Patents

Literature

102results about How to "Efficient attraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

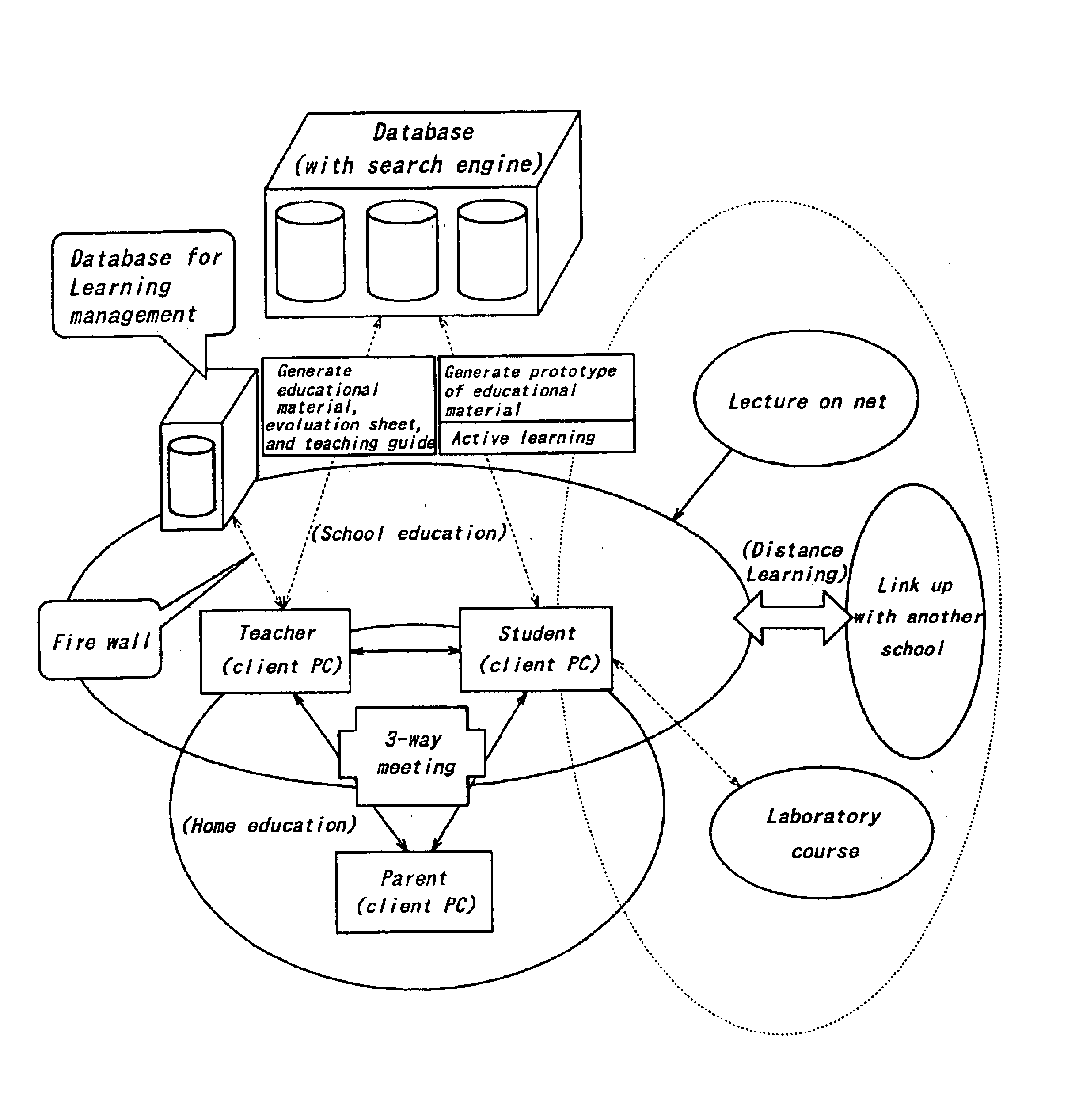

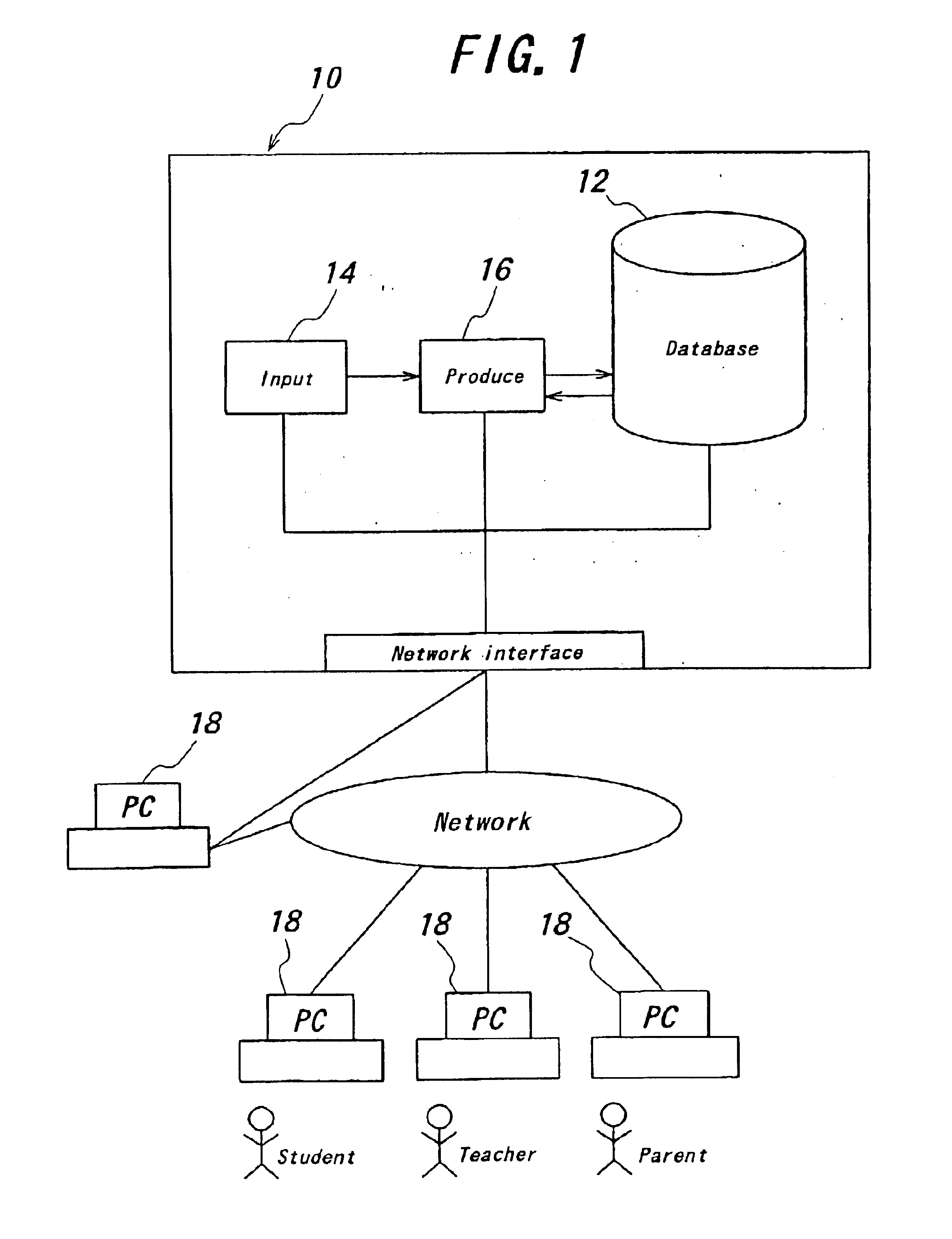

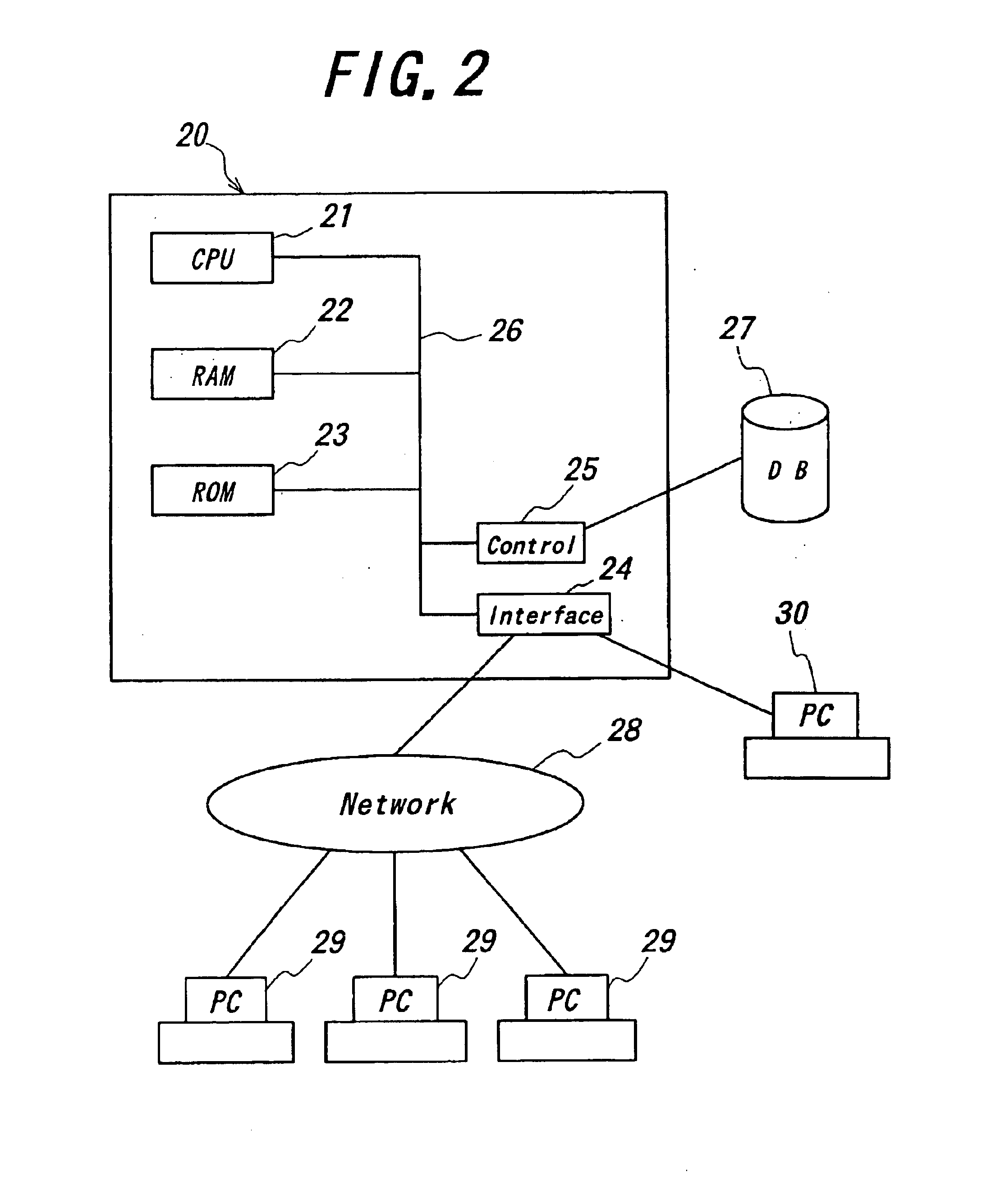

System and method for producing educational material

InactiveUS6865368B2Easily and automaticallyEasily and properly provideData processing applicationsElectrical appliancesSelection criterionKnowledge management

A system for producing an educational material for students. The system has a storing part for storing raw educational materials into a database, an input part for inputting both student-related data and educational environment-related data, and an educational material producing unit for selecting at least one raw educational material from said the database based on predetermined selecting criteria and the inputted student-related data and educational environment-related data to produce educational material from the selected at least one raw educational material.

Owner:SAGA UNIVERSITY

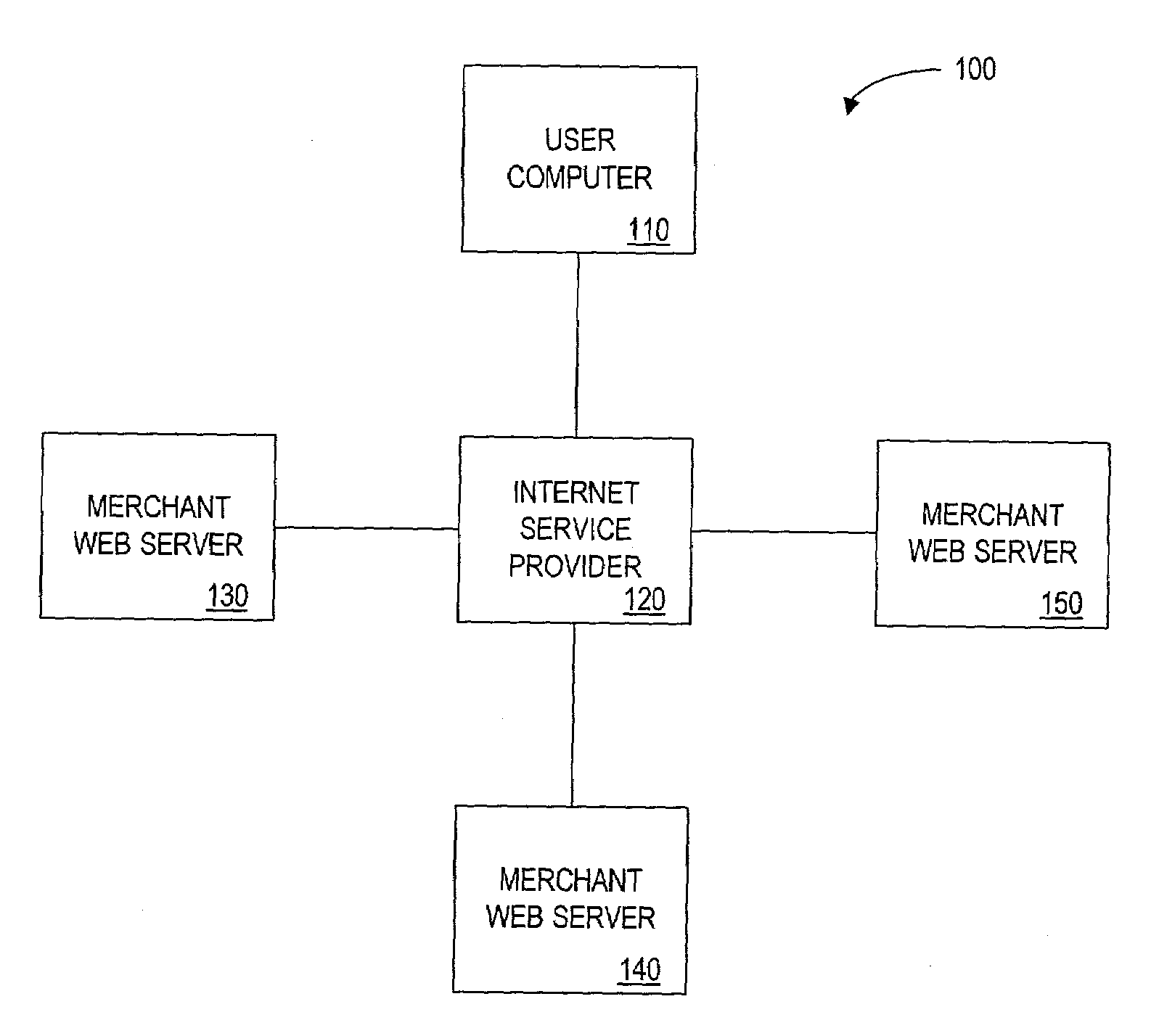

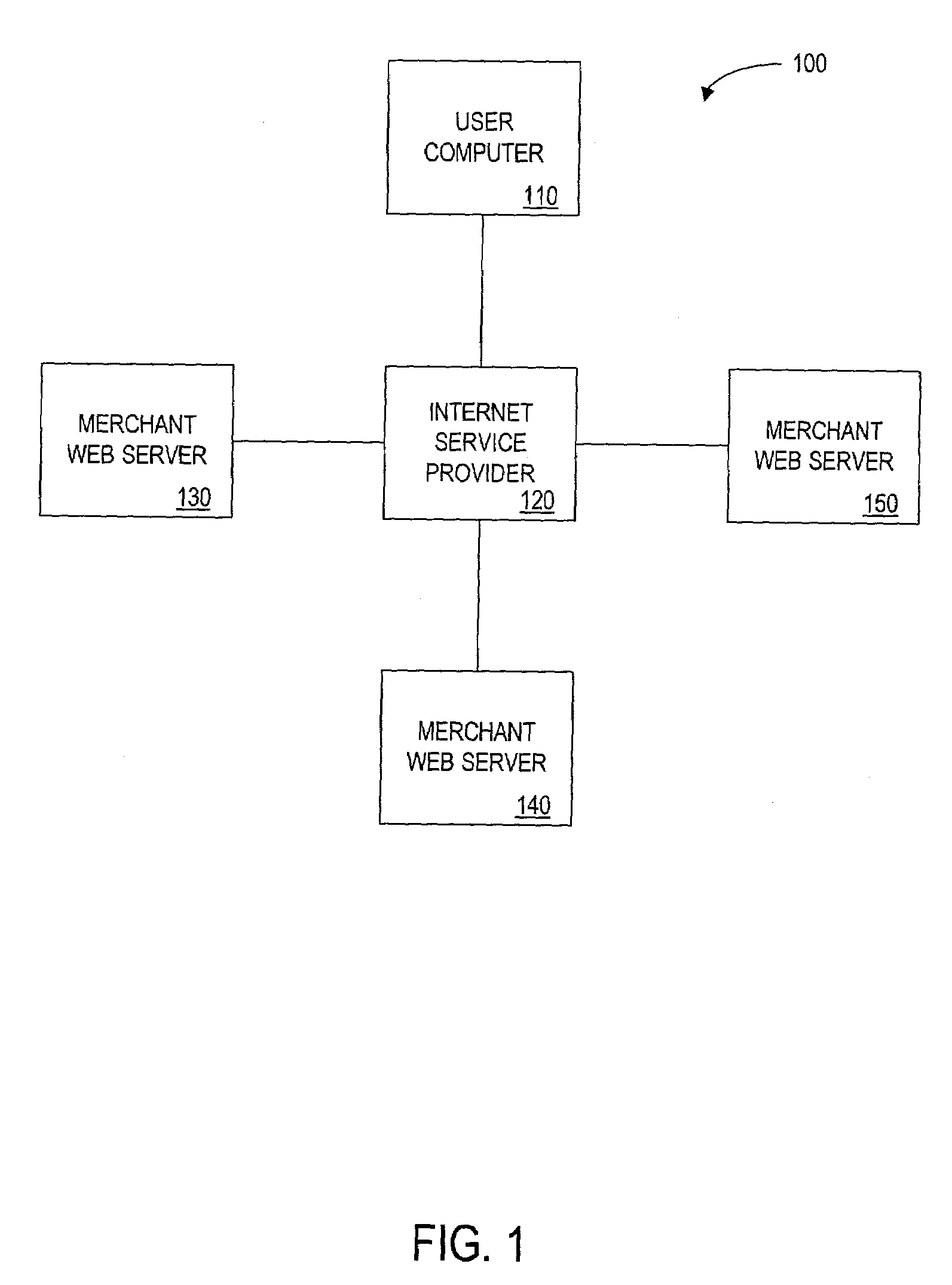

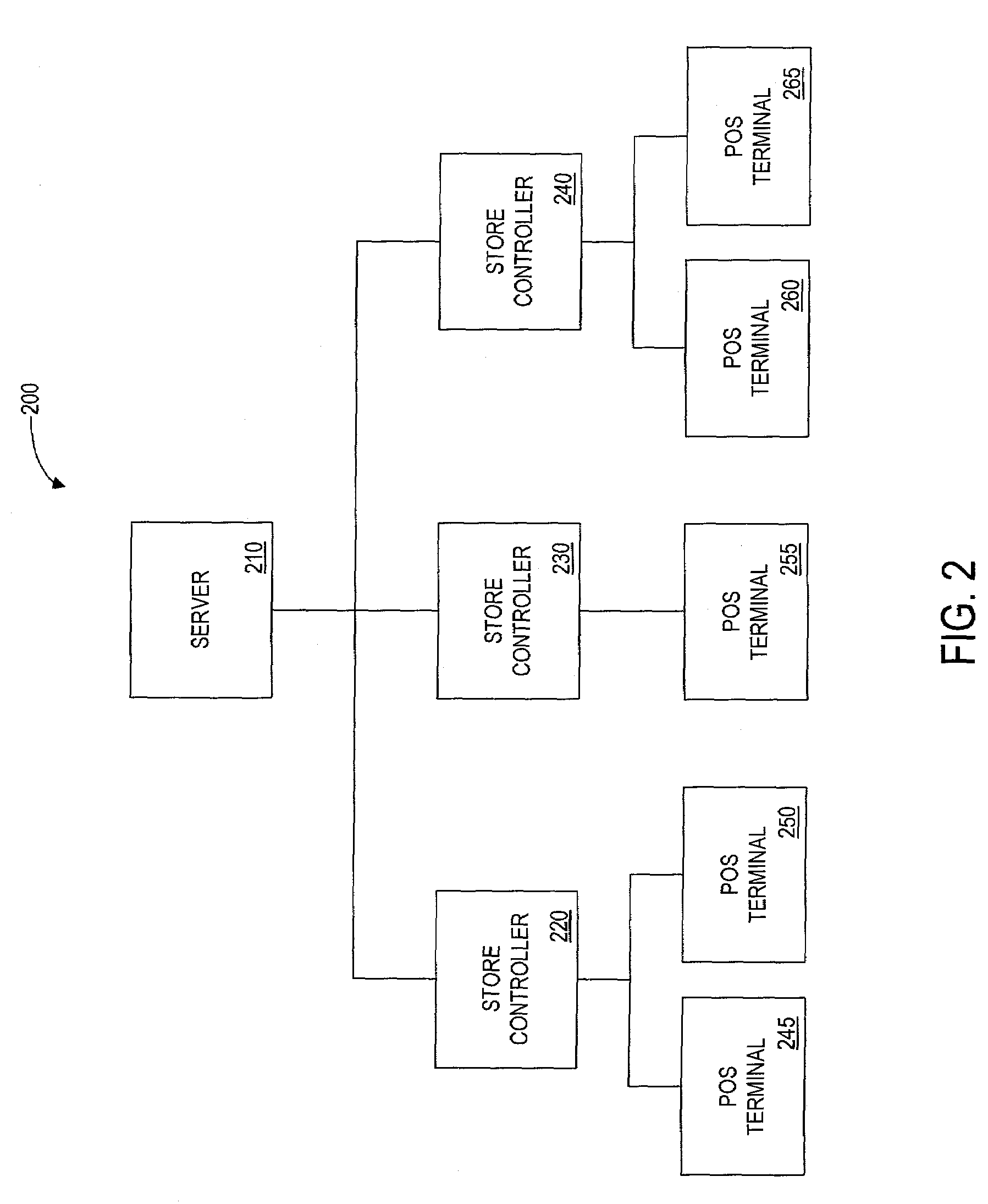

Method and apparatus for defining routing of customers between merchants

InactiveUS7099832B2Efficient attractionSales rate) is lowFinanceCash registersService provisionWorld Wide Web

