A temperature detection method of hot air pipe based on distributed optical fiber

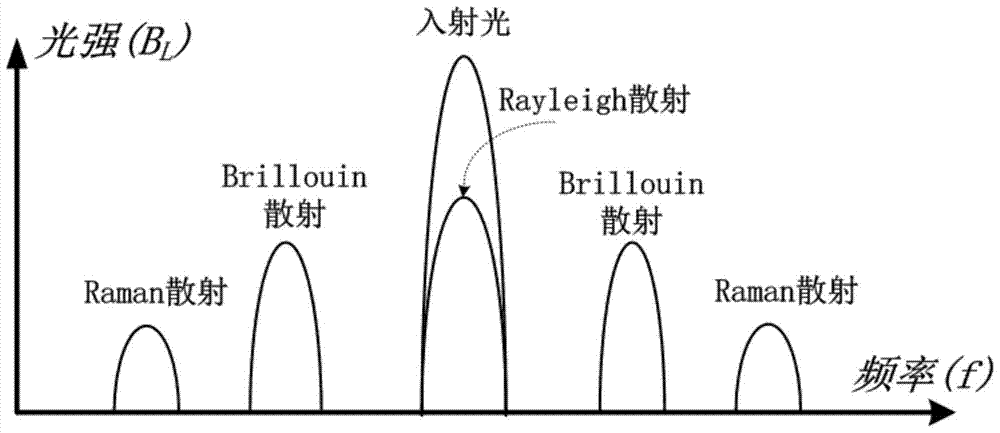

A distributed optical fiber and detection method technology, which is applied in the direction of physical/chemical change thermometers, thermometers, measuring devices, etc., can solve the problems of poor component compatibility, poor optical fiber interchangeability, etc., to improve service life, improve adaptability, The effect of reducing the focal ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

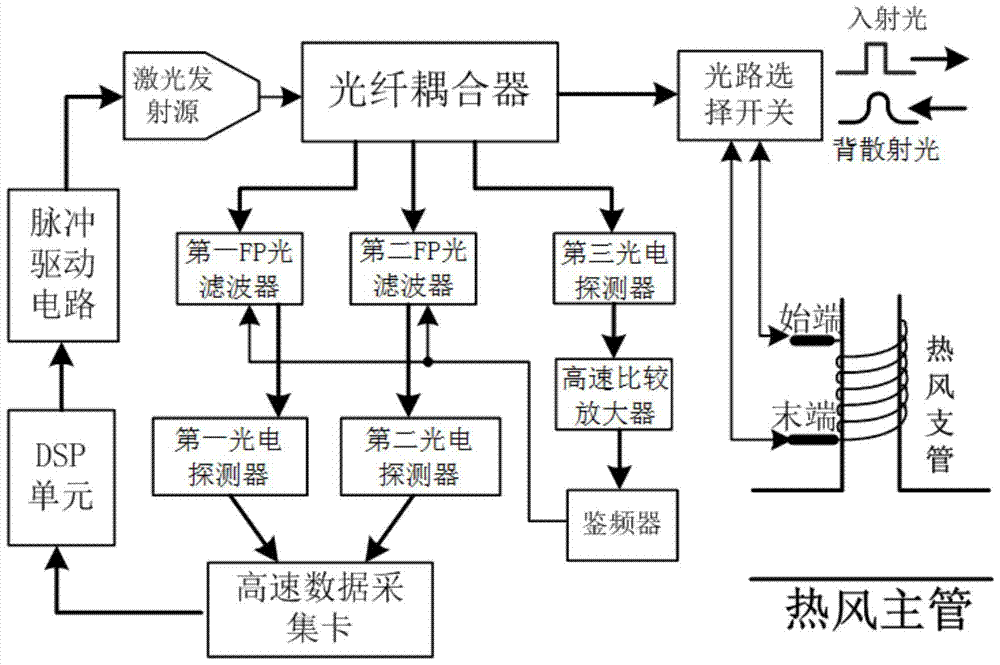

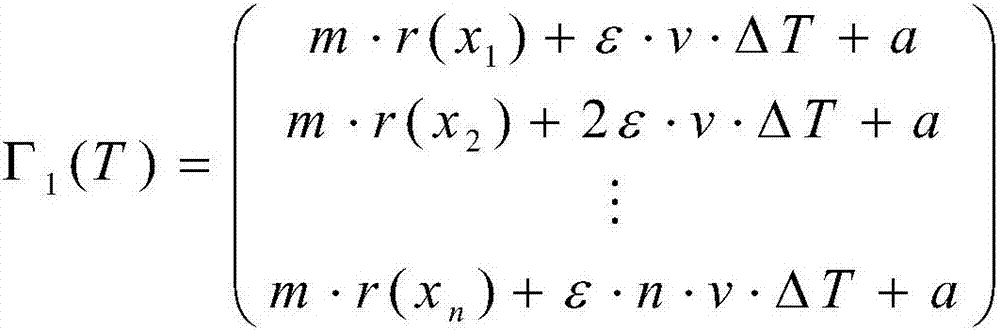

[0041] combine figure 2 , a distributed fiber-based hot air pipe temperature detection system in this embodiment includes a distributed optical fiber sensor and a distributed optical fiber, and the distributed optical fiber is wound on the hot air pipe; the distributed optical fiber sensor includes a laser emission source , pulse drive circuit, optical fiber coupler, optical path selection switch, 2 optical filters, 3 photodetectors, high-speed comparison amplifier, frequency discriminator, high-speed data acquisition card and DSP unit; the DSP unit controls laser emission through the pulse drive circuit The source emits laser light and sends it to the fiber coupler; the fiber coupler is electrically connected to the optical path selection switch, and the beginning and end of the distributed optical fiber are connected to the optical path selection switch; the output end of the fiber coupler is also connected to the first optical filter device, the second optical filter and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com