Preparation method of monomer linear amorphous alloy iron core

An amorphous alloy and linear technology, applied in the field of metallurgy, can solve the problems of high magnetic permeability, low core loss, and high linearity of amorphous alloy iron core, and achieve high magnetic permeability, low core loss, and linearity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

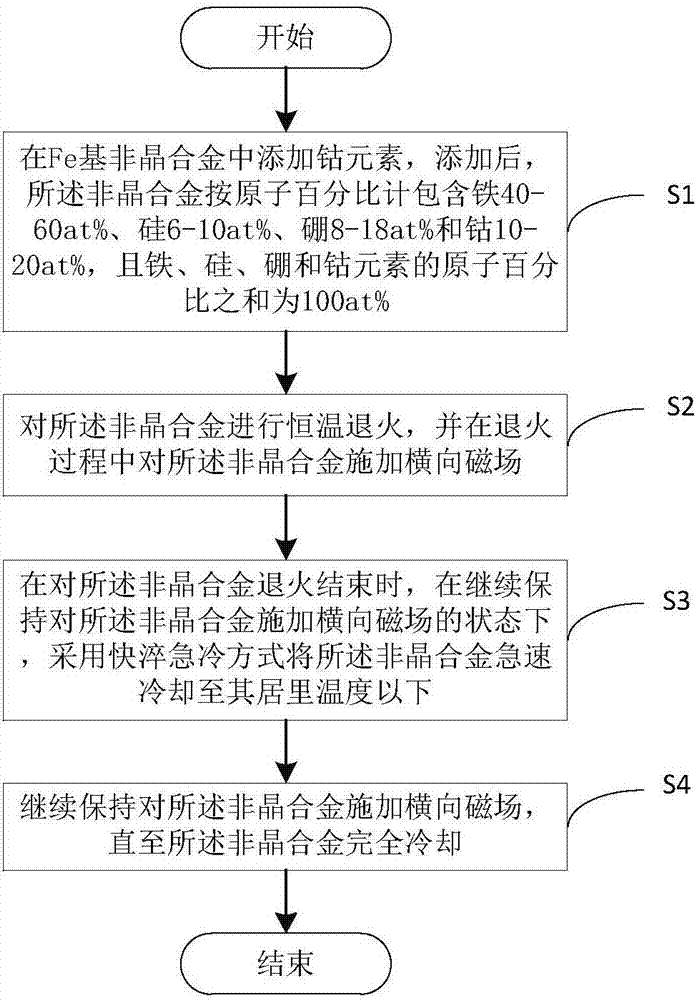

[0029] Such as figure 1 As shown, the method for preparing a single linear amorphous alloy iron core provided by the embodiment of the present invention includes the following steps:

[0030] Step S1: adding cobalt element to the Fe-based amorphous alloy, after the addition, the amorphous alloy contains iron 40-60at%, silicon 6-10at%, boron 8-18at%, and cobalt 10-20at%, and The sum of the atomic percentages of iron, silicon, boron and cobalt elements is 100 at%, and then enter step 2. Adding an appropriate amount of cobalt element with strong ferromagnetism and high magnetic susceptibility on the basis of Fe-based amorphous alloy can increase the hysteresis anisotropy of the amorphous alloy and improve the sensitivity of the alloy to the magnetic field. Specifically, the amorphous alloy contains 55 at% iron, 9 at% silicon, 17 at% boron, and 19 at% cobalt in atomic percent.

[0031] Step S2: Perform constant temperature annealing on the amorphous alloy, and apply a transverse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com