Pneumatic conveying type precision combined seed and fertilizer drill, and miss-seeding and blocking detection method and device thereof

A technology of airflow conveying and clogging detection, which is applied in the direction of interval quantitative sowing machinery, measuring devices, planter parts, etc., and can solve problems affecting measurement results and component wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

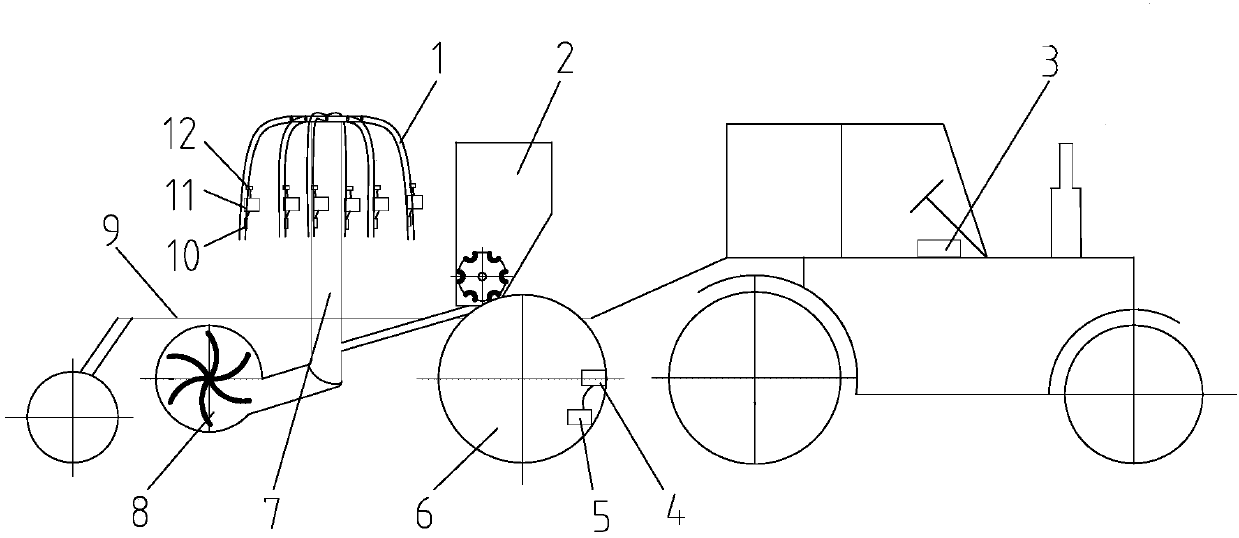

[0047] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

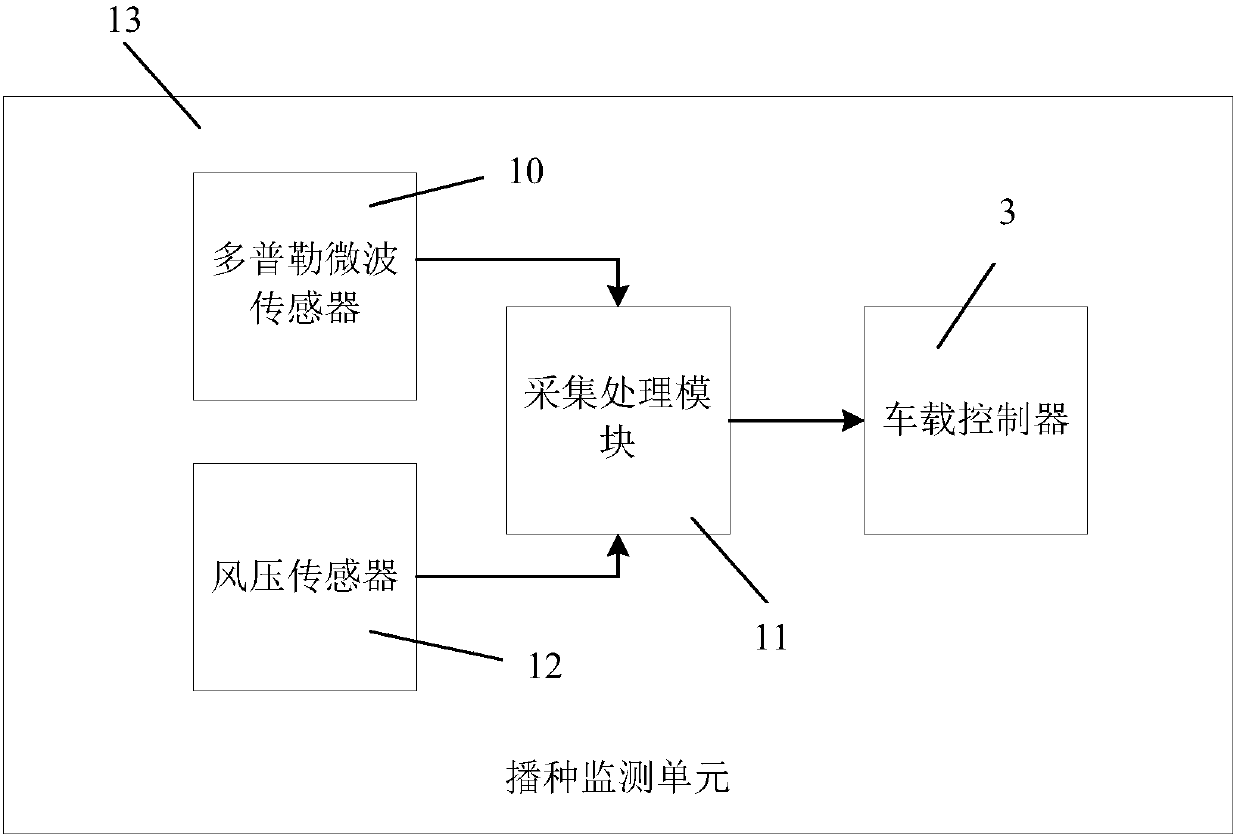

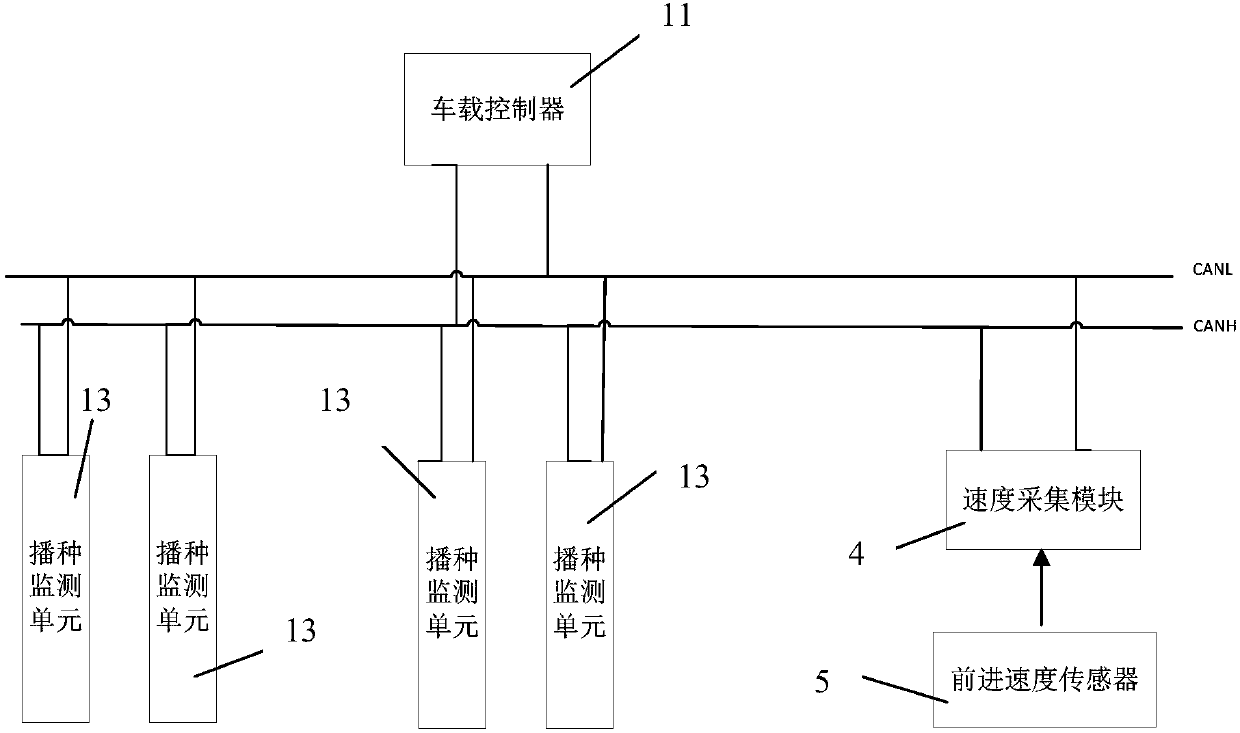

[0048] see figure 1 , figure 1 It is a structural schematic diagram of an airflow conveying precision fertilization seeder according to an embodiment of the present invention. The airflow conveying type precision fertilization seeder of the present invention comprises frame 9 and the driver's cab installed on the frame 9, ground wheel 6, seed box 2, seed pipe 1, blower fan 8 and air distribution system 7, also includes Missed-seeding blockage detection device, because the composition, structure, mutual positional relationship, connection relationship, function, and working principle of each part of the air-flow conveying type precision fertilization seeder are relatively mature existing technologies, so it will not be discussed here. To repeat, the following is only a detailed description of the missed broadcast blockage det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com