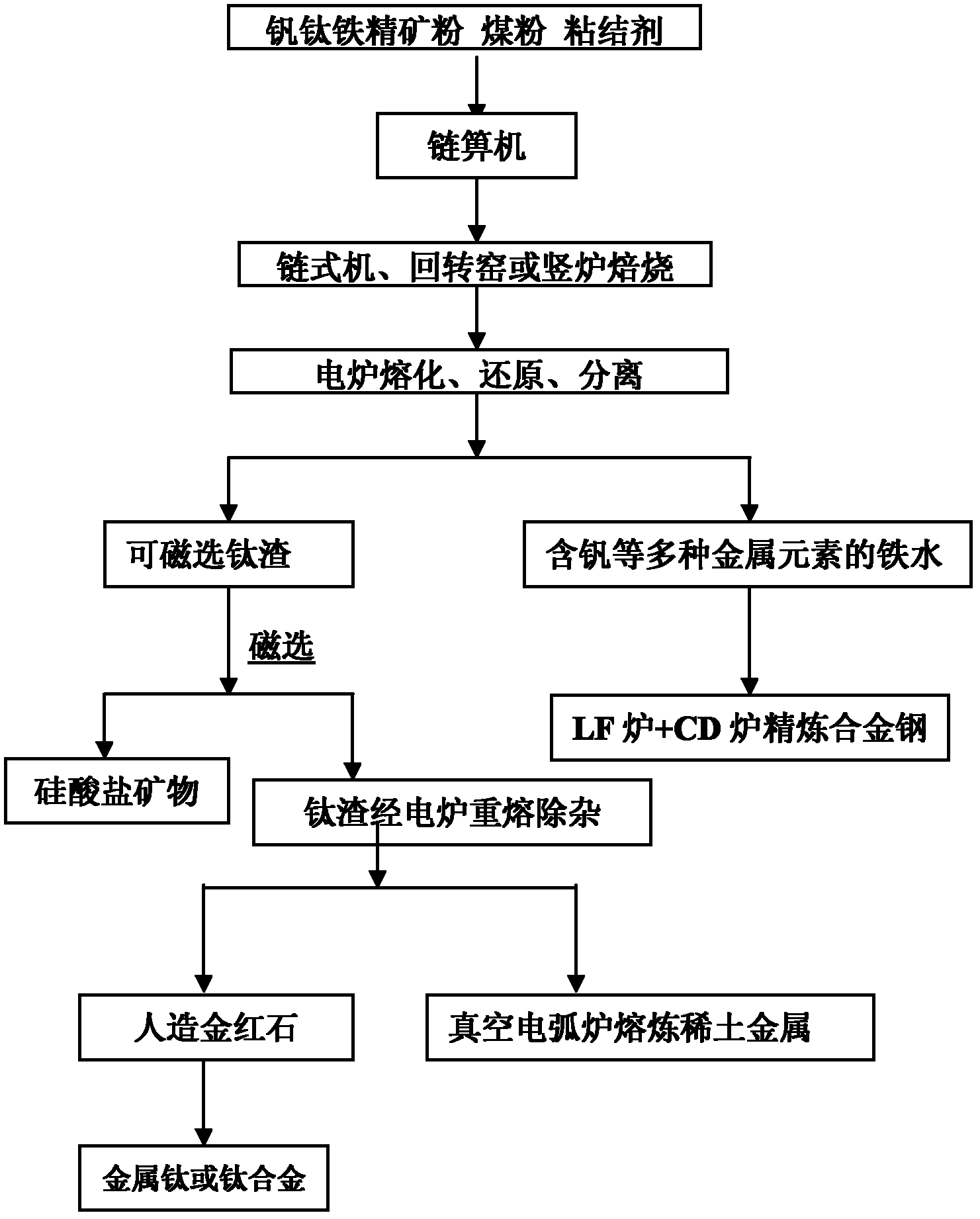

Method for selecting and smelting titanium from vanadium titanomagnetite at low temperature

A technology of vanadium titanomagnetite and ilmenite, applied in the field of metallurgy, can solve the problems of difficult direct reduction, long time and high reduction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