Owner:PAYPAL INC

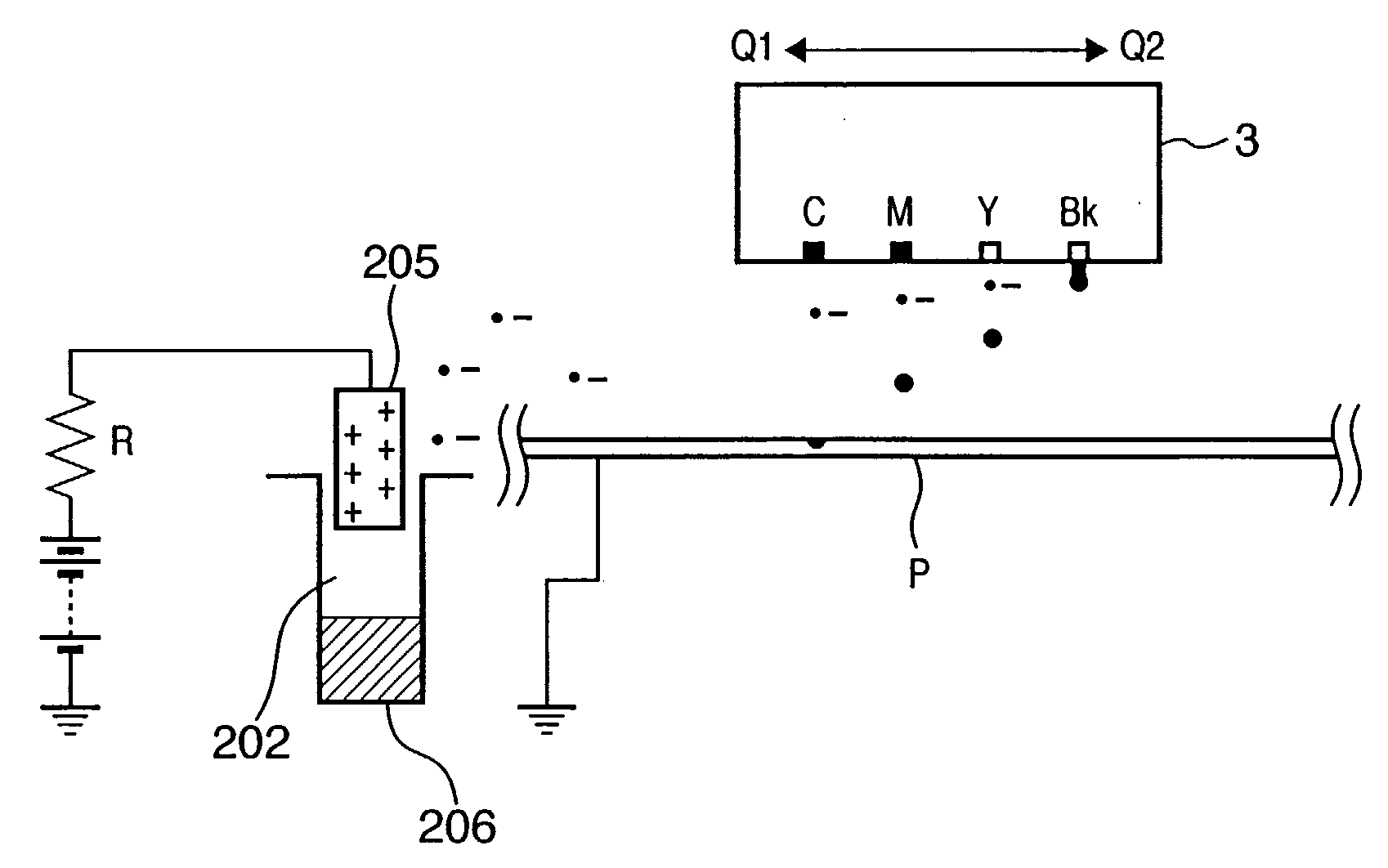

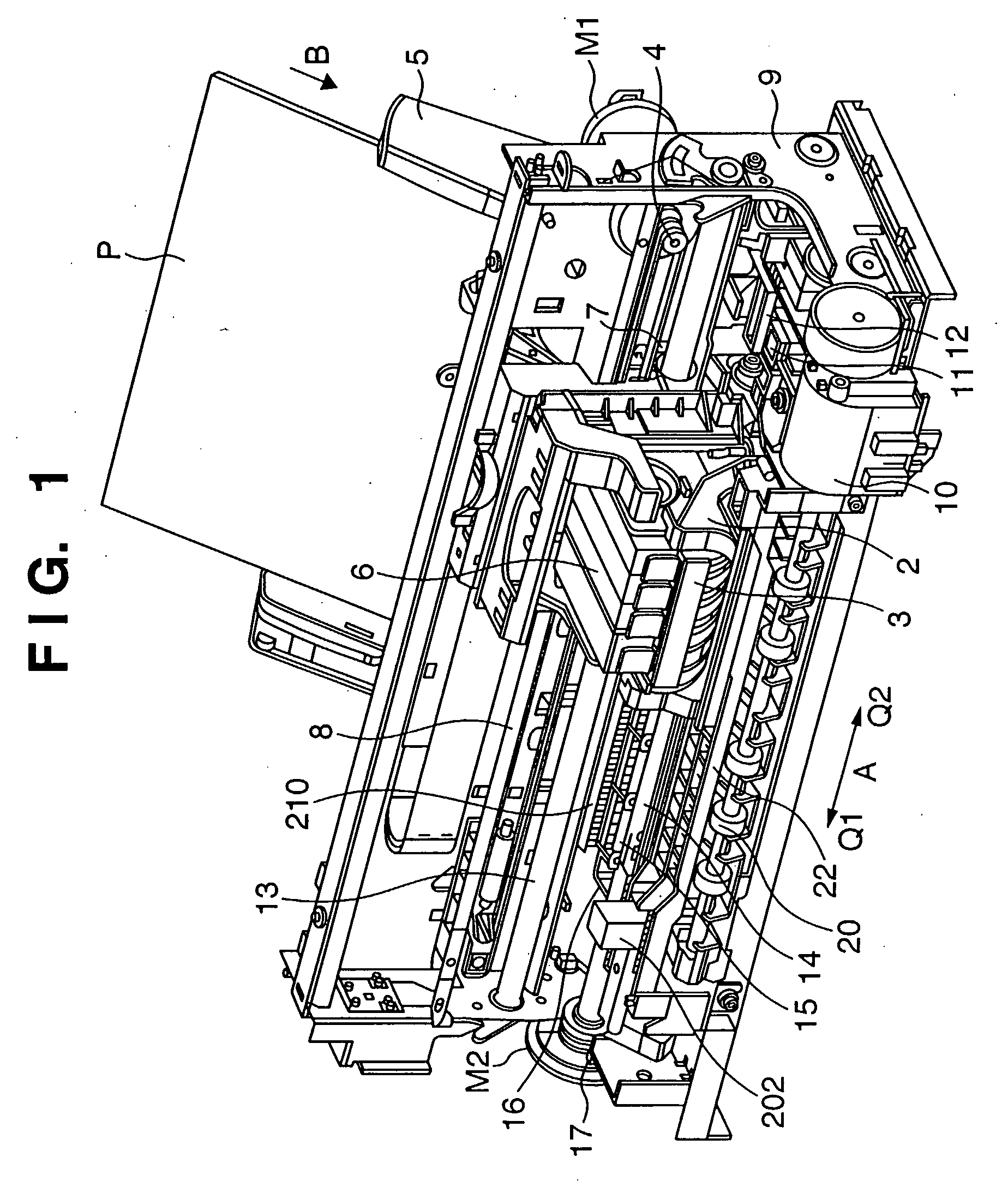

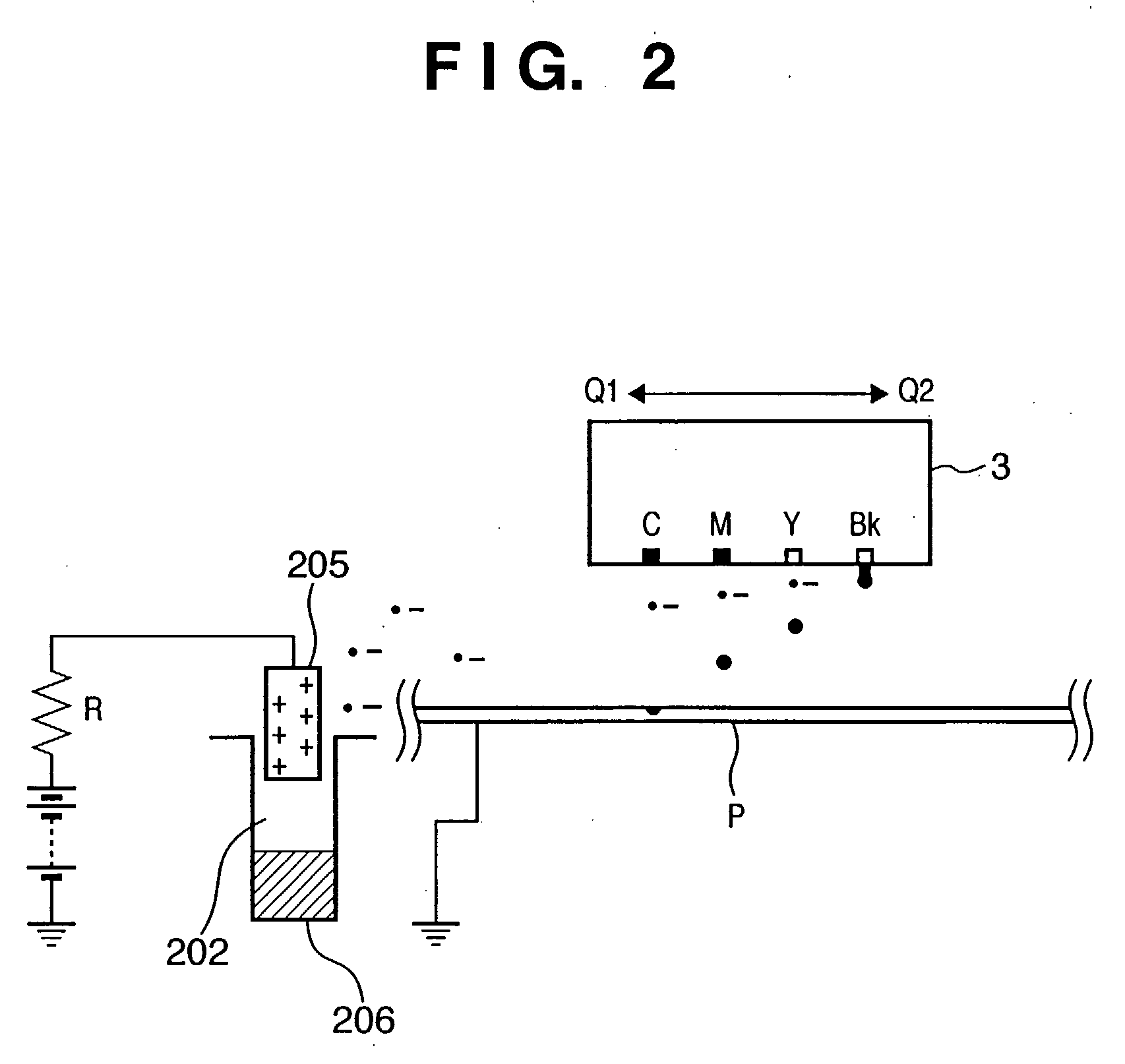

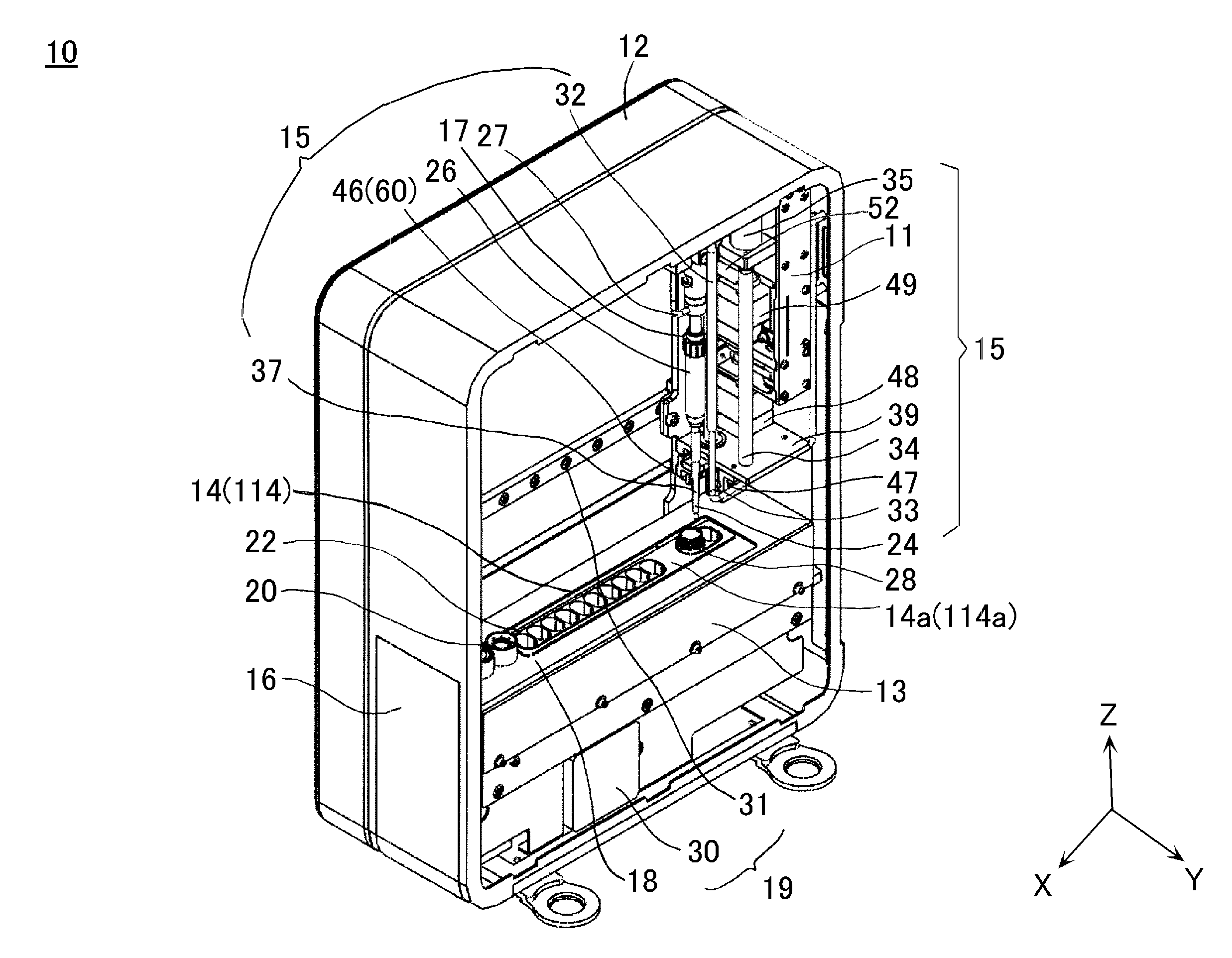

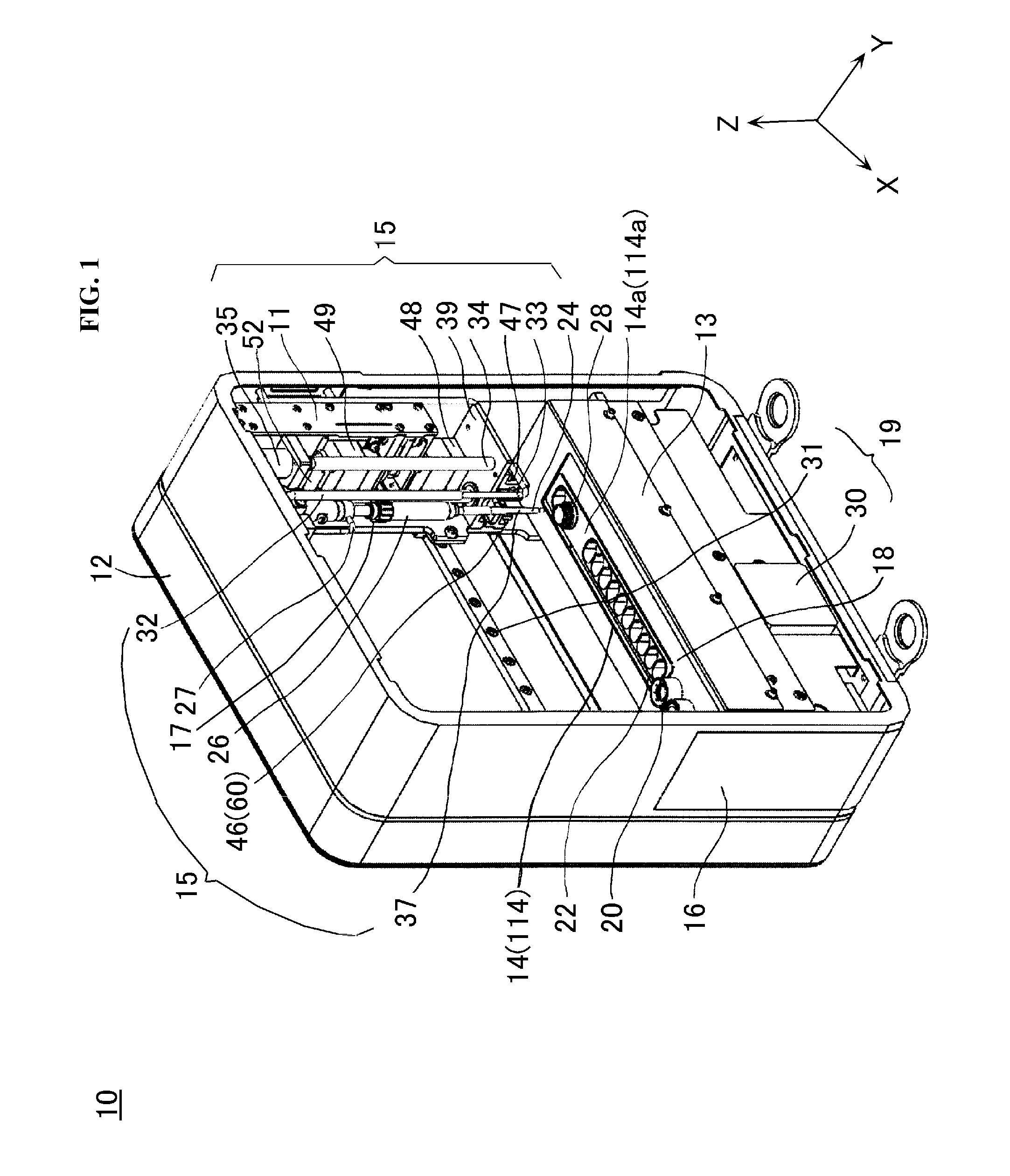

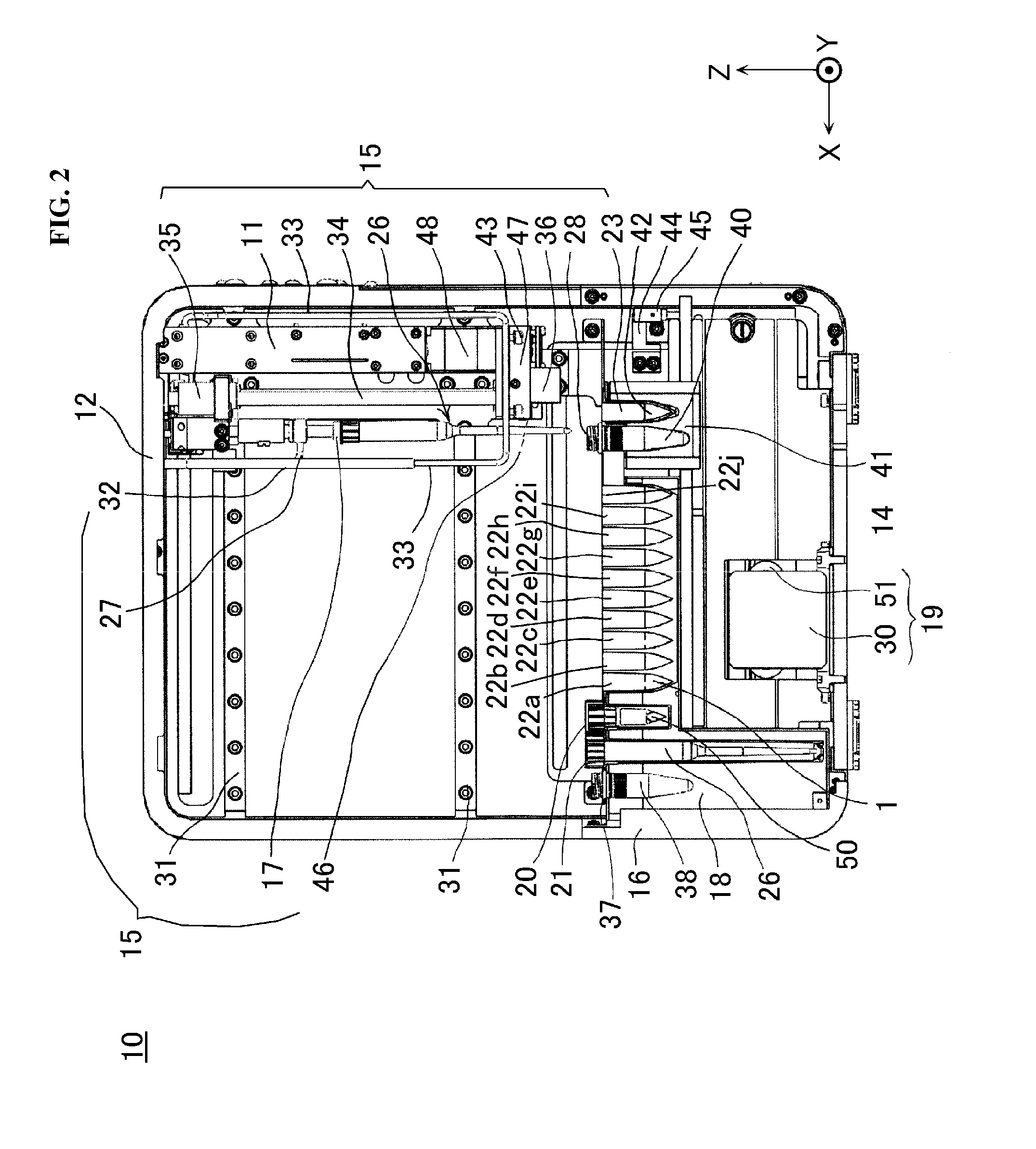

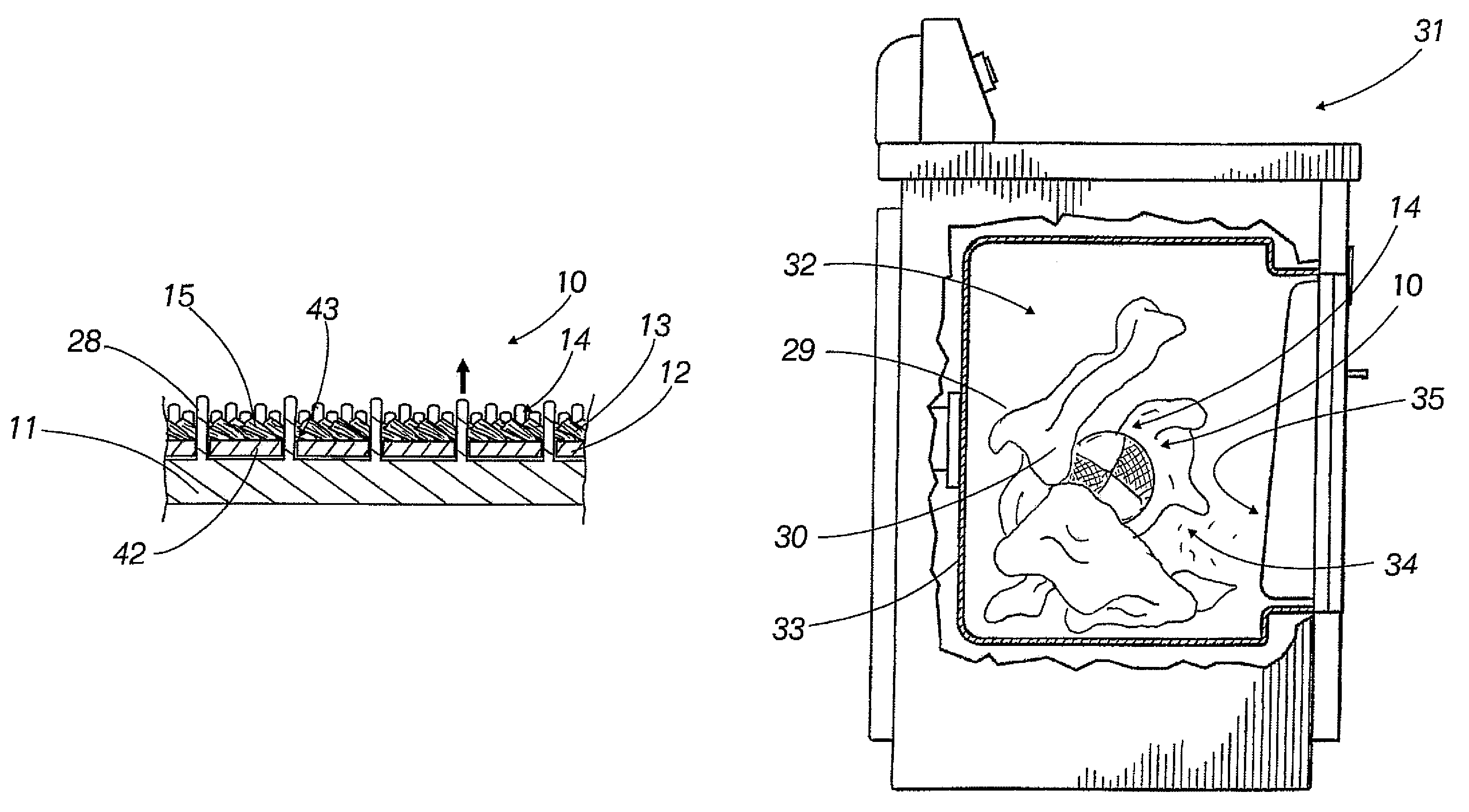

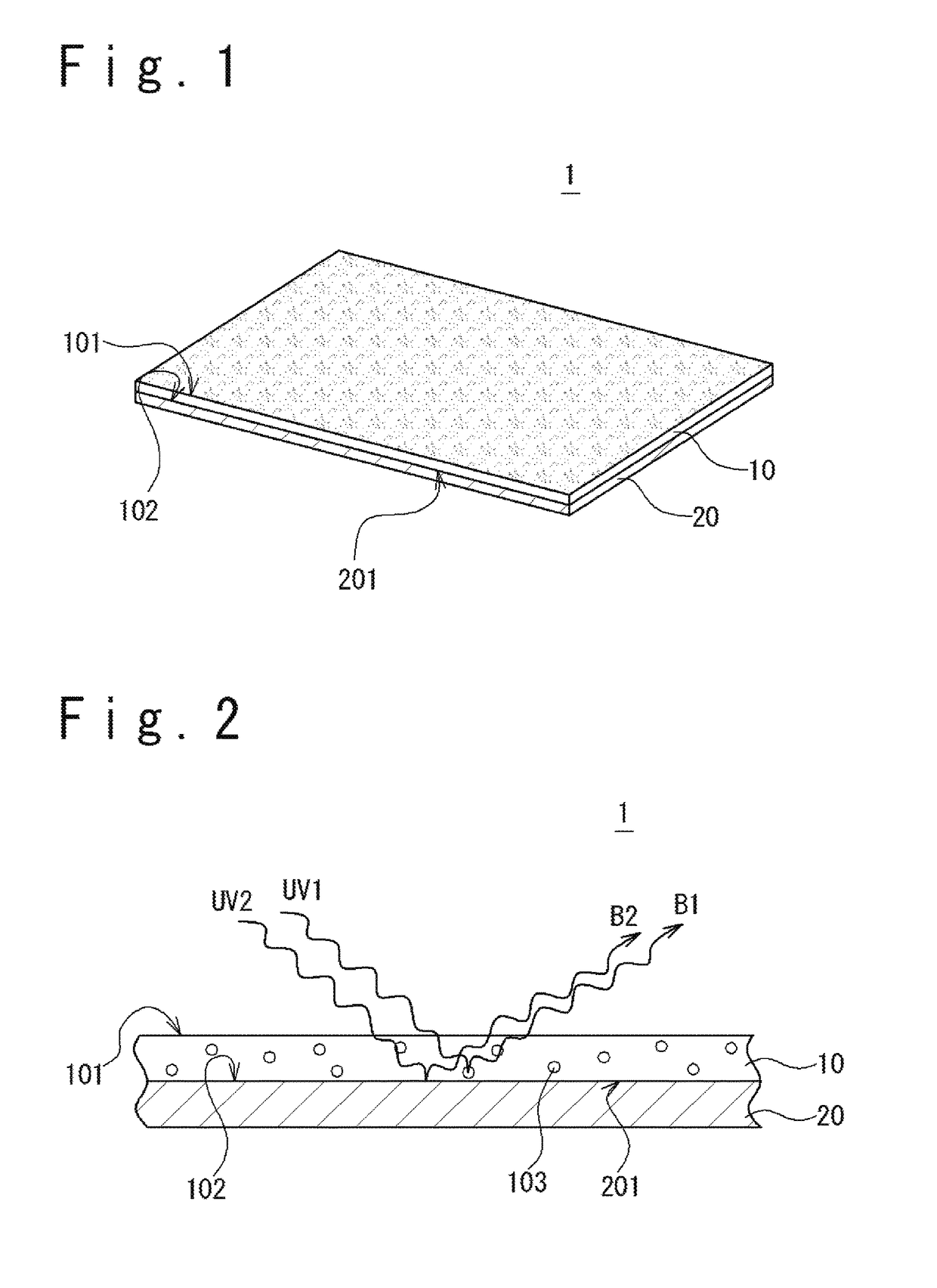

Printing Apparatus, Ink Mist Collecting Method, and Printing Method

InactiveUS20080018707A1High quality printingEfficient attractionOther printing apparatusEngineeringElectrical and Electronics engineering

There are provided a printing apparatus and printing method capable of collecting unwanted ink mist and achieving high-quality printing by fine ink droplets. According to the method, the charges of a printing medium are removed prior to printing, and an ink mist collecting unit having an electrode of a positive polarity is employed. Floating ink mist is collected such that ink mist generated from discharged ink droplets and negatively charged is moved toward the ink mist collecting unit by the electrostatic force.

