Electromagnetic ultrasonic probe

An electromagnetic ultrasonic and magnet technology, which is applied in the field of industrial measurement, can solve the problems of large volume, large sliding resistance, and affect the detection accuracy of the electromagnetic ultrasonic probe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

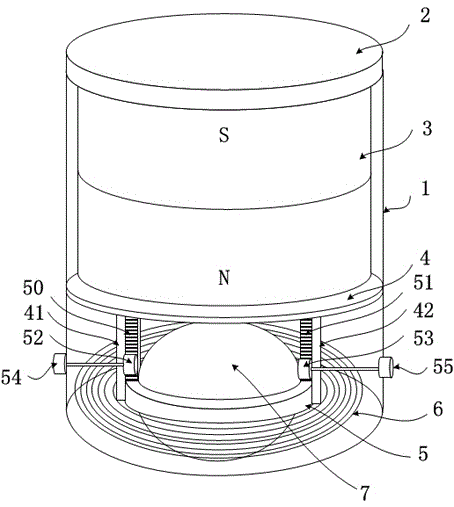

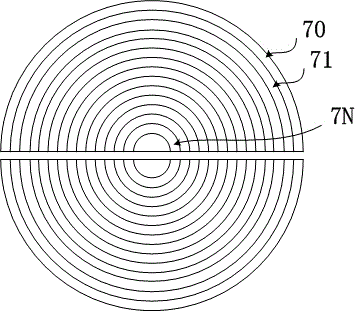

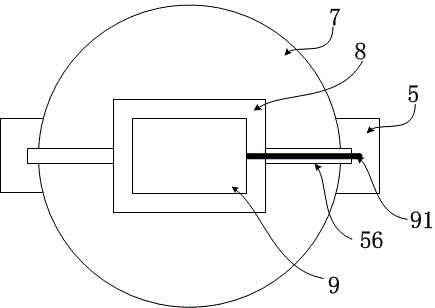

[0022] Such as figure 1 The shown electromagnetic ultrasonic probe comprises a shell 1, a signal processing module 2 is installed on the upper end of the shell 1, a magnet 3 is arranged inside, a coil 6 is arranged at the lower part of the magnet 3, and a ball mechanism is arranged in the center space of the coil 6, and the ball mechanism includes a ball 7. The constraining ring 5 and the ball 7 are limited to roll in the constraining ring 5, and the fixing columns 41 and 42 are fixed at the lower part of the partition 4; If no height adjustment part is added, the length of the ball protruding from the lower part of the probe is the lifting distance between the coil 6 and the workpiece to be measured. But the optimized design that present embodiment proposes is to have vertical rack 50 and 51 on confinement ring 5, and vertical rack 50 and 51 are respectively slidingly connected with fixed column 41 and 42, and gear 52 and 53 are connected with vertical rack 50 and 51 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com