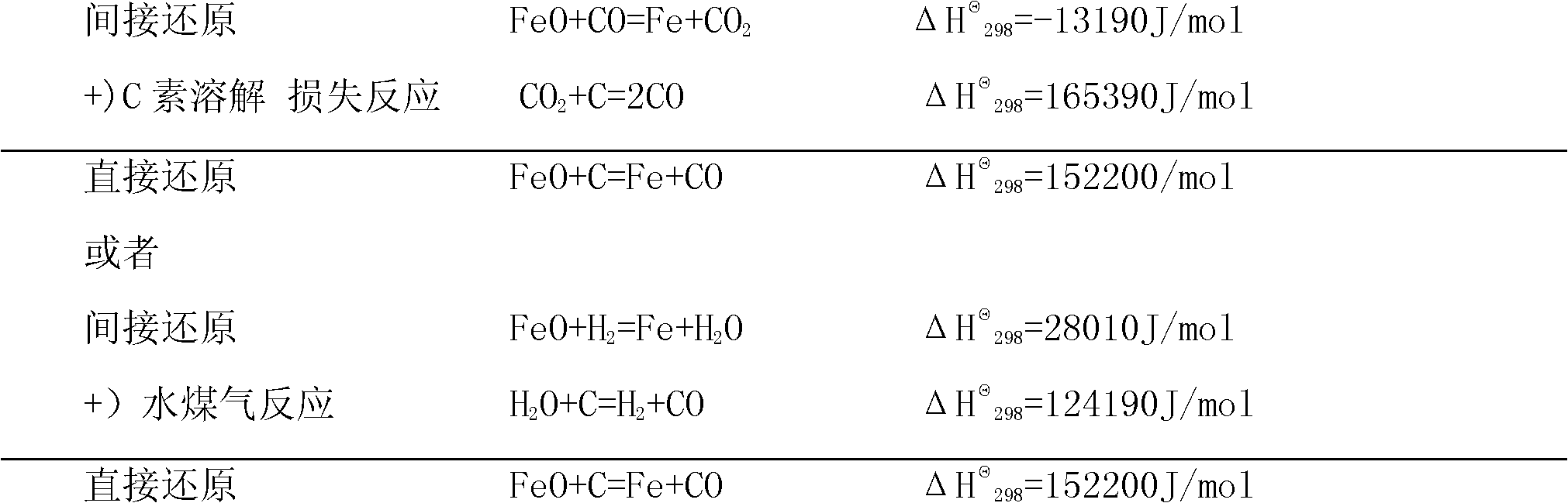

Method used

Image

Examples

Embodiment 1

[0091] A. Mix vanadium-titanium iron concentrate with anthracite and binder (bentonite) to form pellets, and oxidize and roast at 800-900 degrees in a rotary kiln to obtain pellets.

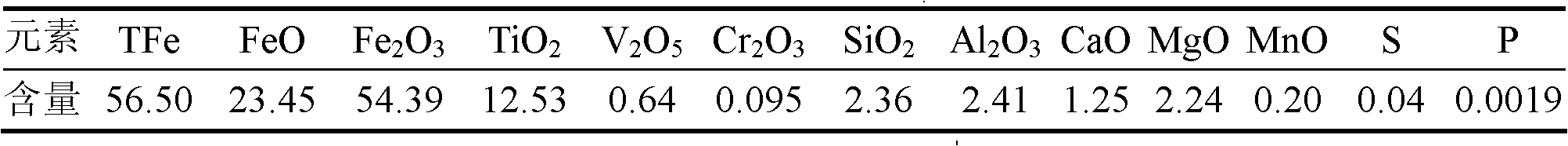

[0092] Among them, the chemical composition of the vanadium-titanium-iron concentrate is shown in Table 1, the anthracite fixed carbon is more than 85%, the sulfur is less than 0.6%, the ash content is less than 10%, and the volatile matter is less than 5%.

[0093] Table 1 Main chemical composition of vanadium-titanium iron concentrate / %

[0094]

[0095] In addition, there are symbiotic associated elements such as titanium (TiO 2 ), iron (TFe), vanadium (V 2 o 5 ), chromium (Cr 2 o 3 ), manganese (Mn), copper (Cu), nickel (Ni), cobalt (Co), scandium (Sc 2 o 3 ), gallium (Ga), selenium (Se), platinum (Pt), sulfur (S), zinc (Zn), arsenic (As), tellurium (Te), ruthenium (Ru), rhodium (Rn), palladium (Pa ), silver (Ag), niobium (Nb), tantalum (Ta), bismuth (Bi), osmium (Os), iridium (Ir),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com