Owner:CANON KK

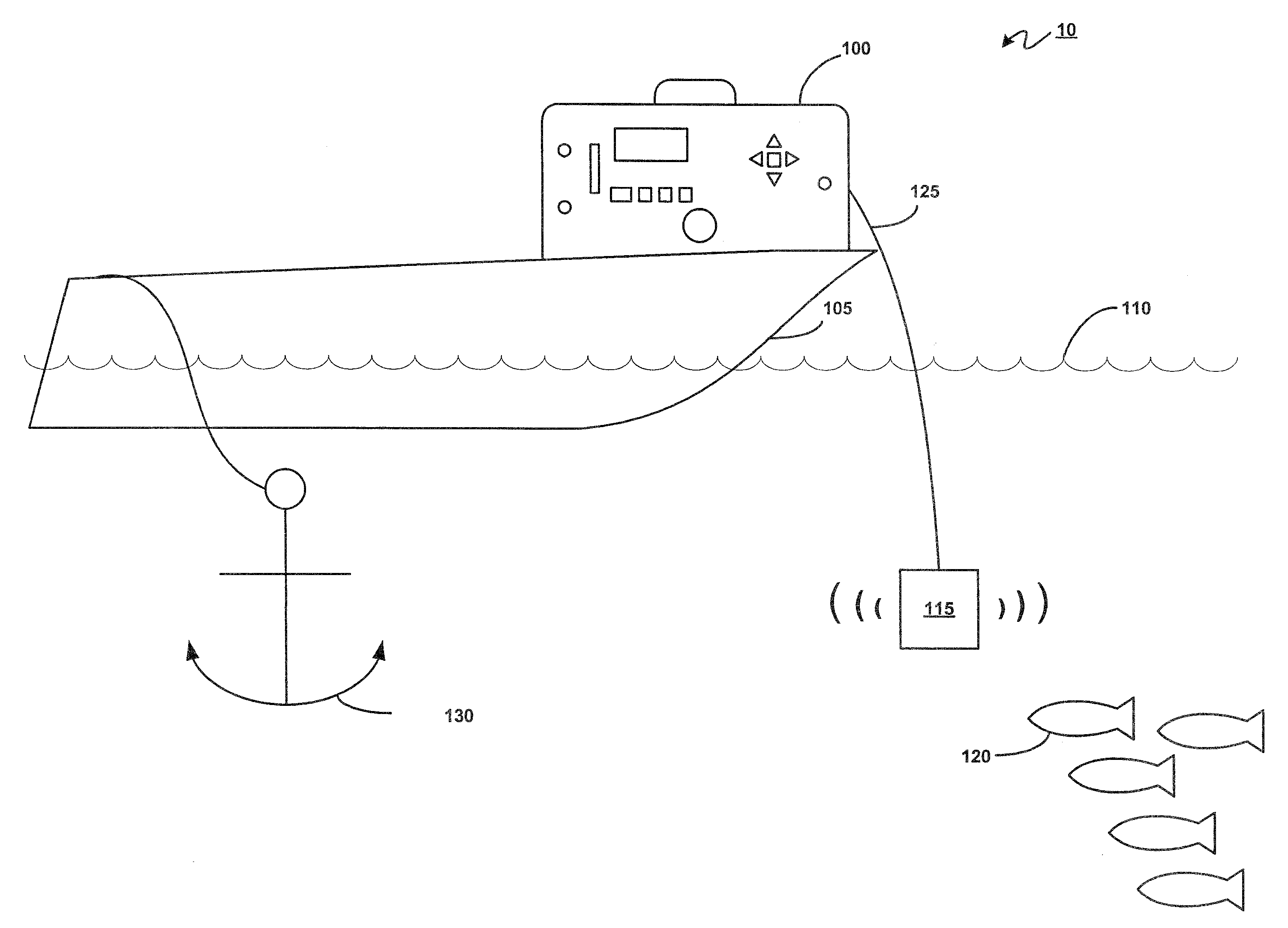

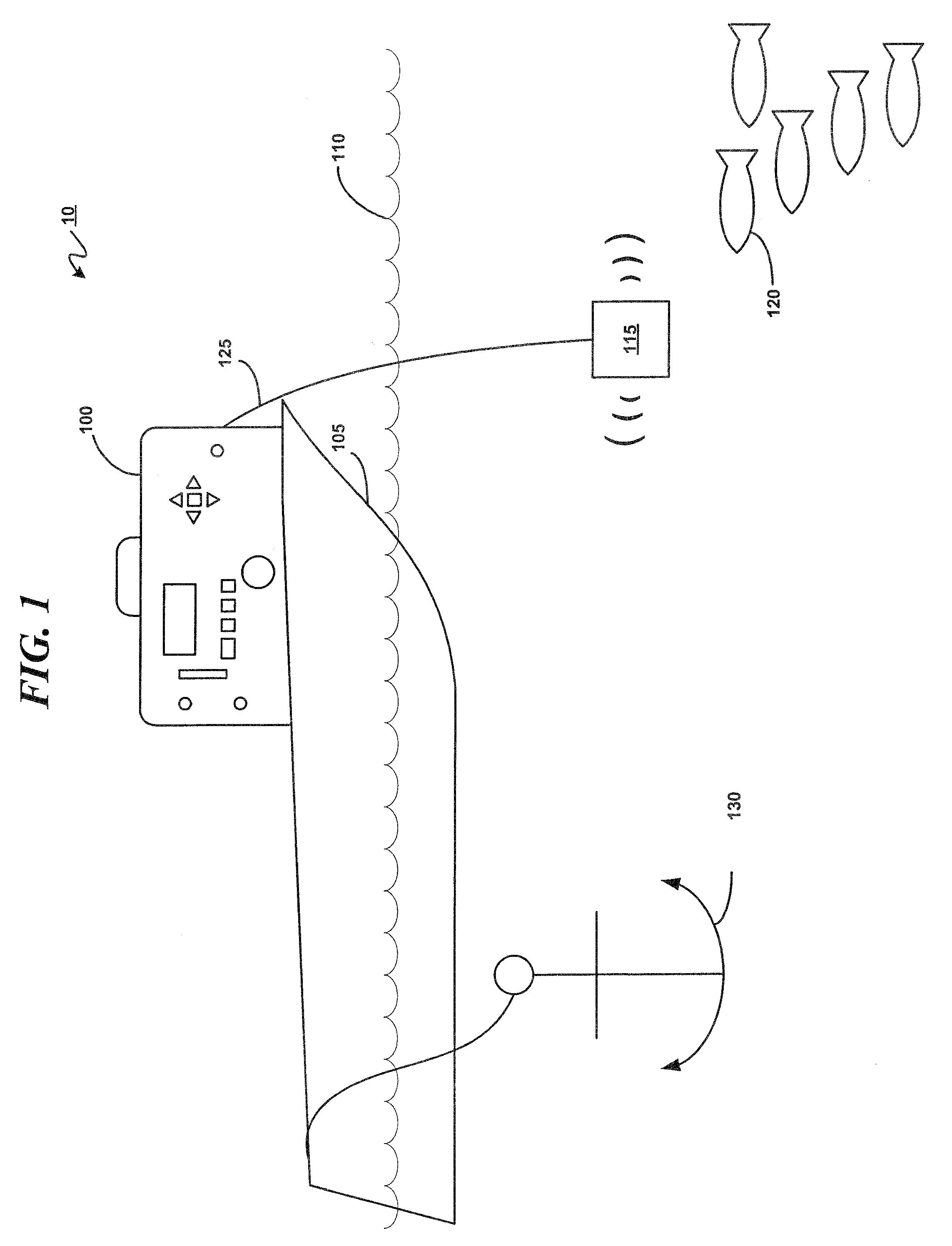

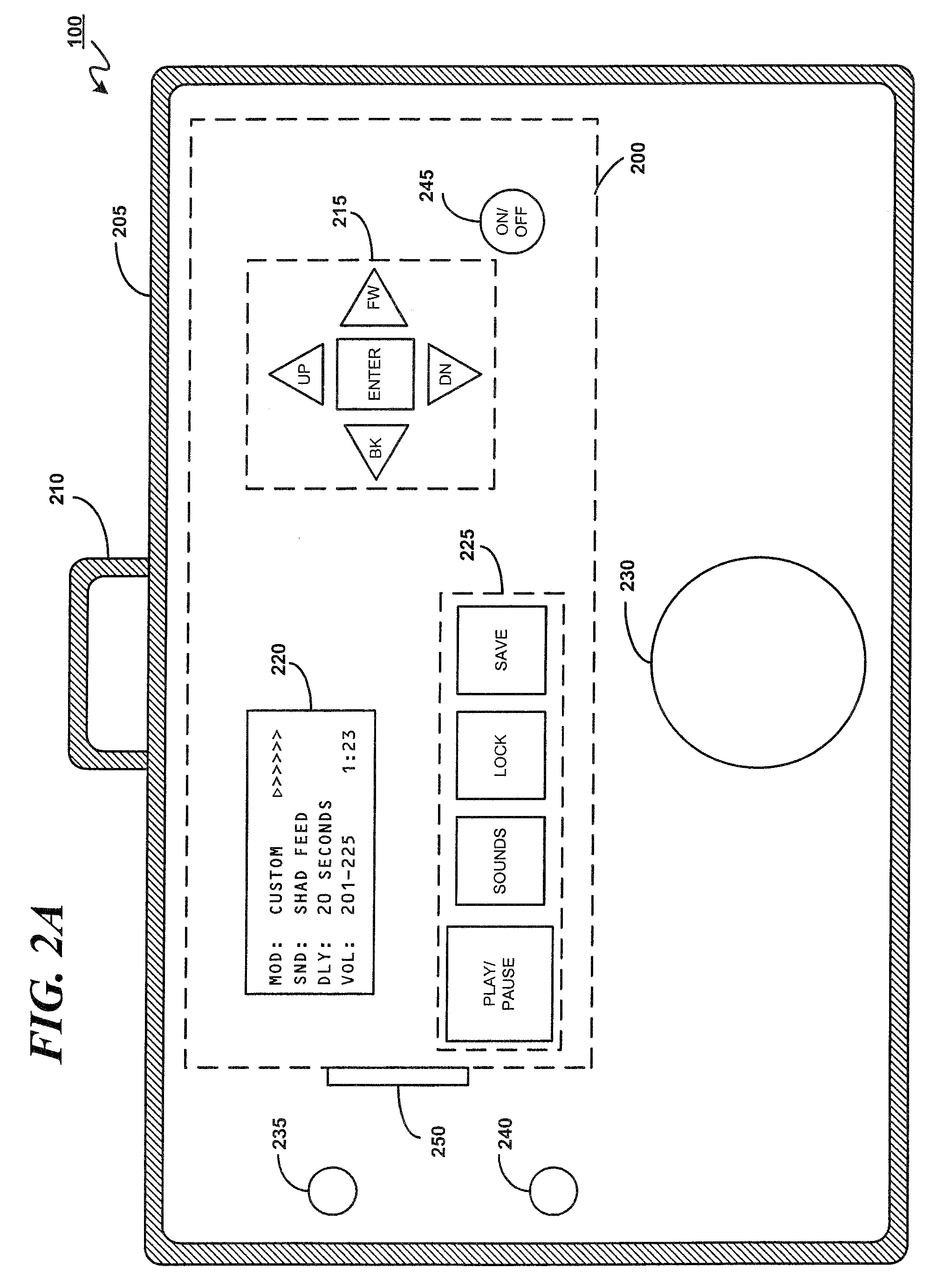

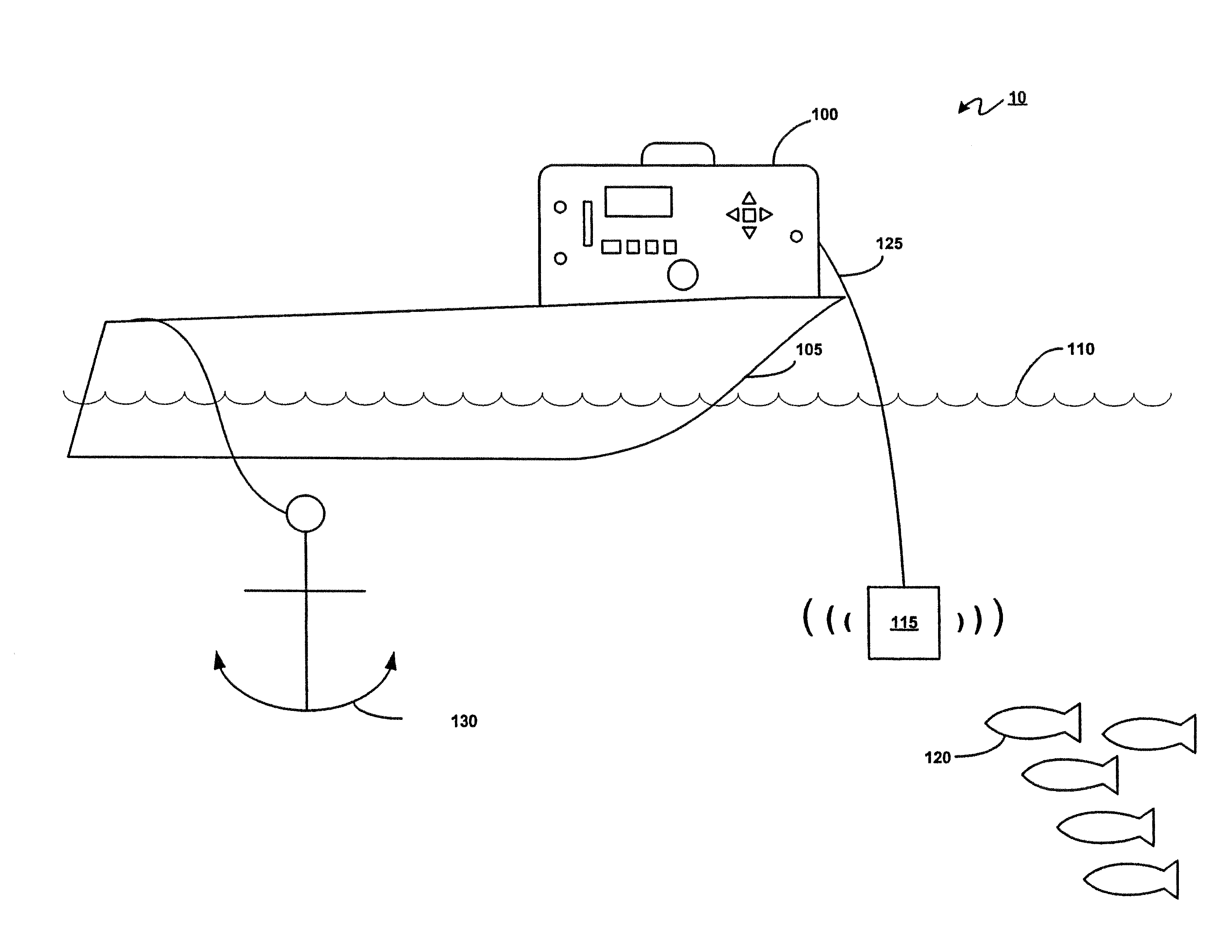

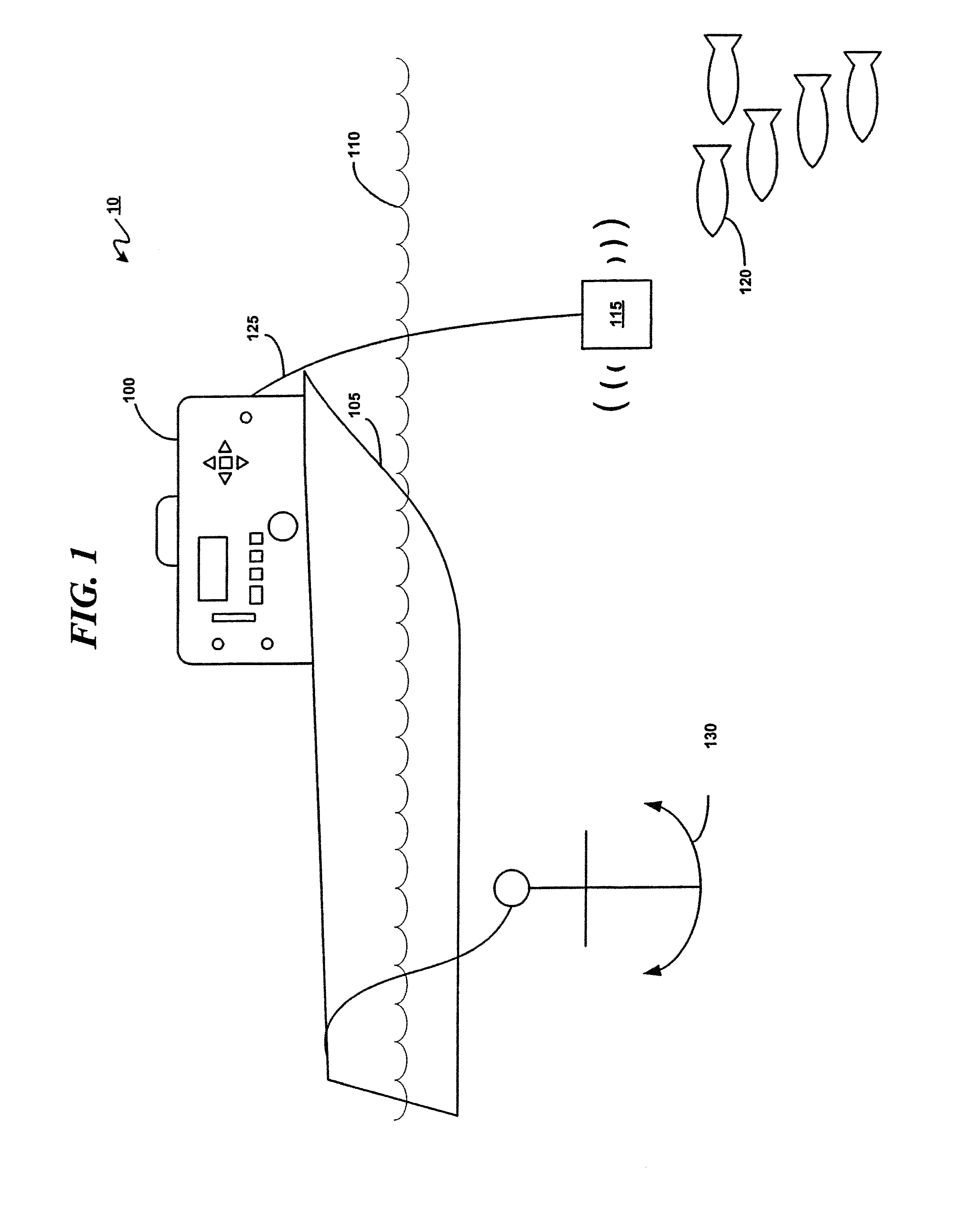

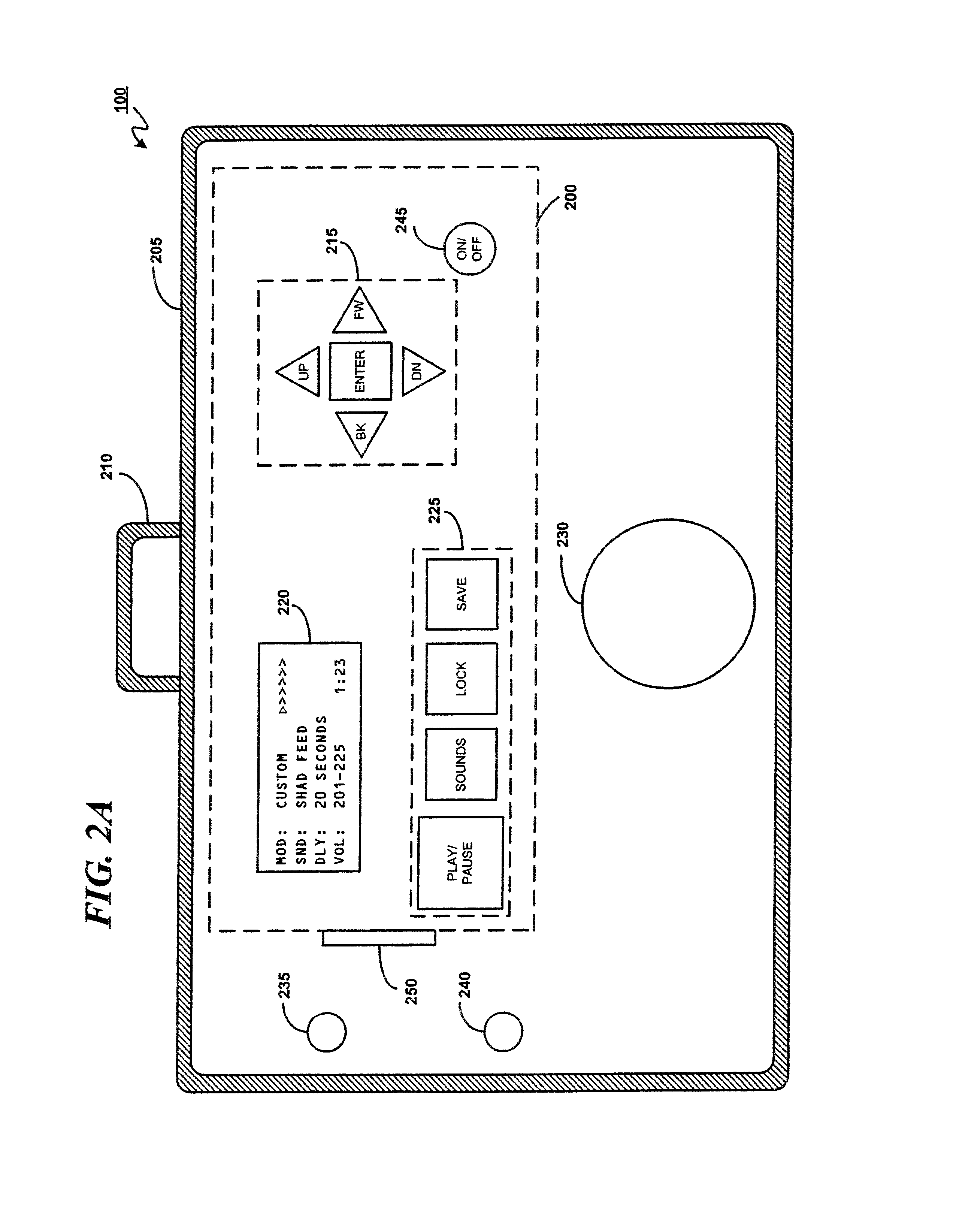

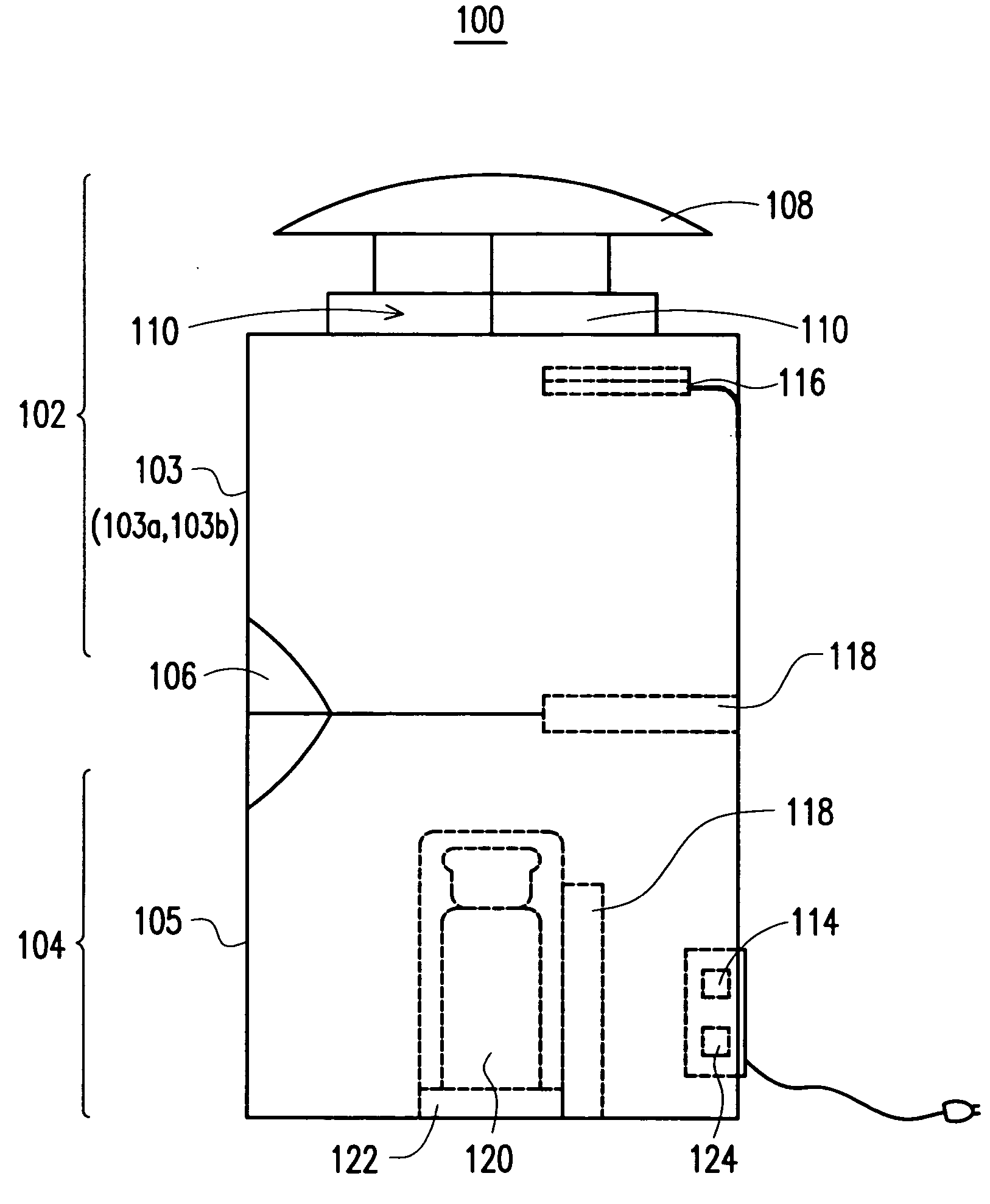

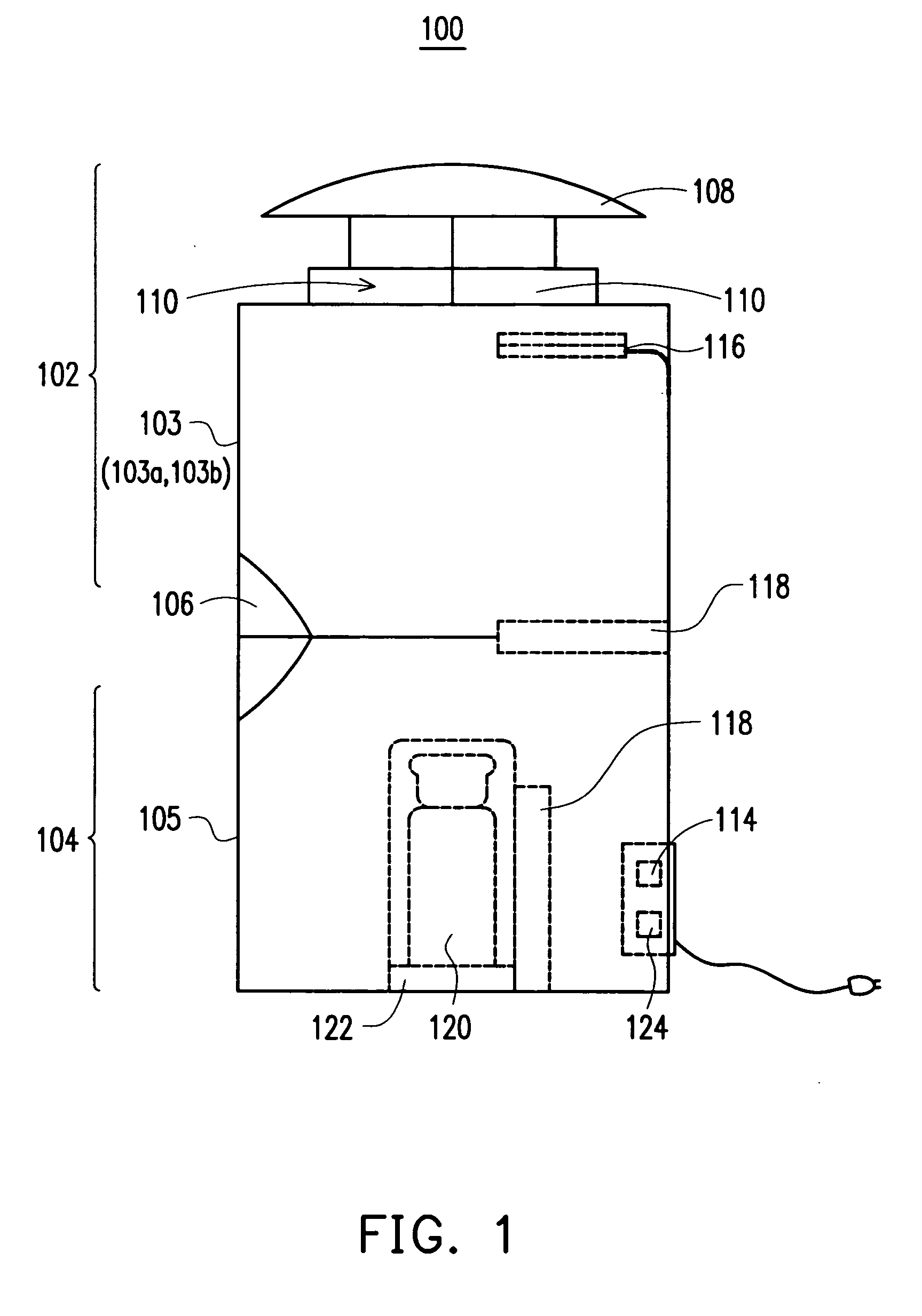

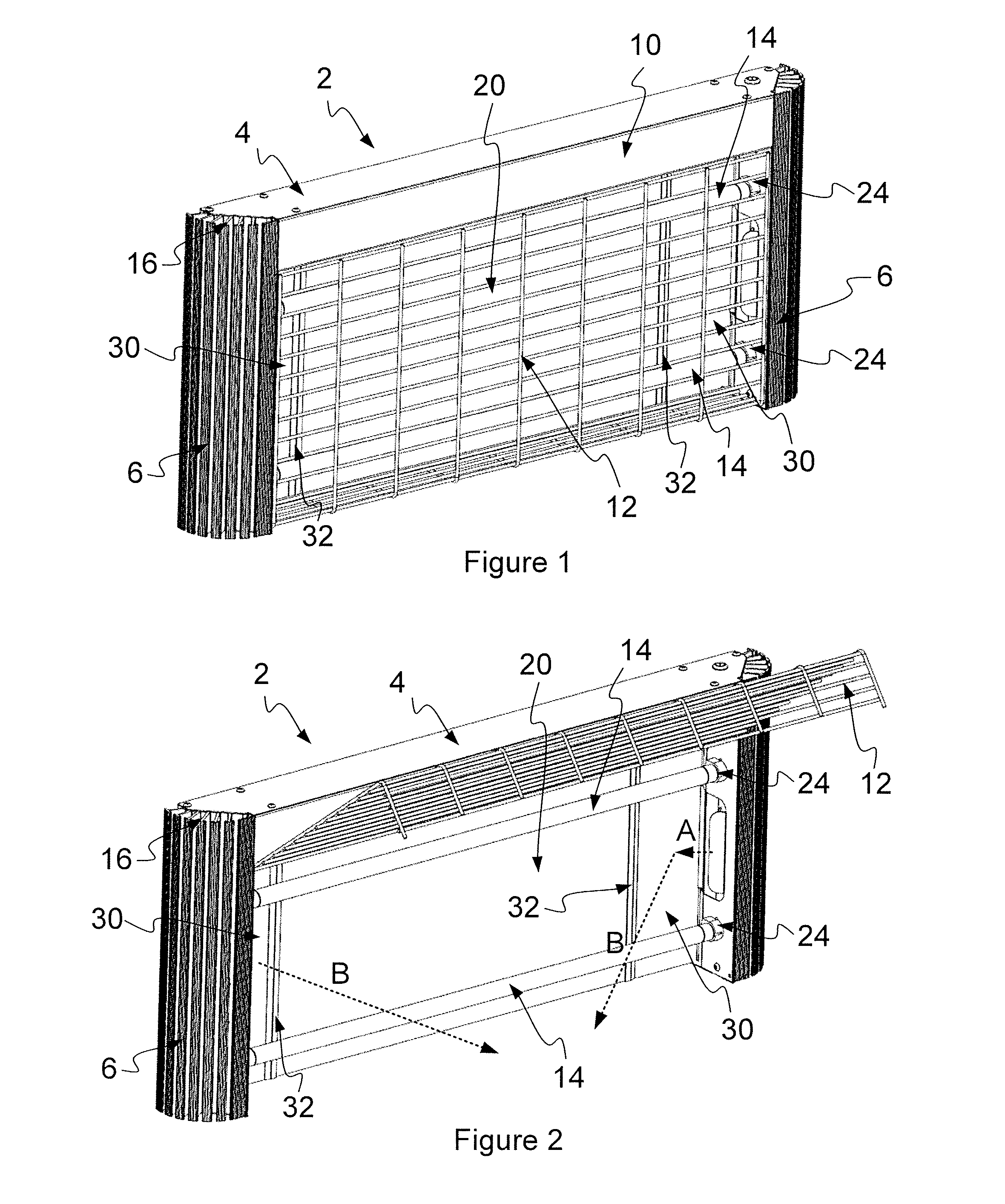

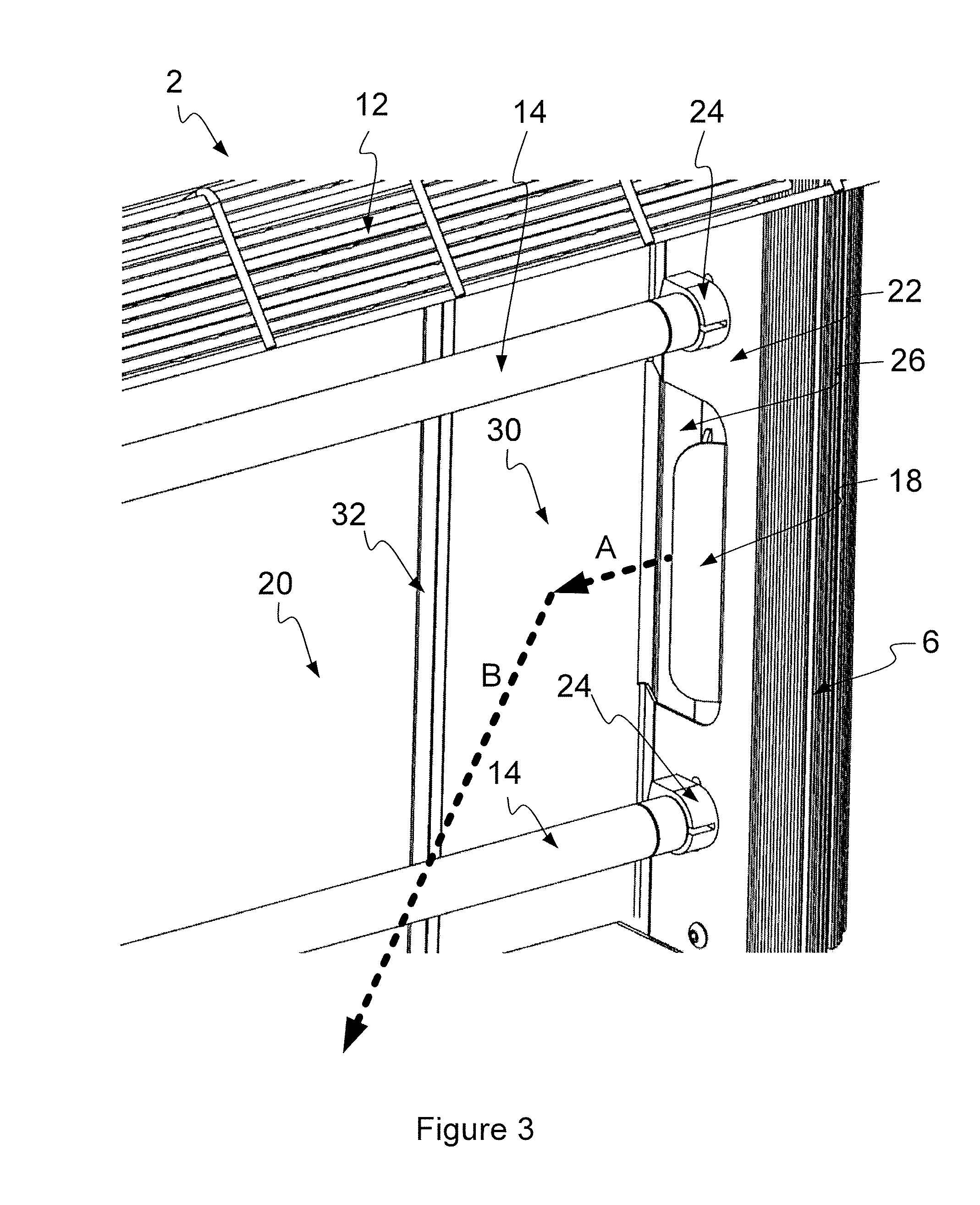

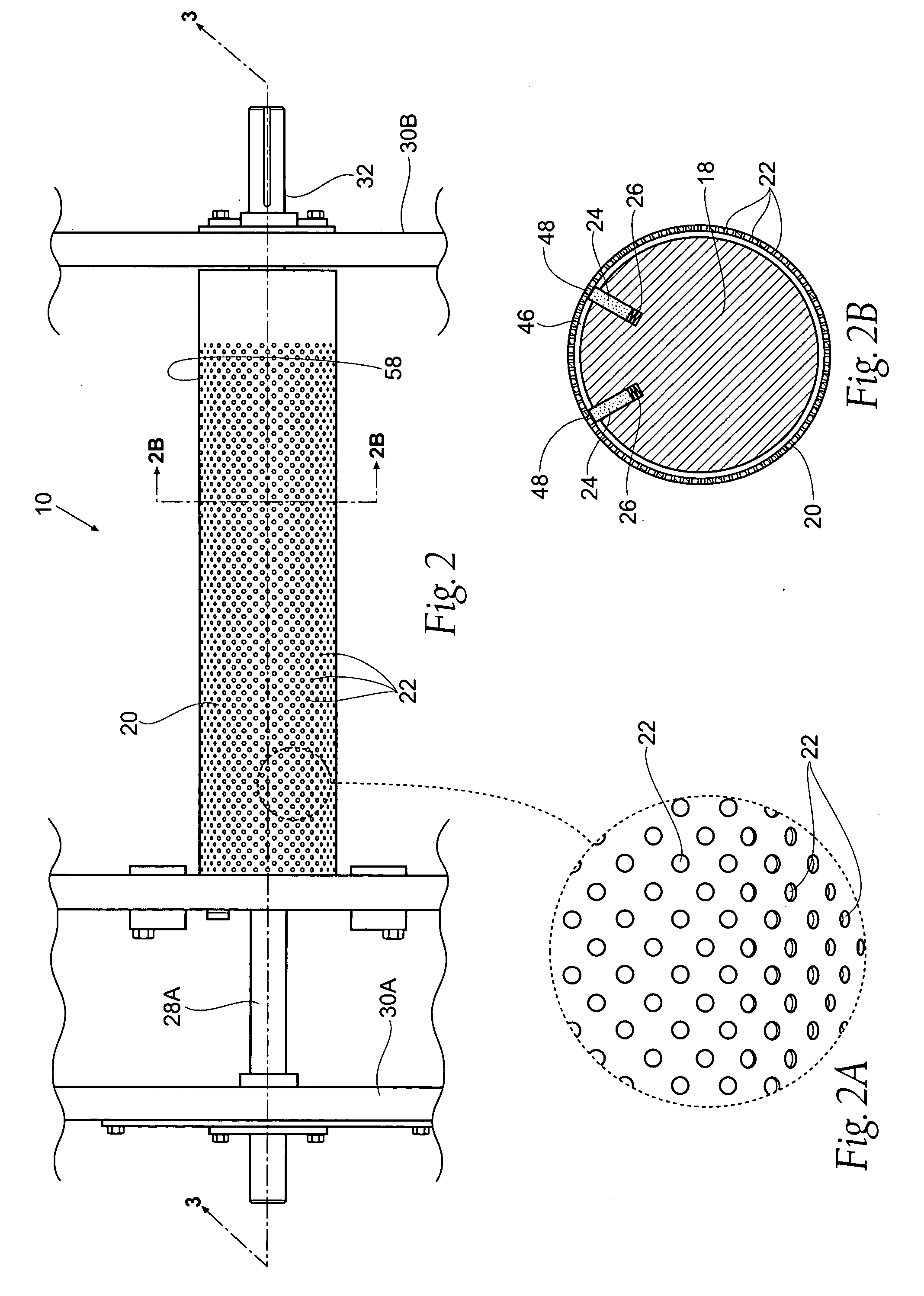

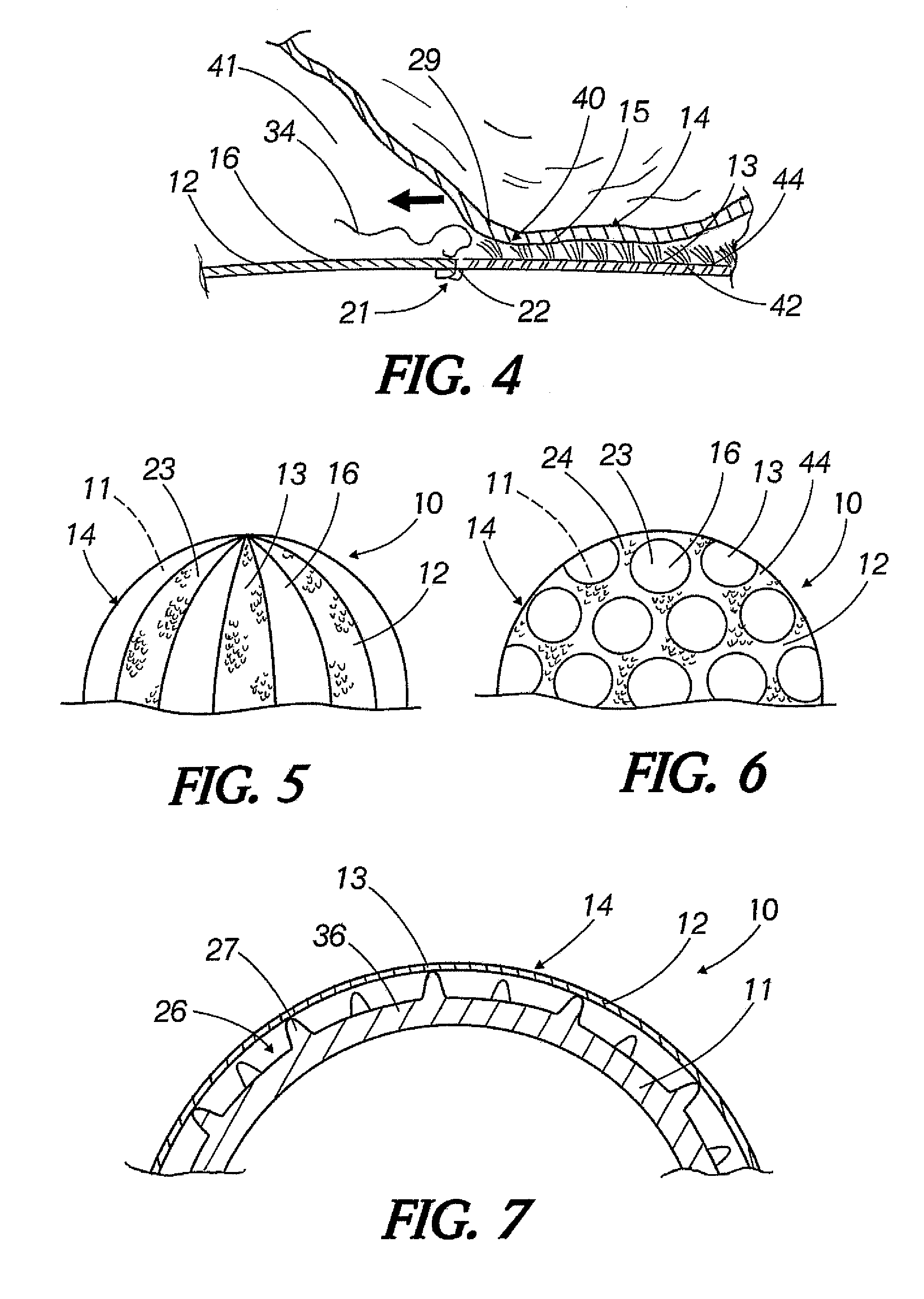

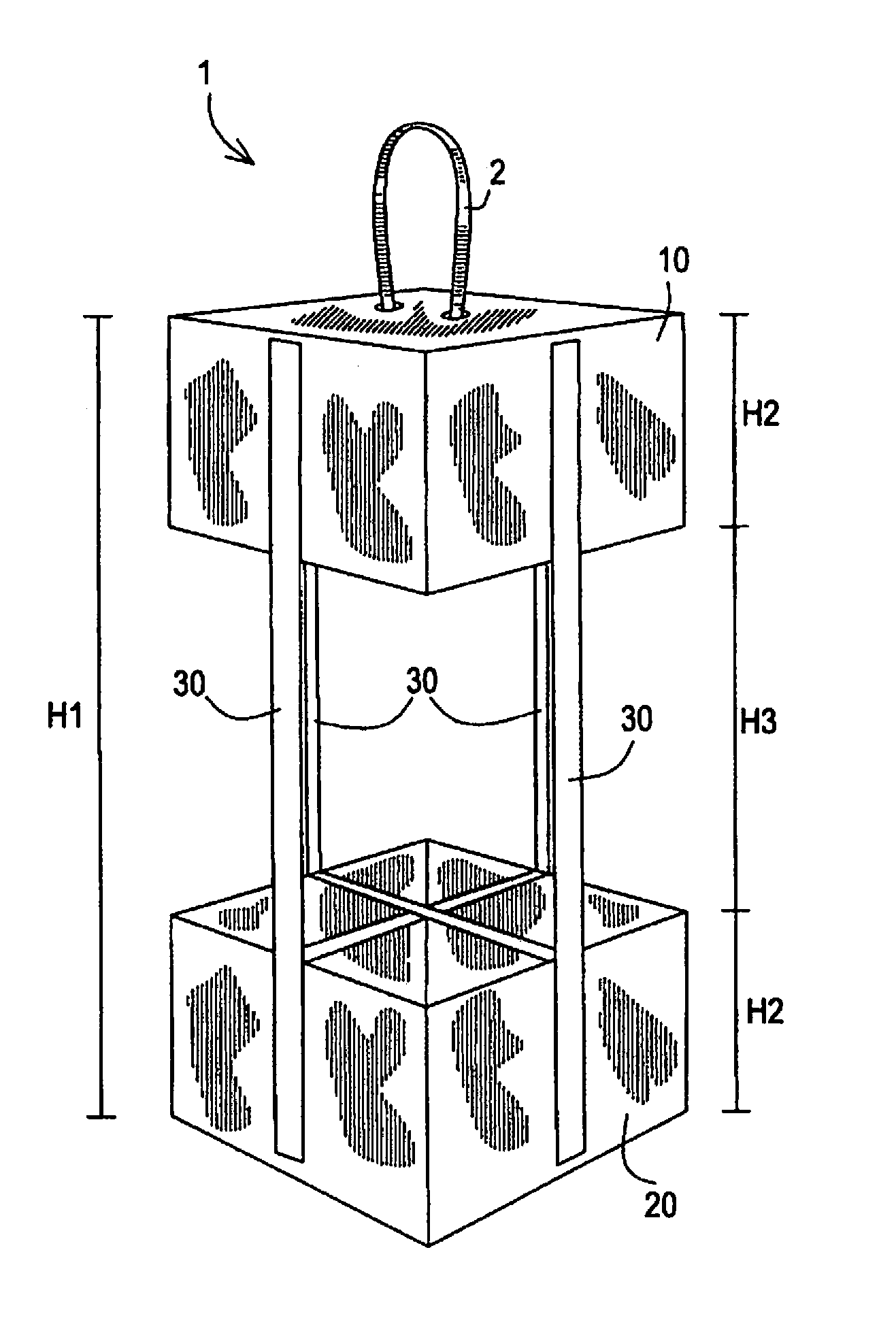

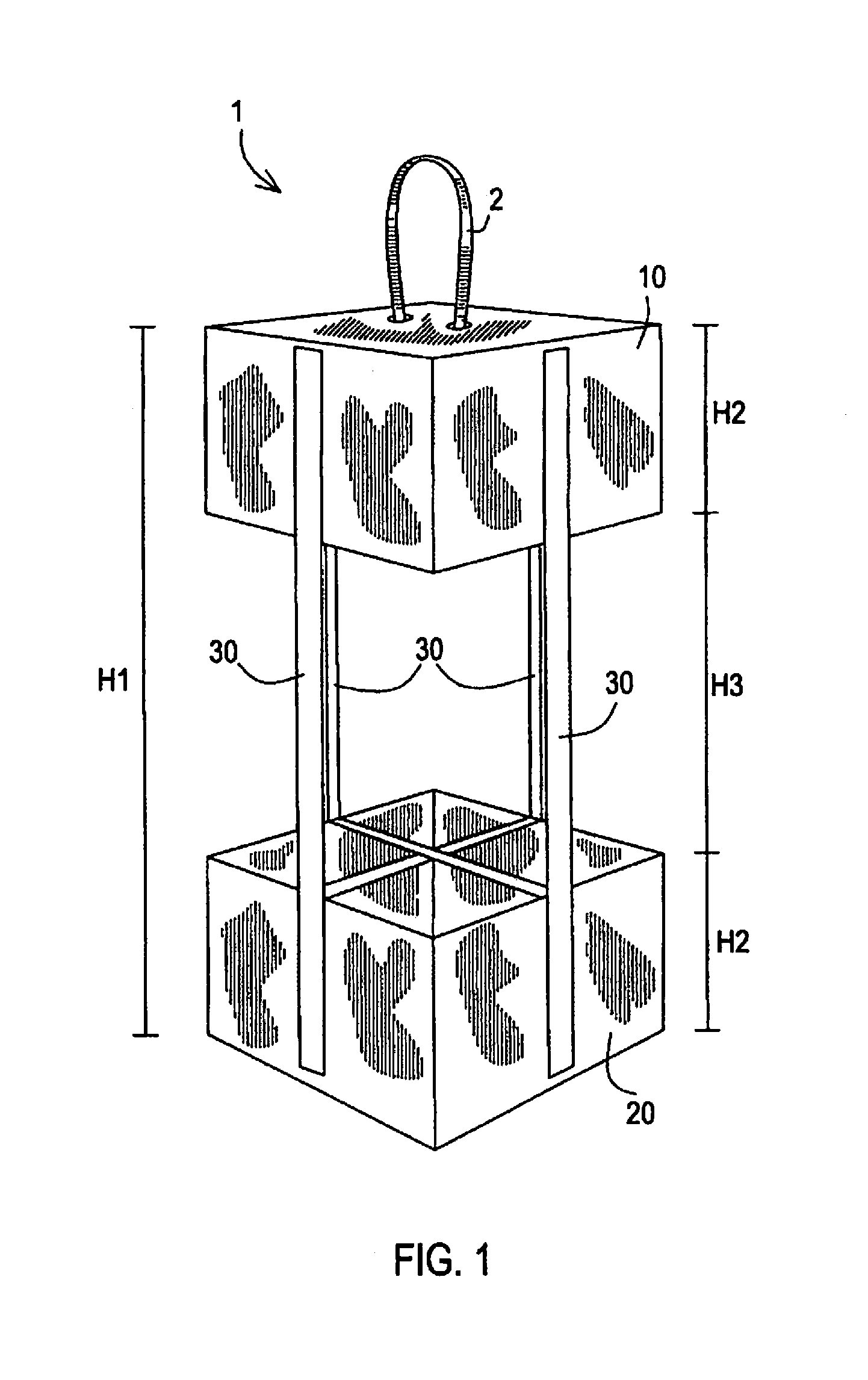

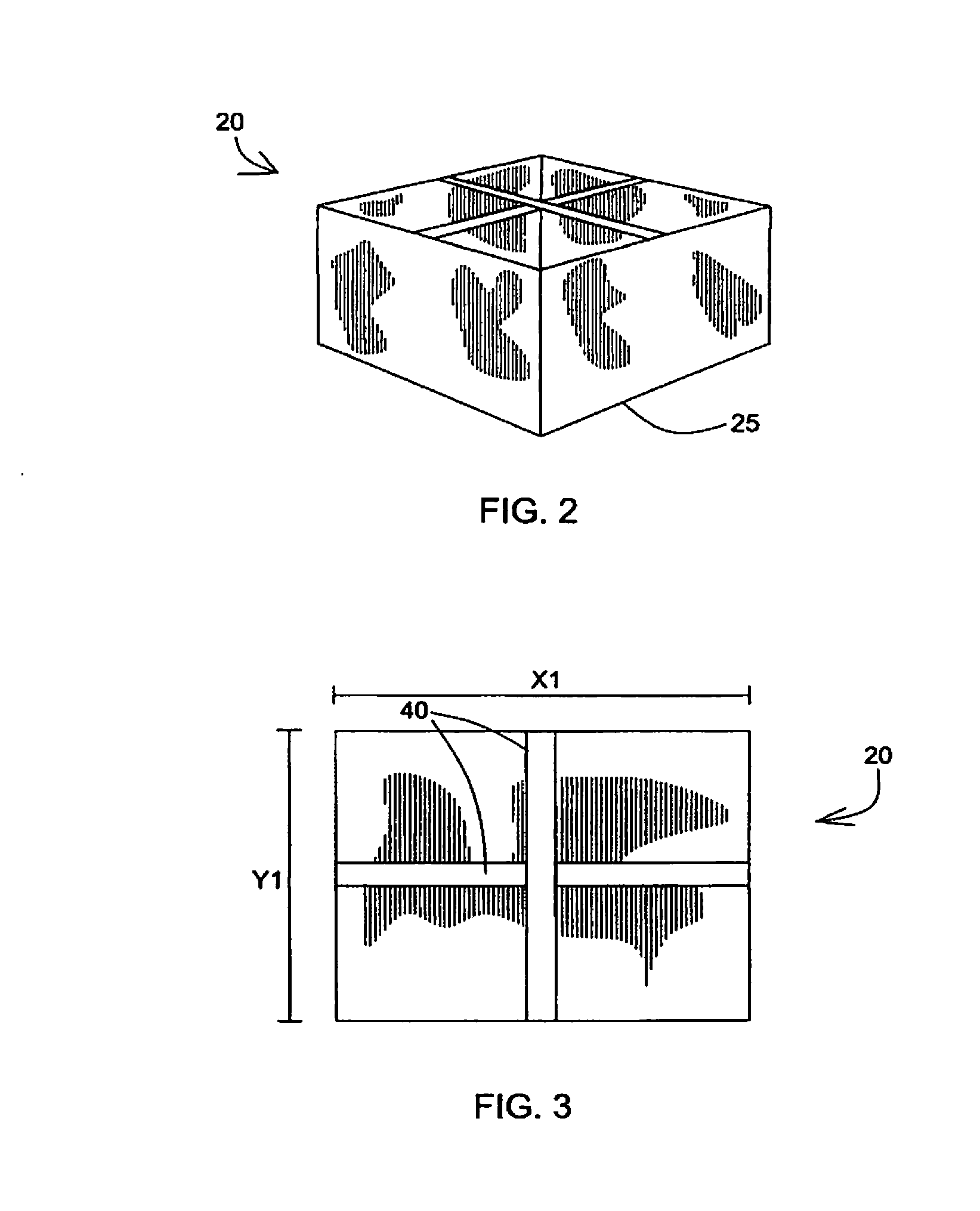

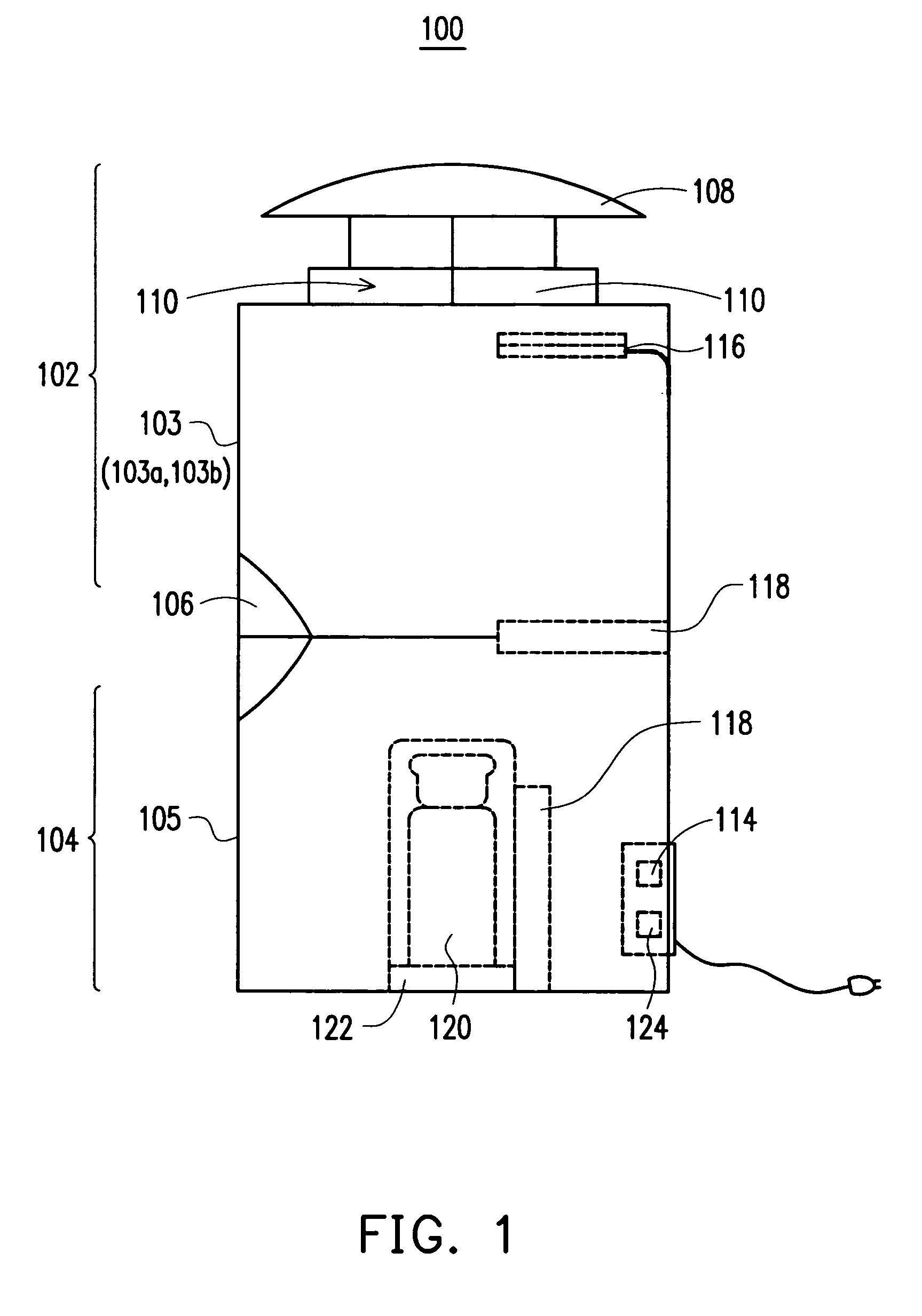

System, method and apparatus for attracting and stimulating aquatic animals

InactiveUS20060268664A1Improve efficiencyIncrease attractionTransmissionFishingHydrophoneDelayed periods

A programmable, customizable system, method, and apparatus for attracting and stimulating aquatic animals are disclosed. The present invention provides for the underwater playback of digitally prerecorded “signature” sounds of prey, and of prey being attacked and eaten, in order to attract fish and other species and stimulate them to strike and feed more aggressively. Playback is achieved by selecting any of a plurality of signature sound recordings stored on a memory device which is located and controlled above water. One sound, all sounds, or a selected sequence of sounds may be selected from the memory device to be played underwater. Underwater playback is achieved by use of a submersible transducer device which may function as both a speaker and a hydrophone. Underwater playback may be customized and controlled above water by providing a number of customized operational modes. For example, a user may select a sound recording to be repeatedly played in a loop, with each iteration separated by a delay period, the length of which is selected by the user. In addition, the user may select a plurality of different sound recordings, and specify the sequence and volume at which they are played underwater, as well as a delay period between each recording. The user may also select all sound recordings to be played at a selected volume level, and the user may further specify a delay period between each recording. Furthermore, the user may select sound recordings to be played underwater at varying volume levels according to selections made by the user.

