4A type zeolite molecular sieve and its preparation method

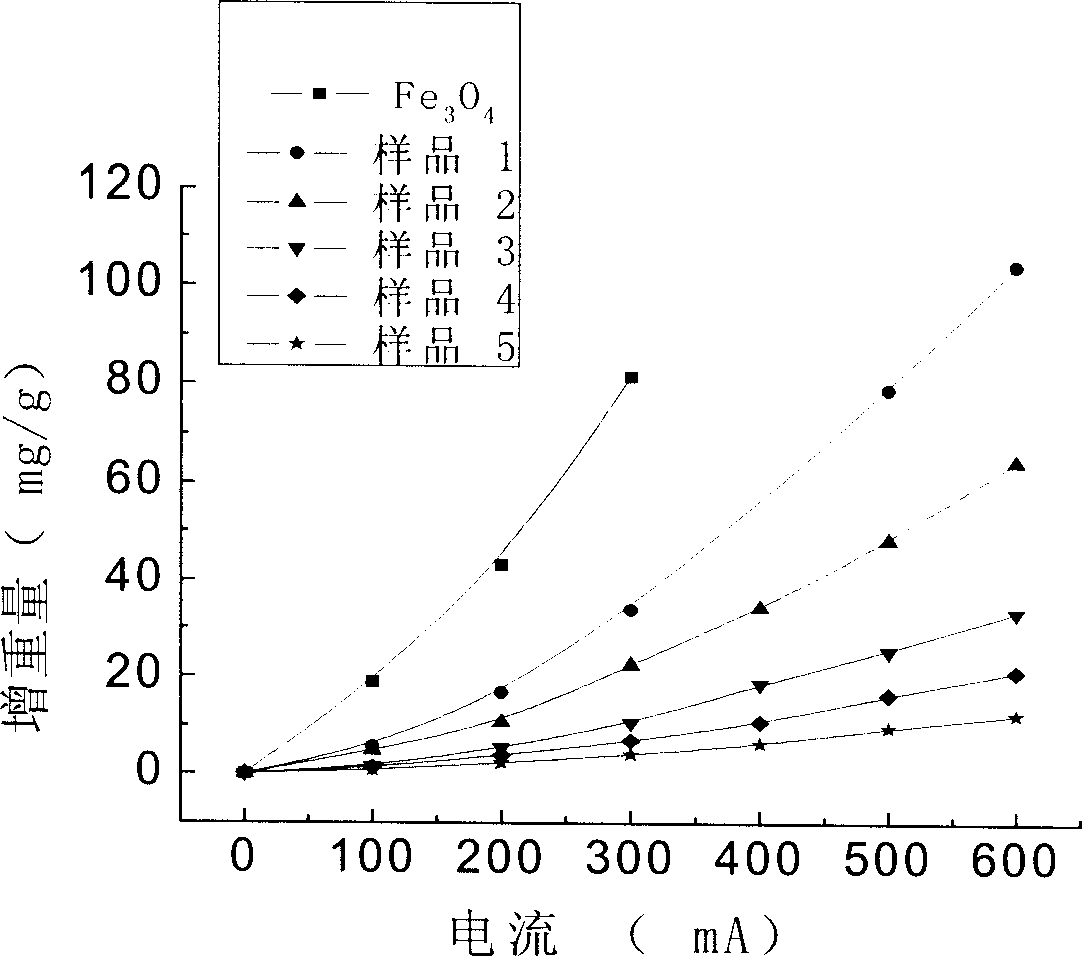

A zeolite molecular sieve, iron ion technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problem of reducing the magnetic properties of zeolite molecular sieve, and achieve the effects of long retention time, uniform particles, and good crystal shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

