Turbine rotor blade of gas turbine

A technology for turbine rotors and gas turbines, applied in the directions of blade support elements, mechanical equipment, engine elements, etc., can solve the problems of aggravation, poor cooling effect in the root area of the blade trailing edge, large temperature and thermal stress, etc., to reduce the loss coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The principle, specific implementation and working process of the present invention will be further described below in conjunction with the accompanying drawings.

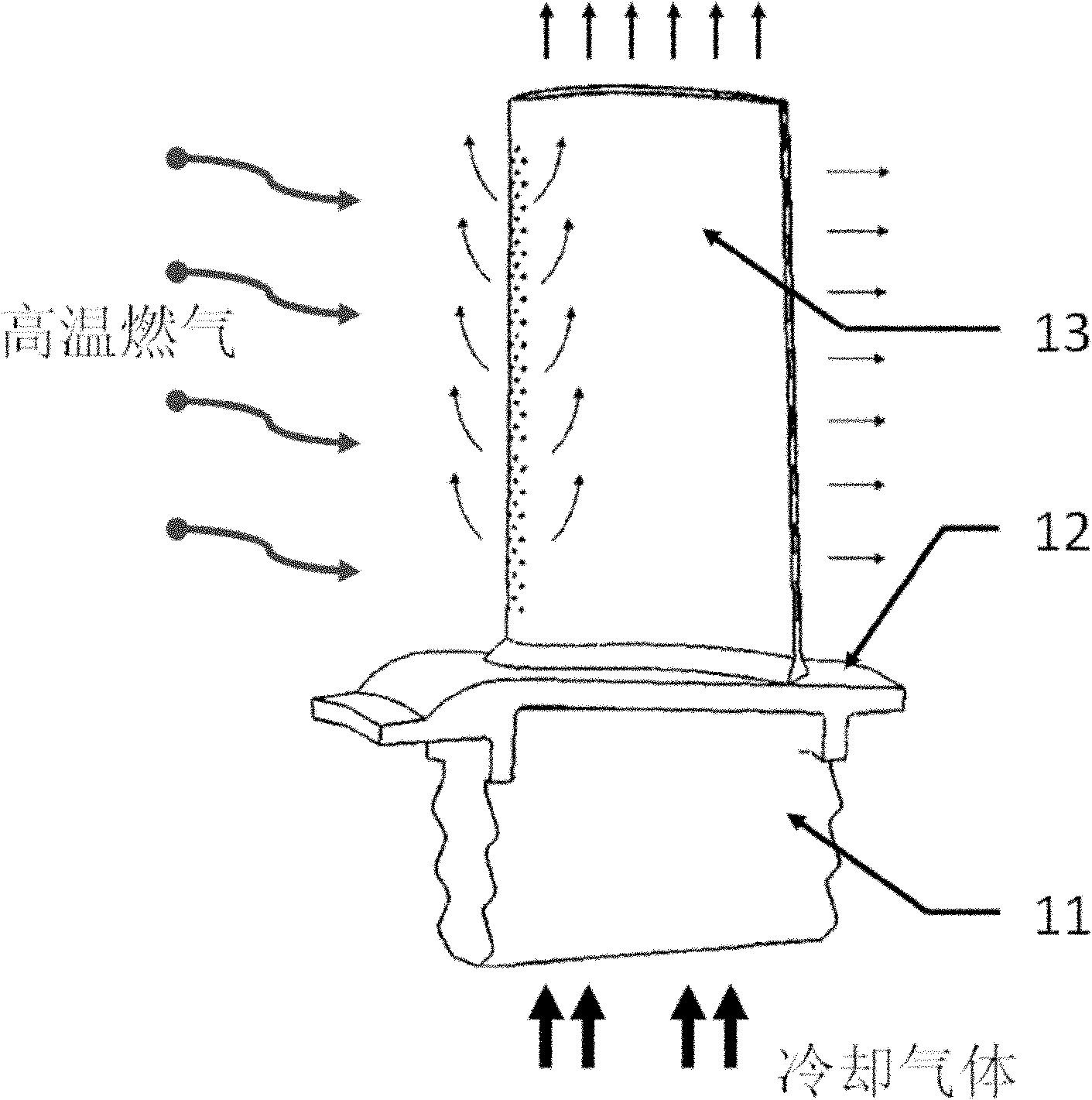

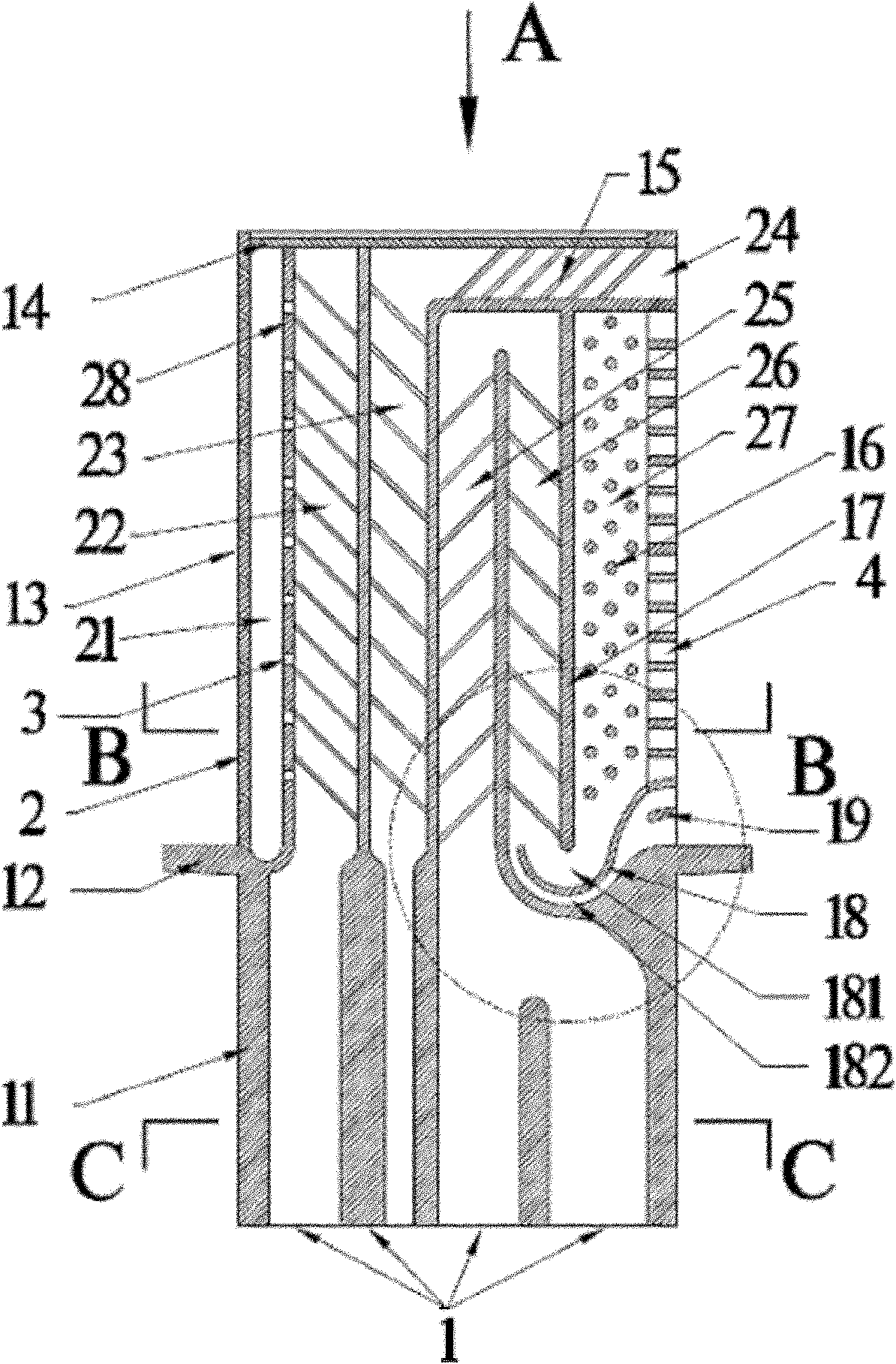

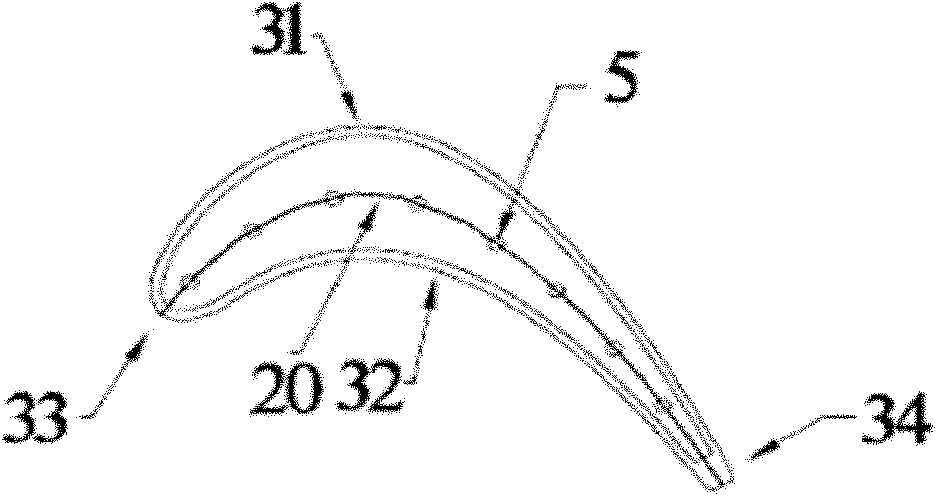

[0023] Accompanying drawing has provided a concrete embodiment of the present invention. figure 1 is a three-dimensional view of a high temperature rotor blade of a gas turbine, which includes a blade profile 13, a blade root 11, and a blade platform 12 between the blade profile and the blade root. Cutting the blade along the arc line 20 of the blade shape, the internal structure of the blade can be obtained, such as figure 2 shown. Inside the blade there are multiple cooling channels for cooling gas flow. The cooling gas is extracted from a suitable position of the compressor, and delivered to the root cooling channel inlet 1 of the rotor blade along the gas turbine rotor shaft system. The size and number of root cooling channel inlets are selected according to the comprehensive consideration of the requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com