Owner:BIOSONIX LLC

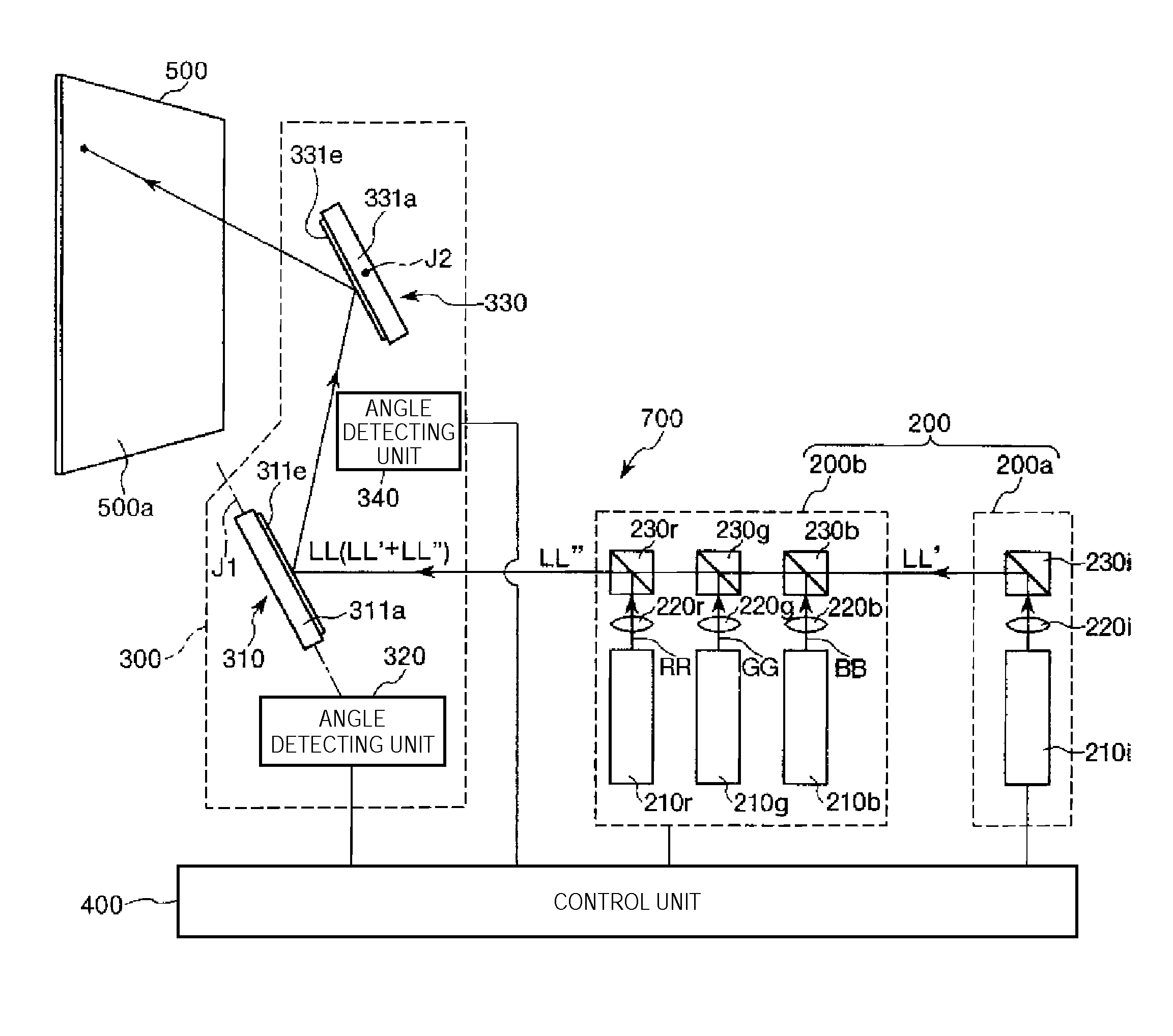

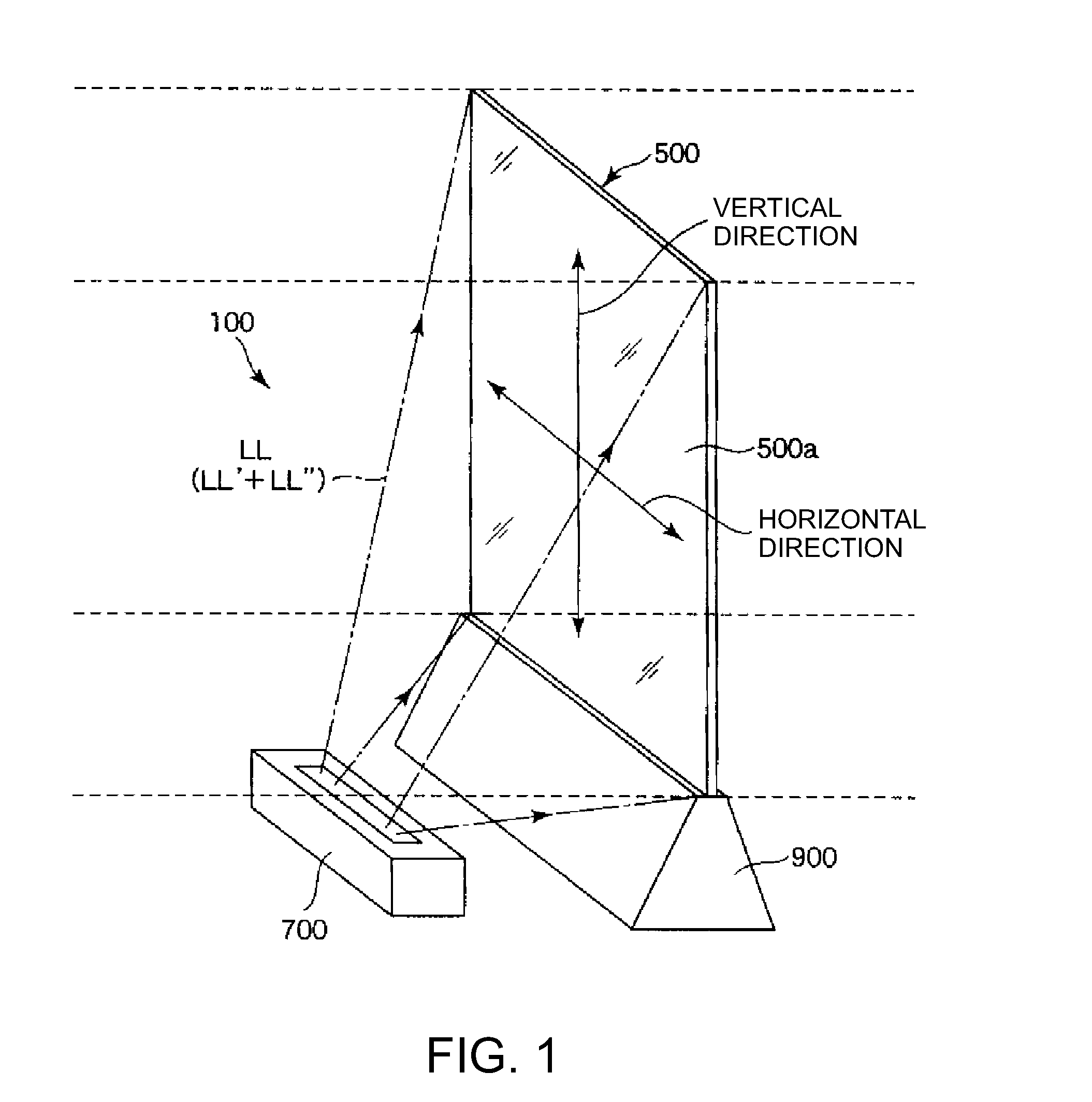

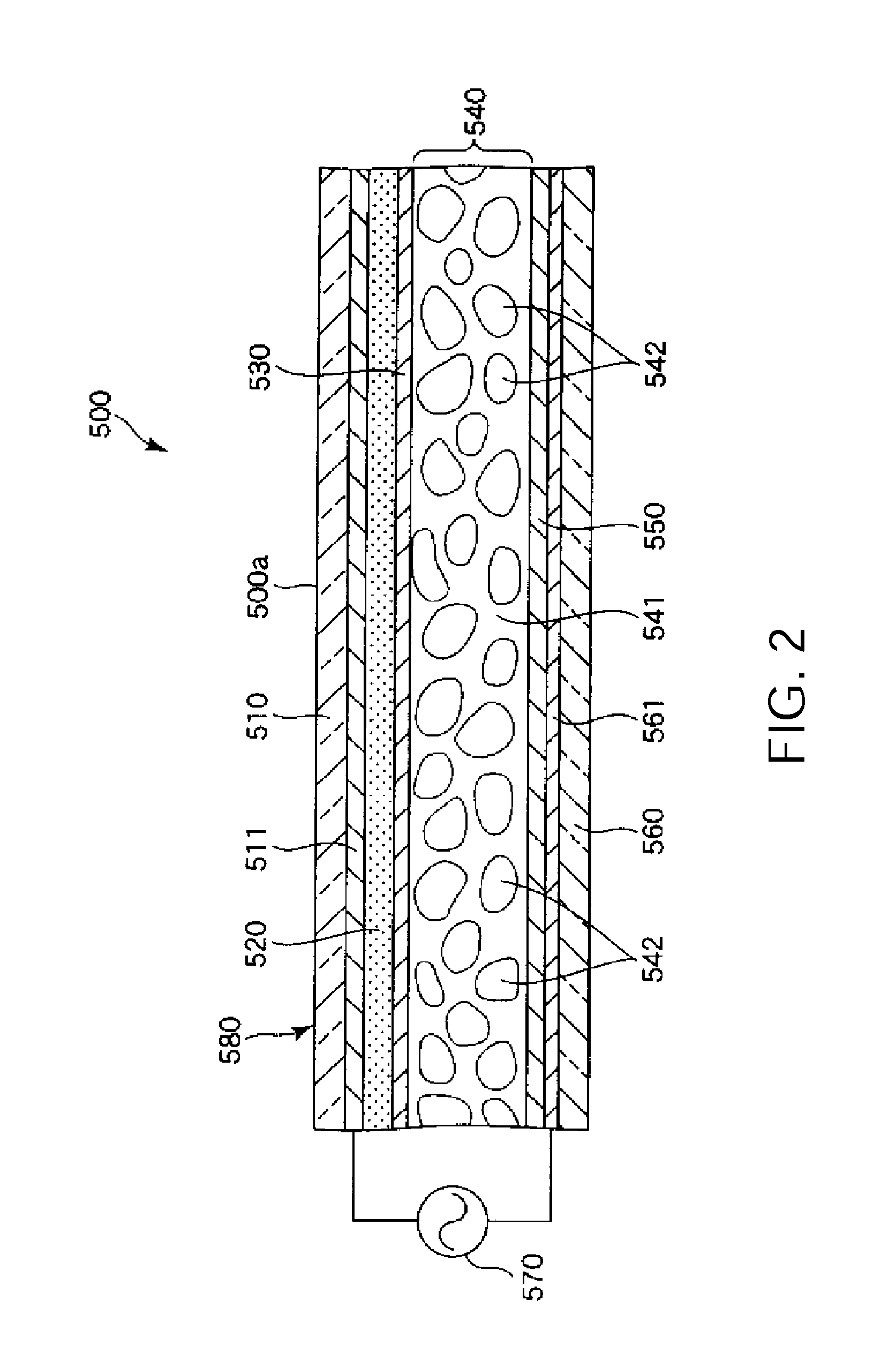

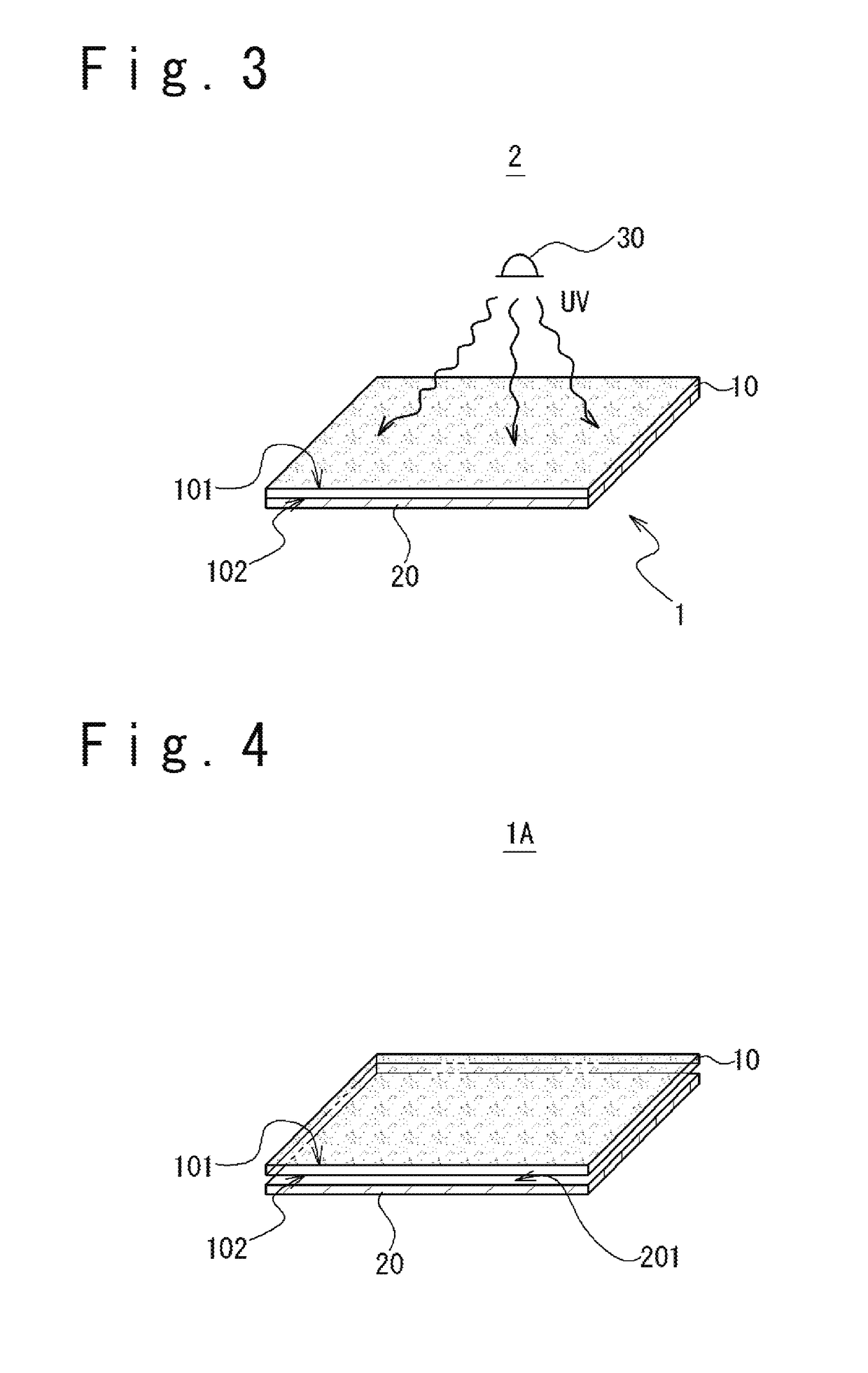

Image forming apparatus and rear projection display apparatus

InactiveUS20110205456A1Efficient attractionBuilt-on/built-in screen projectorsElectric lightingImage formationImage pair

An image forming apparatus includes: a screen having a display surface; and a projector that renders an image by scanning light on the display screen, wherein the screen selects, independently in respective regions of the display surface, a light transmission state in which the light is transmitted and a light diffusion state in which the light is diffused, the screen being configured such that the region where address light is irradiated is in the light diffusion state and the region where the address light is not irradiated is in the light transmission state, and the projector scans the address light on the display surface such that an area of the display surface corresponding to an image displayed on the display surface changes to the light diffusion state.

Owner:SEIKO EPSON CORP

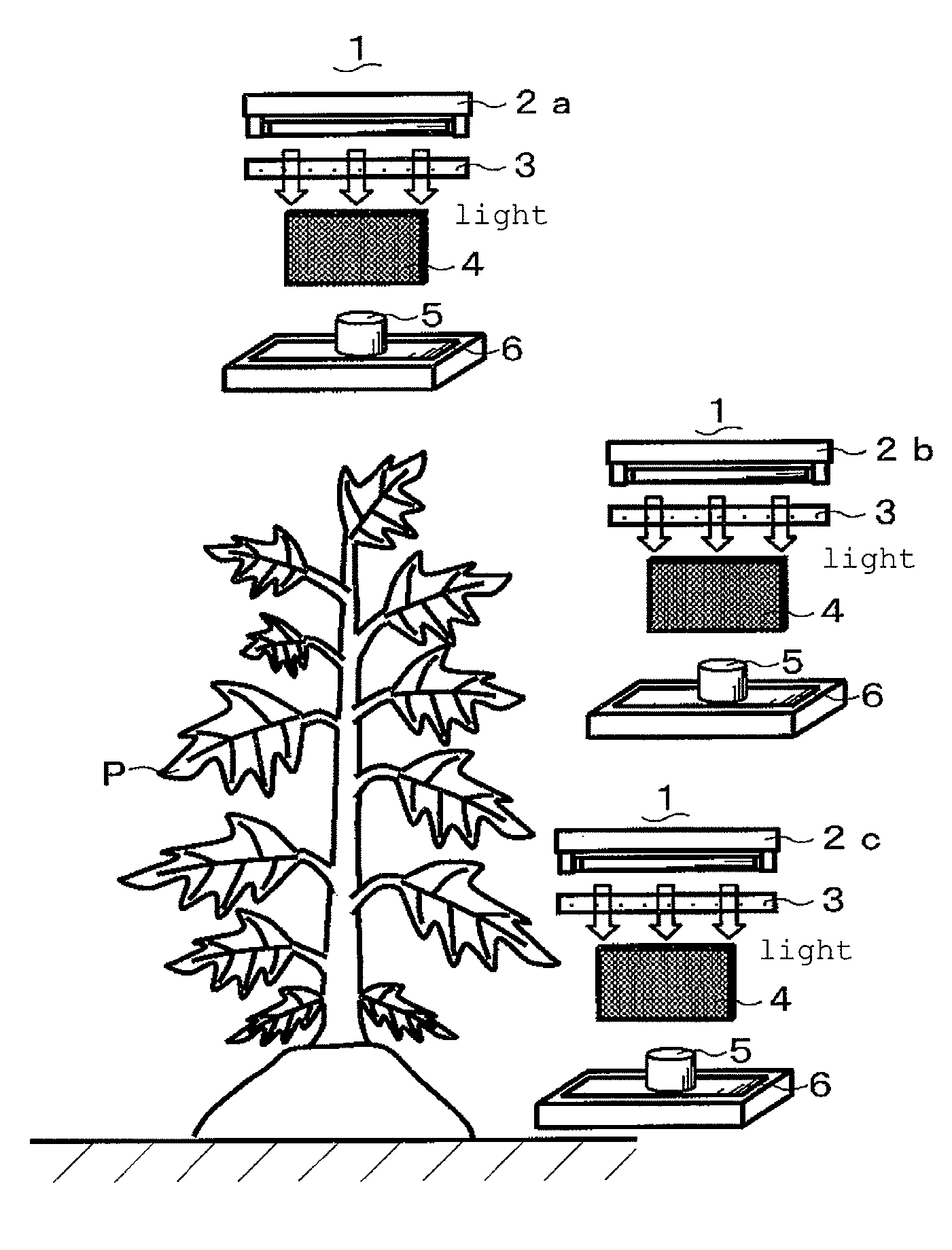

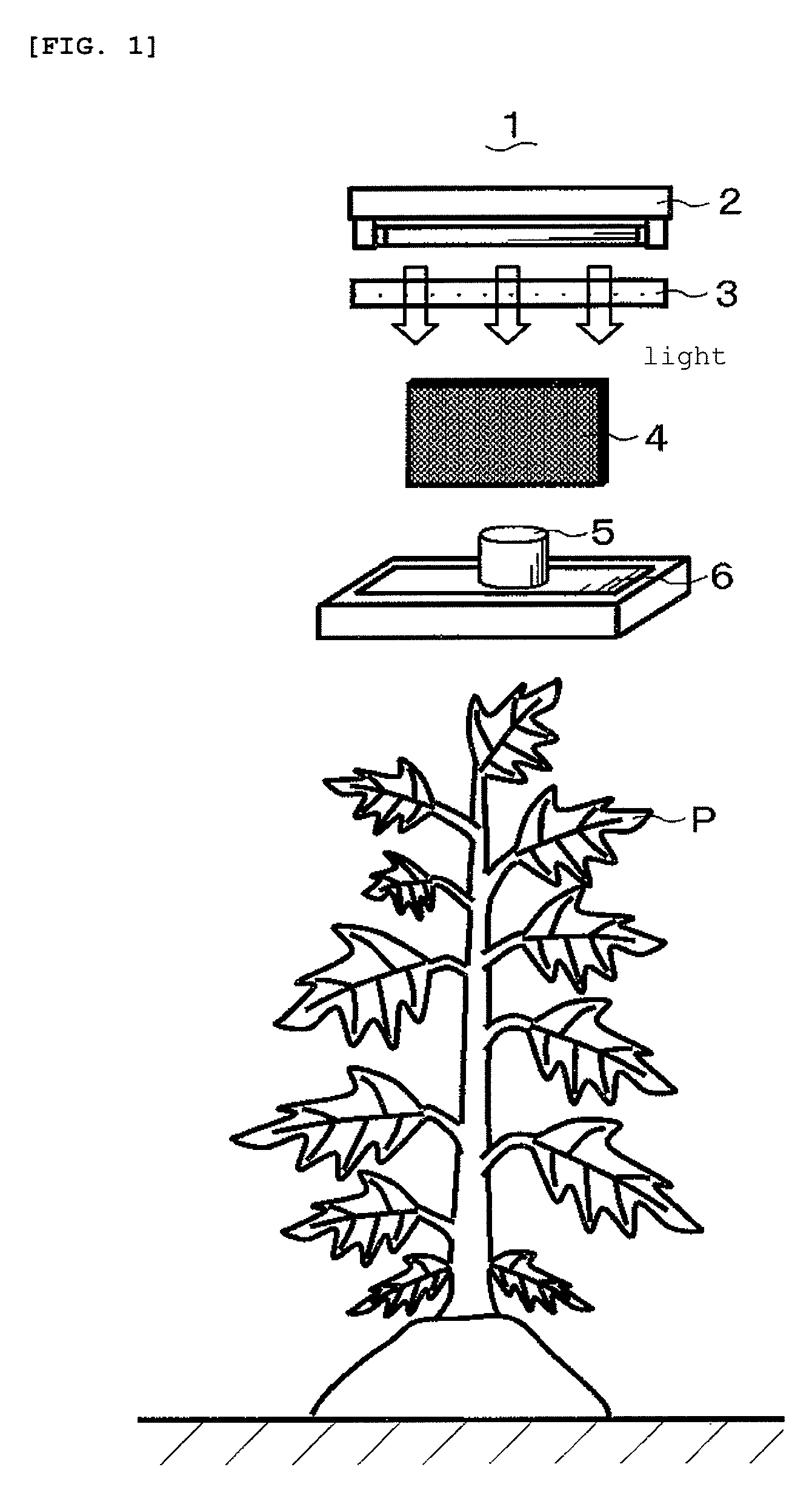

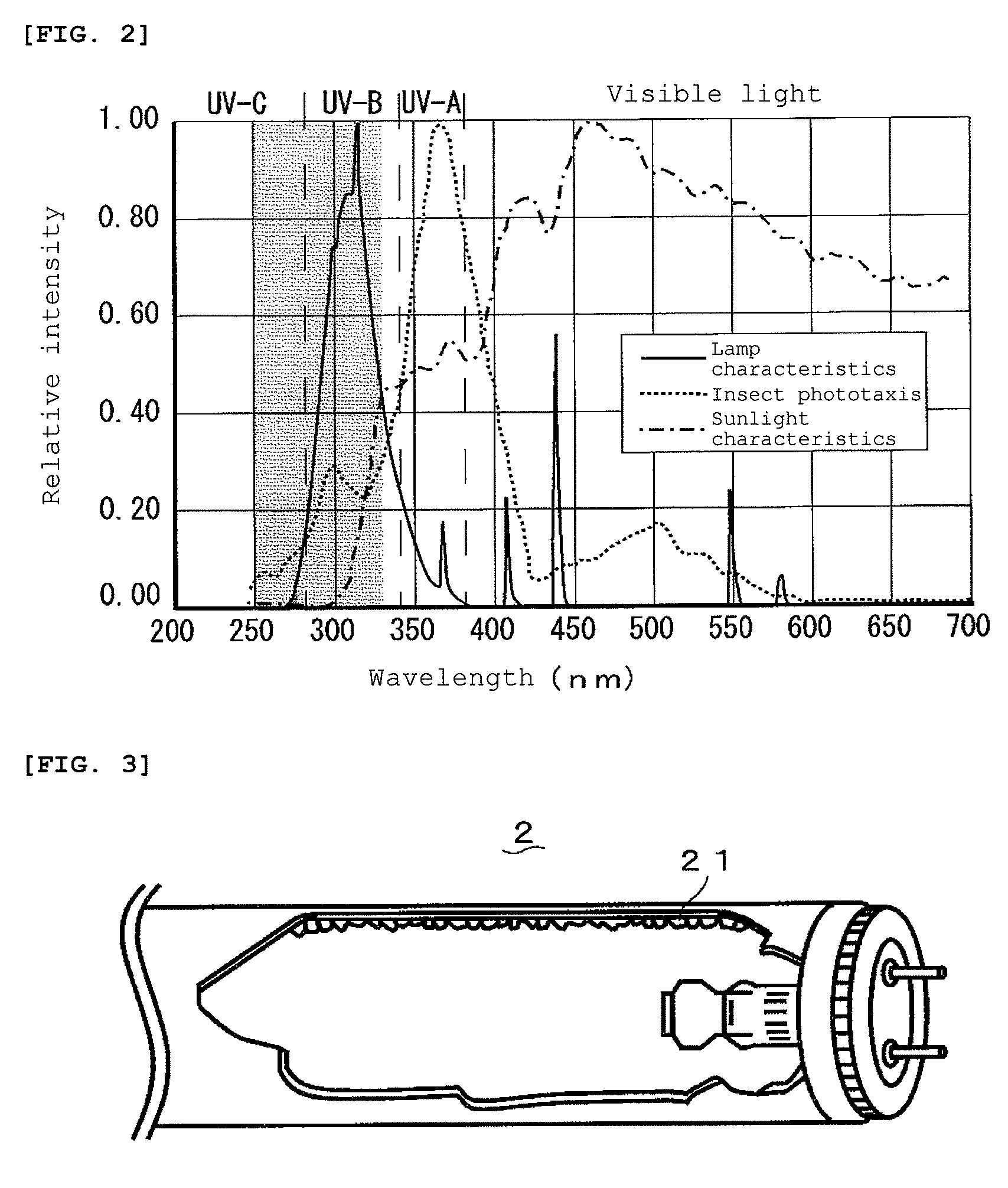

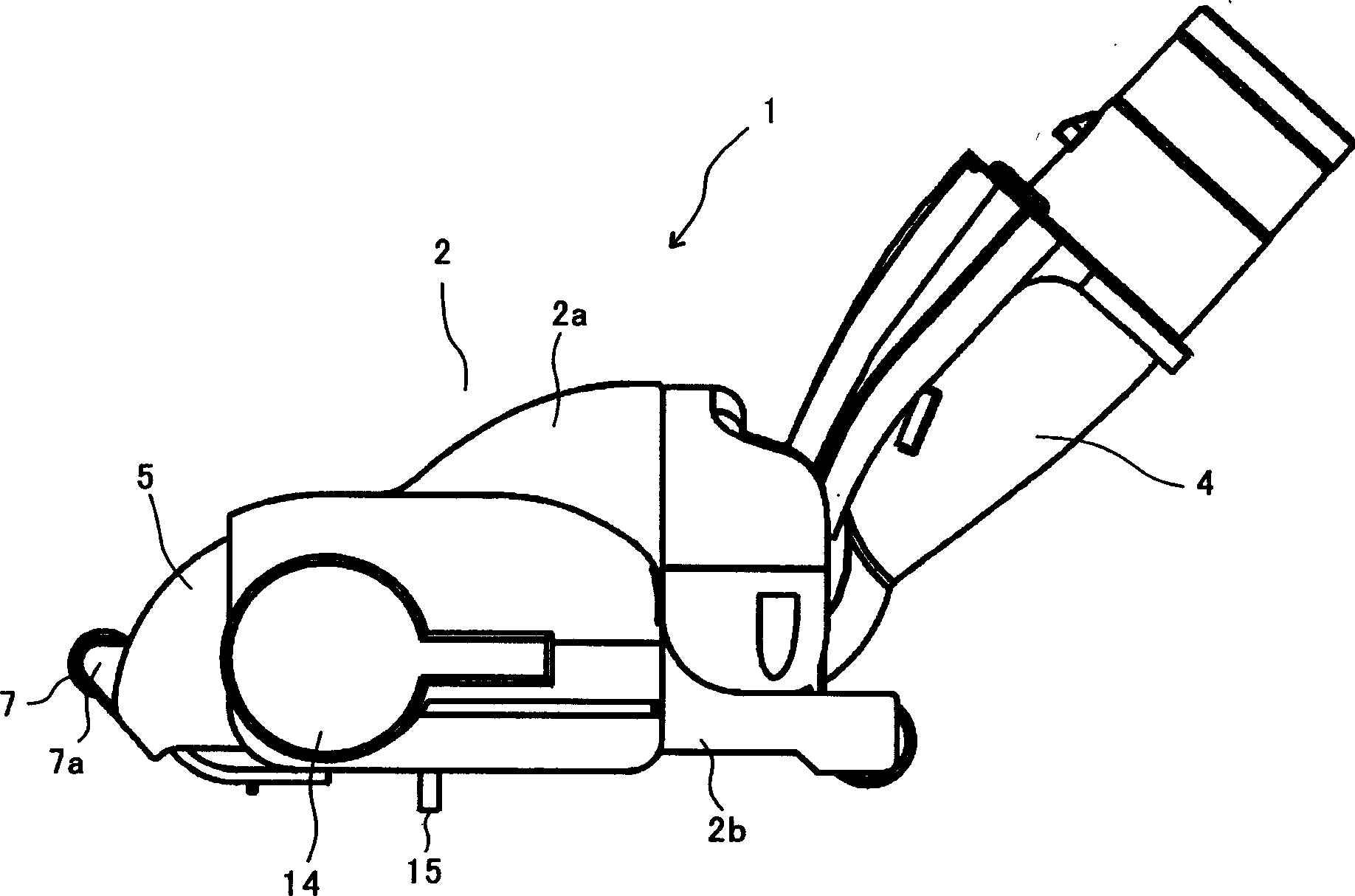

Insect pest-controlling apparatus

InactiveUS20110296740A1Increase contrastStrong attractionInsect catchers and killersLight reflexInsect pest

An insect pest-controlling apparatus (1) includes a light-reflecting attraction unit (4) that reflects sunlight and a trap (6) to trap insects attracted to light reflected by the light-reflecting attraction unit (4). The light-reflecting attraction unit (4) is a reflector whose reflectance of 220 to 390 nm light wavelength components is 5% or less. Because the light-reflecting attraction unit (4) reflects almost no ultraviolet rays, the contrast of ultraviolet rays is increased in the space compared with sunlight by the insect pest-controlling apparatus (1) and diurnal agricultural insect pests are strongly attracted to the light-reflecting attraction unit (4). Accordingly, diurnal agricultural insect pests can be attracted and trapped in large quantities in the daytime.

Owner:PANASONIC CORP

System, method and apparatus for attracting and stimulating aquatic animals

A programmable, customizable system, method, and apparatus for attracting and stimulating aquatic animals are disclosed. The present invention provides for the underwater playback of digitally prerecorded “signature” sounds of prey, and of prey being attacked and eaten, in order to attract fish and other species and stimulate them to strike and feed more aggressively. Playback is achieved by selecting any of a plurality of signature sound recordings stored on a memory device which is located and controlled above water. One sound, all sounds, or a selected sequence of sounds may be selected from the memory device to be played underwater. Underwater playback is achieved by use of a submersible transducer device which may function as both a speaker and a hydrophone. Underwater playback may be customized and controlled above water by providing a number of customized operational modes. For example, a user may select a sound recording to be repeatedly played in a loop, with each iteration separated by a delay period, the length of which is selected by the user. In addition, the user may select a plurality of different sound recordings, and specify the sequence and volume at which they are played underwater, as well as a delay period between each recording. The user may also select all sound recordings to be played at a selected volume level, and the user may further specify a delay period between each recording. Furthermore, the user may select sound recordings to be played underwater at varying volume levels according to selections made by the user.

Owner:BIOSONIX LLC

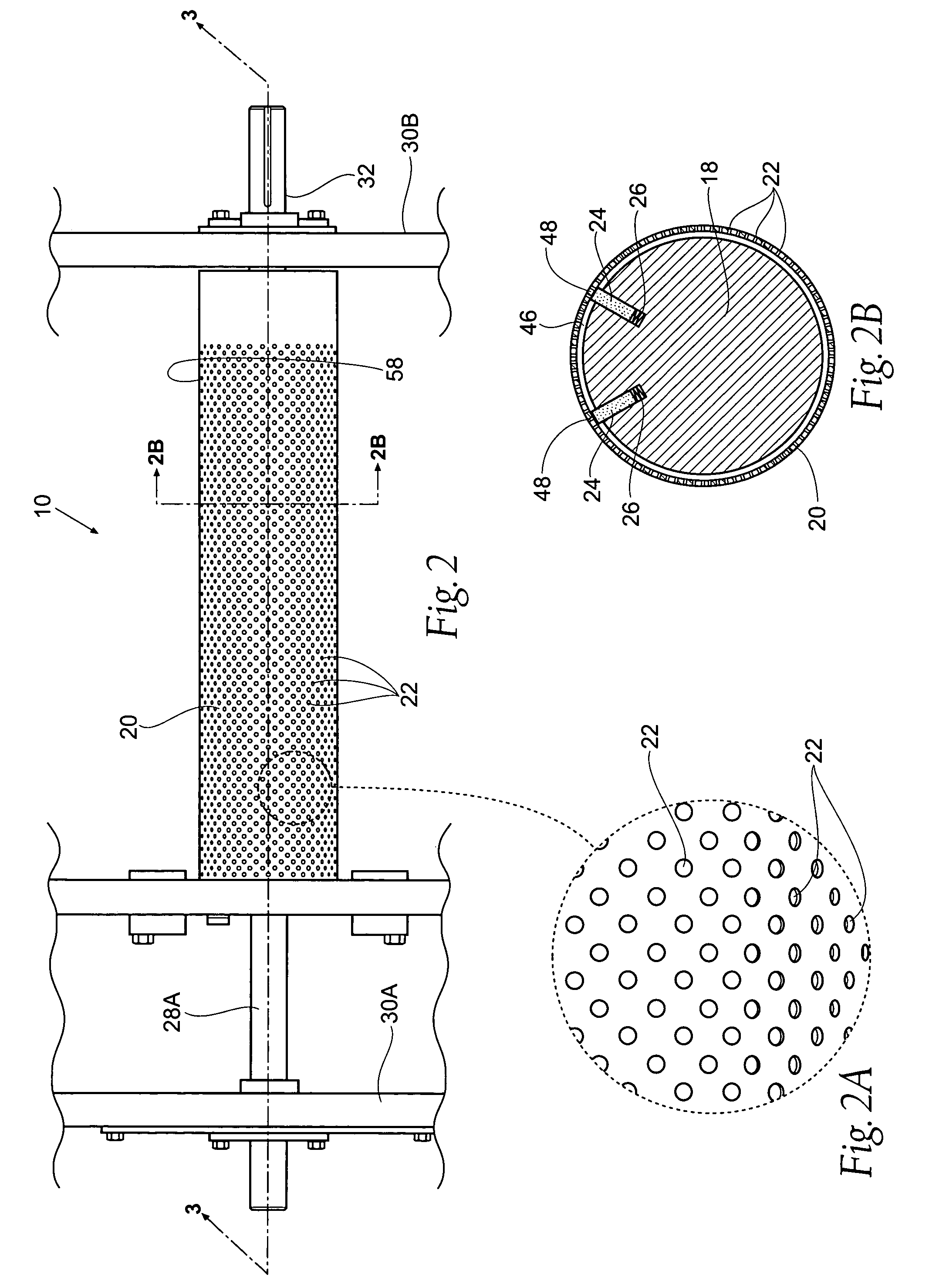

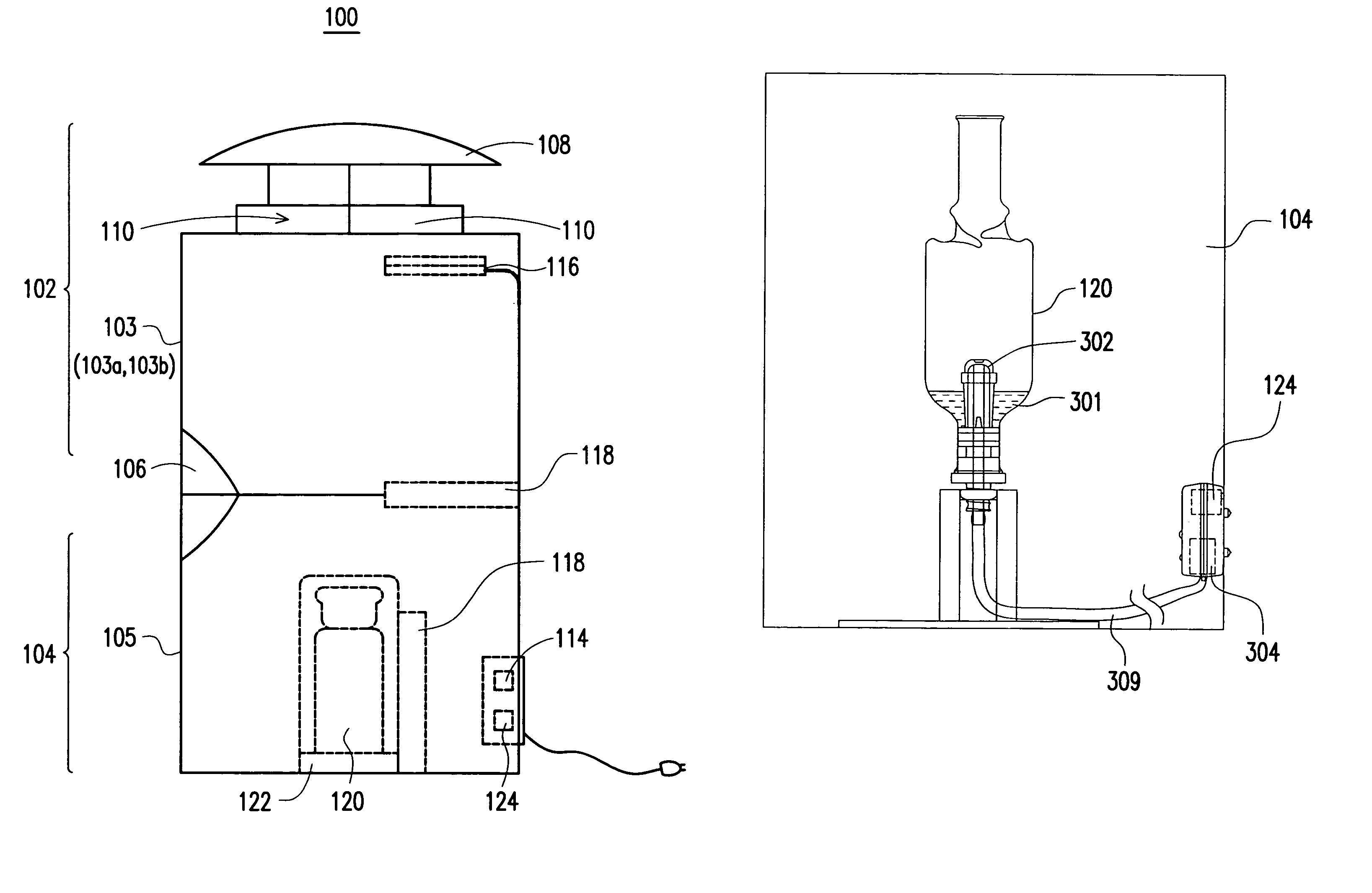

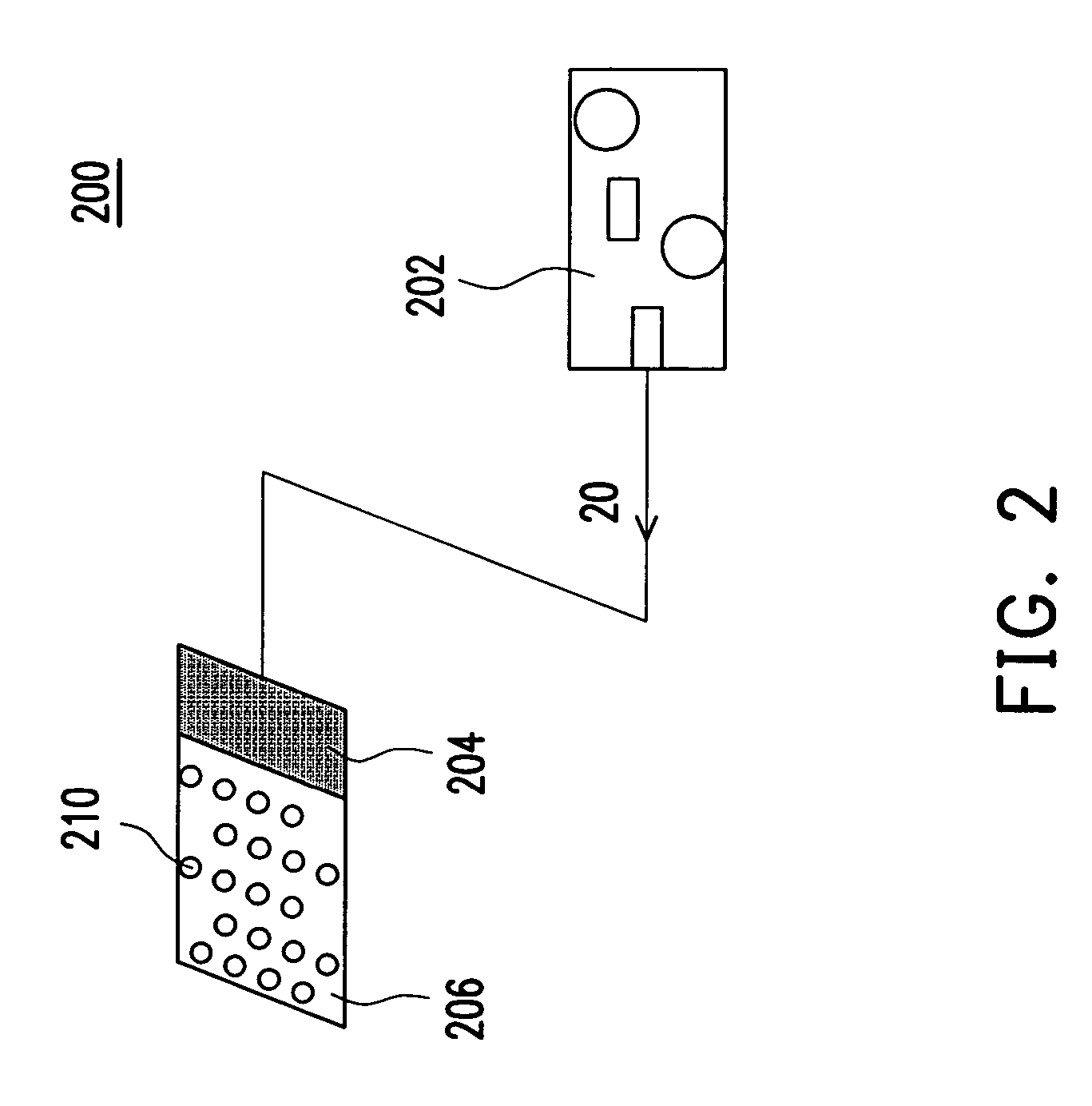

Magnetic reagent, magnetic reagent kit, method for treating magnetic carriers, and treatment device therefor

ActiveUS20120329124A1Increase surface areaQuick snapMaterial nanotechnologyMagnetic paintsMaterials scienceReagent

The present invention relates to a magnetic reagent, a magnetic reagent kit, a method for treating magnetic carriers, and a treatment device therefor, with an object of quickly and efficiently treating magnetic carriers of a micro particle diameter including nanosized magnetic carriers.The magnetic reagent or magnetic reagent kit includes: a plurality of magnetic carriers which can be magnetized by being exposed to a magnetic field, can be bonded to a predetermined chemical substance or living organism in a liquid, and that have a particle diameter that enables them to be suspended in the liquid; and a plurality of treatment promoting magnetic particles which can be magnetized by being exposed to a magnetic field and thus can have the magnetic carriers adsorbed on the surface thereof, are formed so that they can be moved within the liquid by movement of the liquid or by a magnetic field, and promote a treatment for capturing or re-suspension of the magnetic carriers.