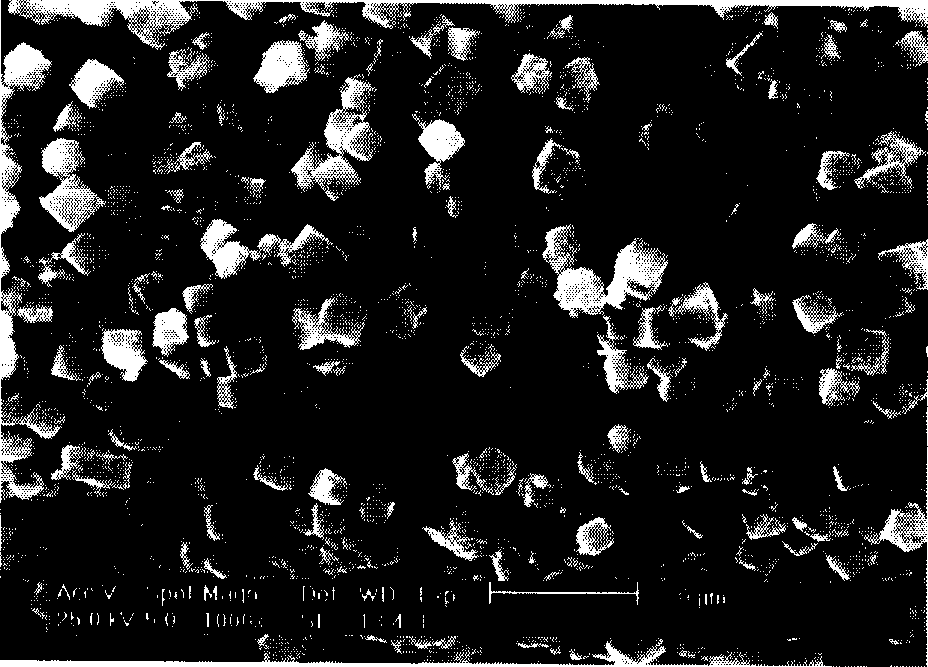

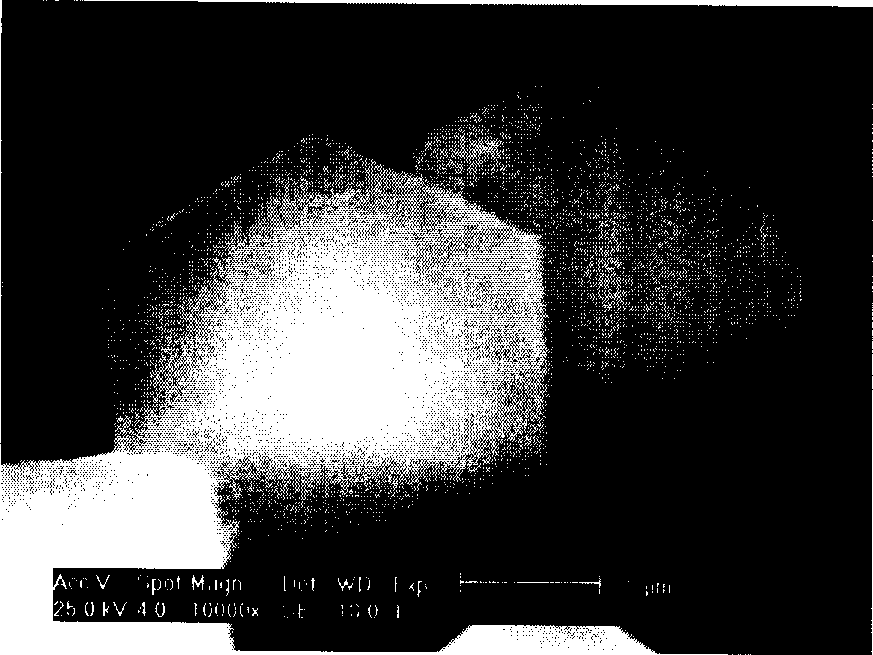

[0033] (1) Synthesis of 4A type zeolite molecular sieve: industrial grade water glass with a modulus of 3.2, NaAlO 2 , NaOH and deionized water are the raw materials for synthesizing 4A zeolite molecular sieves. First, add deionized water, NaOH and NaAlO into a three-necked flask placed in a constant temperature water bath at 40°C 2 , after fully stirring, mixing and dissolving, quickly add water glass, the addition amount is based on the following mass ratio: water glass: NaAlO 2 : NaOH: deionized water = 11:10:8:200, mix the glue for 30-40 minutes to make it into a uniform white gel, then adjust the temperature to 95°C within 40-60 minutes, stop stirring, and let stand Constant temperature crystallization for 6 to 8 hours. After crystallization, filter and separate the obtained crystalline product, wash with deionized water until neutral, and finally dry at 110°C to obtain white powder 4A zeolite molecular sieve. figure 2 It is a low magnification scanning electron microsc...

Embodiment 2

[0037] (1) Synthesis of 4A-type zeolite molecular sieve: the specific preparation process is the same as step (1) in Example 1.

[0038] (2) Preparation of iron ion solution and ammonia solution: the specific preparation process is the same as step (2) in Example 1.

[0039] (3) Magnetically modified 4A zeolite molecular sieve by chemical precipitation method: take 200 mL of the iron ion solution prepared in step (2) and place it in a three-neck flask with constant temperature water bath temperature control, and add it to step (1) at a temperature of 40 ° C to synthesize 3g of 4A-type zeolite molecular sieve white powder, while stirring the feed liquid in the there-necked flask, slowly add 150mL of dilute ammonia solution prepared in step (2) dropwise, so that the slowly generated magnetic iron-containing oxide is settled and loaded on the 4A-type zeolite molecular sieve Surface, after the reaction is completed, filter the solid phase product, wash with deionized water until n...

Embodiment 3

[0041] (1) Synthesis of 4A-type zeolite molecular sieve: the specific preparation process is the same as step (1) in Example 1.

[0042] (2) Preparation of iron ion solution and ammonia solution: the specific preparation process is the same as step (2) in Example 1.

[0043] (3) Magnetically modified 4A zeolite molecular sieve by chemical precipitation method: Take 200mL of the iron ion solution prepared in step (2) and place it in a three-neck flask with constant temperature water bath temperature control, and add it to step (1) at a temperature of 50°C to synthesize 4g of the 4A type zeolite molecular sieve white powder, while stirring the feed liquid in the there-necked flask, slowly add 150mL of the dilute ammonia solution prepared in step (2) dropwise, so that the slowly generated magnetic iron-containing oxide is settled and loaded on the 4A type zeolite molecular sieve On the surface, after the reaction is completed, the solid phase product is filtered, washed with deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com