Apparatus, machine, method and use for checking cigarette head quality

A technology of cigarette butts and machines, which is applied in the field of devices for inspecting the quality of cigarette butts, and achieves the effect of small loss coefficient and small structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

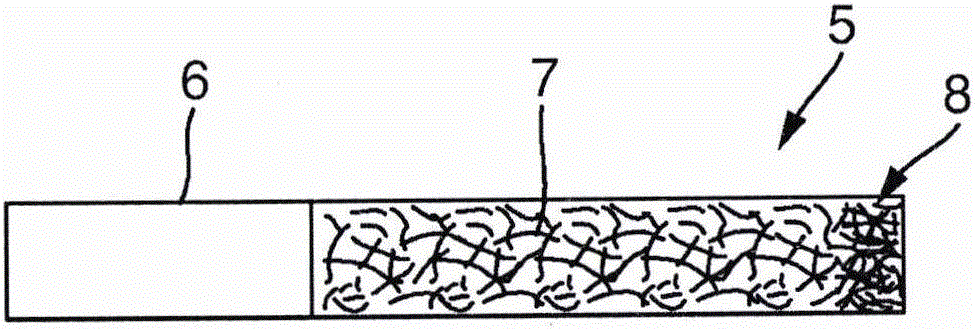

[0039] figure 1 A cigarette 5 is shown schematically together with its components. The cigarette has a filter 6 and a tobacco rod 7 with tobacco. The tobacco in the tobacco rod 7 is compacted at the lighting end, ie at the end opposite the filter 6 . This butt stuffer 8 acts as a plug and prevents tobacco from falling out of the cigarette 5 . The butt filler 8 also gives the cigarette 5 an impression of high quality.

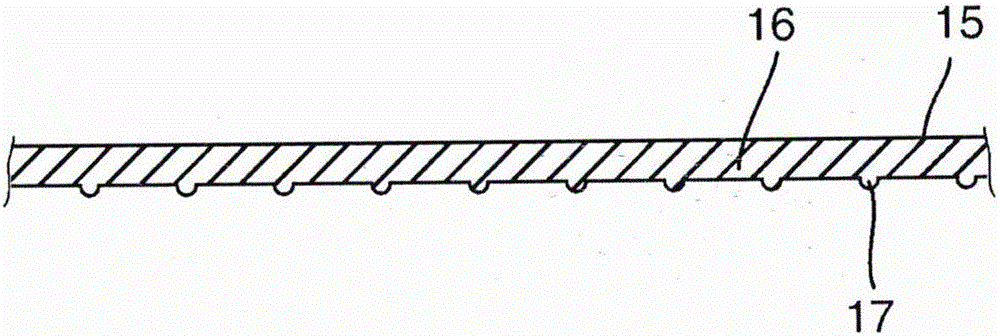

[0040] exist figure 2 shows schematically how to manufacture the butt filler 8 . Relating to details from a cigarette rod making machine in which tobacco rods are made. In the position shown, the loose tobacco has been scattered from below onto the suction belt conveyor 15 and is held on the suction belt as a loose tobacco layer 16 by means of the suction air. It is not shown that the tobacco layer 16 is subsequently wrapped with a wrapping paper in a bong apparatus and shaped into a tobacco rod with a circular cross section.

[0041] When fluffing onto ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com