Owner:UNIVERSAL BIO RESEARCH CO LTD

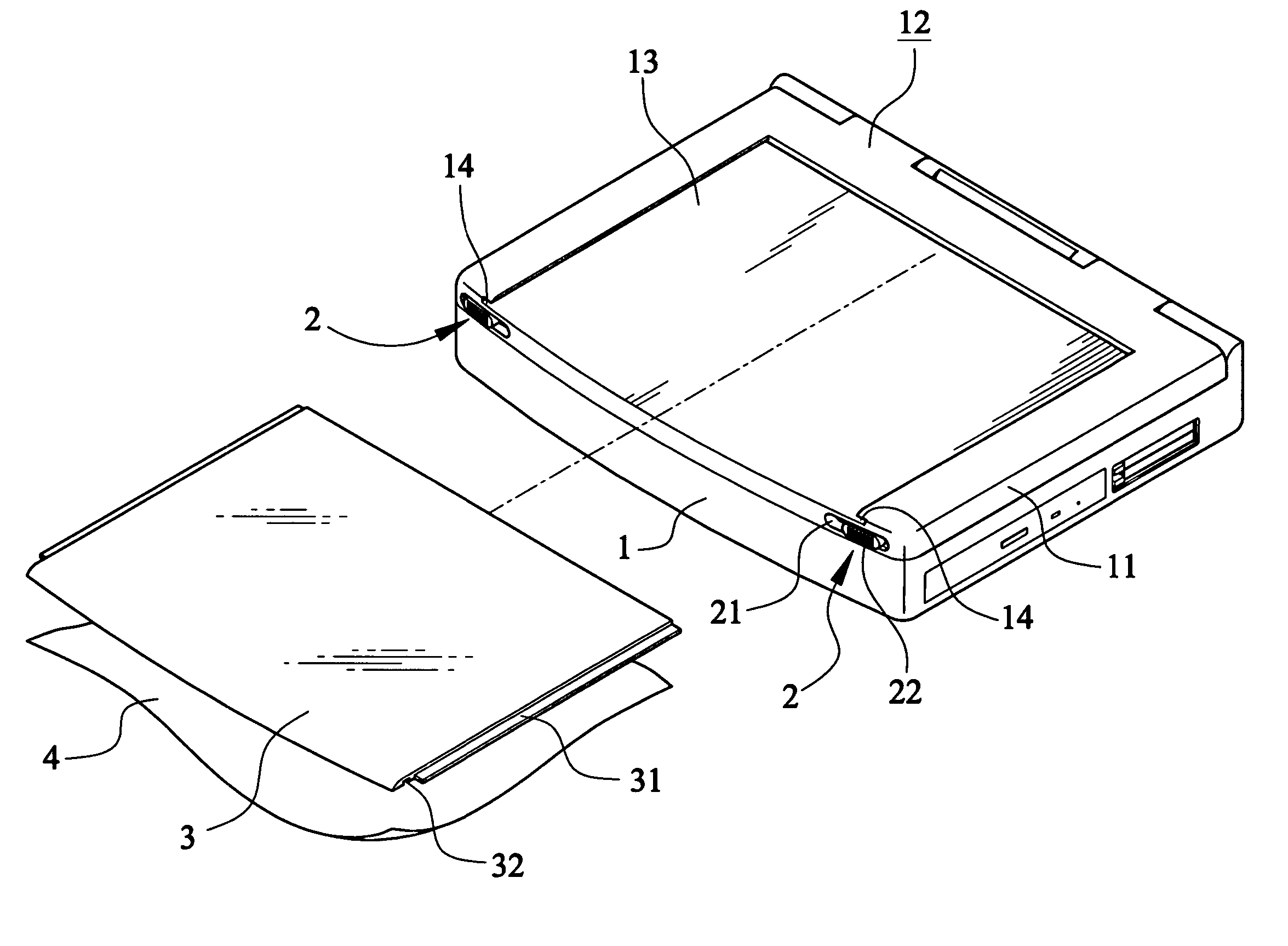

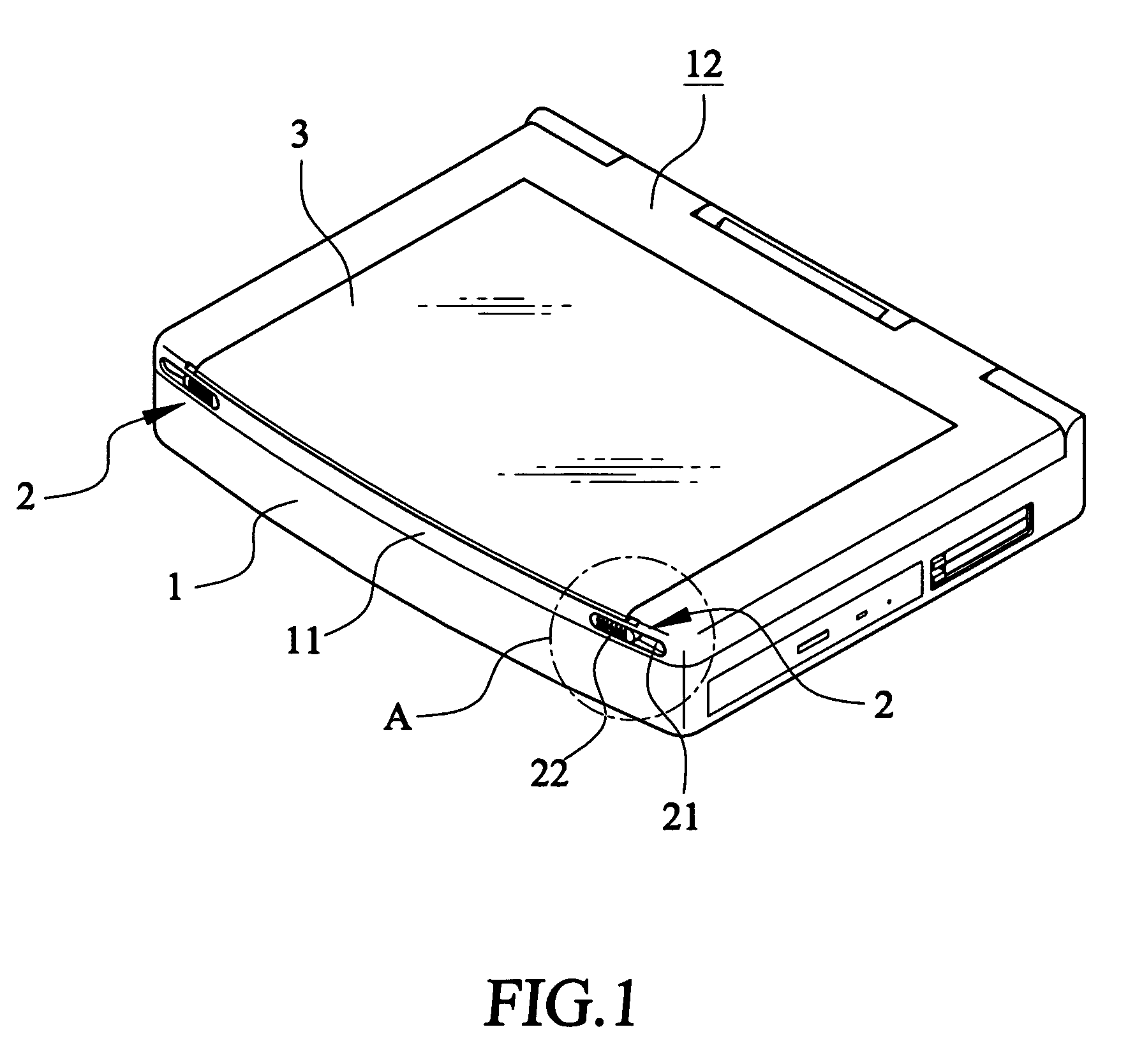

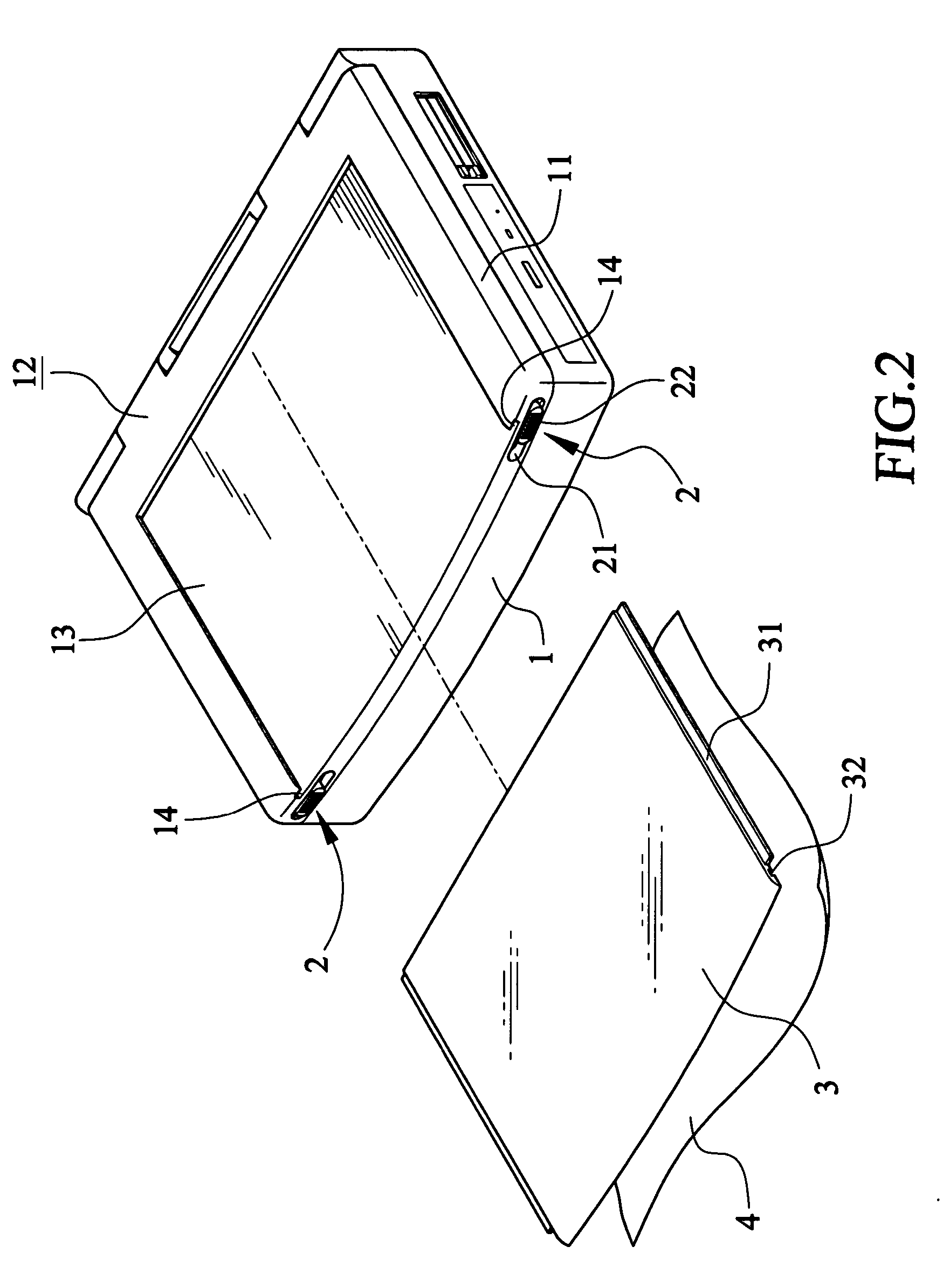

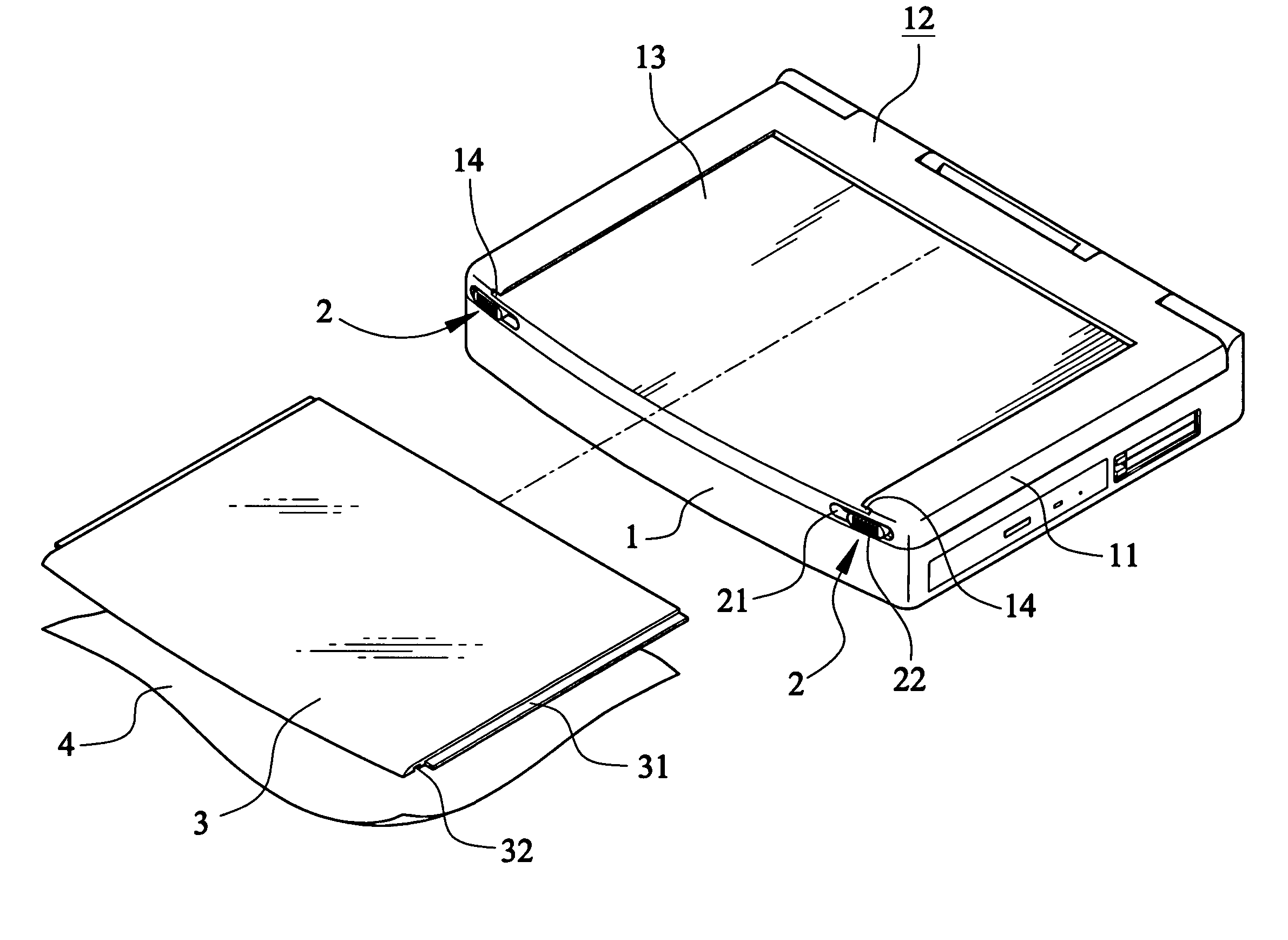

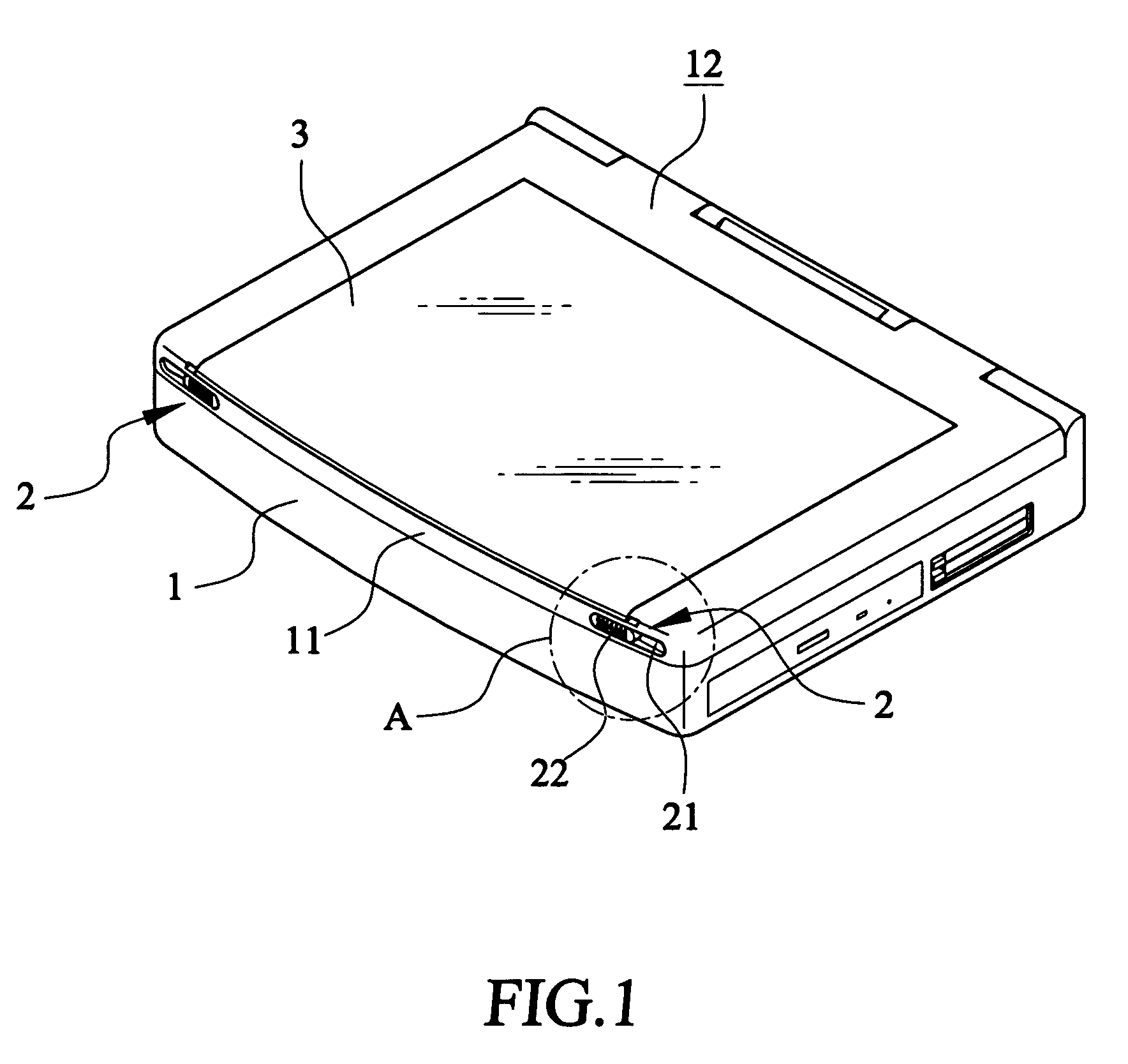

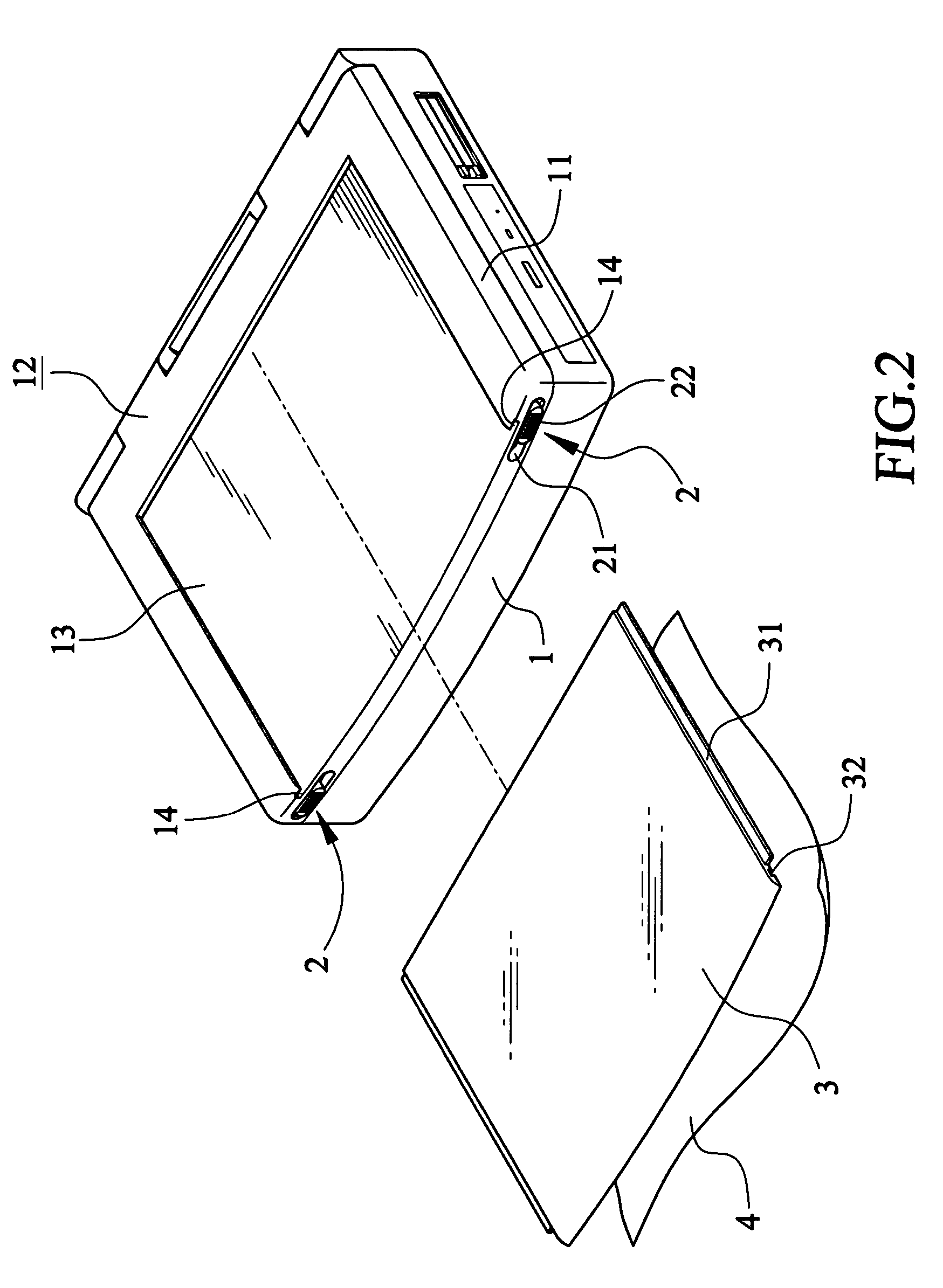

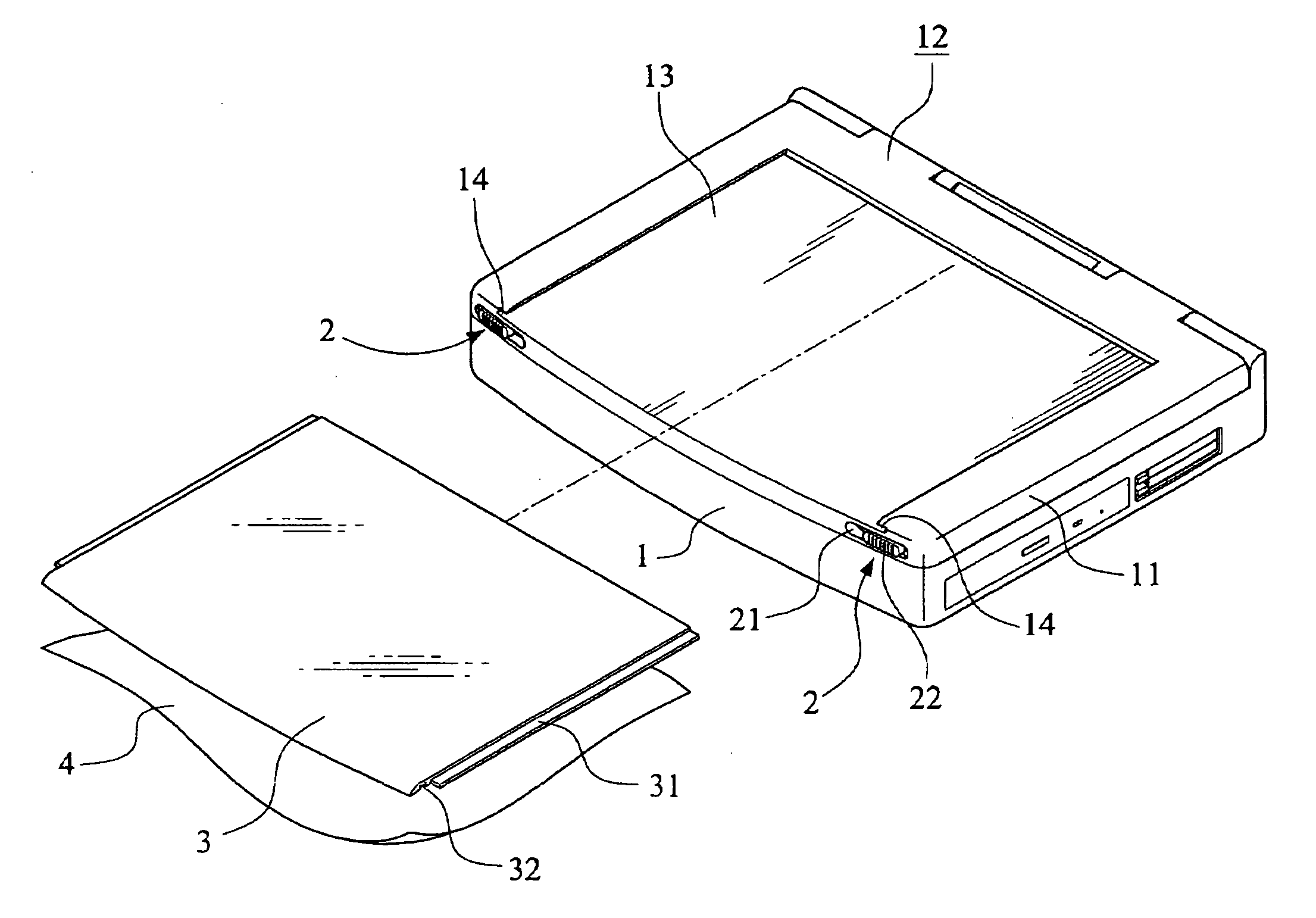

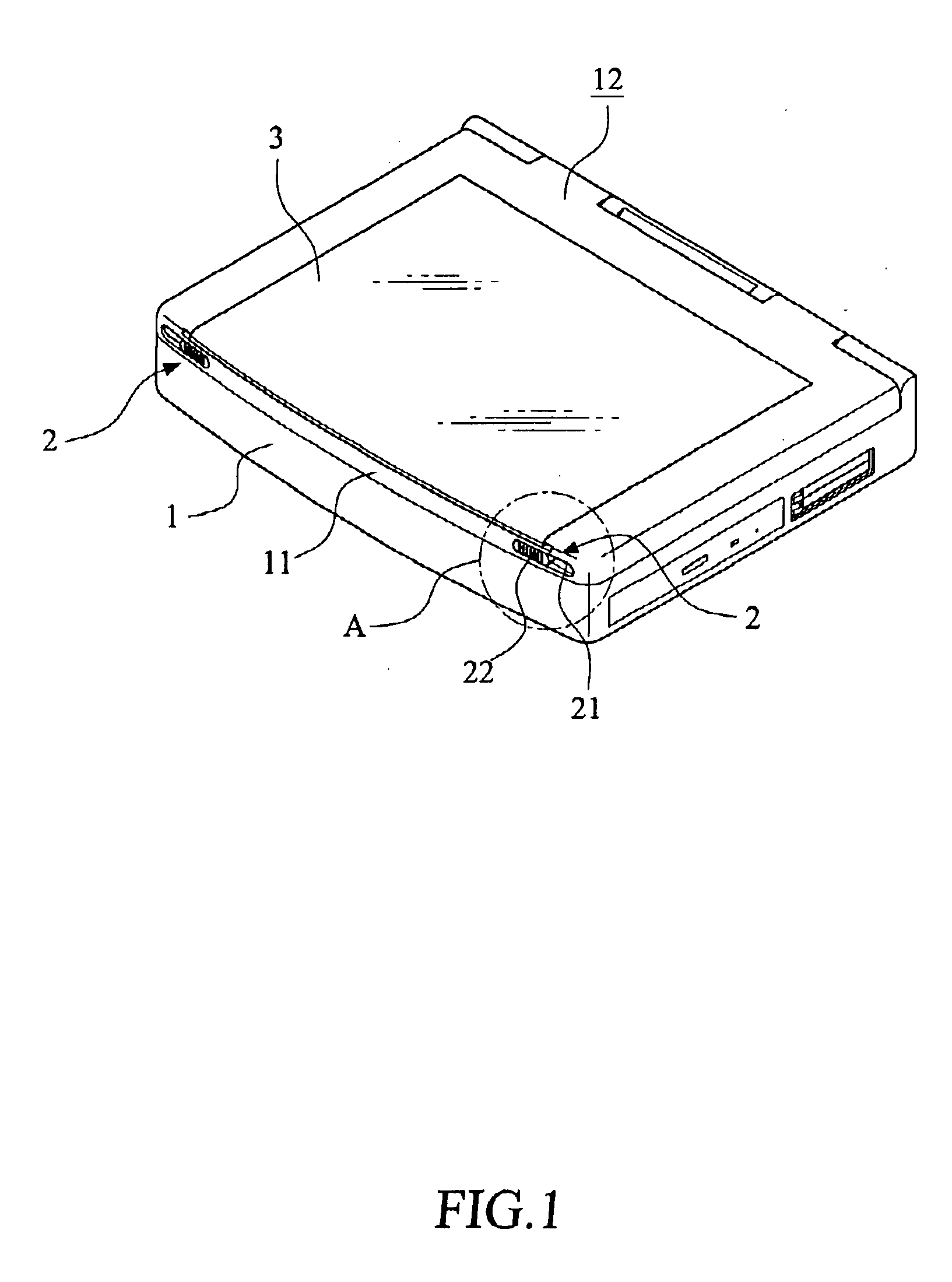

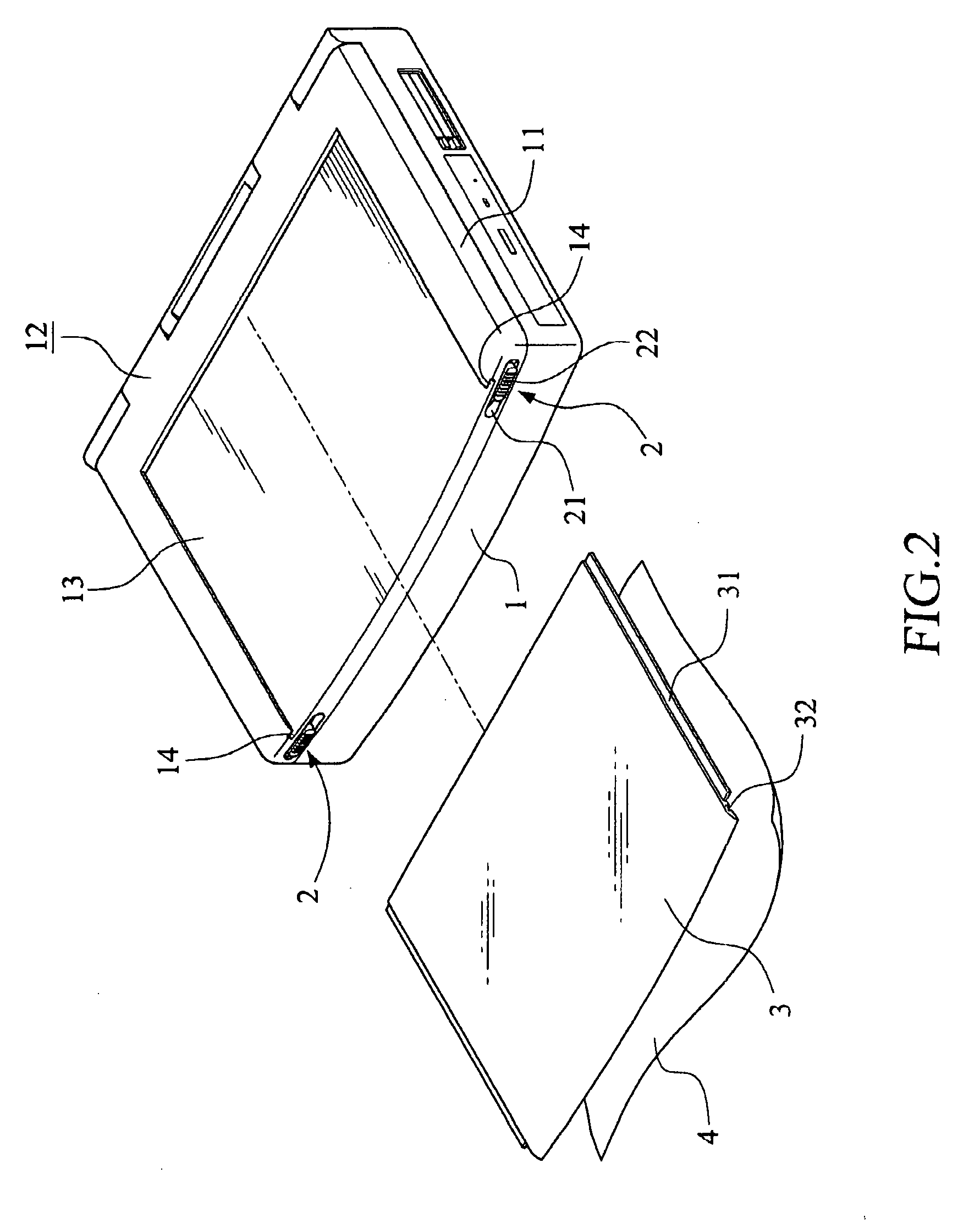

Replaceable liquid crystal display back plate for portable computer

InactiveUS20050213291A1Efficient attractionDetails for portable computersNon-functional elementsLiquid-crystal displayLocking mechanism

A replaceable liquid crystal display back plate for portable computer includes a back plate forming part of a housing of a liquid crystal display of a portable computer and being provided on an outer surface with a flat recess; a replaceable cover plate adapted to fitly set in and cover the flat recess on the back plate; and a locking mechanism operable between a locked position, in which the replaceable cover plate is locked to the flat recess, and an unlocked position, in which the replaceable cover plate is separable from the flat recess to be replaced with another one. The replaceable cover plate is made of a transparent material, and may have a pictorial layer provided between it and the flat recess.

Owner:MITAC TECH CORP

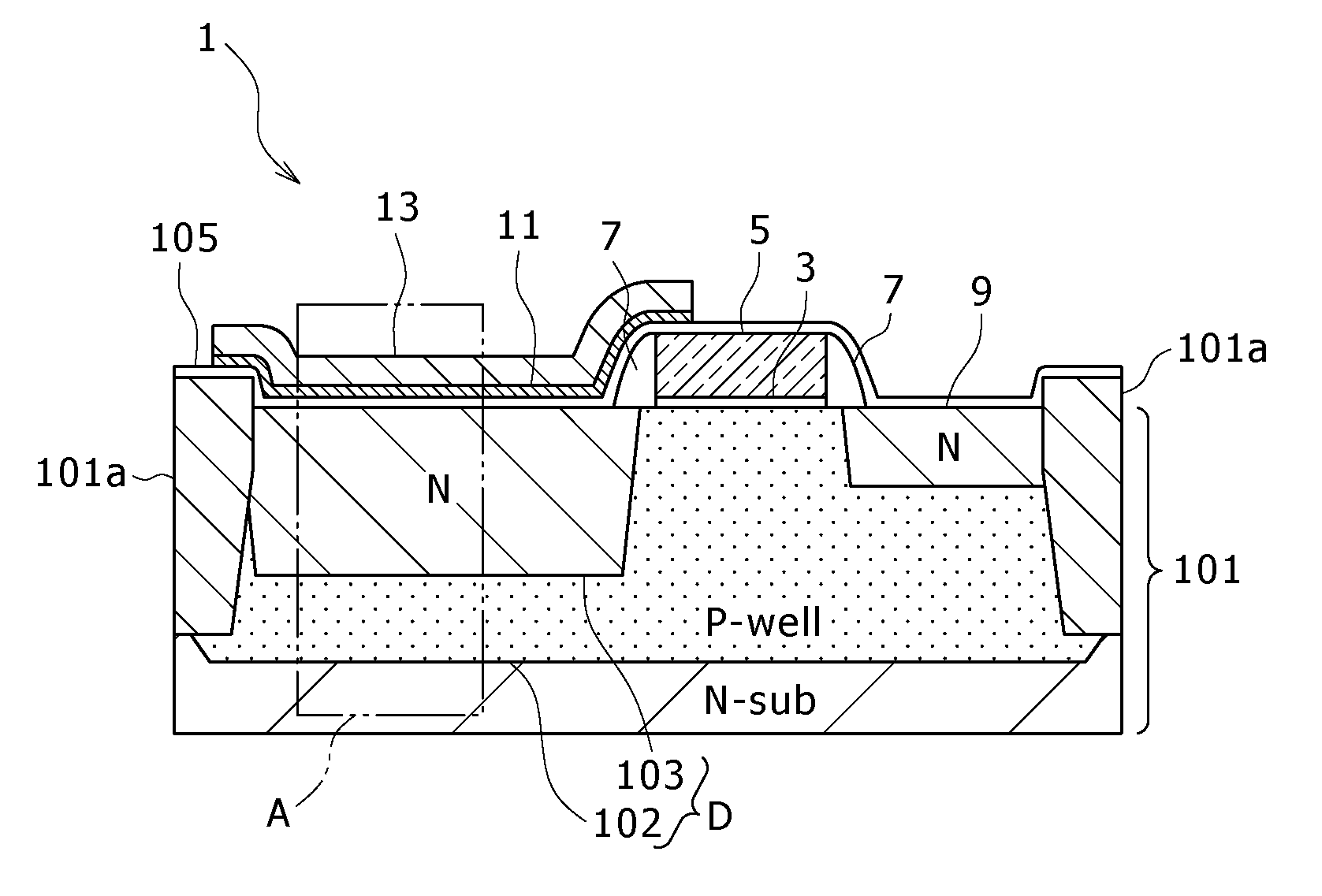

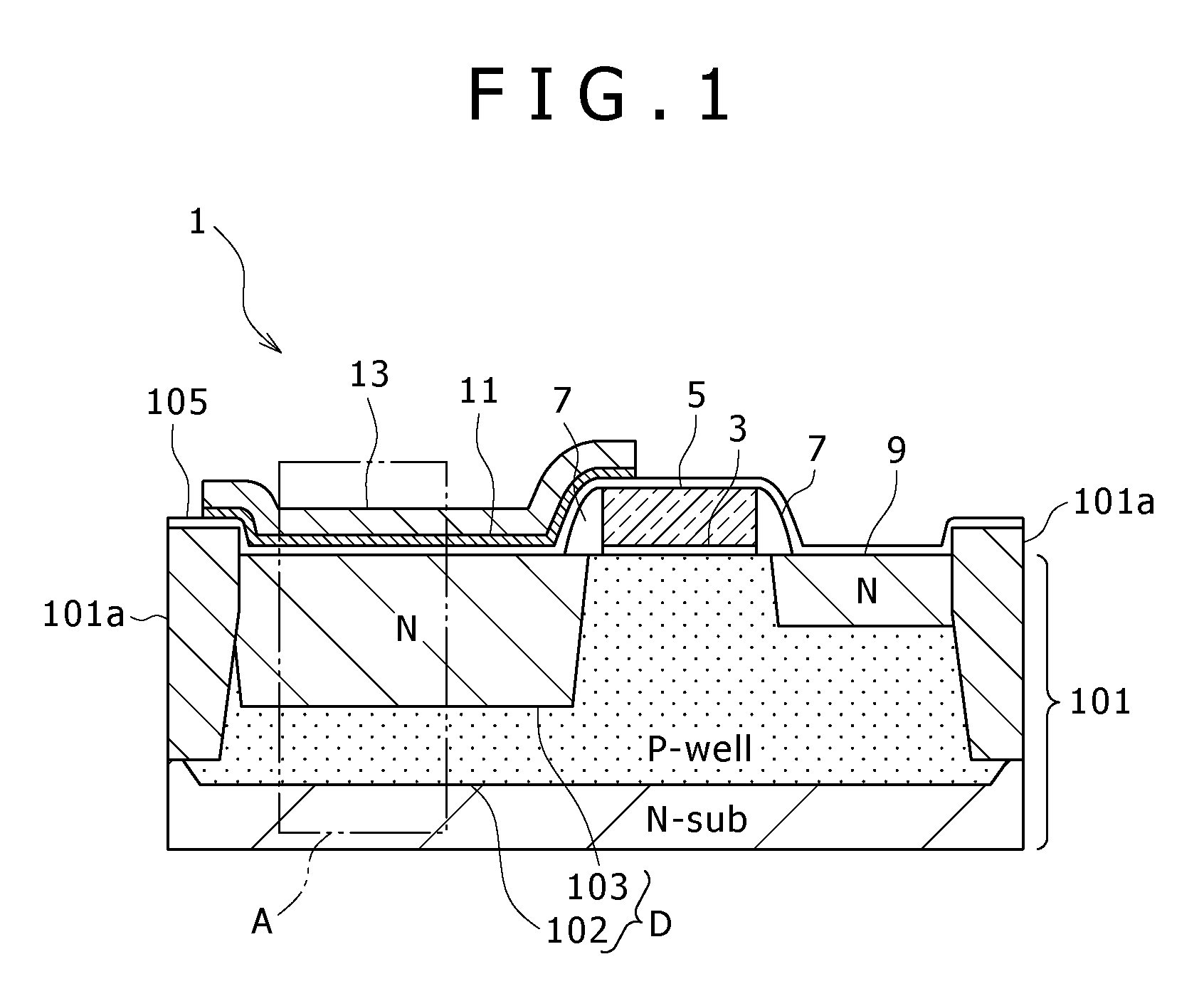

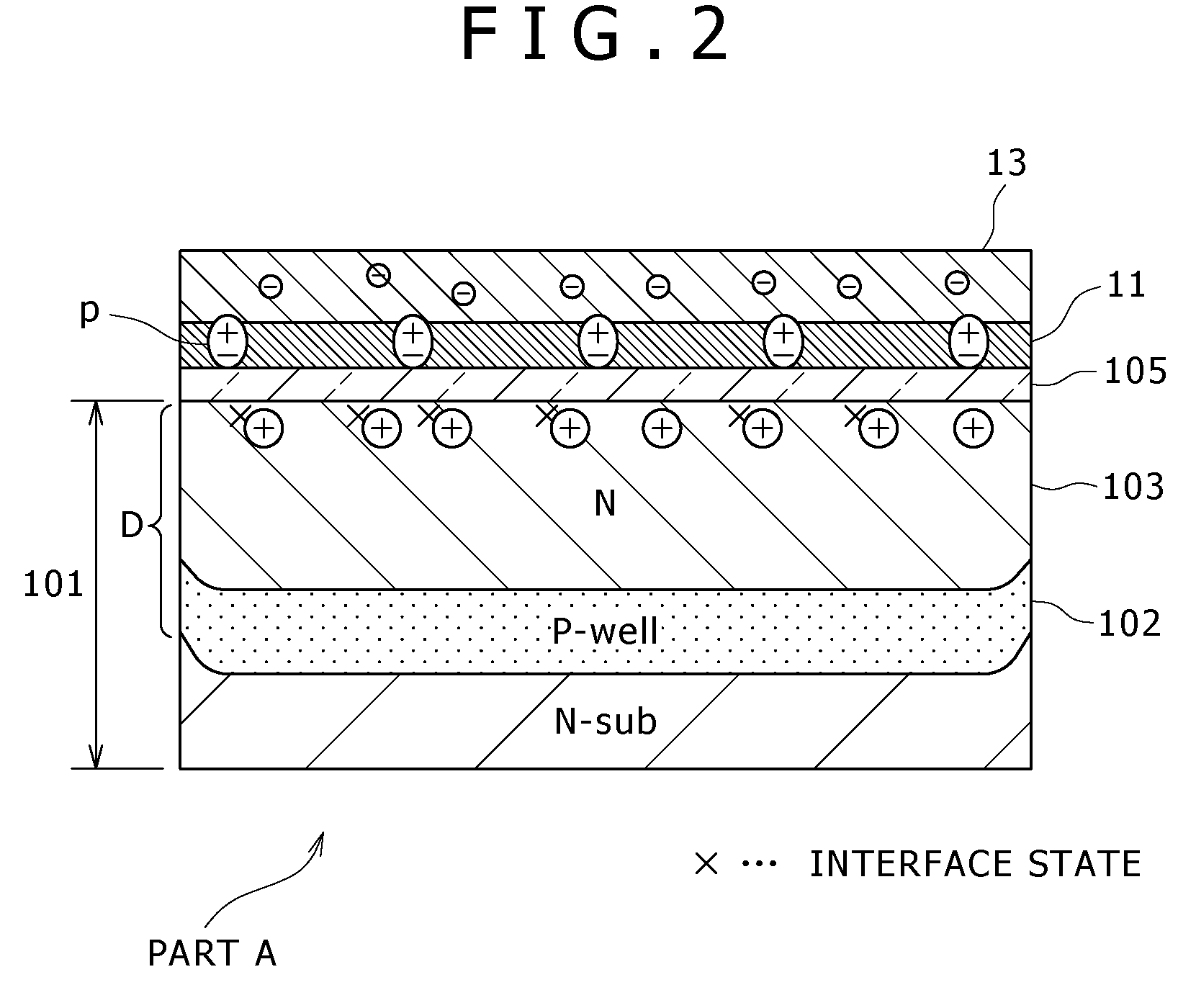

Solid-state imaging device

ActiveUS20090230496A1Total current dropEfficient transferSolid-state devicesRadiation controlled devicesImpurity diffusionSurface layer

Disclosed herein is a solid-state imaging device including: a semiconductor substrate; a sensor of impurity diffusion layer formed on the surface layer of said semiconductor substrate; a negative charge accumulation layer formed on said sensor from an insulating material containing a first metallic substance; and an interfacial layer formed between said sensor and said negative charge accumulation layer from an insulating material containing a second metallic substance having greater electronegativity than said first metallic substance.

