Special spraying device for wind-power tower

A technology for wind power towers and special devices, which is applied to the device and coating of the surface coating liquid, which can solve the problems of paint waste, spray leakage, sagging, etc., and achieve the effect of improving the quality of spraying and reducing paint waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

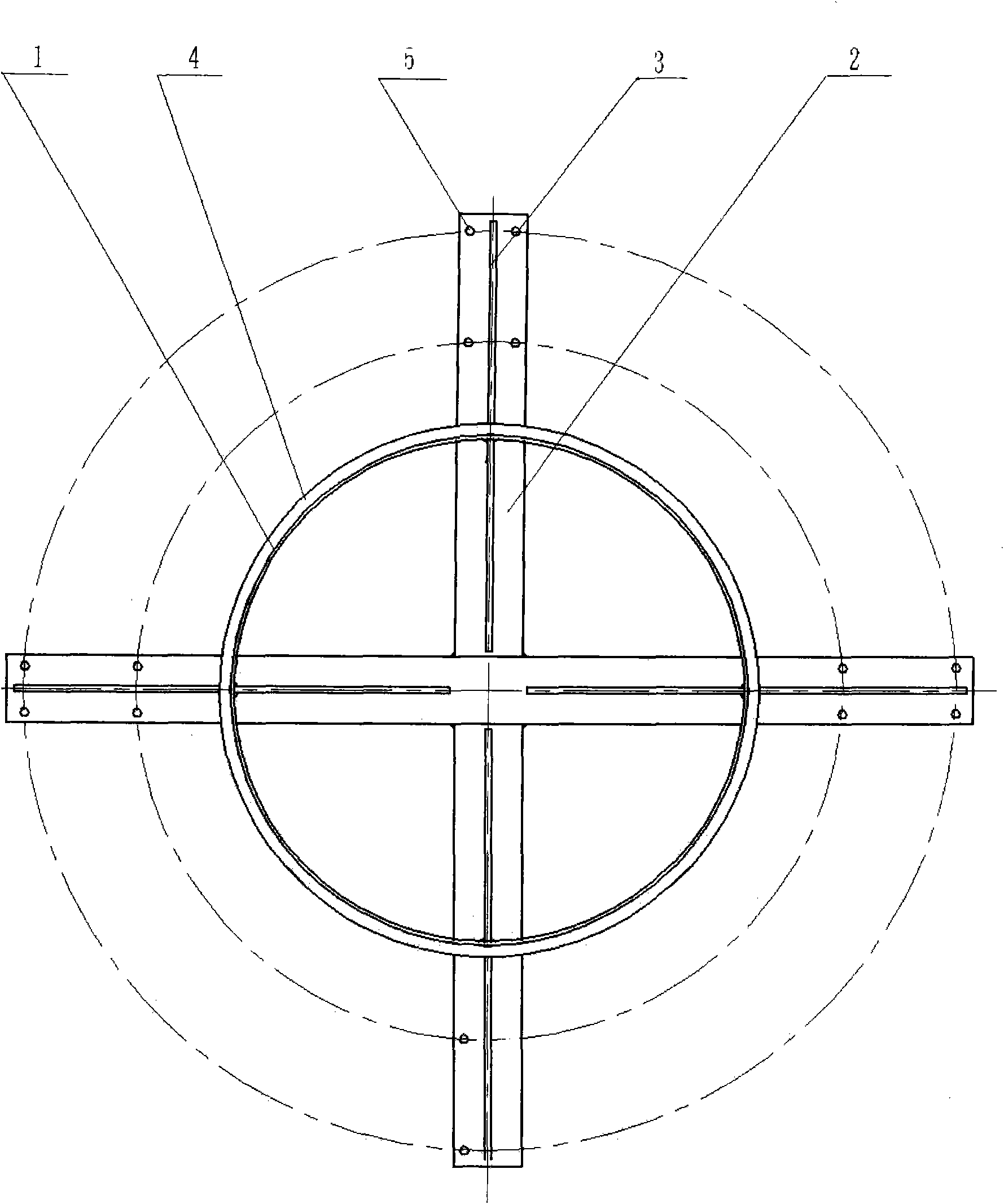

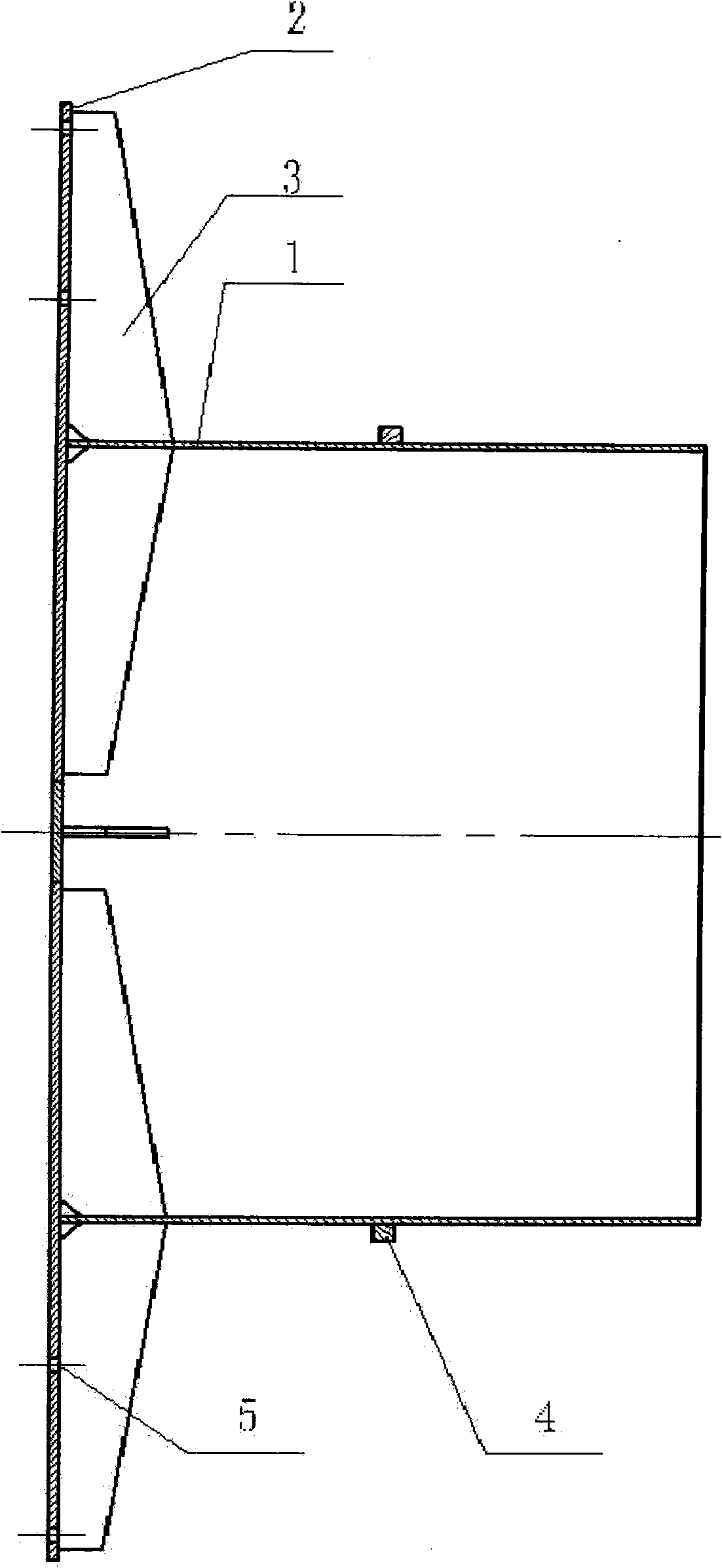

[0024] Step 1: Place the positioning and fixing plate 2 composed of steel plates (δ32) on the platform for leveling according to the requirements of the drawing, and weld the cross-shaped positioning and fixing plate 2 firmly by manual butt welding. Find the center point, mark the roller, bolt hole location line and drill the bolt holes.

[0025] Step 2: Roll the drum 1 into a circle, weld the longitudinal seam of the drum 1 by automatic welding, and calibrate the circle to pass.

[0026] Step 3: Put the roller 1 on the leveled positioning and fixing plate 2 on the platform, and position and fix it by the roller positioning line on the positioning and fixing plate 2. Rib 3 is positioned according to the requirements of the drawing, and fixed on the drum 1 and the positioning and fixing plate 2.

[0027] Step 4: Weld the positioned and point-fixed ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com