Low-temperature co-sintered ceramic microwave and millimeter wave material

A technology of low-temperature co-fired ceramics and ceramic materials, applied in the field of low-temperature co-fired ceramic microwave and millimeter-wave materials, can solve the problem of inability to achieve high quality factor, and achieve the effect of low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

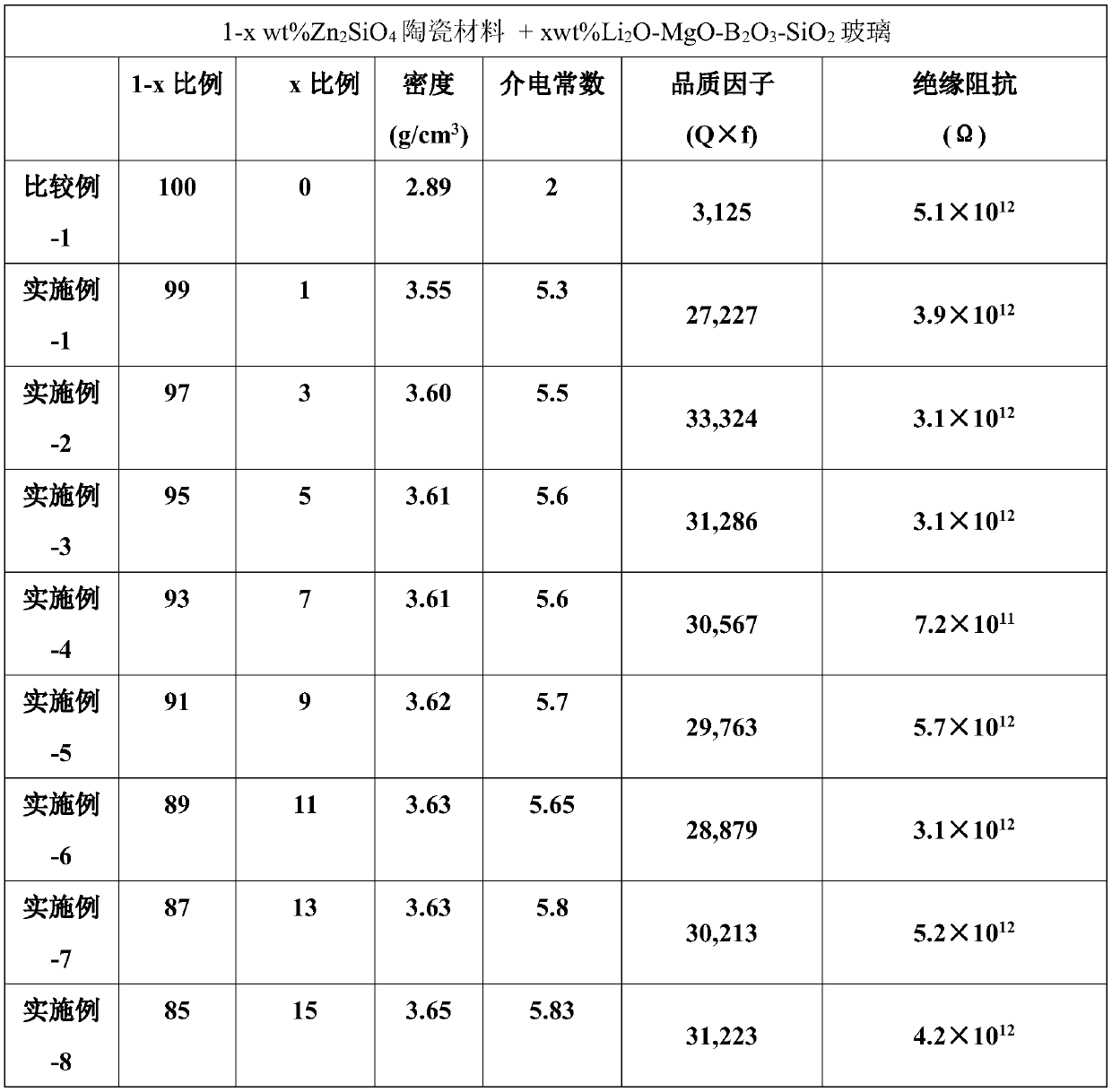

Embodiment 1

[0038] When 99wt% Zn 2 SiO 4 Ceramic material mixed with 1wt% Li 2 O-MgO-B 2 o 3 -SiO 2 When the glass is sintered at 800°C, it can be found that the ceramic is dense after sintering, with a dielectric constant of 5.3, a quality factor of 27,227GHz, and an insulation resistance of 3.9×10 12 , material and suitable for co-firing with silver.

Embodiment 2

[0040] When 97wt% Zn 2 SiO 4 Ceramic material mixed with 3wt% Li 2 O-MgO-B 2 o 3 -SiO 2 When the glass is sintered at 800°C, it can be found that the ceramic is dense after sintering, with a dielectric constant of 5.5, a quality factor of 33,324GHz, and an insulation resistance of 3.1×10 12 , material and suitable for co-firing with silver.

Embodiment 3

[0042] When 95wt% Zn 2 SiO 4 Ceramic material mixed with 5wt% Li 2 O-MgO-B 2 o 3 -SiO 2 When the glass is sintered at 800°C, it can be found that the ceramics are dense after sintering, with a dielectric constant of 5.6, a quality factor of 31,286GHz, and an insulation resistance of 3.1×10 12 , material and suitable for co-firing with silver.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality factor | aaaaa | aaaaa |

| Quality factor | aaaaa | aaaaa |

| Quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com