Owner:SONY CORP

Replaceable liquid crystal display back plate for portable computer

InactiveUS7292434B2Efficient attractionDetails for portable computersNon-functional elementsLiquid-crystal displayLocking mechanism

A replaceable liquid crystal display back plate for portable computer includes a back plate forming part of a housing of a liquid crystal display of a portable computer and being provided on an outer surface with a flat recess; a replaceable cover plate adapted to fitly set in and cover the flat recess on the back plate; and a locking mechanism operable between a locked position, in which the replaceable cover plate is locked to the flat recess, and an unlocked position, in which the replaceable cover plate is separable from the flat recess to be replaced with another one. The replaceable cover plate is made of a transparent material, and may have a pictorial layer provided between it and the flat recess.

Owner:MITAC TECH CORP

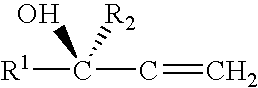

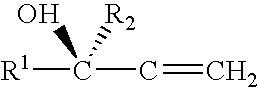

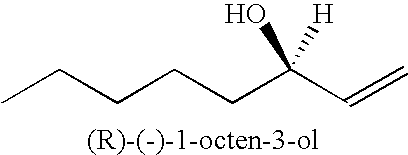

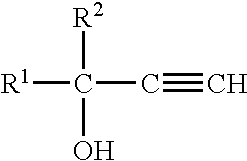

Method and compositions for attracting mosquitoes employing (R)-(-) isomers of 1-alken-3-ols

InactiveUS20060193881A1Superiorly usefulEfficient attractionBiocideHydroxy compound active ingredientsSaturated aliphatic hydrocarbonsAliphatic hydrocarbon

The predominately (R)-(-) isomer of 1-alken-3-ol compounds of the formula: where R1 is a saturated aliphatic hydrocarbon group containing from 1 to about 12 carbon atoms, and R2 is hydrogen, are most effective attractants for mosquitoes.

Owner:BEDOUKIAN RES

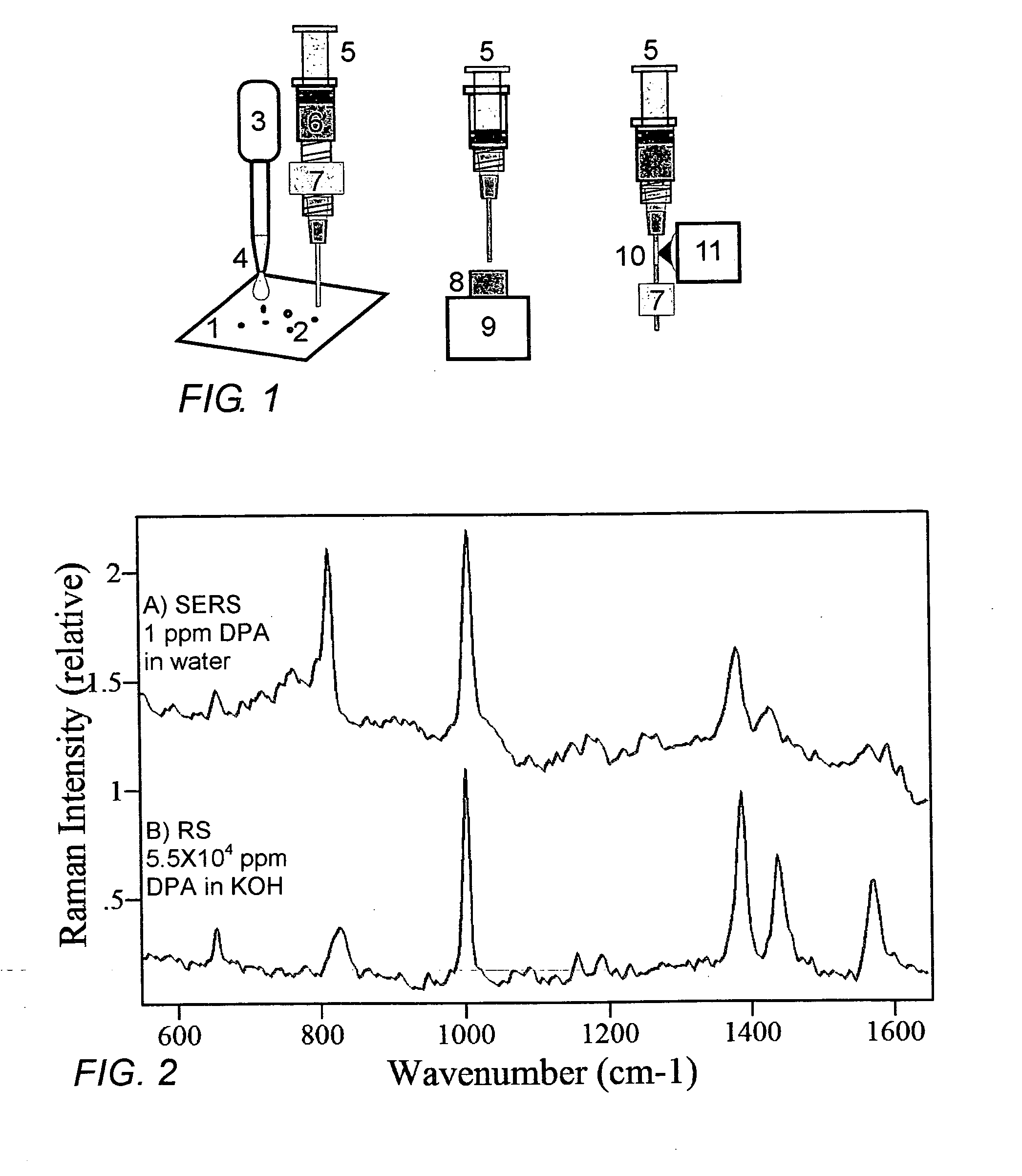

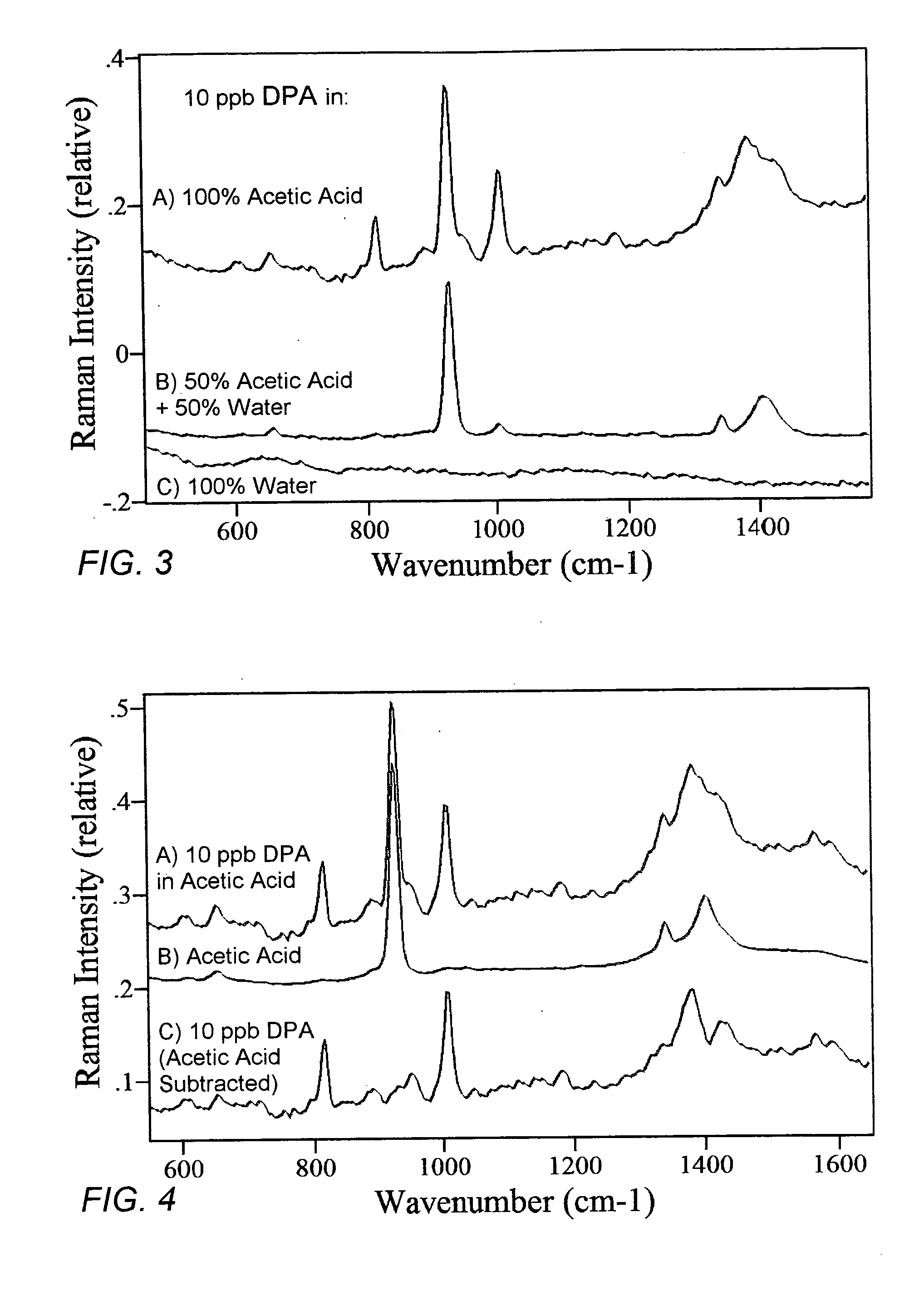

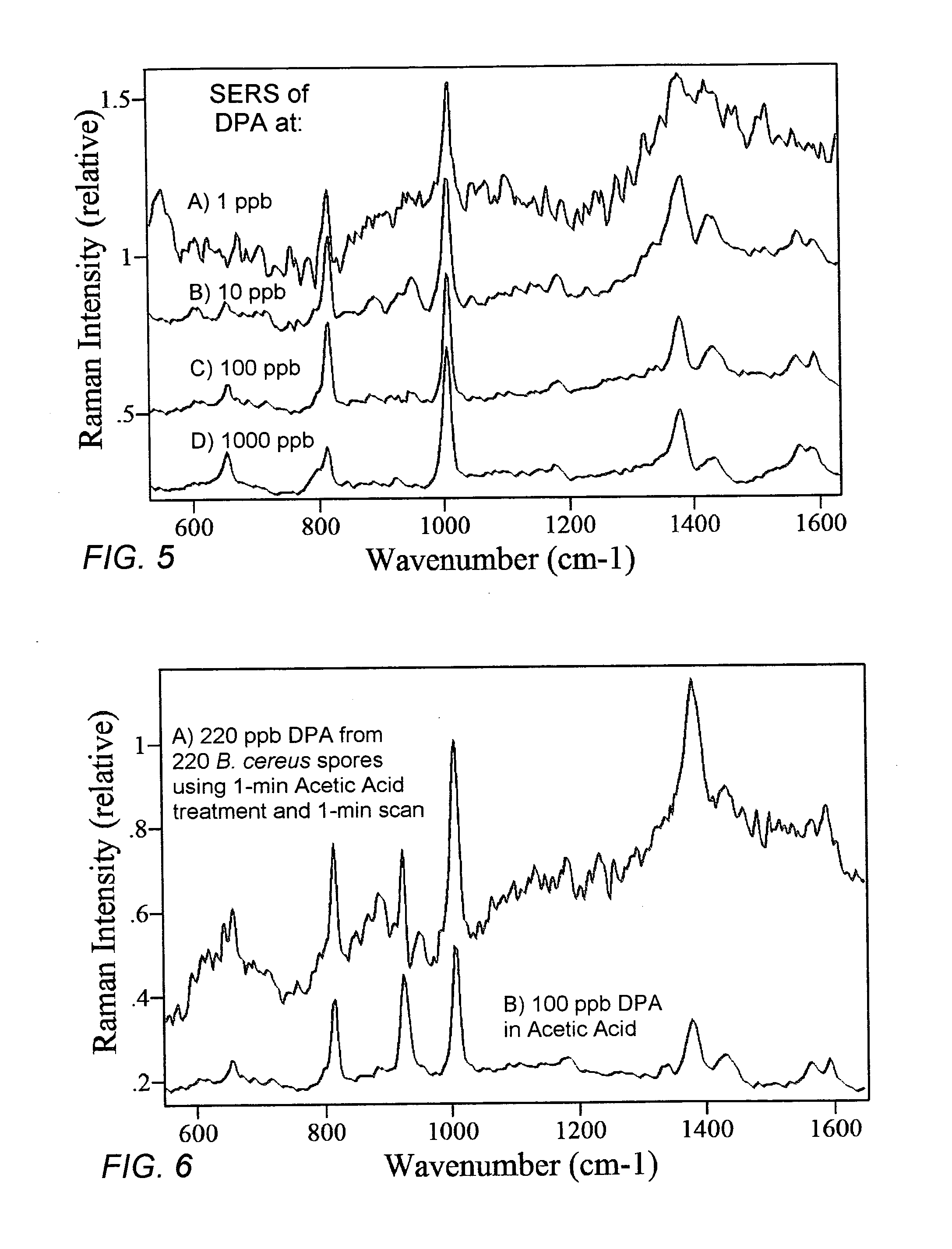

Method for effecting the rapid release of a signature chemical from bacterial endospores, and for detection thereof

ActiveUS20060257891A1Easy accessEfficient separationMicrobiological testing/measurementLibrary screeningFood borneSurface-enhanced Raman spectroscopy

A weak organic acid is used to effect the release of CaDPA from Bacillus or Clostridium endospores, rapidly and at room temperature, to enable detection and measurement of DPA and thereby the assessment of risk associated with exposure to Bacillus anthracis, Clostridium botulinum, and like spores. The method can be applied to airborne, food-borne, and water-borne spores, as well as to spores collected from surfaces or contained in body fluids, and analysis is advantageously carried out using surface-enhanced Raman spectroscopy.

Owner:REAL TIME ANALYZERS

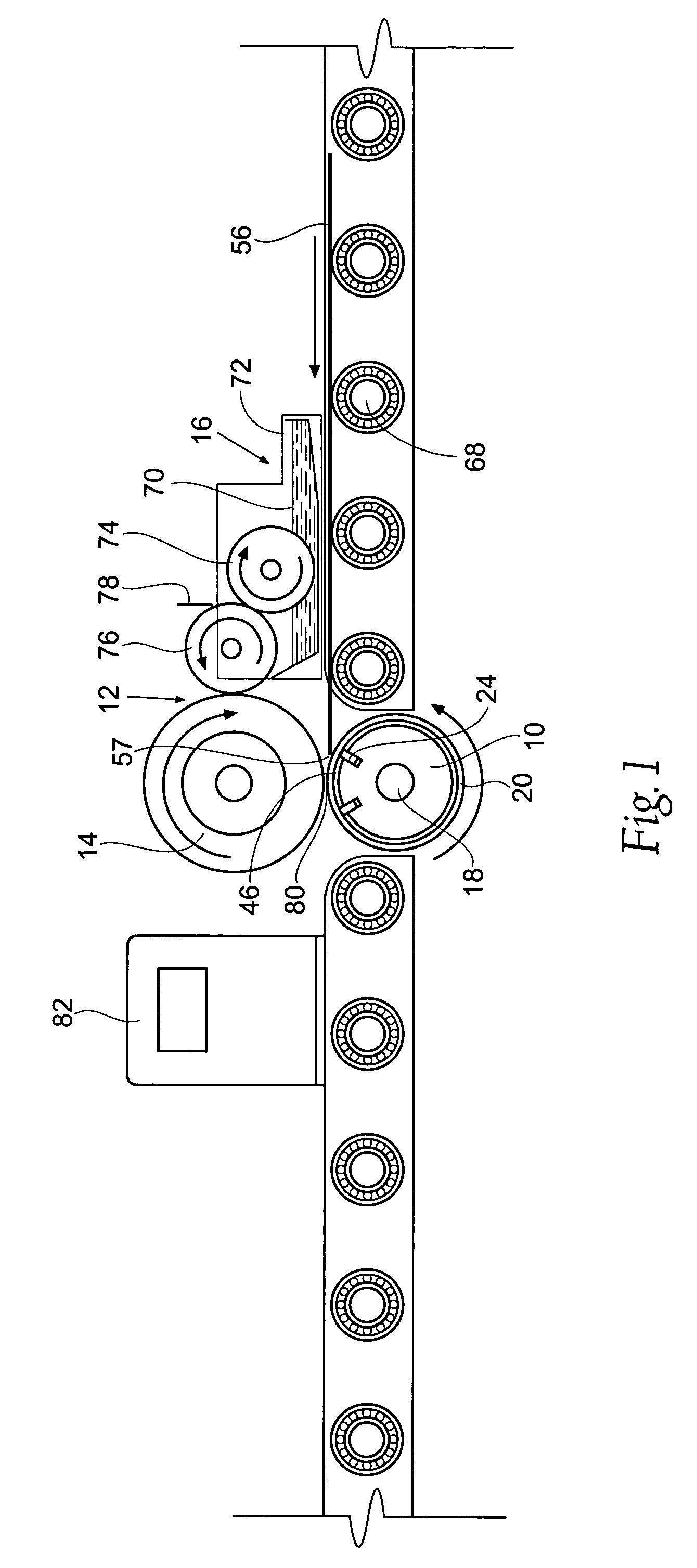

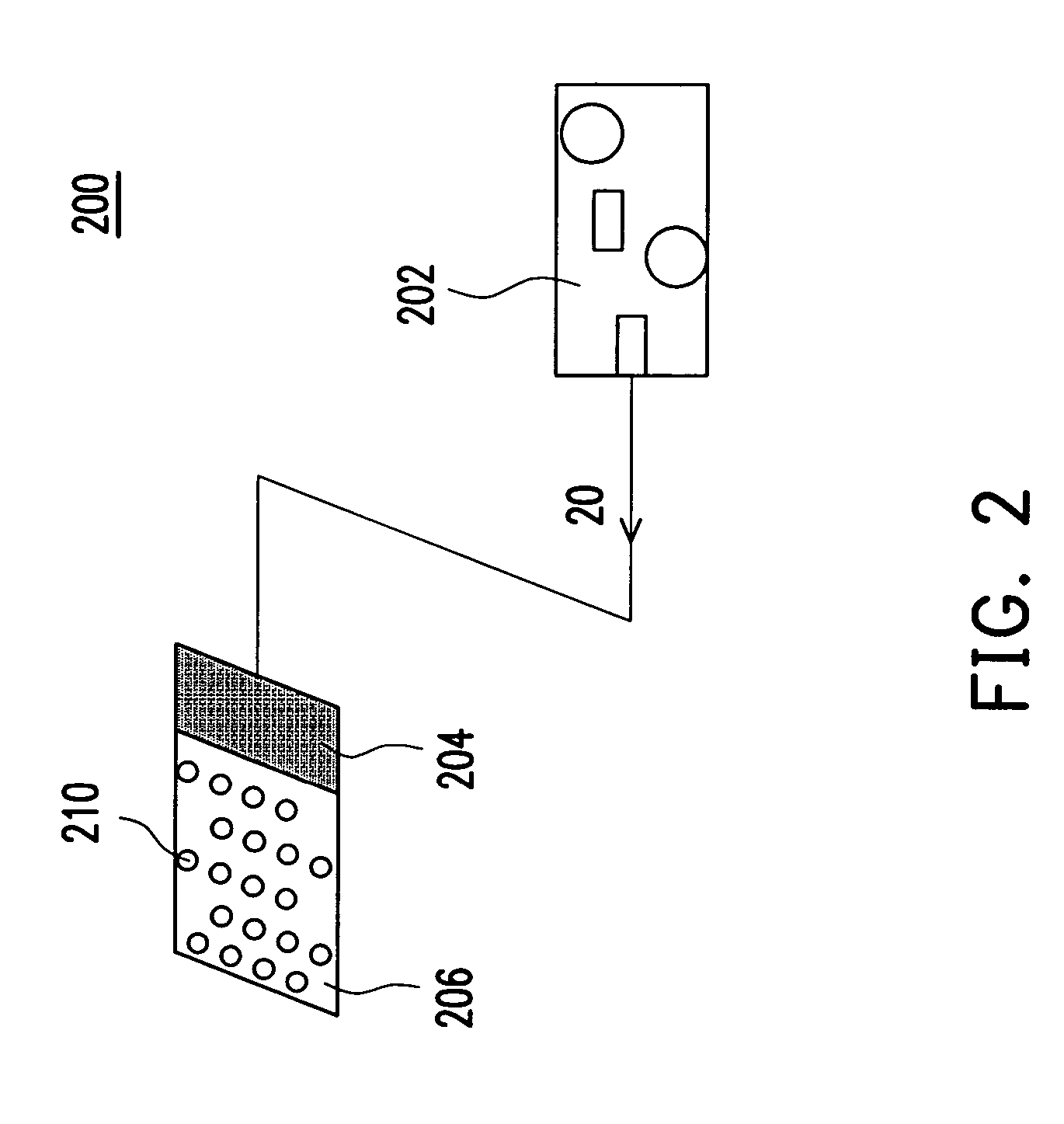

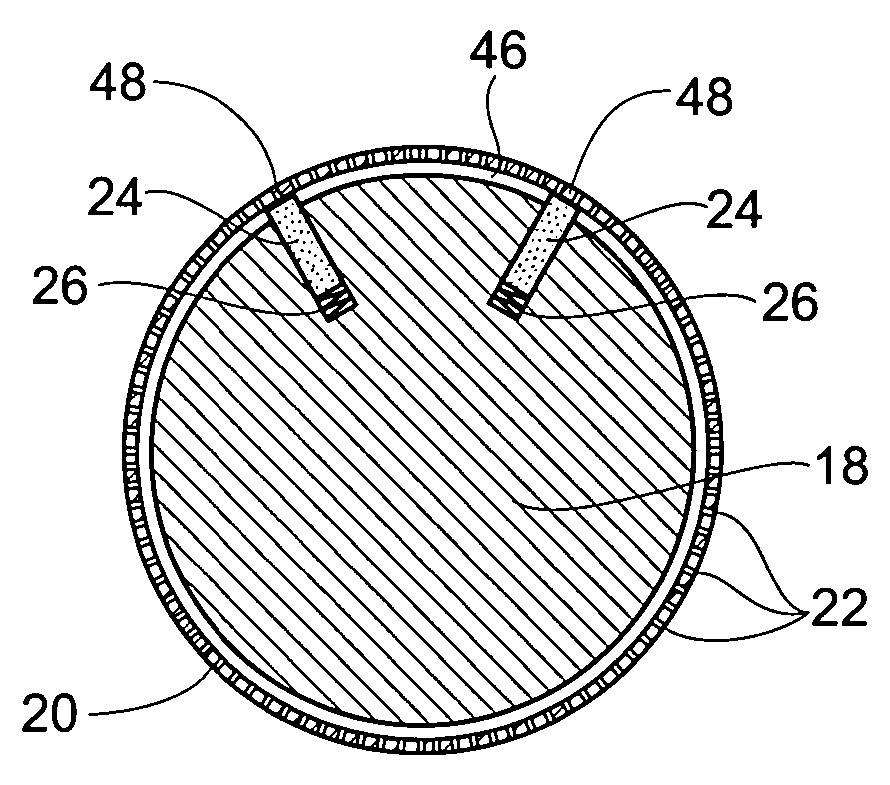

Method and apparatus for treating sheets including a vacuum roller for retaining sheets in curved configuration

InactiveUS7367264B2Efficient attractionPlaten pressesPretreated surfacesBiomedical engineeringCoating

An apparatus and method for retaining individual sheets of substrate in a curved configuration during coating or printing is disclosed.

Owner:BEAUDRY WALLACE J

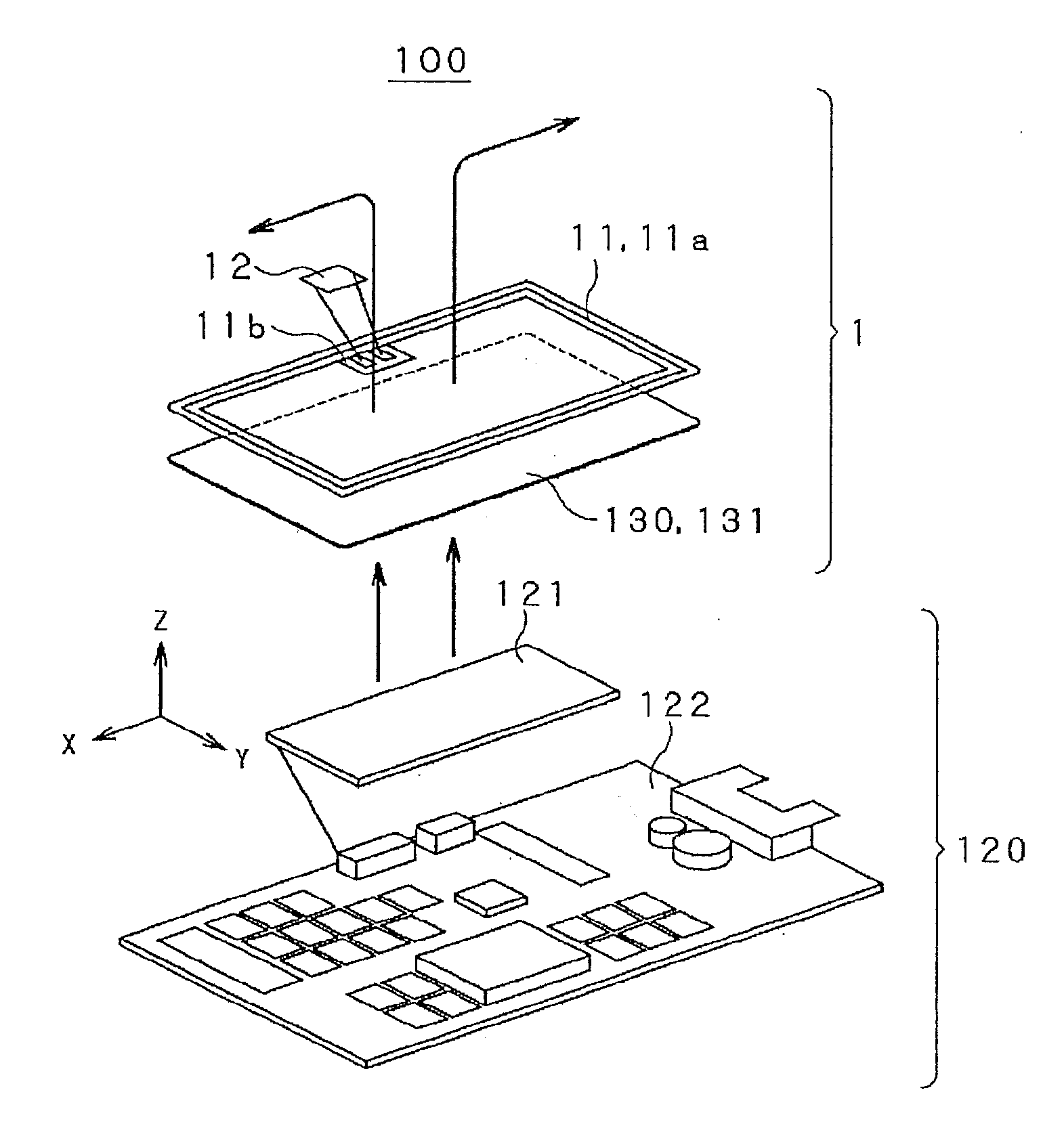

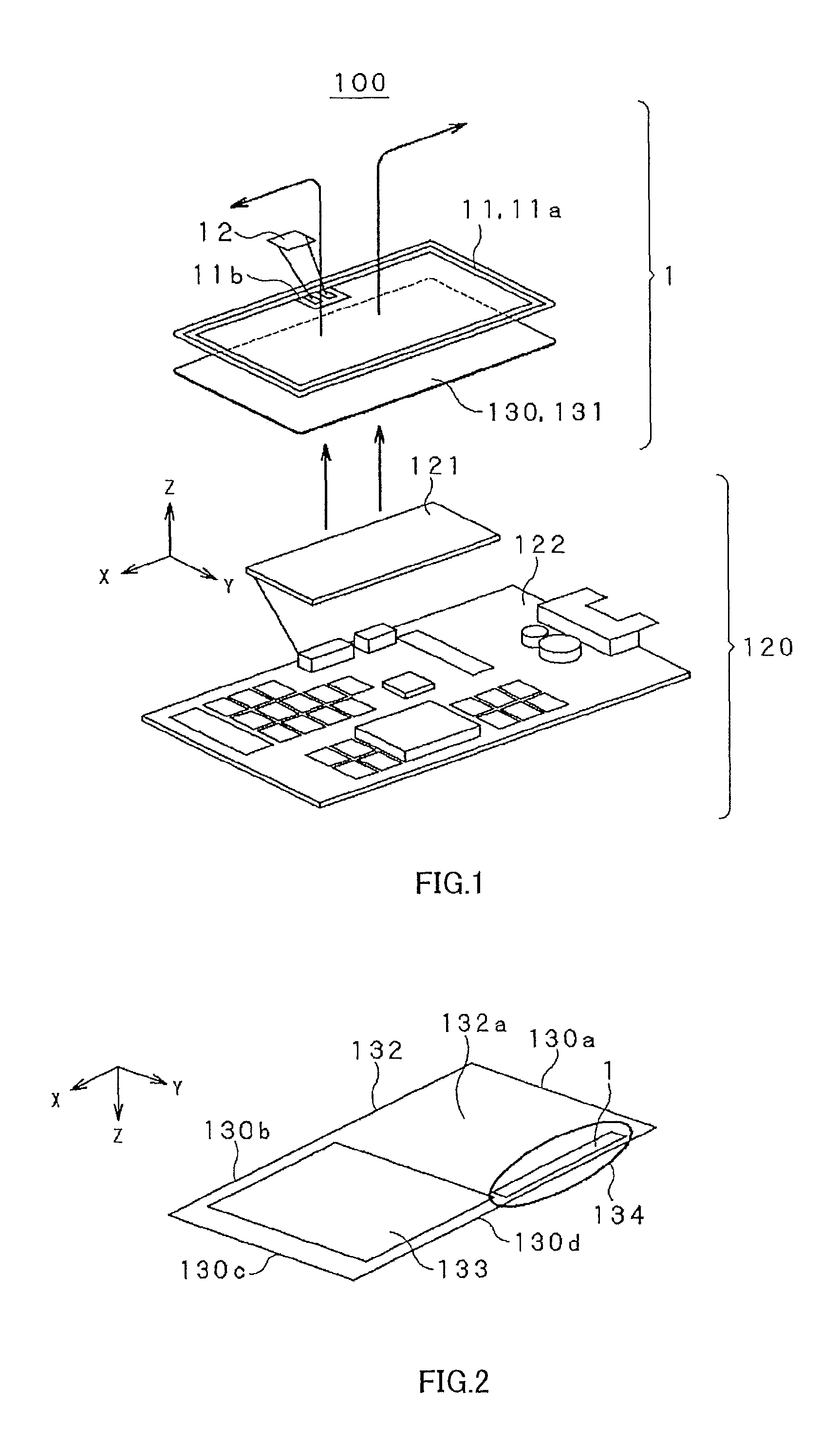

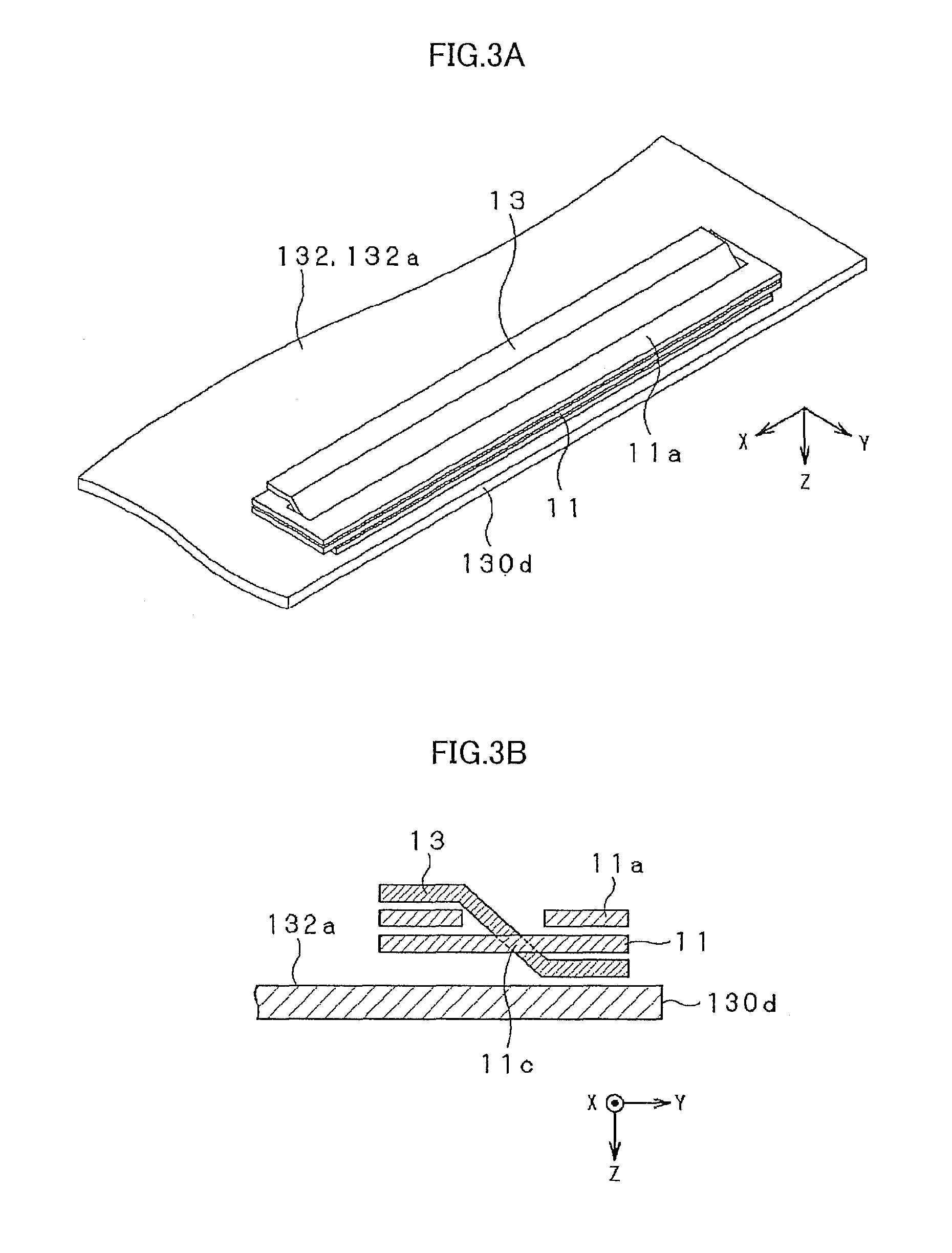

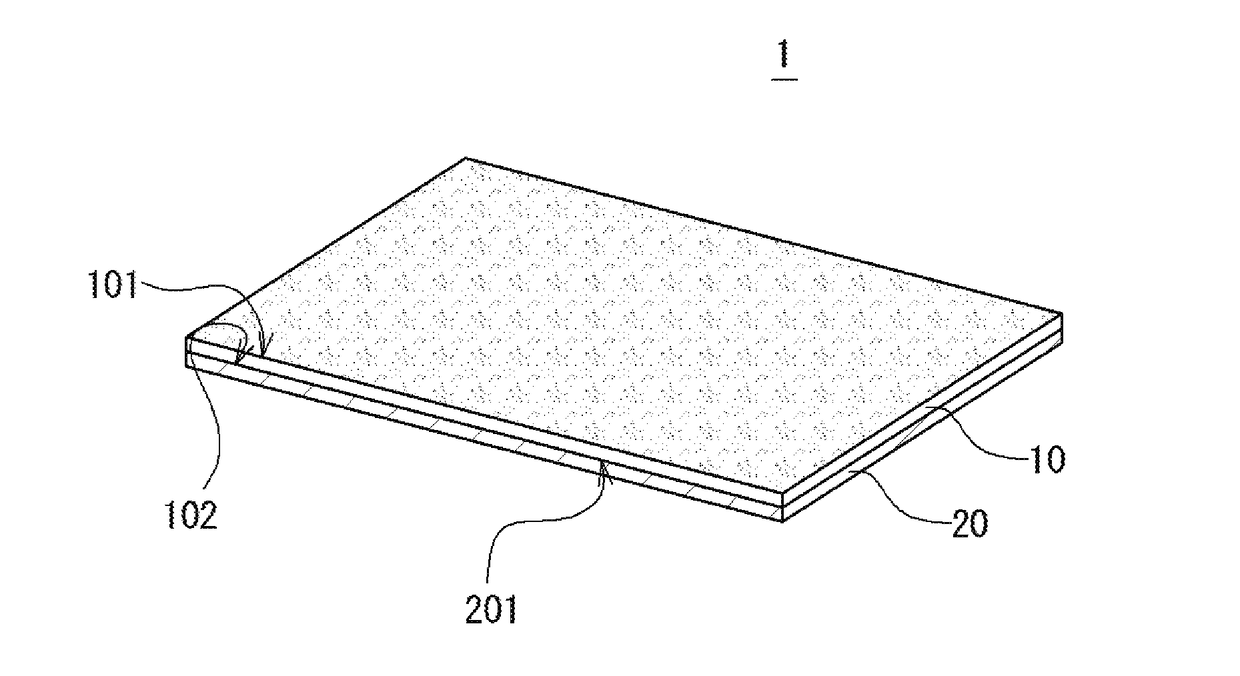

Antenna device and communication device

ActiveUS8849195B2Small sizeReduce thicknessLoop antennas with ferromagnetic coreNear-field transmissionPower flowEngineering

The present invention provides a communication device that can reduce a housing of an electronic device in size and thickness when the communication device is built in the electronic device. The communication device includes: an antenna coil (11a) arranged on an outer peripheral portion (134) of a housing (131) surface facing a reader / writer (120) of a mobile phone (130); a magnetic sheet (13) that attracts a magnetic field transmitted from the reader / writer (120) to the antenna coil (11a); and a communication processing unit (12) that is driven by a current flowing in the antenna coil (11a) and performs communication with the reader / writer (120), wherein the magnetic sheet (13) is arranged on the reader / writer (120) side of the antenna coil (11a) at a center portion (132a), and the antenna coil (11a) is arranged on the reader / writer (120) side on an outer periphery (130d) side.

