Coupled leakage cable

A leaky cable and coupling technology, applied in circuits, electrical components, leaky waveguide antennas, etc., can solve the problems of poor electrical performance of leaky cables, single insulation layer structure, etc., achieve good moisture resistance, excellent electrical performance, and reduce loss coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

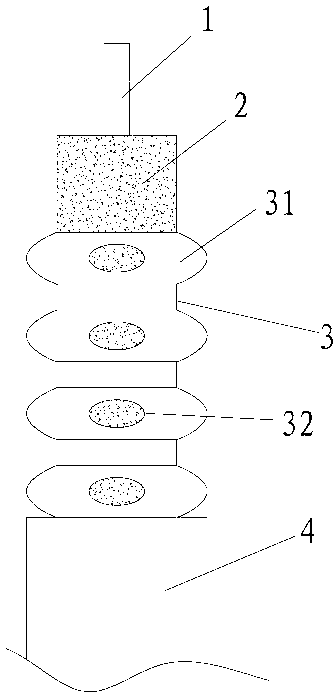

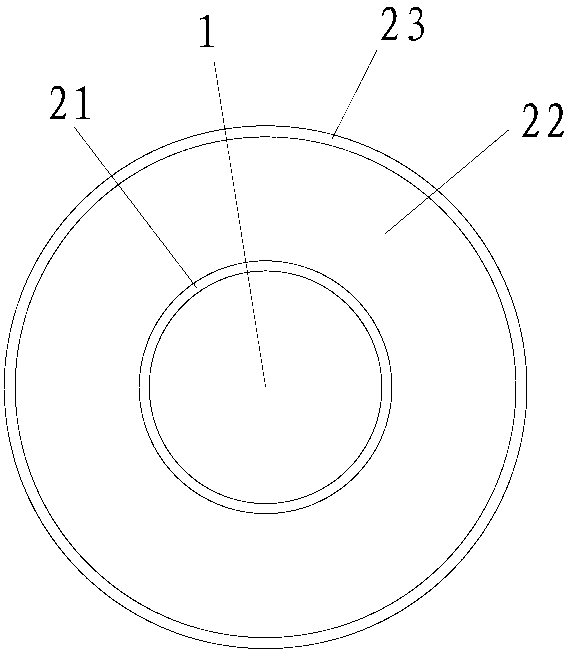

[0018] Embodiment 1: as Figure 1-2 As shown, a coupled leaky cable includes an inner conductor 1, an insulating layer 2 covering the inner conductor 1, an outer conductor 3 covering the insulating layer 2, and an outer conductor covering the outer conductor 3, the outer sheath 4, the outer conductor 3 has a plurality of smooth ring-shaped protrusions 31 distributed in parallel to make the outer conductor 3 wrinkled, each of the ring-shaped protrusions 31 has a smooth The insulating layer 2 includes an inner thin layer 21 covering the inner conductor 1, a foam layer 22 covering the inner thin layer 21, and an outer layer covering the foam layer 22. Thin layer 23; foaming degree of foam layer 22 ≥ 85%; distance between adjacent ring-shaped protrusions 31 is 7 mm; outer conductor 3 has a peak outer diameter of 24 mm and a wave trough outer diameter of 21 mm; inner conductor 1 The diameter is 10 mm; the outer diameter of the insulating layer 2 is 18 mm; the holes 32 are oval; th...

Embodiment 2

[0035] Embodiment 2: The difference with Embodiment 1 is that the distance between adjacent annular protrusions 31 is 5 mm; the outer diameter of the crest of the outer conductor 3 is 22 mm, and the outer diameter of the trough is 20 mm; the diameter of the inner conductor 1 is 8mm; the outer diameter of the insulating layer 2 is 14mm; the hole 32 is oval; the number of holes 32 on each annular protrusion 31 is 5, and they are evenly distributed.

[0036] The preparation method is similar to Example 1.

Embodiment 3

[0037] Embodiment 3: The difference with Embodiment 1 is that the distance between adjacent annular protrusions 31 is 10mm; the outer diameter of the crest of the outer conductor 3 is 25mm, and the outer diameter of the trough is 22mm; the diameter of the inner conductor 1 is 12 mm; the outer diameter of the insulating layer 2 is 20 mm; the holes 32 are oval; the number of holes 32 on each annular protrusion 31 is 6, and the holes 32 are evenly distributed.

[0038] The preparation method is similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com