Interior permanent magnet rotor and method for manufacturing the same

A manufacturing method and magnet technology, which are applied in the field of manufacturing magnet-embedded rotors and magnet-embedded rotors, and can solve problems such as permanent magnets being easily demagnetized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

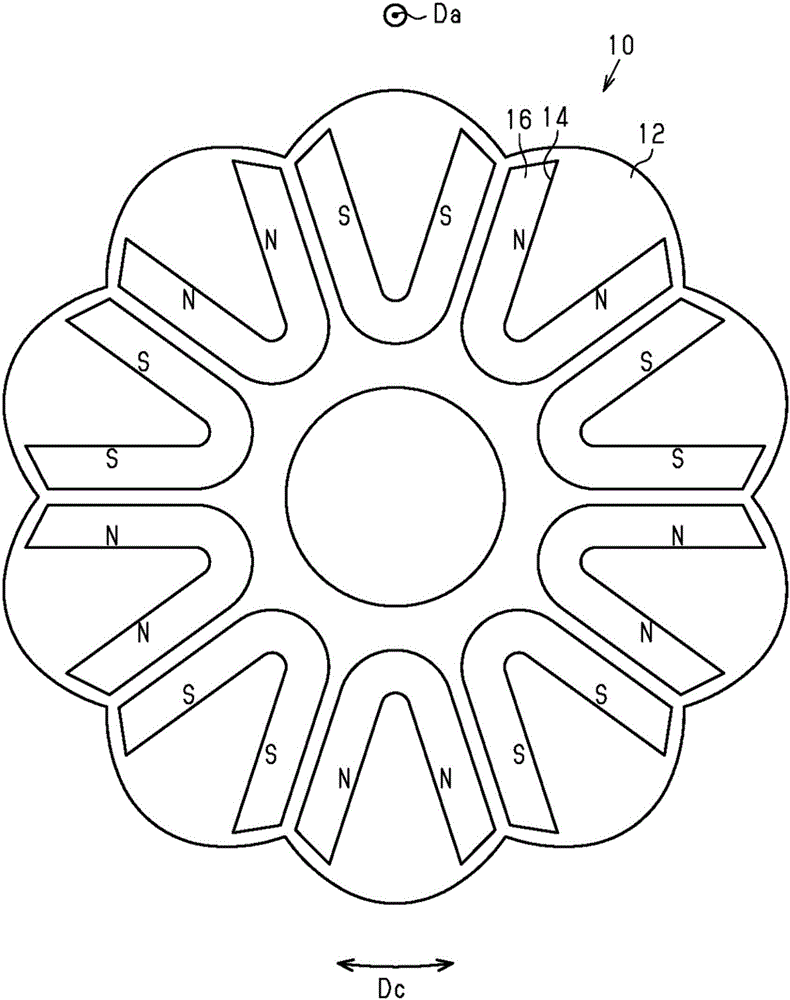

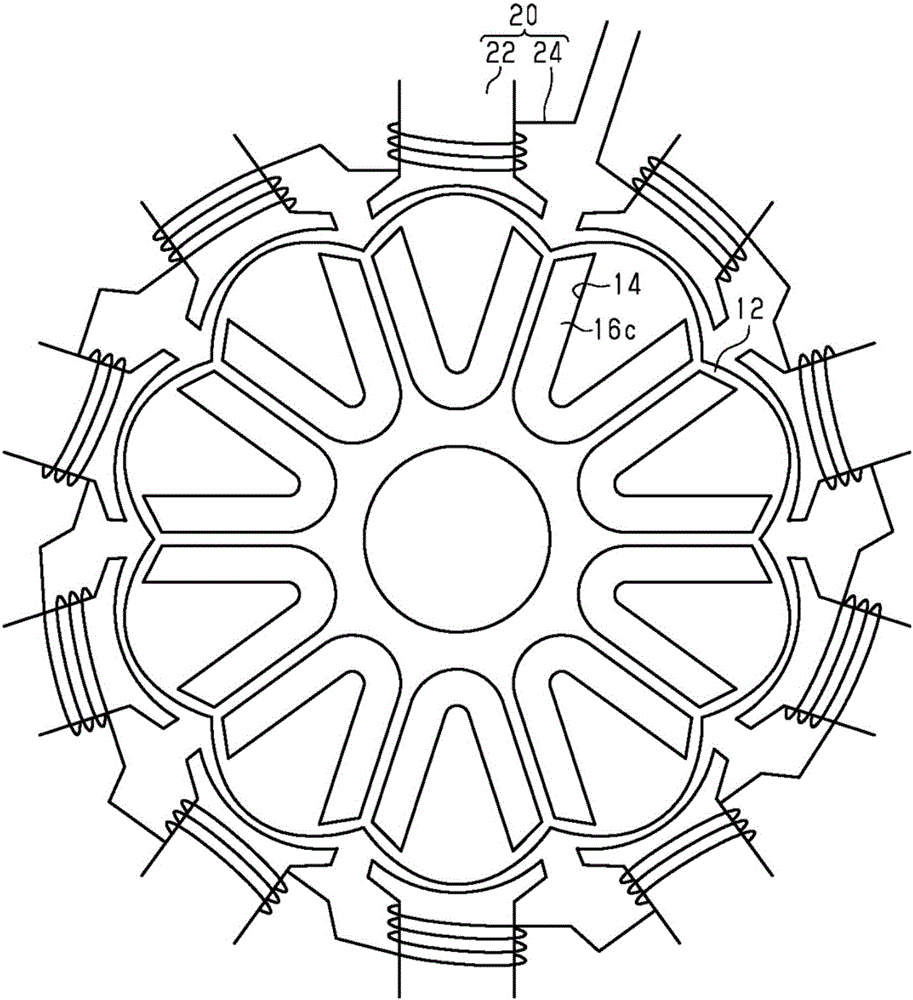

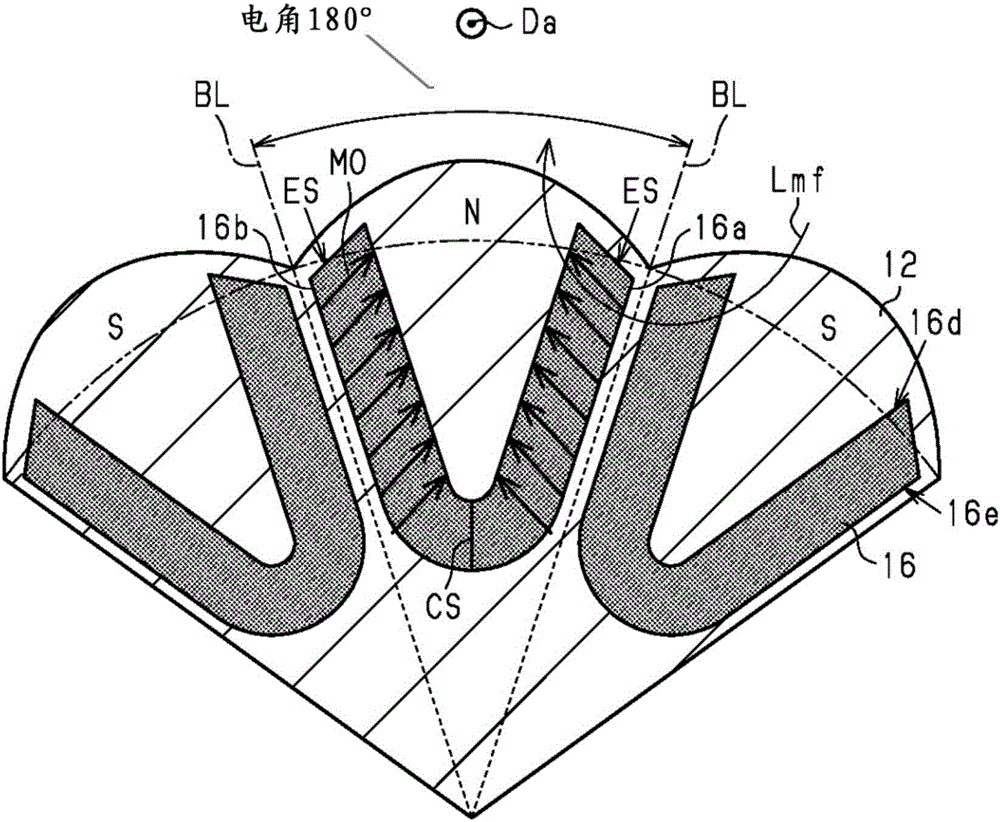

[0038] Next, a first embodiment of a magnet-embedded rotor will be described with reference to the drawings. figure 1 The illustrated rotor 10 is built into an embedded magnet synchronous motor (IPMSM). The IPMSM constitutes an electric power steering (EPS). The rotor 10 includes a magnetic core 12 and permanent magnets 16 formed of a soft magnetic material. The magnetic core 12 is formed by laminating a plurality of silicon steel sheets, that is, electromagnetic steel sheets, and has functions of holding a magnetic circuit, the permanent magnets 16 , and generating and transmitting rotational torque. The magnetic core 12 has ten insertion holes 14 penetrating in the axial direction Da. The cross-sectional shape of the insertion hole 14 perpendicular to the axial direction Da is substantially U-shaped. The insertion holes 14 are evenly arranged in the circumferential direction Dc of the magnetic core 12 . A permanent magnet 16 is embedded in the insertion hole 14 . The pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com