Owner:DEXERIALS CORP

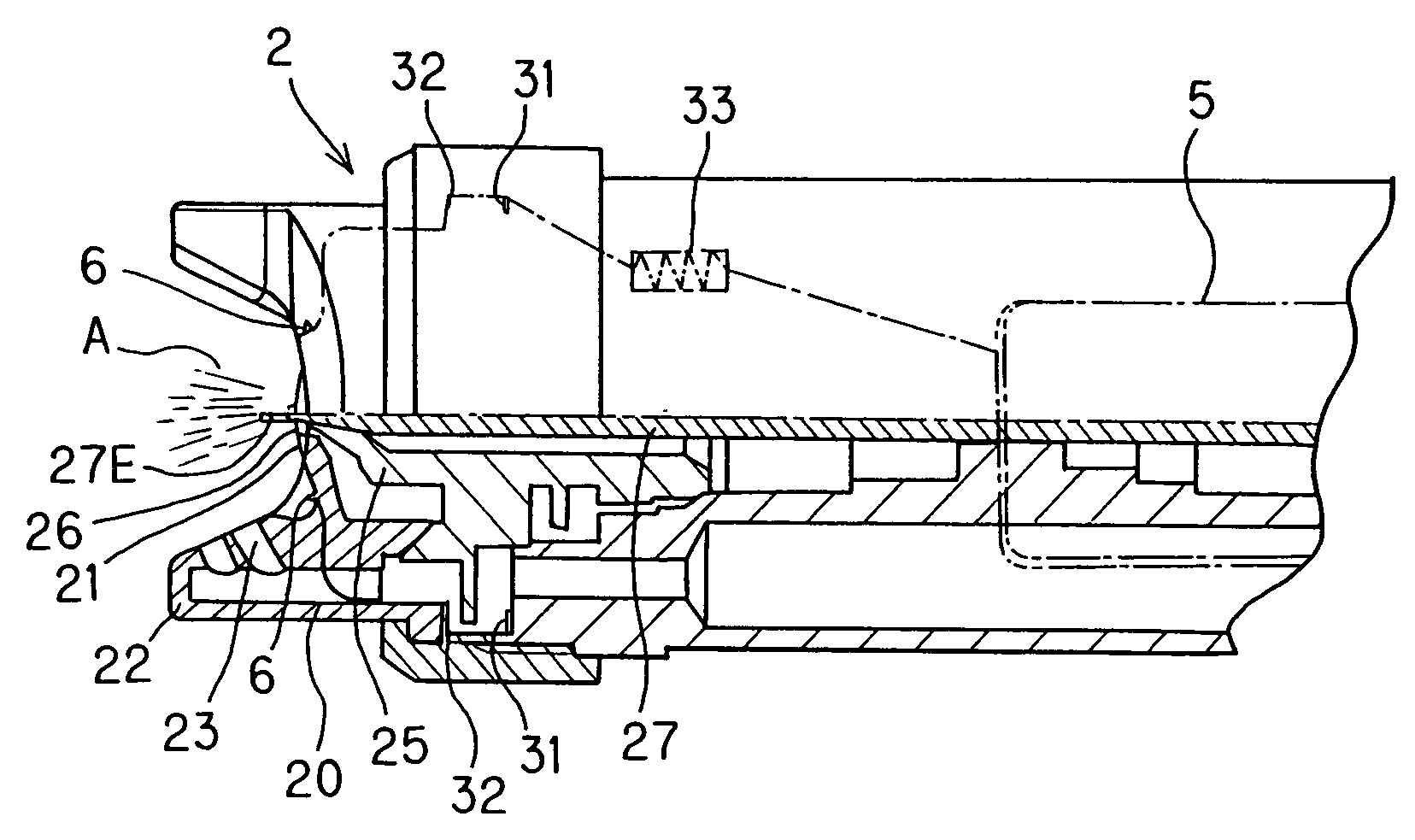

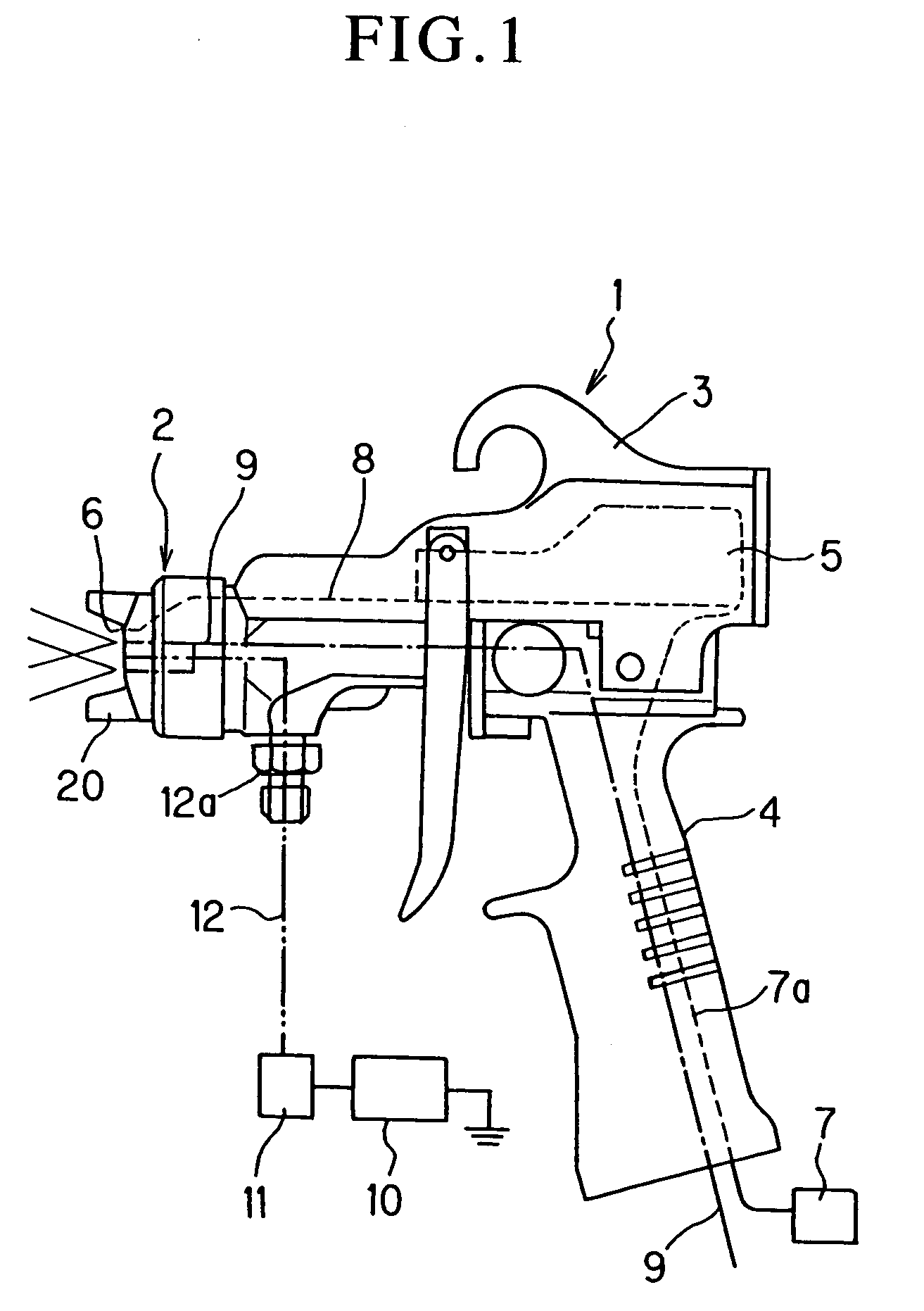

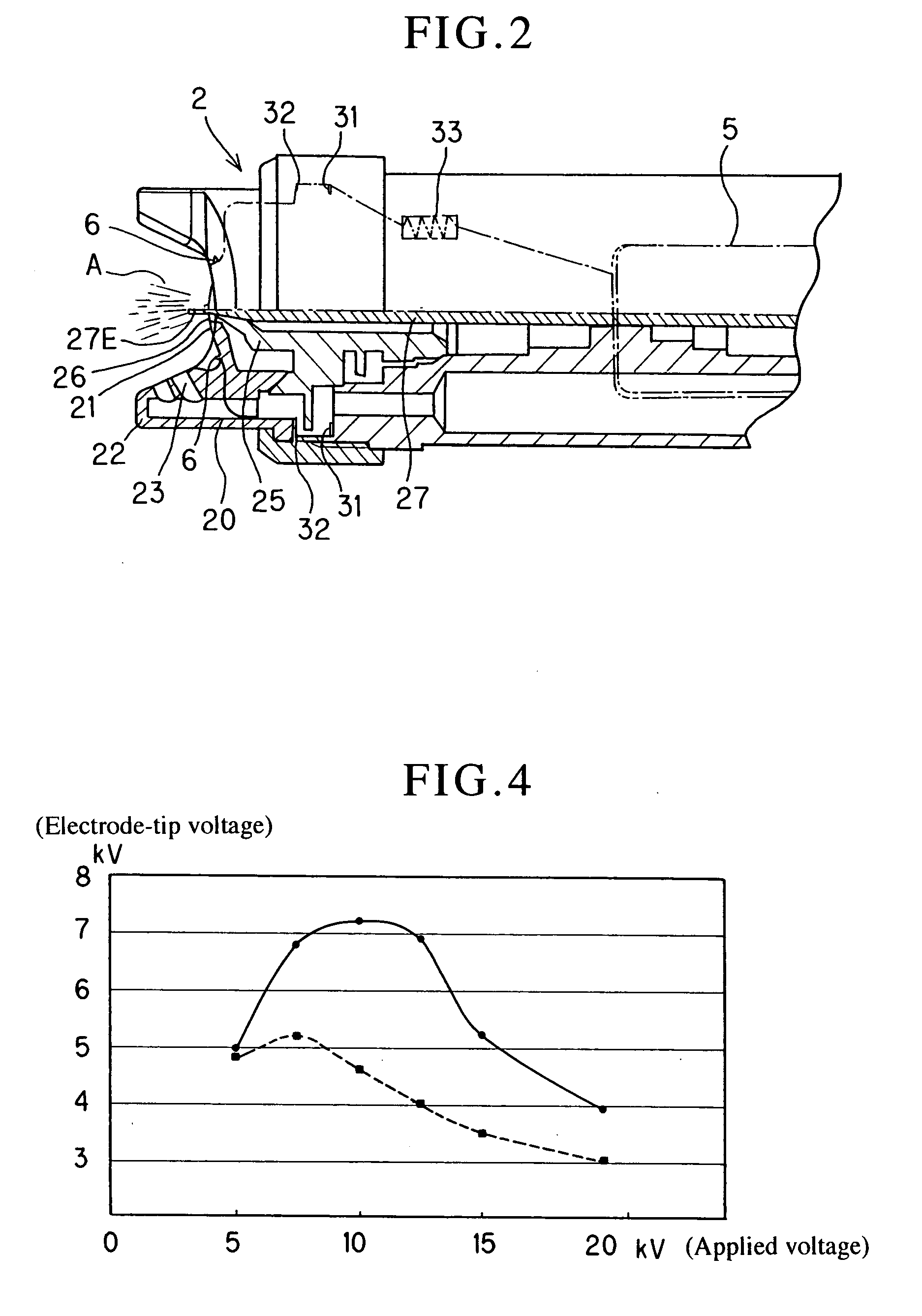

Electrostatic Coating Spray Gun and Electrostatic Coating Method

InactiveUS20080213499A1Easy to operateImprove securityLiquid surface applicatorsLiquid spraying apparatusElectricityLow voltage

When conductive paint is coated by electrostatic coating, the electrostatic charging has many problems. The external electrode is prevailingly used in most of the electrostatic coating spray guns but has many problems in operability, safety, practical usability, etc. when the guns are designed compact. The electrostatic coating spray guns need to be improved in operability, safer with electrostatic charging at a lower voltage, and smaller in structure. To solve such problems, there is provided an improved electrostatic coating spray gun (1) in which an atomizer (2) is provided at the front end thereof to atomize paint jet from a paint nozzle (25) disposed at the center of the atomizer (2) and electrostatically charge the atomized paint particles at a high voltage for attraction to an object to be coated, set at ground potential, charging electrodes (6) as external electrodes are provided on the inner front surface of an air cap (20) or the inner surface of the air cap (20) and a compressed air passage is formed between a paint jet port (26) at the ground potential and the charging electrodes (6). At charging, compressed air prevents discharge from the charging electrodes toward the paint at the ground potential to efficiently ensure ionizing discharge with necessary potential being retained at the charging electrodes (6) and effective charging of paint particles. Since voltage drop is thus prevented, a lower voltage may be used for necessary charging of the paint particles.

Owner:ANEST IWATA CORP

Microbe-mediated method for attracting mosquitoes and apparatus thereof

The present invention provides an apparatus and method for attracting mosquitoes by using the microbe product as the mosquito bait as well as simulating the human emanated odors. A bait-releasing unit / means is included to enhance the release of the mosquito bait. A well-controlled heating assembly can be used to generate a suitable thermal gradient for simulating body temperature and evaporating the bait. The microbe product comprises at least a sterilized supernatant of a bacterial incubation product. The apparatus of this invention can further include electrocution grids or insecticide webs to destroy attracted mosquitoes.

Owner:BIOWARE TECH

Insect capturing device

ActiveUS20170006847A1Reduced effectivenessMaximise light reflectionInsect catchers and killersInsectLight-emitting diode

An insect capturing device and a method of using the same. The insect capturing device includes a housing. The insect capturing device also includes an insect disabling portion. The insect capturing device also includes one or more light emitting diodes (LEDs) operable to emit light for attracting insects. The insect capturing device further includes a reflection surface. The LEDs are oriented to direct light onto the reflection surface for reflecting the light out from the housing to attract insects onto the in sect disabling portion.

Owner:KILLGERM GROUP

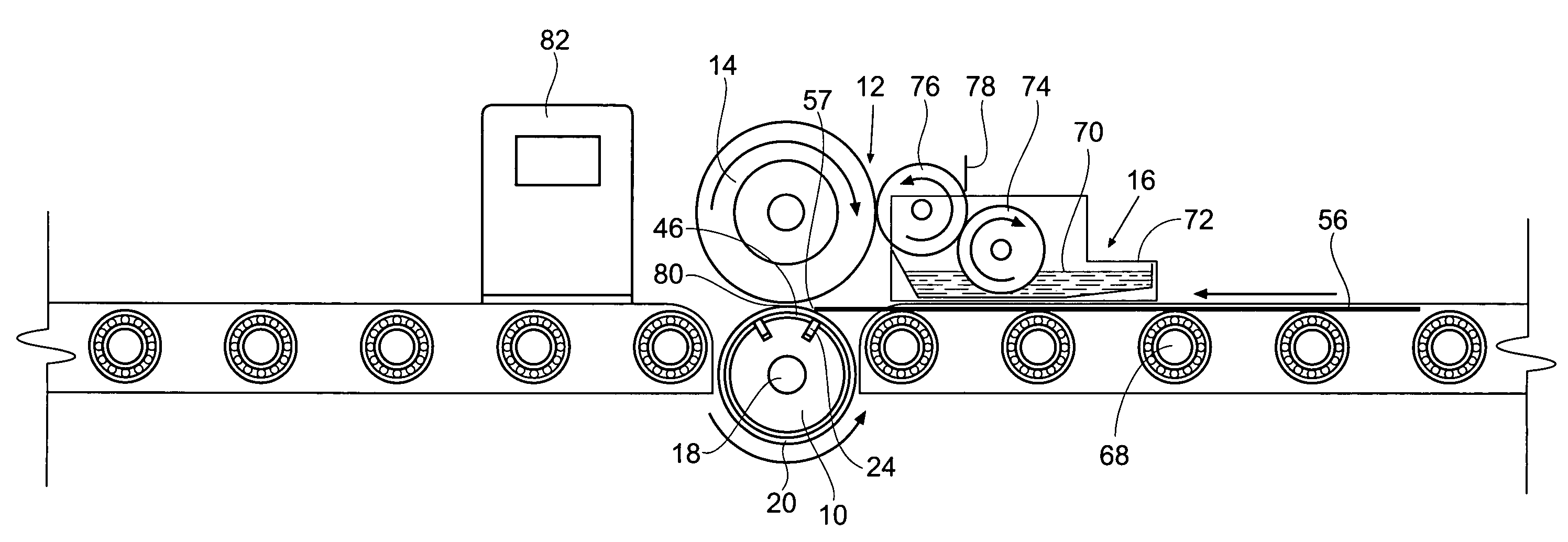

Method and apparatus for retaining individual sheet substrates in a curved configuration

InactiveUS20060021534A1Facilitates retentionEfficient attractionPlaten pressesPretreated surfacesBiomedical engineeringCoating

An apparatus and method for retaining individual sheets of substrate in a curved configuration during coating or printing is disclosed.

Owner:BEAUDRY WALLACE J

Method and compositions for attracting mosquitoes

InactiveUS6866858B2Efficient attractionBiocideHydroxy compound active ingredientsAliphatic hydrocarbonOrganic chemistry

1-Alkyn-3-ol compounds of the formula: where R1 is a saturated aliphatic hydrocarbon group containing from 1 to about 12 carbon atoms, and R2 is a hydrogen, are effective attractants for mosquitoes.

Owner:BIOSENSORY INC +2

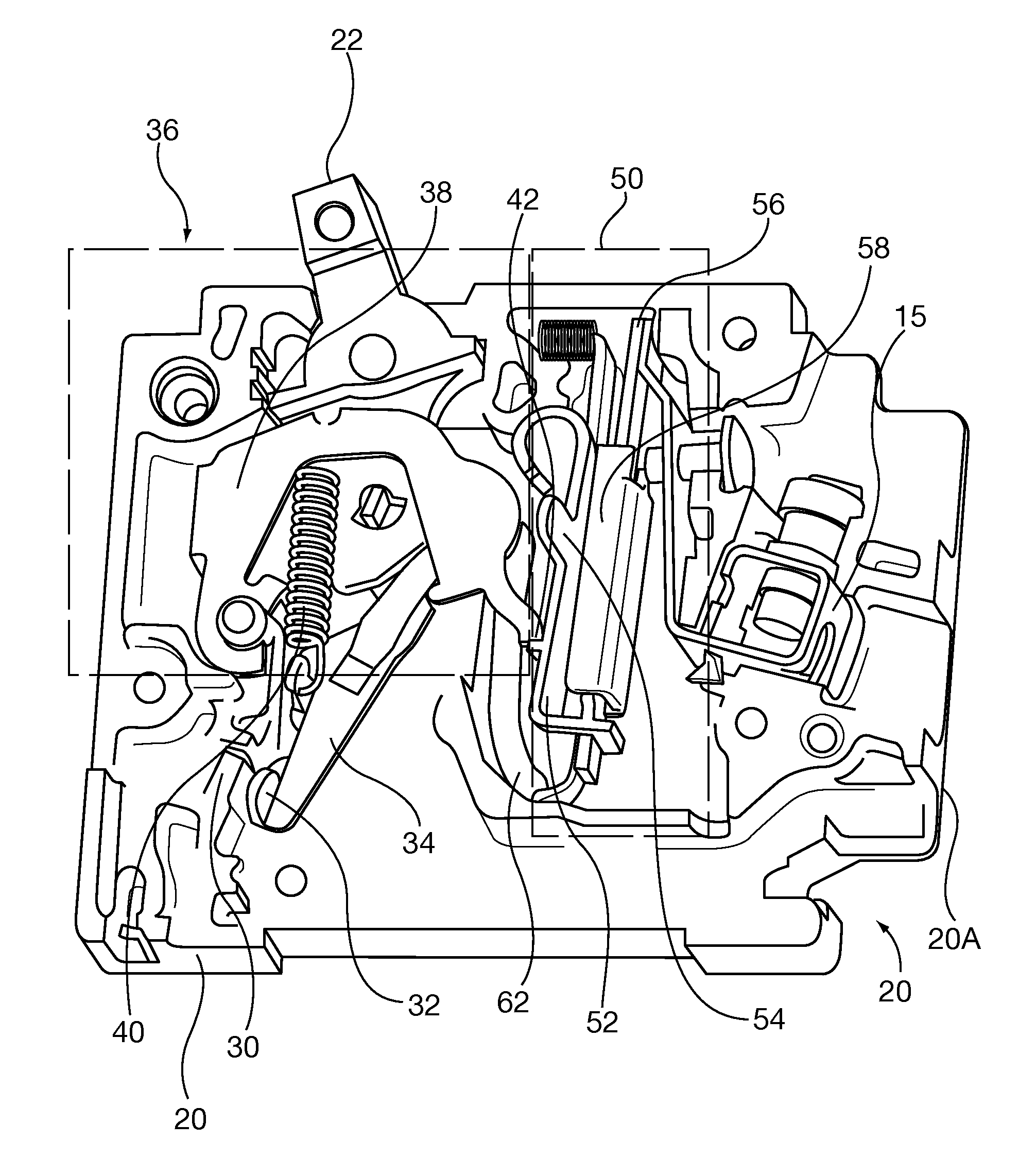

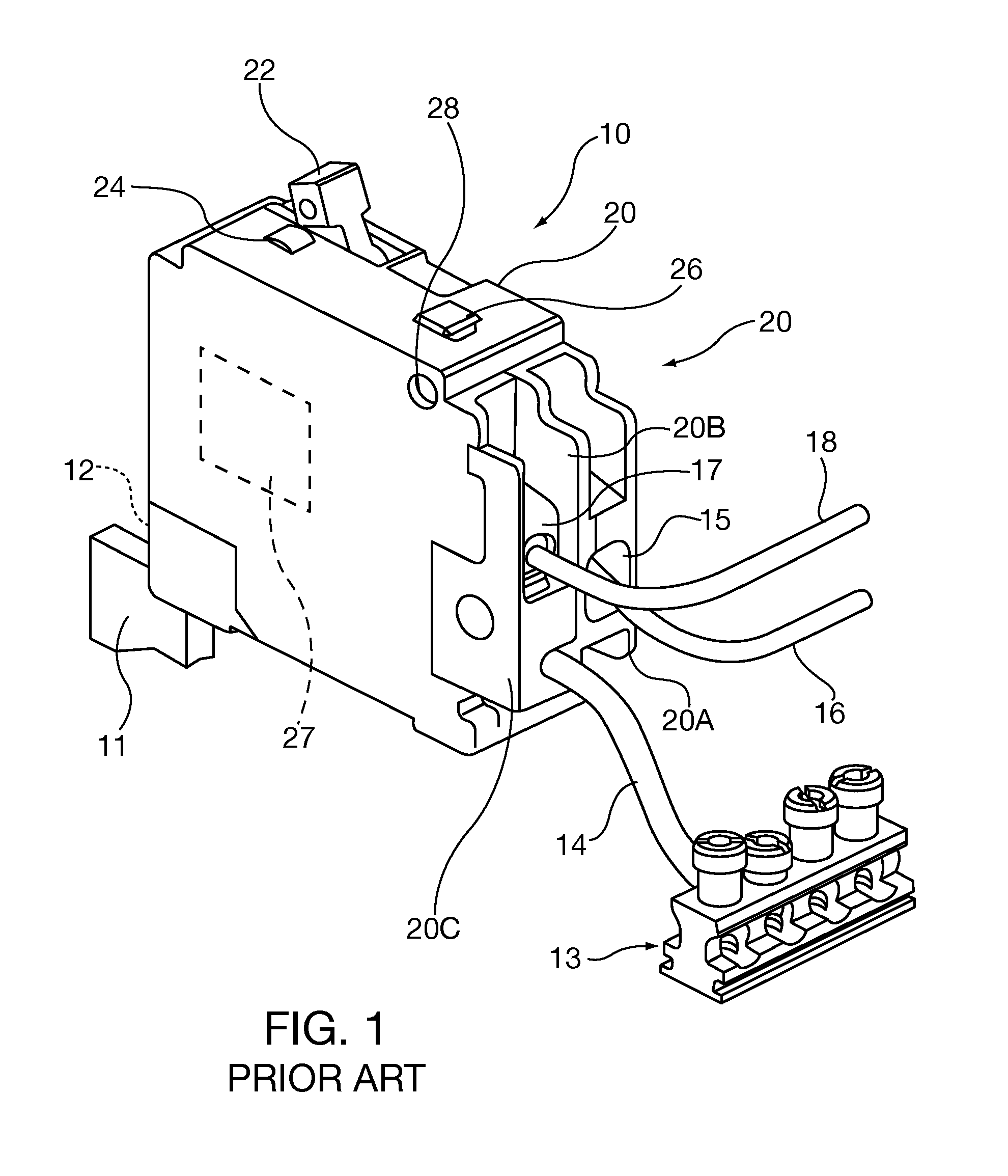

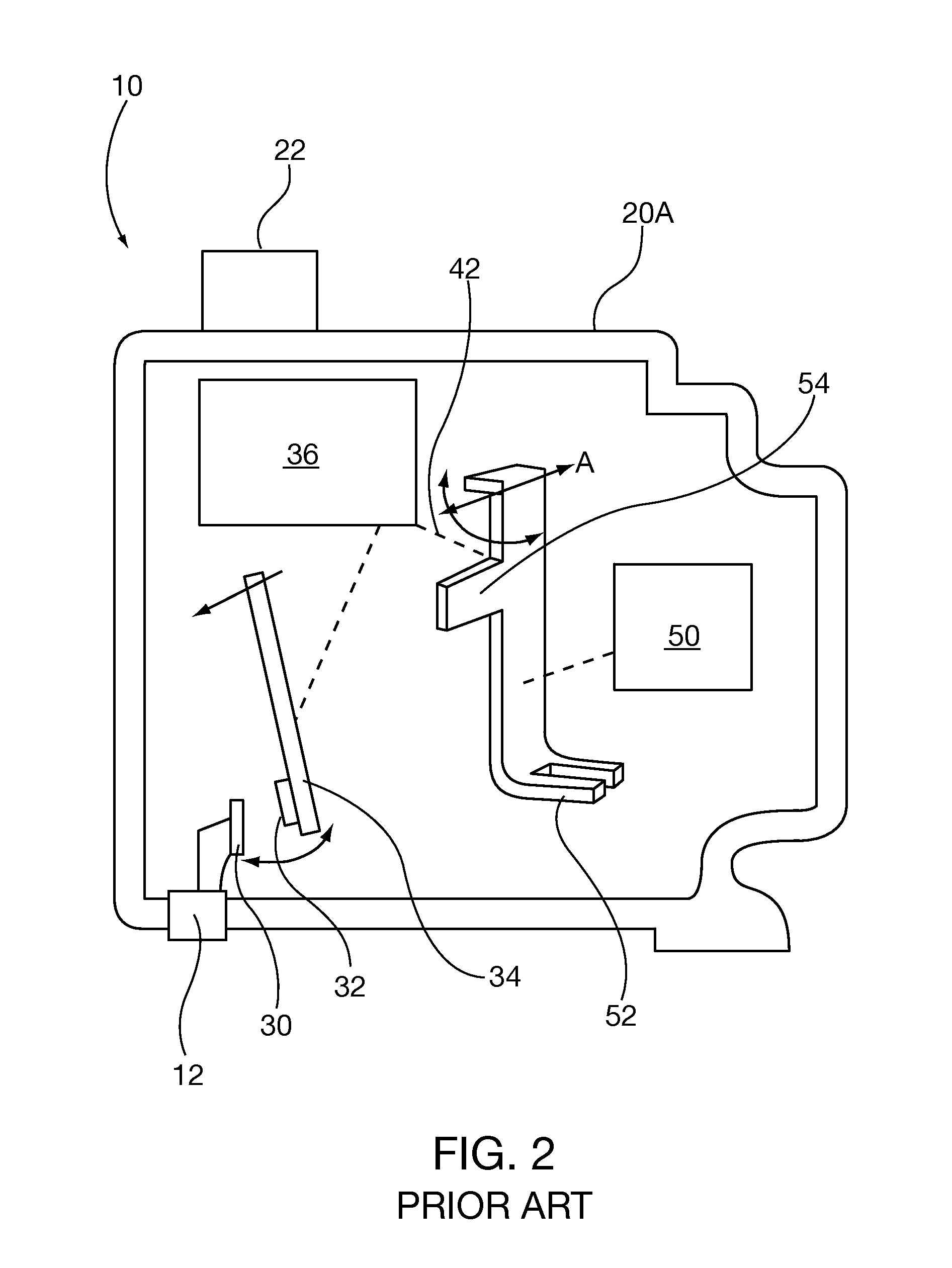

Electromagnet Assembly Directly Driving Latch Of An Electronic Circuit Breaker

ActiveUS20100073113A1Efficient attractionSwitches with electromagnetic openingSwitch operated by falling currentRange of motionReciprocating motion

A circuit breaker includes a trip unit and an electronic fault detection unit sharing a common trip latch for causing the circuit breaker to trip upon detection of a fault by either unit. The circuit breaker has an electromagnet for causing the circuit breaker to trip upon detection of a fault by an electronic fault detection unit. The electromagnet is oriented in the housing proximal the trip latch without any components interposed between them, and directly attracts the latch. Advantageously the electromagnet orientation does not impact operation or the range of motion of the latch or other trip unit components. Advantageously the circuit breaker of the present invention does not increase the trip latch mass, its bulk swept volume through its range of motion or require additional linkage components that potentially might increase trip cycle time. In some embodiments the electromagnet core is reciprocable.

Owner:SIEMENS IND INC

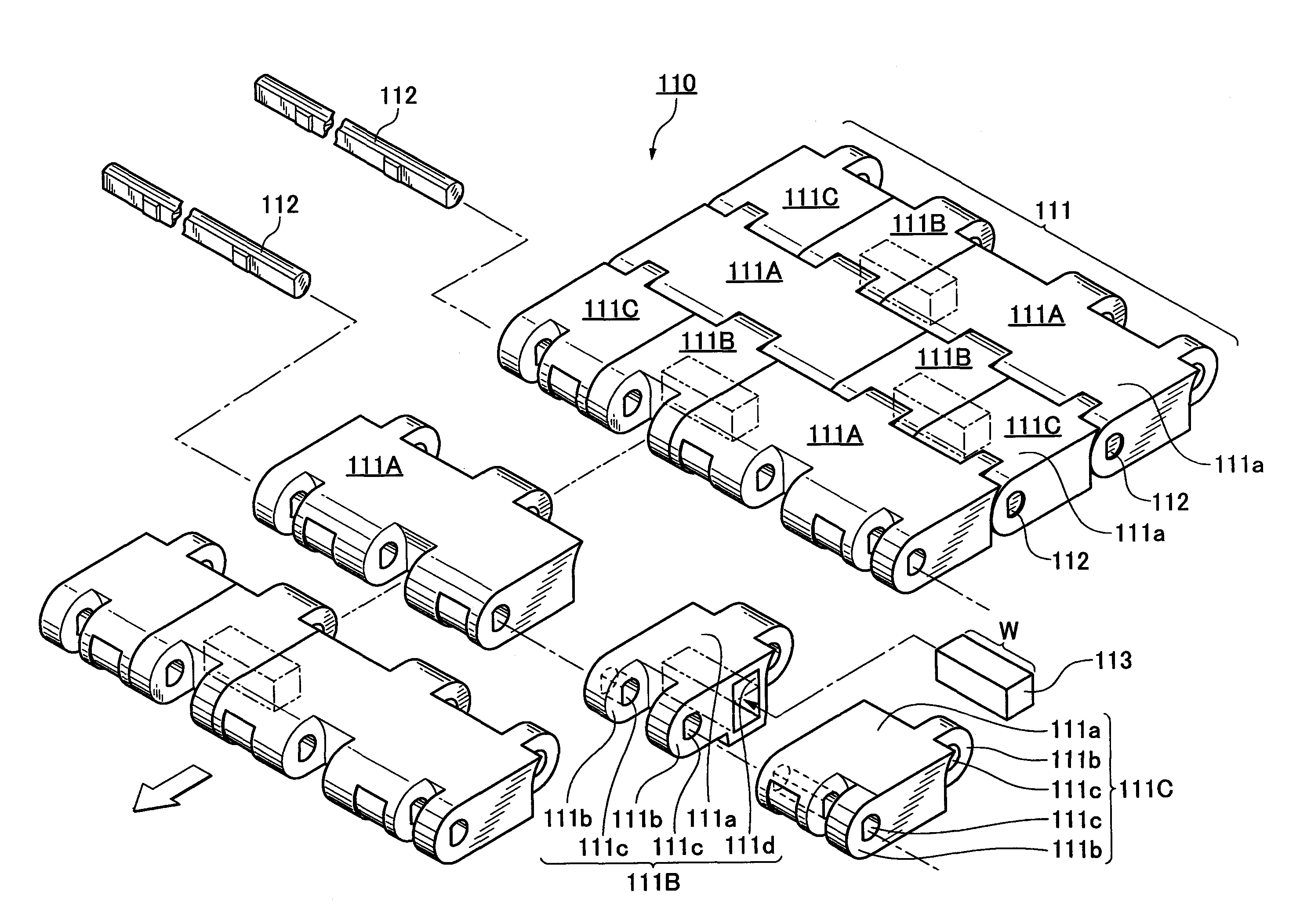

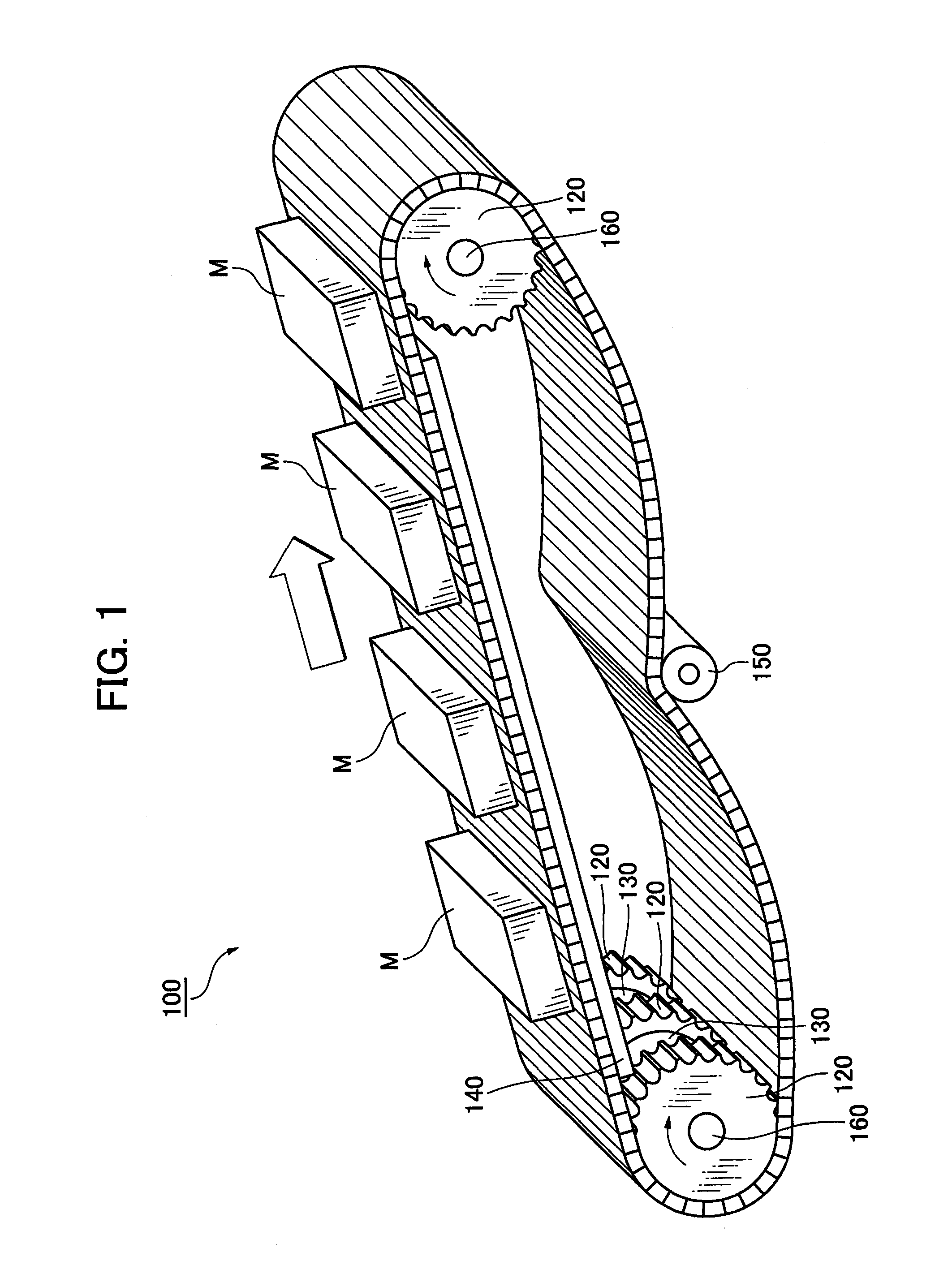

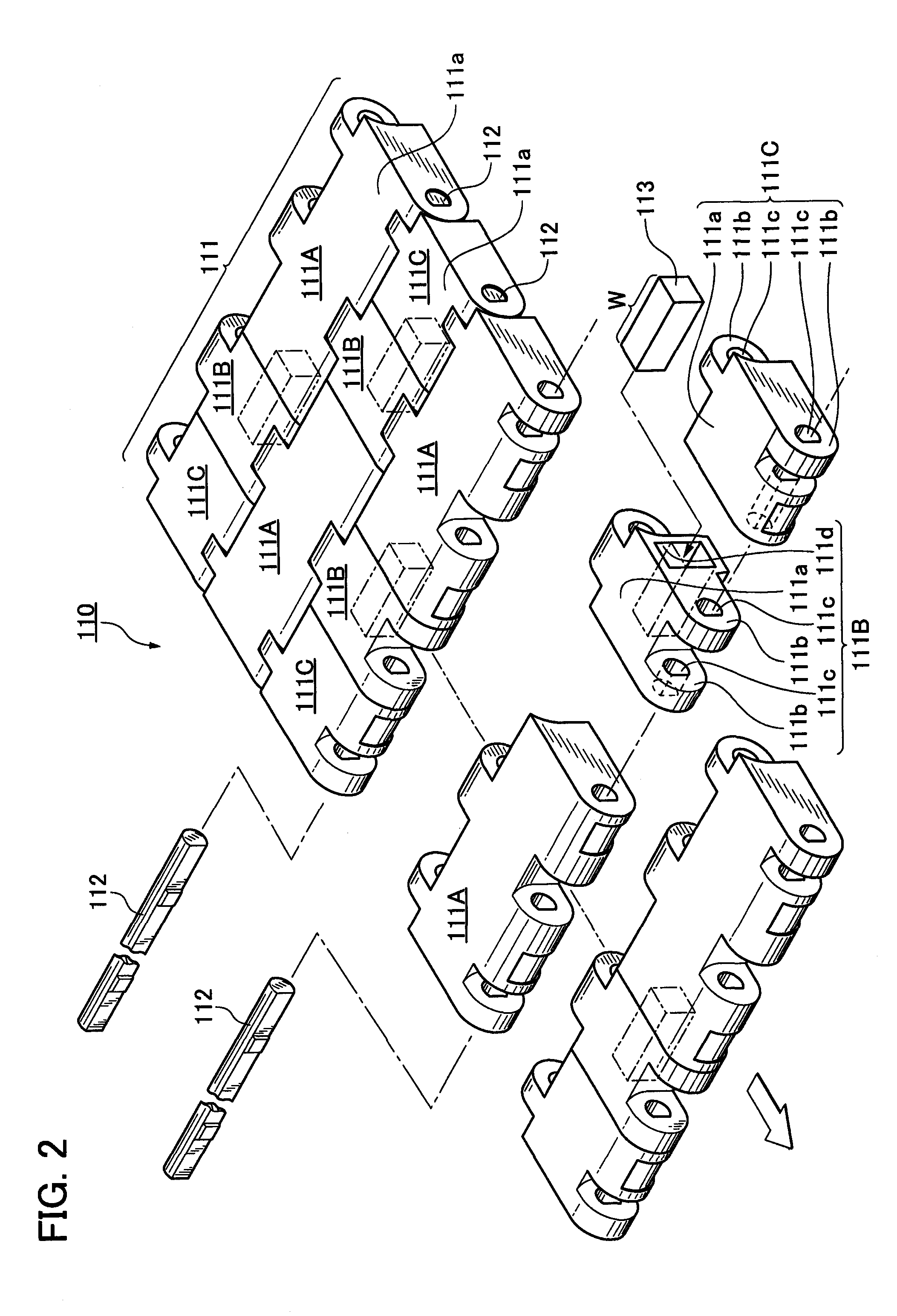

Chain conveyor system

The invention provides a chain conveyor system capable of avoiding damages and vibration noise by securely attracting and retaining metallic magnetic articles in inclined conveyor lines or slippery wet conveyor lines and of providing ready transfer or relay of the articles to other conveyors or equipment also in a conveyor terminal carry-out area. The chain conveyor system comprises a conveyor chain having article-attracting magnet pieces for attracting and retaining articles on loading surfaces thereof and an article-separating device that is disposed coaxially with a sprocket wrapped by and engaging with the conveyor chain and has article-separating magnet pieces that cut the attraction of the article-attracting magnet pieces with the articles on an outer circumferential parts of a free roller.

