Glass ceramic applied to rear cover of mobile terminal for 5G communication and reinforced glass ceramic

A technology of glass-ceramics and mobile terminals, applied in the field of glass-ceramics, can solve problems such as being unable to adapt to the back cover of 5G mobile terminals, and achieve the effects of low magnetic loss, high mechanical properties, and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

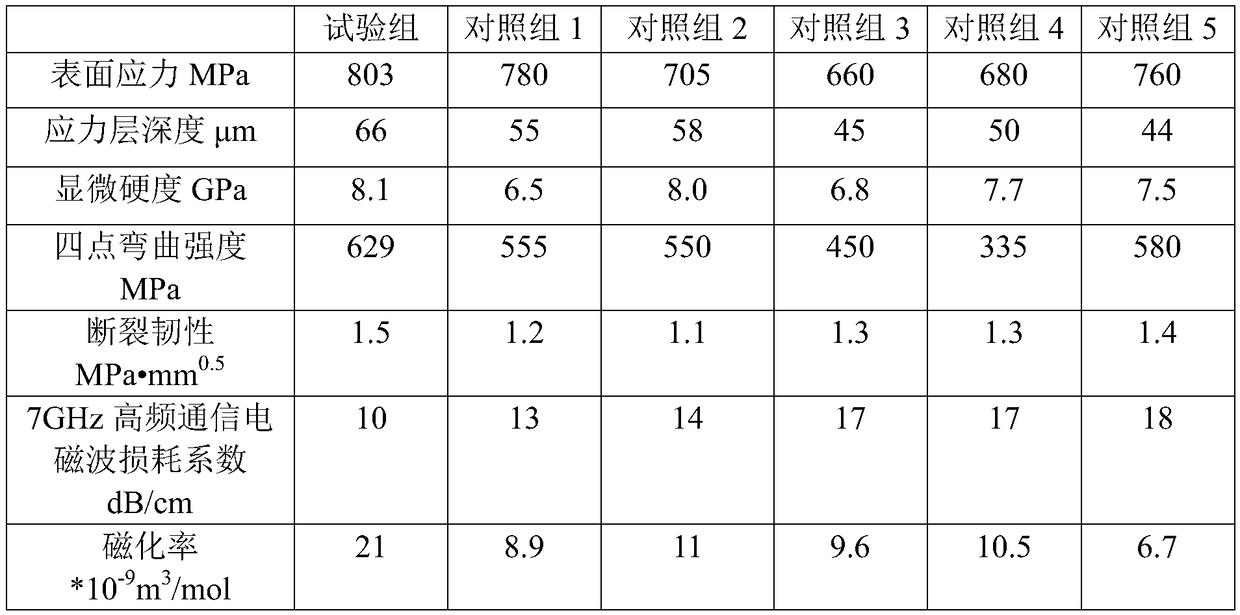

Examples

Embodiment 1

[0043] A kind of glass ceramics, in terms of mass percentage of oxide, the composition of the glass ceramics is SiO 2 50%, Al 2 o 3 12%, Na 2 O 13%, K 2 O 2%, Li 2 O 3%, MgO 7%, TiO 2 6%, Eu 2 o 3 1%, P 2 o 5 3%, Fe 2 o 3 2%, Sb 2 o 3 1%. The glass-ceramic in this example is a high-strength and low-magnetic-loss basic glass-ceramic for the back cover of a 5G communication mobile terminal, with a microhardness of 7.6GPa, a four-point bending strength of 216Mpa, and a fracture toughness of K IC Up to 0.9MPa·mm 0.5 ; For 7GHz high-frequency communication electromagnetic wave loss coefficient is 14dB / cm, magnetic susceptibility is 3.8×10 -9 m 3 / mol, the magnetic moment is 4.8×10 -24 J / T.

Embodiment 2

[0045] A kind of glass ceramics, in terms of mass percentage of oxide, the composition of the glass ceramics is SiO 2 70%, Al 2 o 3 10%, Na 2 O 8%, K 2 O 2%, MgO 2%, TiO 2 4%, ZnO 1%, Eu 2 o 3 1%, P 2 o 5 1%, Fe 2 o 3 1%. The glass-ceramic of this embodiment can be used as the base glass-ceramic of high strength and low magnetic loss for the back cover of a 5G communication mobile terminal, with a microhardness of 5.6GPa, a four-point bending strength of 163Mpa, and a fracture toughness of K IC Up to 0.6MPa·mm 0.5 ; For 7GHz high-frequency communication electromagnetic wave loss coefficient is 18dB / cm, magnetic susceptibility is 3.5×10 -9 m 3 / mol, the magnetic moment is 5.6×10 -24 J / T.

Embodiment 3

[0047] A kind of glass ceramics, in terms of mass percentage of oxide, the composition of the glass ceramics is SiO 2 45%, Al 2 o 3 12%, Na 2 O 10%, K 2 O 1.5%, MgO 2.5%, ZrO 2 10%, Li 2 O 3%, TiO 2 5%, ZnO 2%, Eu 2 o 3 3%, P 2 o 5 1%, Fe 2 o 3 4%, Y 2 o 3 1%. The glass-ceramic of this embodiment can be used as the base glass-ceramic of high strength and low magnetic loss for the back cover of the 5G communication mobile terminal, with a microhardness of 6.5GPa, a four-point bending strength of 235Mpa, and a fracture toughness of K IC Up to 0.9MPa·mm 0.5 ; For 7GHz high-frequency communication electromagnetic wave loss coefficient is 10dB / cm, magnetic susceptibility is 2.1×10 -8 m 3 / mol, the magnetic moment is 2.1×10 -23 J / T.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com