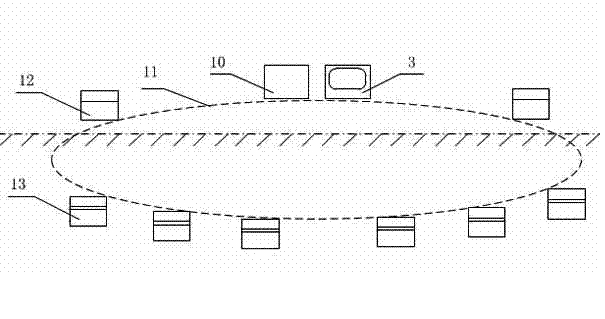

[0020] The vibration of the equipment is closely related to the shaft speed. The vibration of the equipment is also related to the temperature of the bearing or some parts. The faster the speed, the higher the vibration frequency and the greater the vibration intensity. The higher the bearing temperature, the greater the vibration intensity. Therefore, the present invention proposes a vibration monitoring method in which the equipment is not only equipped with a vibration sensor, but also equipped with a speed sensor, a temperature sensor and other sensors, and at least three sensor signals ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com