Dusting head for floor

A technology for cleaning head, floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

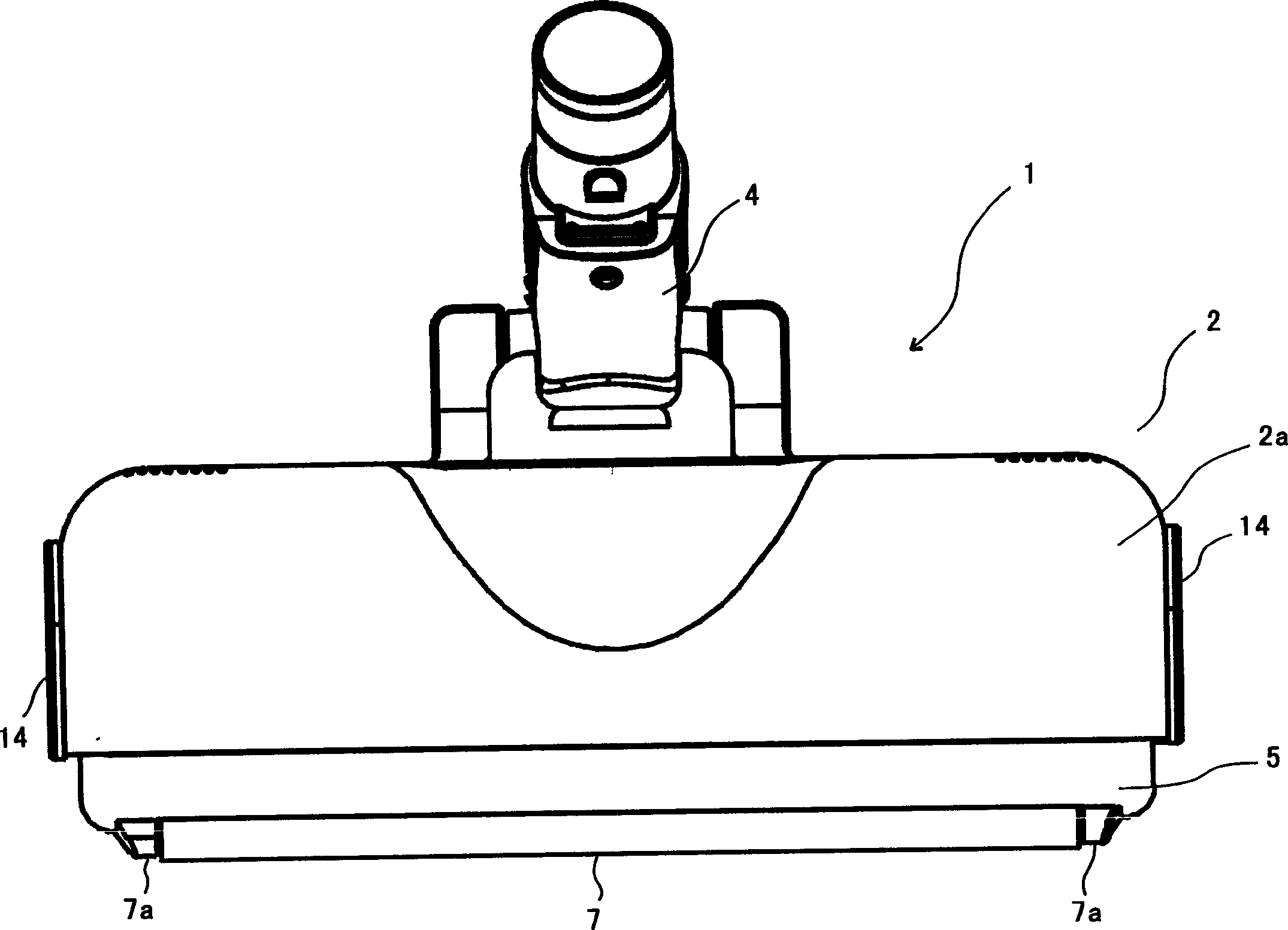

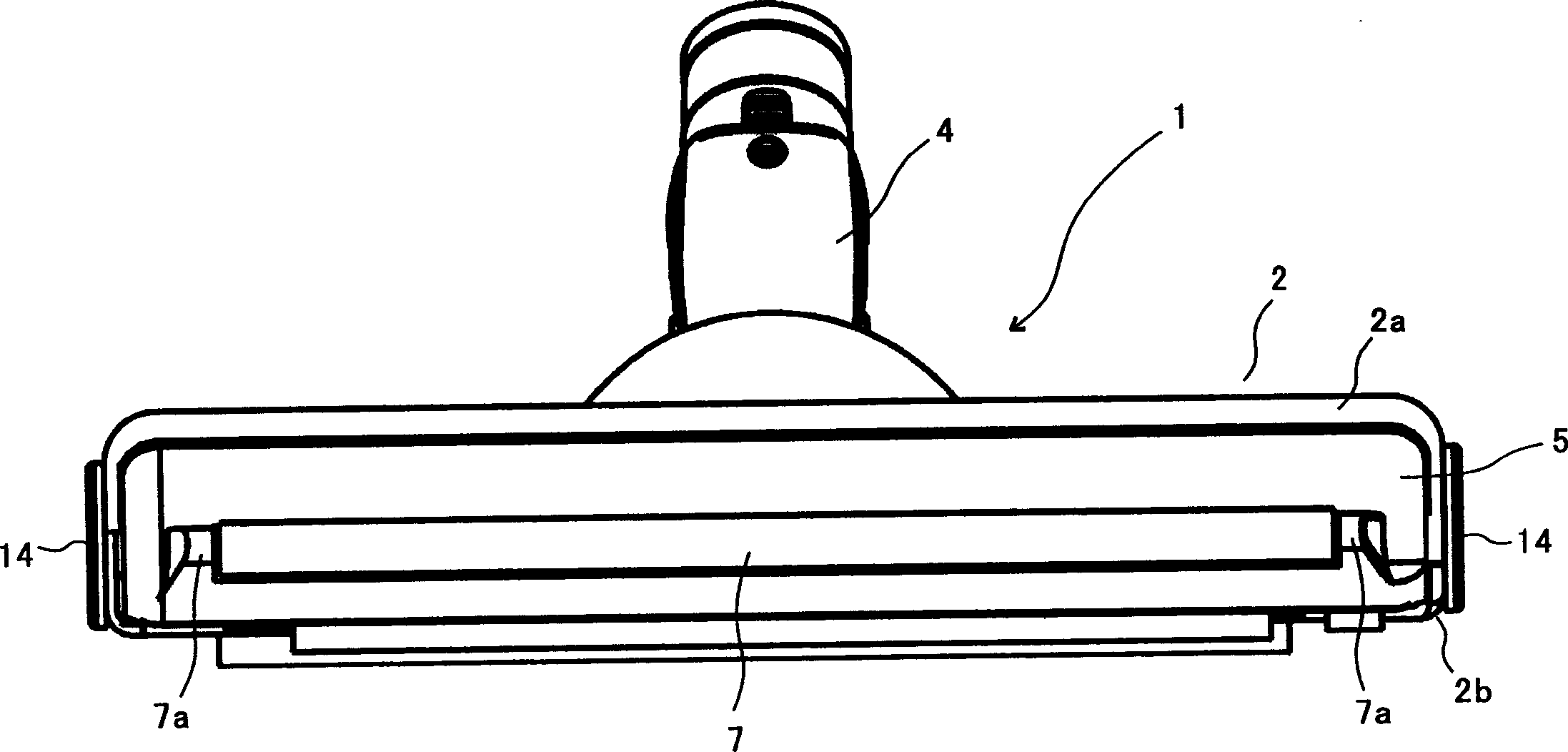

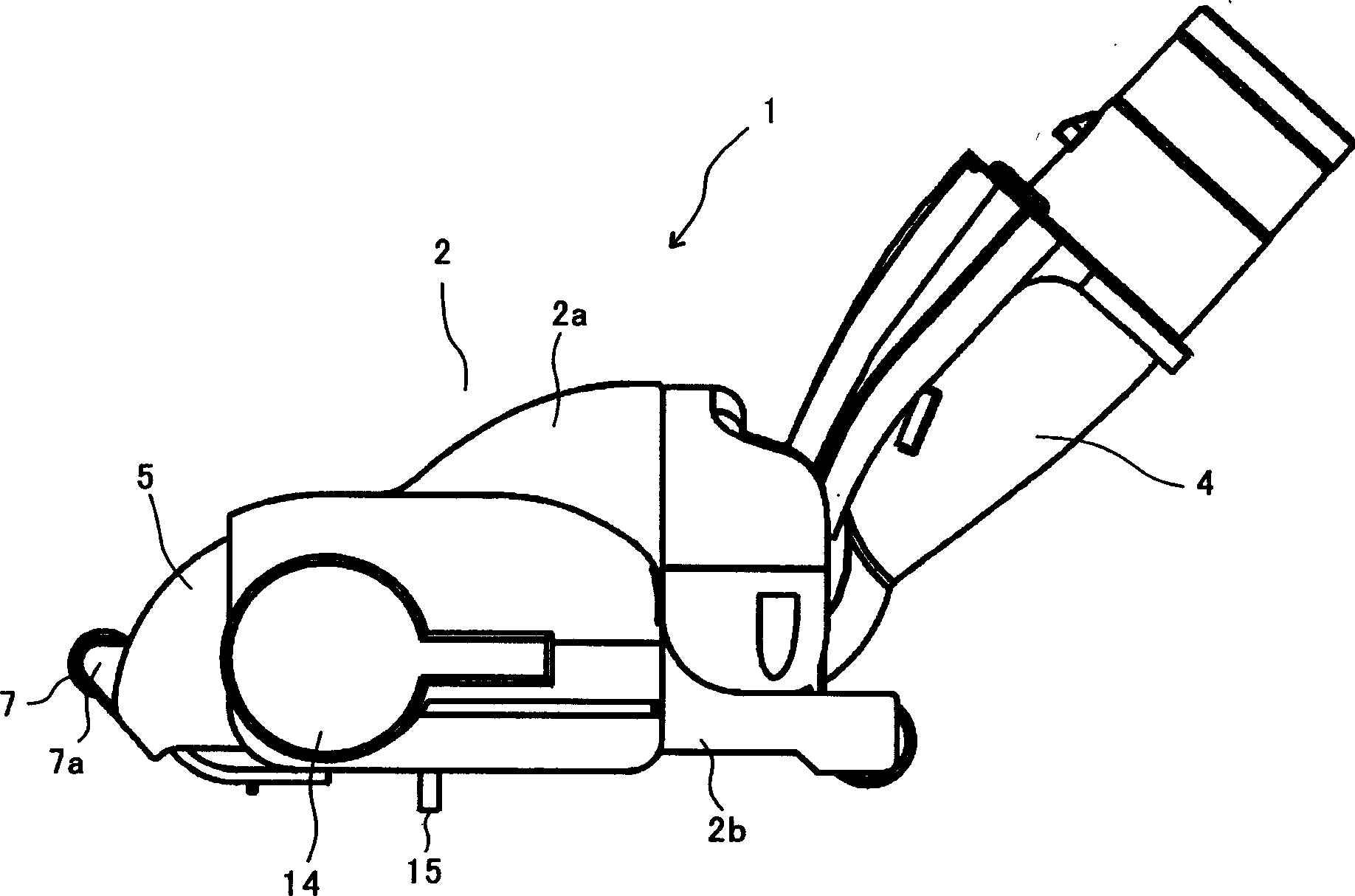

[0041] Figure 1 to Figure 10 It is a figure showing the structure and function of one embodiment of the floor cleaning head of the present invention.

[0042] Figure 1 to Figure 10 The shown floor cleaning head 1 is composed of a horizontally long cleaning head main body box 2, a rotating brush 3, an elbow joint 4 and a cover 5, and the cleaning head main body box 2 is composed of an upper case 2a and a lower case 2b, and A suction port 6 with a wide range of openings is formed from the bottom to the front, and the rotating brush 3 is rotatably supported on both ends in the longitudinal direction of the main body pipe 2 of the cleaning head through the bearing portion. The elbow joint 4 communicates with the suction port 6 At the same time, it can be rotatably installed on the rear side of the dust-absorbing head main body box 2 up and down, and the cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com