Flexible cable jumper device and method for manufacturing same

A manufacturing method and flexible cable technology, applied in the direction of cable/conductor manufacturing, conductive connection, insulated cables, etc., can solve the problems of unfavorable disassembly, deterioration of substrate loss coefficient, etc., and achieve low loss of heat resistance, small loss coefficient, and durability Excellent heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] For a full understanding of the present invention and its operational advantages and objects achieved according to the embodiments of the present invention, reference should be made to the accompanying drawings which illustrate preferred embodiments of the present invention and the accompanying drawings.

[0057] When describing preferred embodiments of the present invention, well-known techniques that may unnecessarily obscure the gist of the present invention or repetitive descriptions are reduced or omitted.

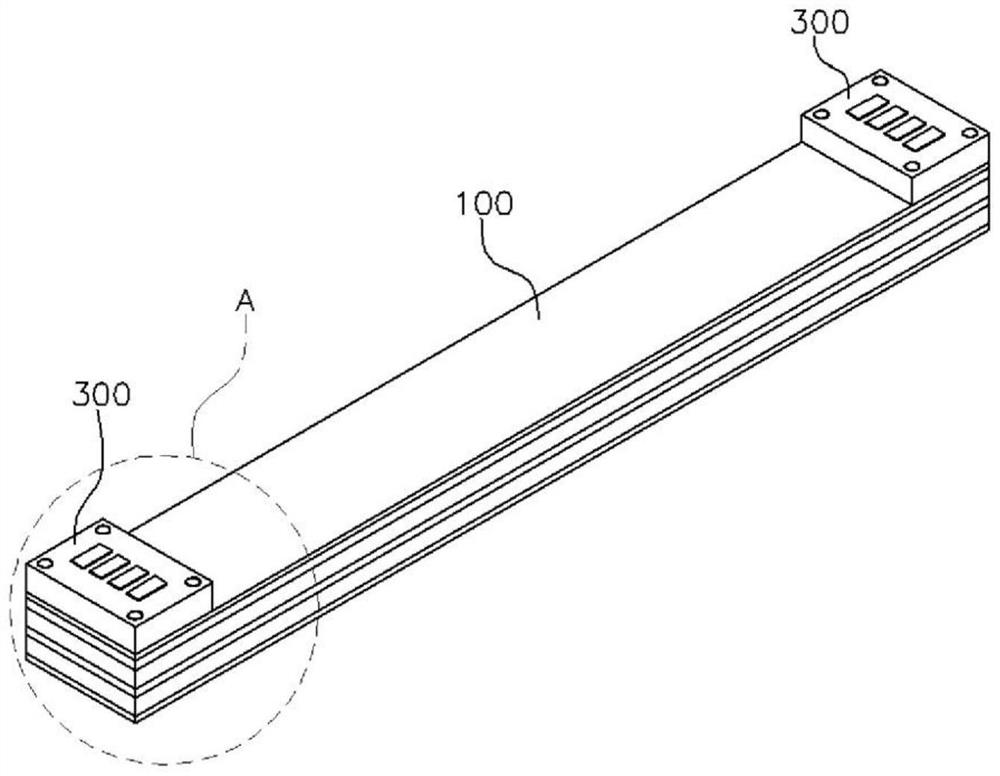

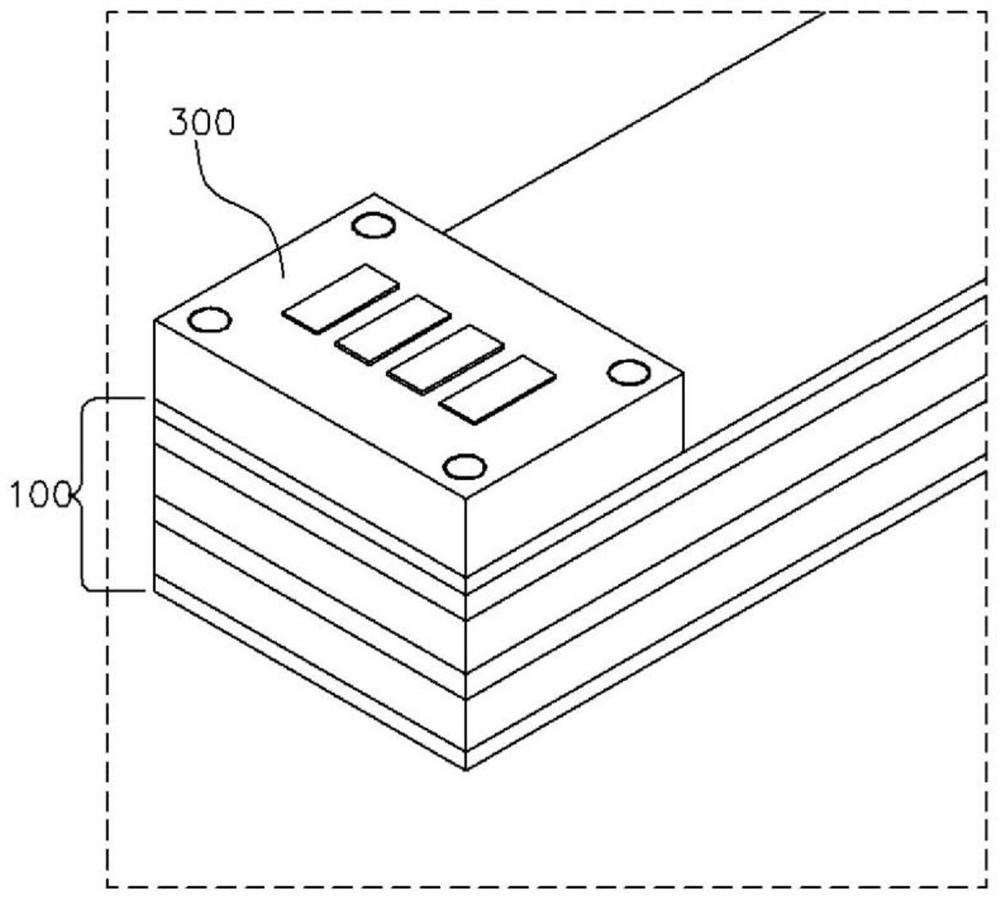

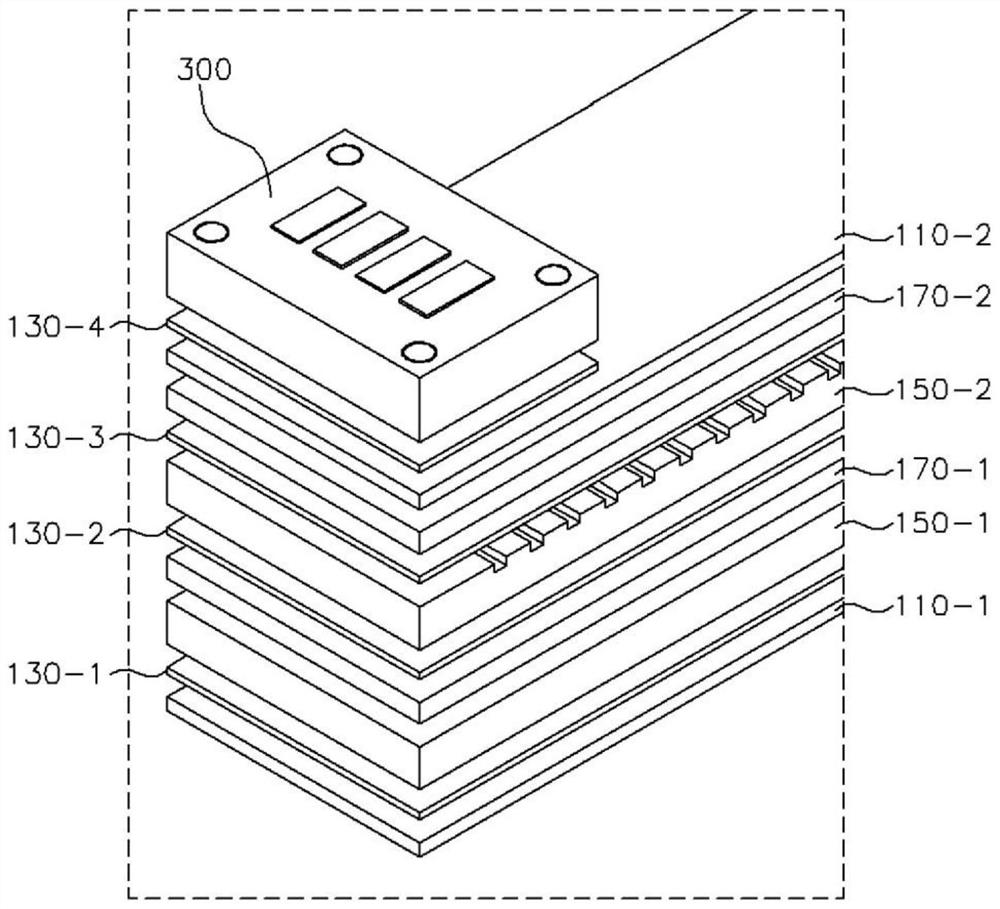

[0058] figure 1 It is a flexible cable jumper assembled with a plug in a flexible cable jumper structure according to an embodiment of the present invention, figure 2 Shows figure 1 The cross-sectional shape of the area shown in A, image 3 express figure 1 The stacked structure of the flexible cable jumper structure in area A shown.

[0059] Below, refer to Figure 1 to Figure 3 A flexible cable jumper according to one embodiment of the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com