Owner:TSUBAKIMOTO CHAIN CO

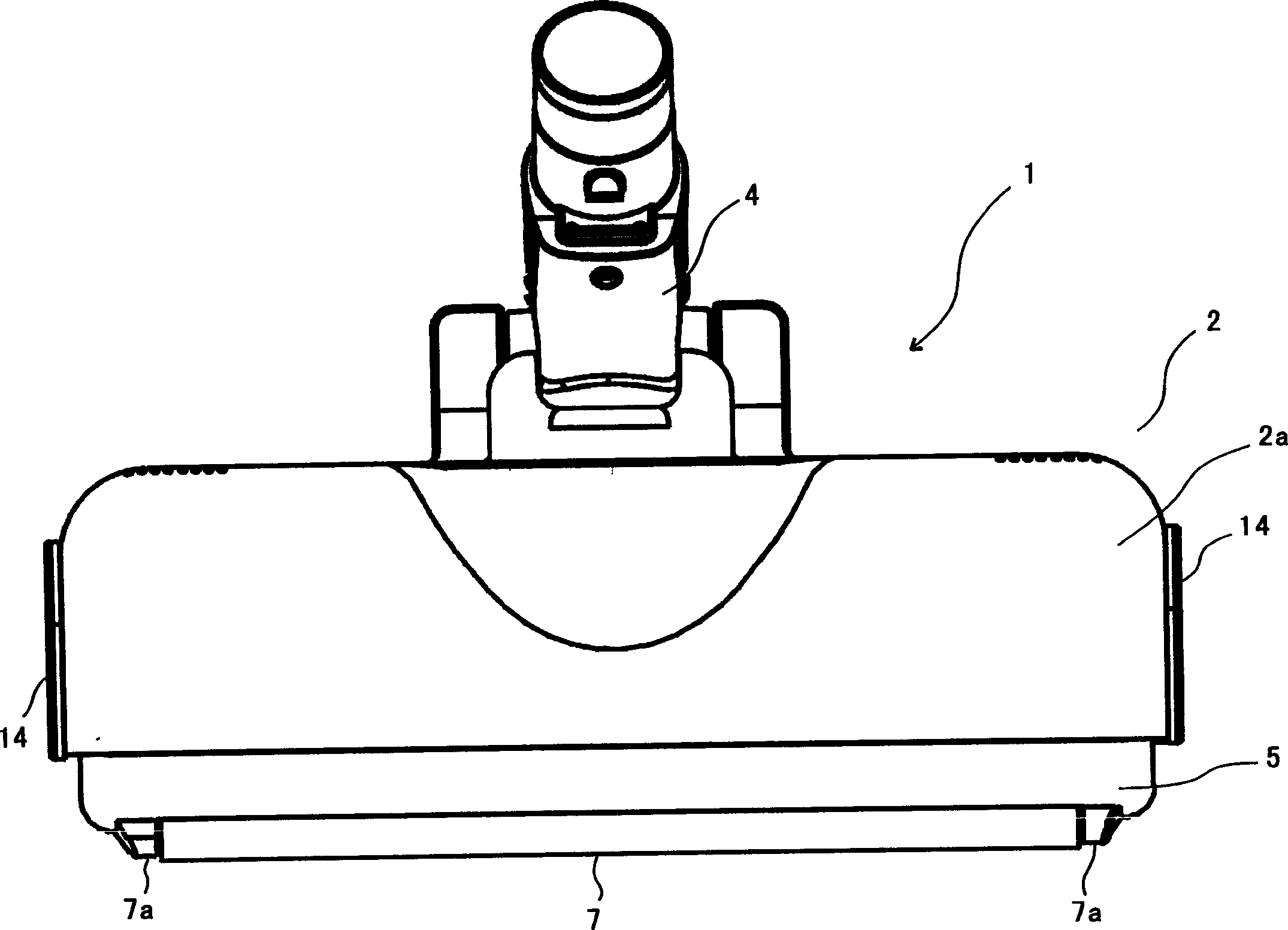

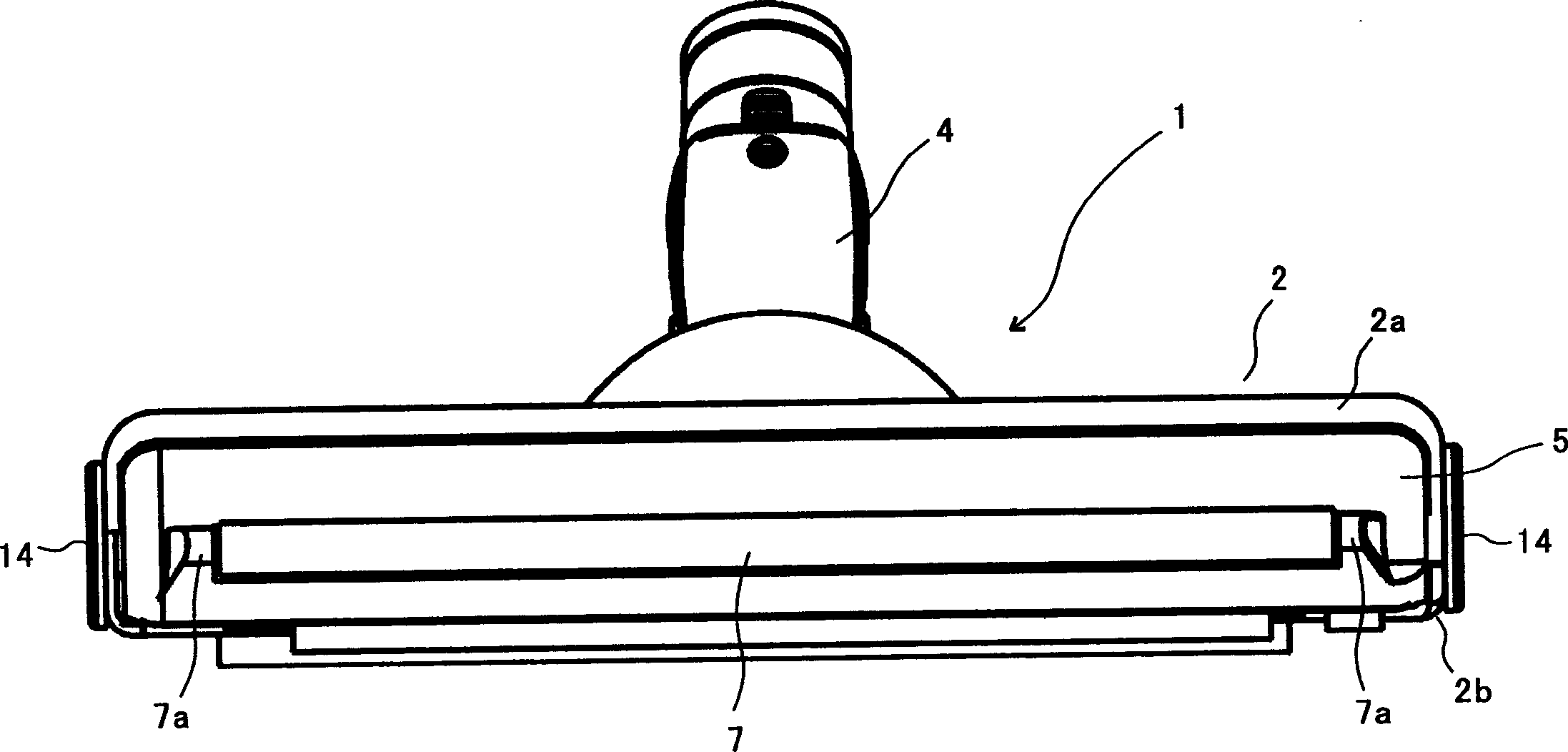

Dusting head for floor

The floor suction port 1 includes a suction hole 6 opening from a bottom face to at least a part of front face of a suction implement body case 2, a cover 5 which constitutes a front wall of the suction port body case 2 and is attached vertically rotatably to the suction port body case 2, and the cover 5 closes a front side part 6b of the suction hole 6 at the downward rotated position and opens the front side part 6b of the hole 6 at the upward rotated position rotated in contact with the wall face W. The cover 5 is provided with an abutting member (raised cloth 7b covering the outer peripheral surface of a roller 7) a soft and easily slidable at a part abutting on the wall face. To provide a floor suction port which can efficiently suck dust accumulating on a floor by a wall, is prevented from damaging wall faces and furniture and is smoothly rotatable. .

Owner:SANYO ELECTRIC CO LTD

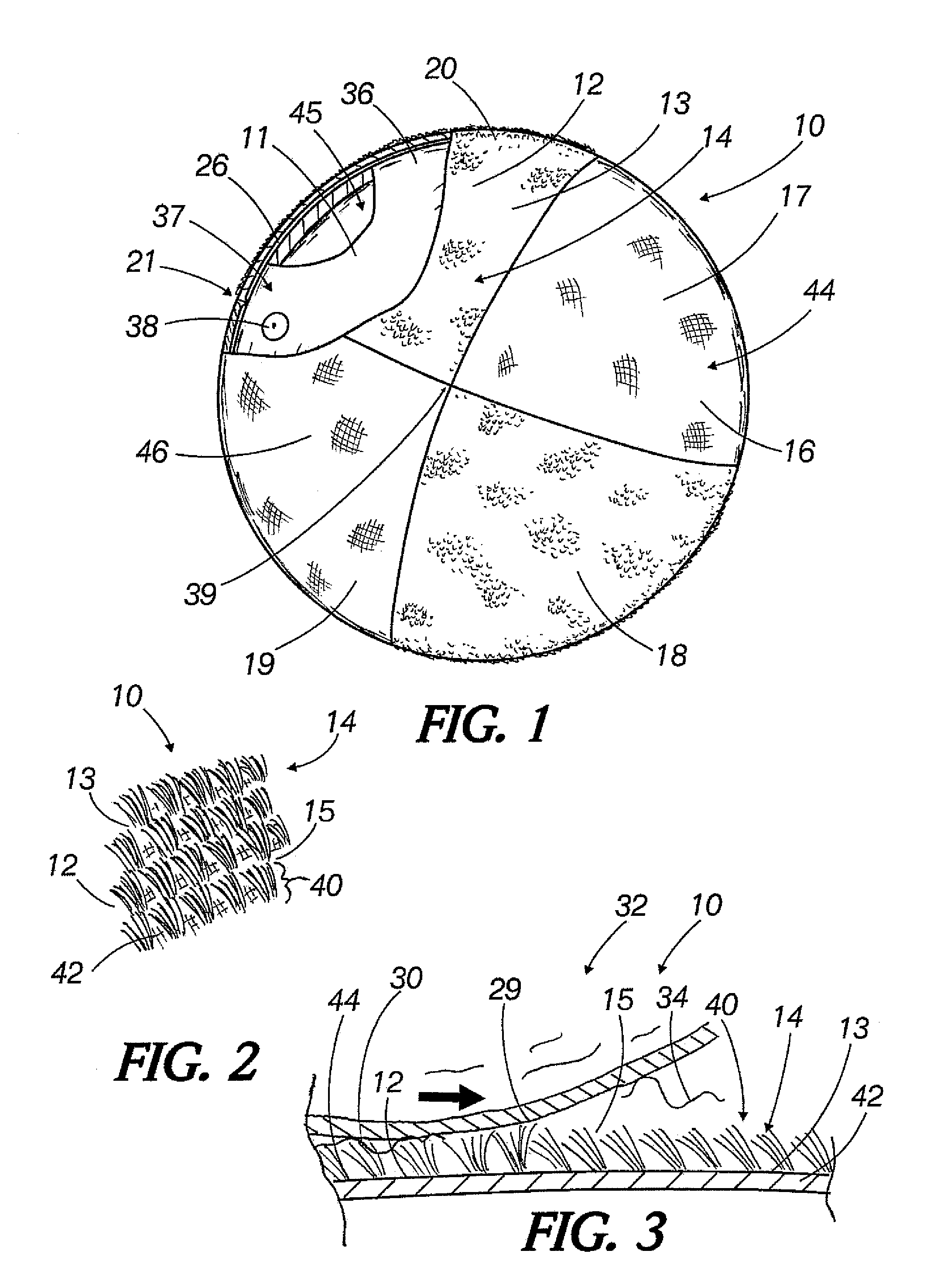

Laundering aid removing adherent matter from fabric articles

InactiveUS7441345B2Improve actionReduce static clingDrying solid materials without heatTextiles and paperEngineeringAnimal hair

A laundering aid having a core member, such as an elastomeric ball member, that includes a covering comprising an abrasive or brush-like material adapted for engaging and lifting matter, such animal hair, adherent to the surface of fabric articles when the laundering aid is placed into contact with clothing and other fabric articles within an operating tumble-type clothes dryer. The covering may further include a second material comprising a material that substantially lacks characteristics for lifting matter from other fabric, the first material being disposed adjacent to or over the first material to form a series of discrete sections having different properties that facilitate the dislodgement and or removal of the hair or other fine matter. The exemplary elastomeric ball member may be inflated for shape retention, while allowing for expansion when heated during the drying cycle. An exemplary method for using the laundering aid comprises the steps providing a laundering aid comprising a brush-like or abrasive outer covering adapted to engage and lift adherent matter and introducing the device into a tumble-type dryer with one more fabric articles, then operating the dryer until the adherent matter on the fabric articles has been substantially dislodged and vented from the drying chamber.

Owner:MAGIC FUR BALL

Replaceable liquid crystal display back plate for portable computer

InactiveUS20080019089A1Efficient attractionCasings/cabinets/drawers detailsDetails for portable computersLiquid-crystal displayComputer engineering

A replaceable liquid crystal display back plate for portable computer includes a back plate forming part of a housing of a liquid crystal display of a portable computer and being provided on an outer surface with a flat area. The flat area has a pair of outer edges provided at two opposed laterally outer sides of the flat area on the back plate, and a plurality of notches formed on the outer edges. A guide mechanism includes a plurality of L-shaped tabs provided at two laterally inner sides of the replaceable cover plate corresponding to the outer edges formed on the flat area of the back plate. When the replaceable cover plate is vertically downward set in the flat area on the back plate, the L-shaped tabs of the replaceable cover plate pass the notches of the back plate and then the replaceable cover plate is horizontally slid along the outer edges, so that the replaceable cover plate covers on the flat area of the back plate.

Owner:MITAC TECH CORP

Insect trapping unit and insect trap

An insect trapping unit that is provided with an adhesive sheet that includes a fluorescent brightening agent and that can transmit ultraviolet rays, and with a reflective member that reflects ultraviolet rays that have been transmitted through the adhesive sheet. The adhesive sheet is provided with an adhesive surface and with a rear surface that is on the opposite side from the adhesive surface. The reflective member faces the rear surface of the adhesive sheet.

Owner:HOHTO SHOJI

Fly Attractant System with Toxicant-Treated Cords

ActiveUS20130081324A1Efficient attractionEfficient killingInsect catchers and killersPoisonToxicantEngineering

Systems, devices, apparatus and methods of attracting and capturing flies with toxicant treated darkened cords and printed or painted strips on sidewalls of housings. The darkened cords and strips black to confuse flies into believing they are cracks and crevices. Flies feed off the insecticide treated strips and are killed over time. At least one black line over a blue background can simulate a harborage to attract flying insects. At least one black line over a sticky surface card can be used. Geometrical housing shapes can include triangular, pentagon, cylindrical, rectangular, square, cube and / or other geometrical shapes. Housings can be tied off to be suspended. Second housings can be suspended beneath a main housing by attaching strips to the lower suspended housing. The housings can also work in an unassembled state where planar type sheets can be mounted on a wall.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

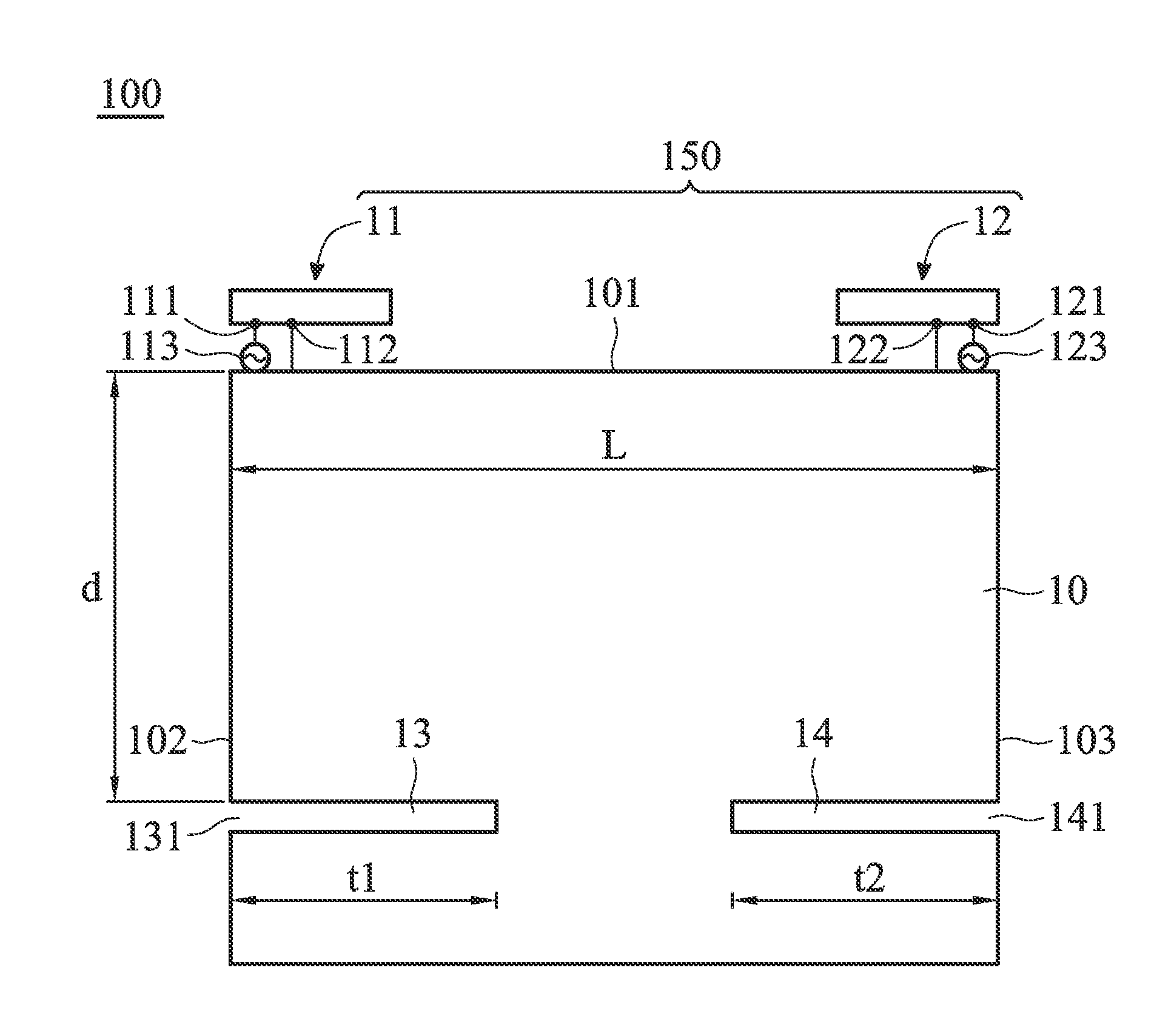

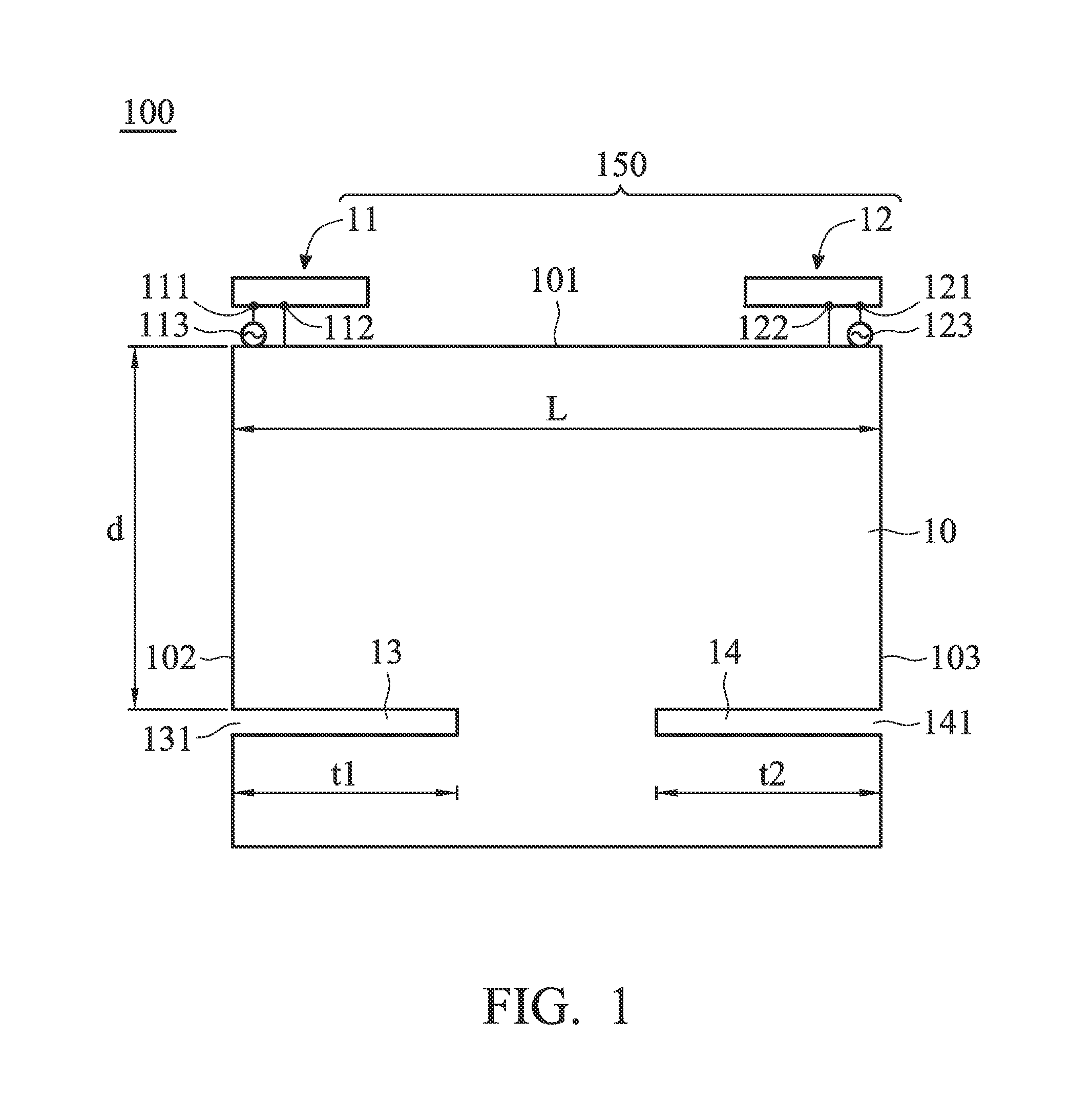

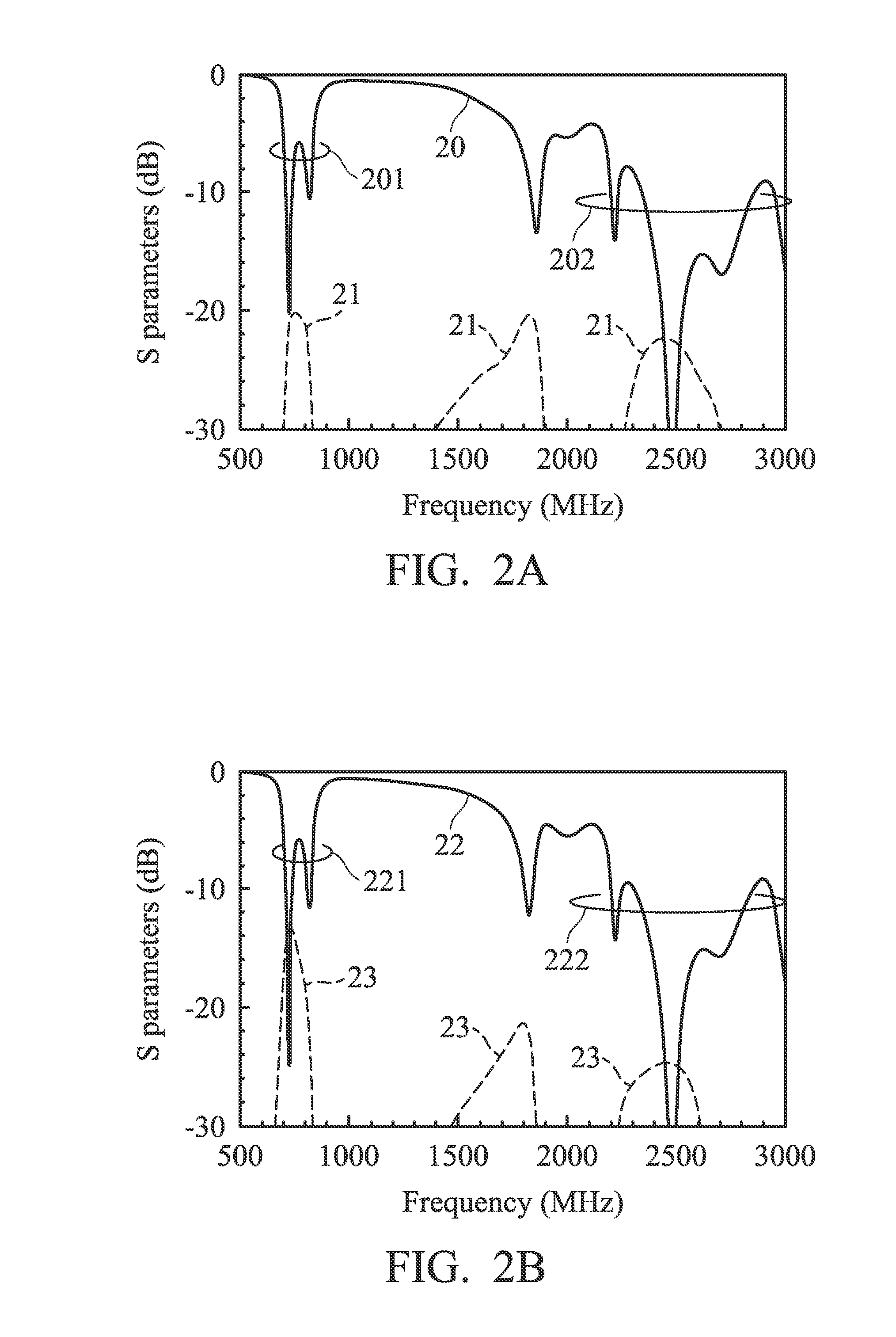

Communication device and MIMO (multi-input multi-output) antenna system therein

InactiveUS20130300625A1High isolationMaintain efficiencyAntenna earthingsIndependent non-interacting antenna combinationsPhysicsFrequency band

A communication device including a ground plane and an antenna system is provided. The antenna system includes at least two antennas, which are both located at a first edge of the ground plane and operate in at least a first band. The ground plane has at least one slit, and an open end of the slit is located at a second edge adjacent to the first edge. The open end of the slit has a distance of at least 0.2 wavelength of a frequency in the first band to the first edge. When the antenna system operates in the first band, the slit can attract excited surface currents on the ground plane, thereby causing weaker surface currents flowing along the first edge of the ground plane. The coupling between the at least two antennas in the antenna system is hence decreased.

Owner:ACER INC

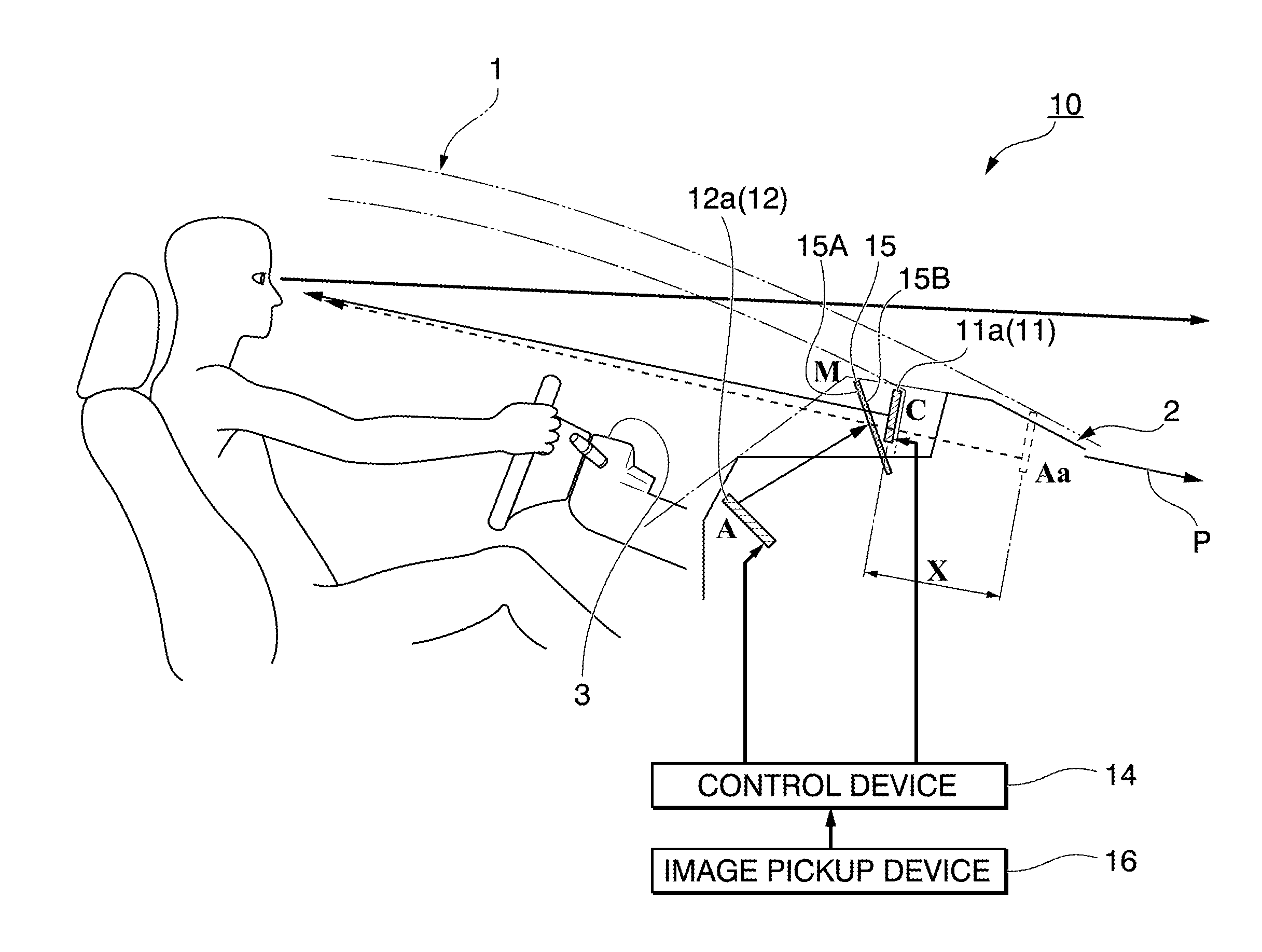

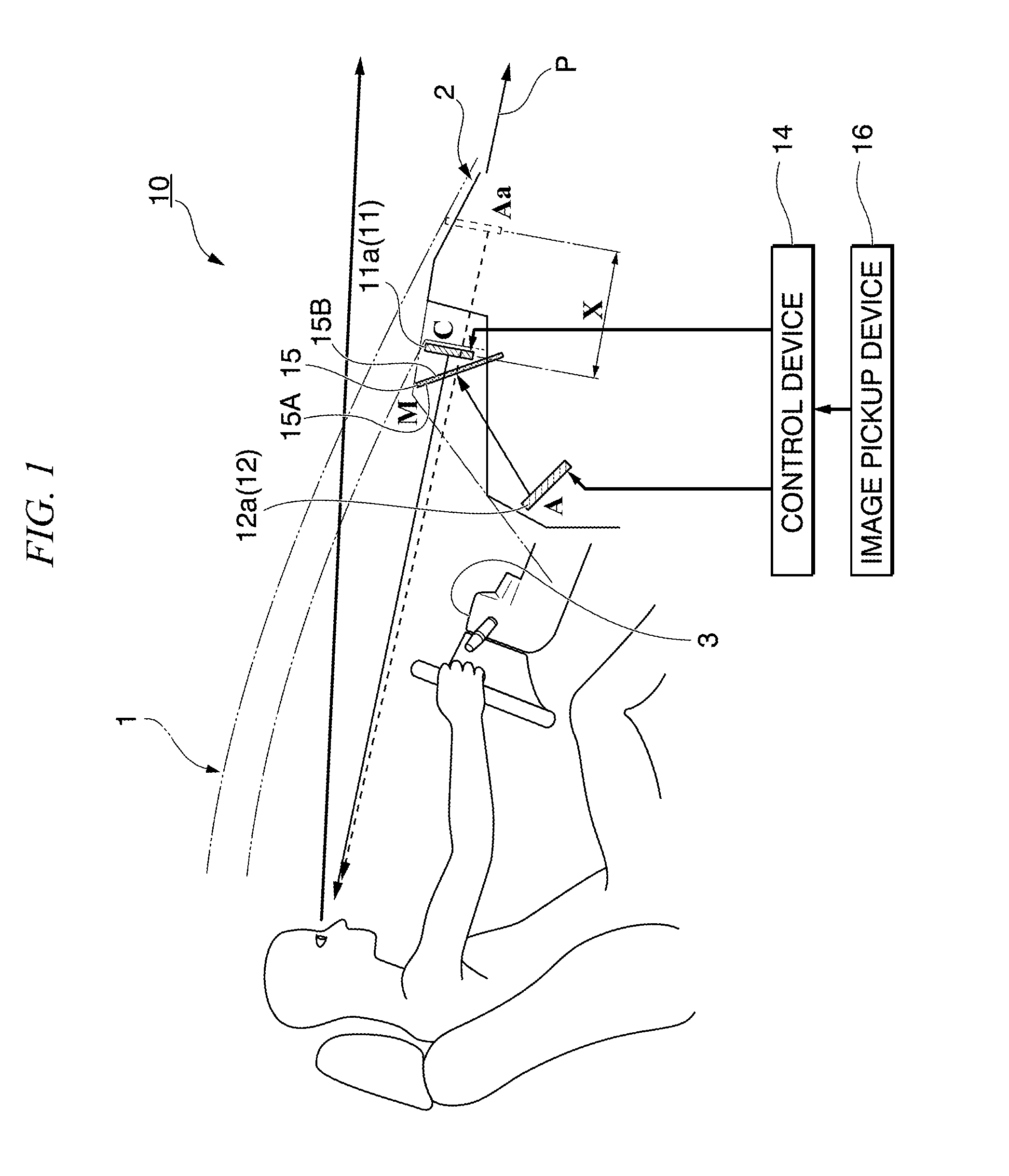

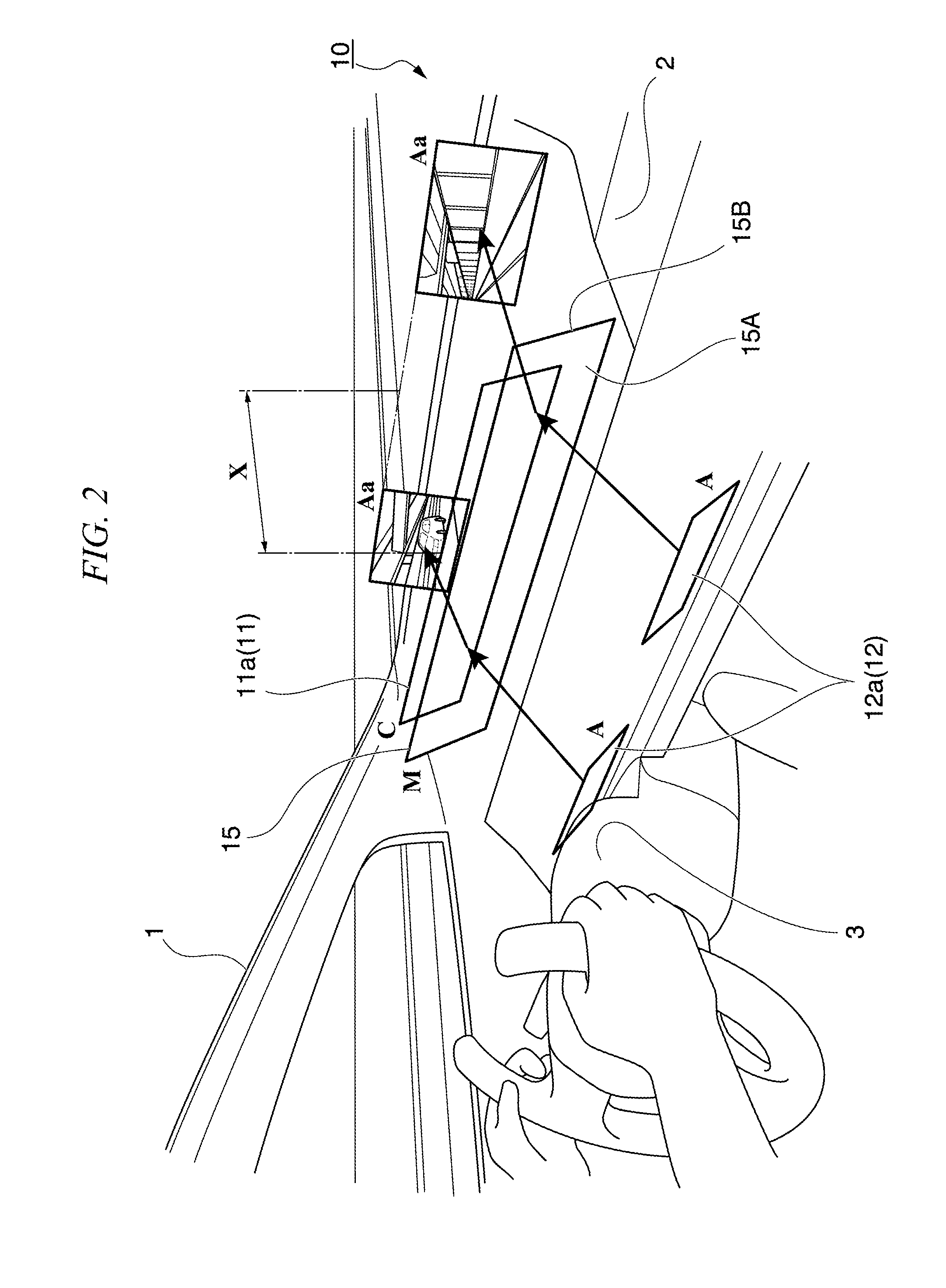

Vehicle display apparatus

ActiveUS20150070157A1Easy to identifyAttract attentionAnti-collision systemsOptical signallingDisplay deviceReal-time computing

A vehicle display apparatus includes a plurality of display devices that superpose and display a plurality of pieces of information by displaying information at each position of a plurality of different positions in a predetermined direction towards the front of a vehicle that can be viewed by a driver of the vehicle, and includes as at least one of the plurality of display devices, an attention attracting display device that displays as the information, attention attracting information on the nearest side to the driver in the predetermined direction.

Owner:HONDA MOTOR CO LTD

Microbe-mediated method for attracting mosquitoes and apparatus thereof

The present invention provides an apparatus and method for attracting mosquitoes by using the microbe product as the mosquito bait as well as simulating the human emanated odors. A bait-releasing unit / means is included to enhance the release of the mosquito bait. A well-controlled heating assembly can be used to generate a suitable thermal gradient for simulating body temperature and evaporating the bait. The microbe product comprises at least a sterilized supernatant of a bacterial incubation product. The apparatus of this invention can further include electrocution grids or insecticide webs to destroy attracted mosquitoes.

Owner:BIOWARE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com