Oil storage oil gas recovery online monitoring system

A technology of oil depot and video monitoring system, which is applied in the field of online monitoring system for oil depot oil and gas recovery, which can solve the problems of oil loss environment, non-compliance of emissions, monitoring of oil and gas recovery in oil depot, etc., and achieve real-time and effectiveness High, labor cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

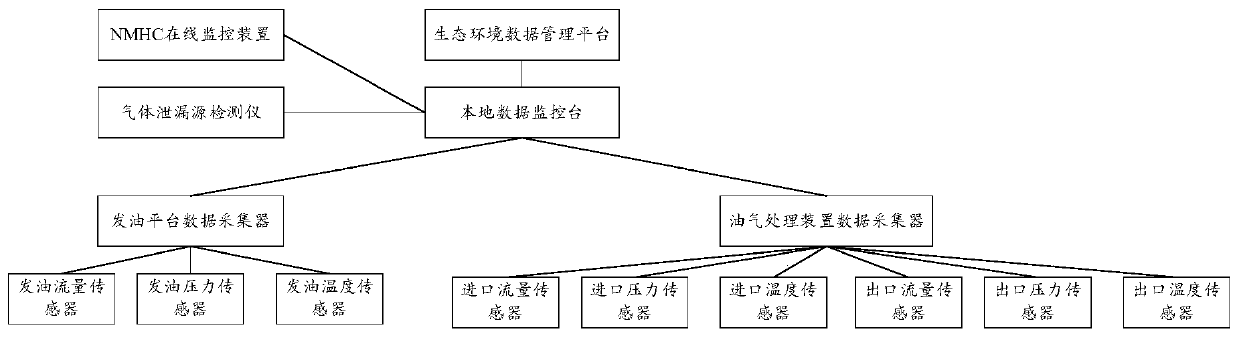

[0023] Such as figure 1 As shown, the embodiment of the present invention provides an online monitoring system for oil and gas recovery in an oil depot. An oil distribution platform data collector is installed at the end of the oil depot, and the oil distribution platform data collector is connected to the oil and gas recovery pipeline respectively. The oil and gas flow sensor, the oil and gas pressure sensor and the oil and gas temperature sensor installed on the oil storage depot are equipped with an oil and gas processing device data collector, and the oil and gas processing device data collectors are respectively The inlet oil and gas flow sensor, the inlet oil and gas pressure sensor and the inlet oil and gas temperature sensor installed at the oil and gas inlet of the oil and gas processing device, and the outlet oil and gas flow sensor, the outlet oil and gas pressure sensor and the outlet oil and gas temperature installed at the outlet of the oil and gas processing devi...

Embodiment 2

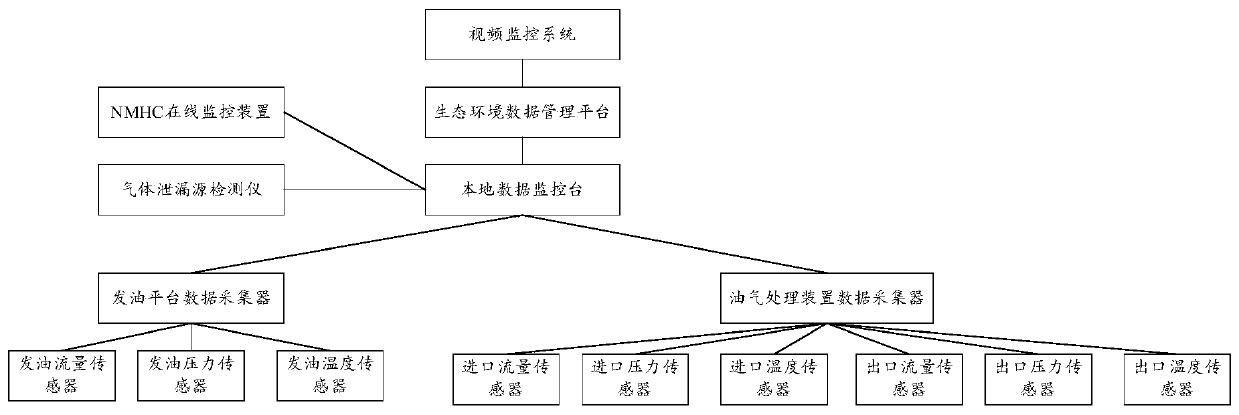

[0036] Such as figure 2 As shown, the embodiment of the present invention also provides an online monitoring system for oil and gas recovery in an oil depot, which is compatible with such figure 1 The ones shown are basically the same, the difference is that a video monitoring system is installed in the oil storage depot, and the video monitoring system communicates with the local data monitoring station.

[0037] In this embodiment, the video monitoring system is installed at the outlet of the oil delivery pipe of the oil depot. The video monitoring system is mainly used to monitor whether gas or liquid leakage occurs at the outlet of the oil delivery pipe when filling the oil tanker, and send the monitoring results to the local data monitoring station for management.

[0038] In this embodiment, the video monitoring system can actively send the monitoring results, that is, the captured video data, to the local data monitoring station according to the monitoring results; T...

Embodiment 3

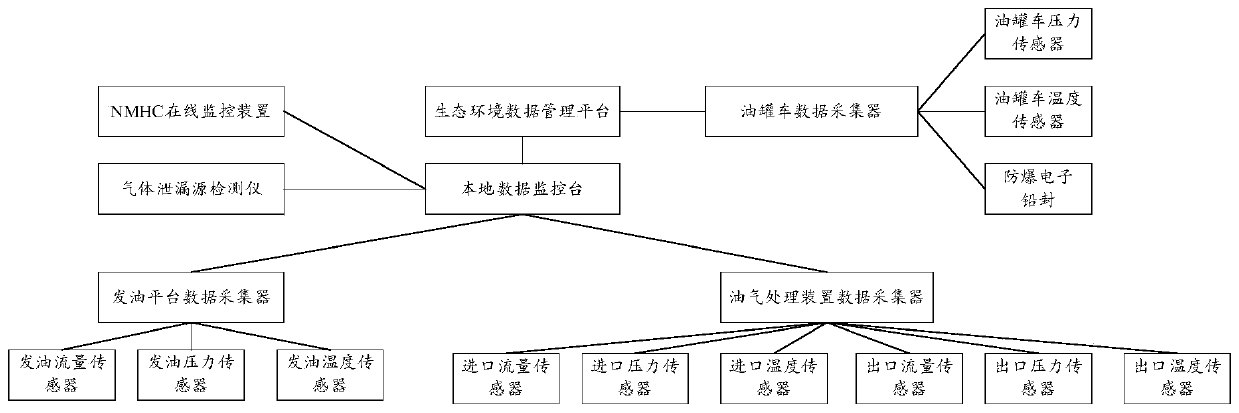

[0041] Such as image 3 As shown, the embodiment of the present invention also provides an online monitoring system for oil and gas recovery in an oil depot, which is compatible with such figure 1 The ones shown are basically the same, the difference is that it also includes: an oil and gas flow sensor, the oil and gas flow sensor is arranged on the pipeline of the emergency discharge port at the inlet of the oil and gas processing device, and the oil and gas flow sensor is connected with the oil and gas processing device The data collector communicates.

[0042] By setting the oil and gas flow sensor, the gas discharge quality of the emergency discharge port can be further monitored, which further improves the monitoring integrity and comprehensiveness of the gas recovery monitoring system of the oil depot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com