Energy-saving high-efficiency servo drive paper box printing mechanism

A servo-driven, carton printing technology, applied to printing machines, rotary printing machines, printing, etc., can solve problems such as inability to reduce energy consumption, inability to achieve non-stop plate change, and inability to effectively improve work efficiency and machine utilization. , to achieve the effect of improving work efficiency and machine utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

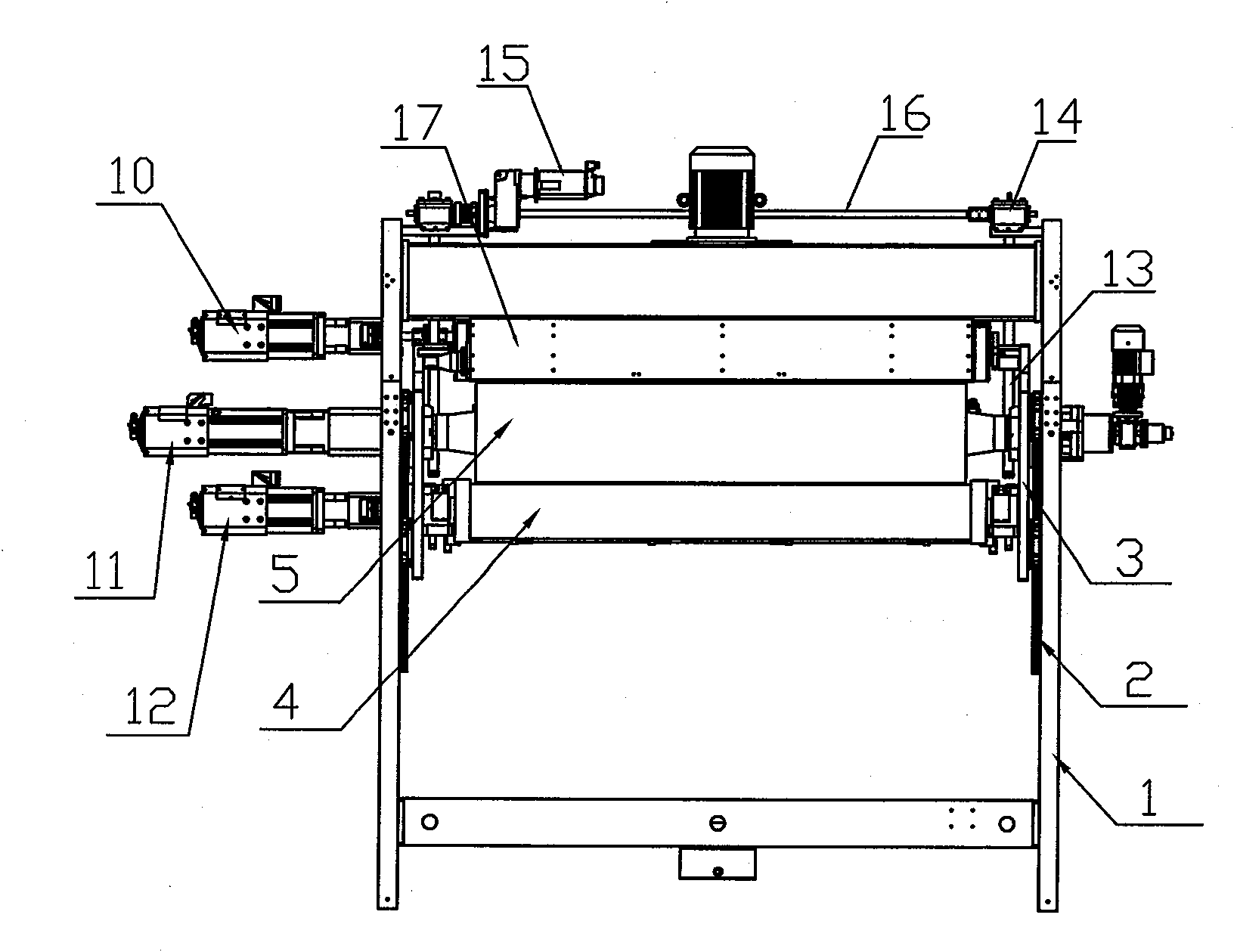

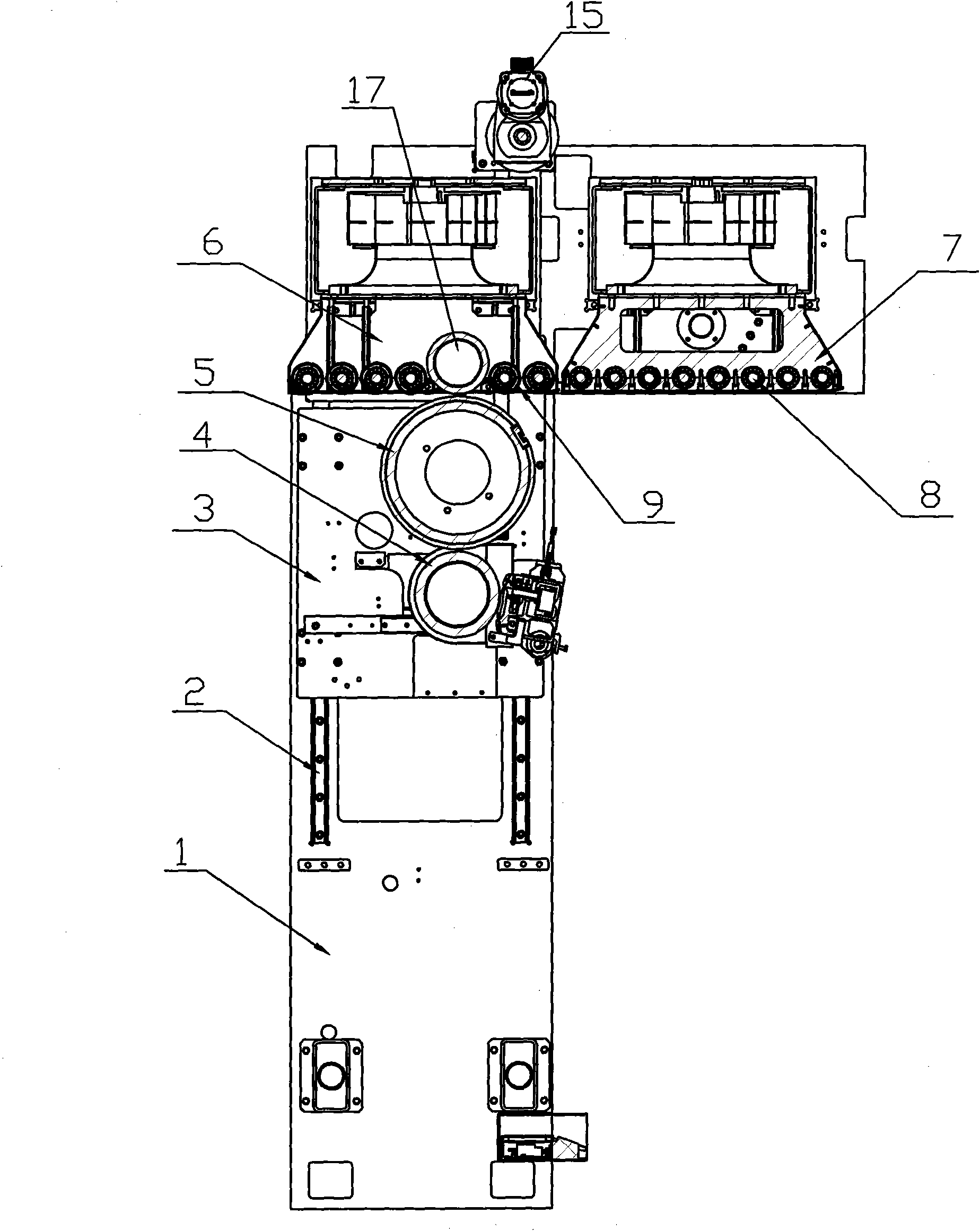

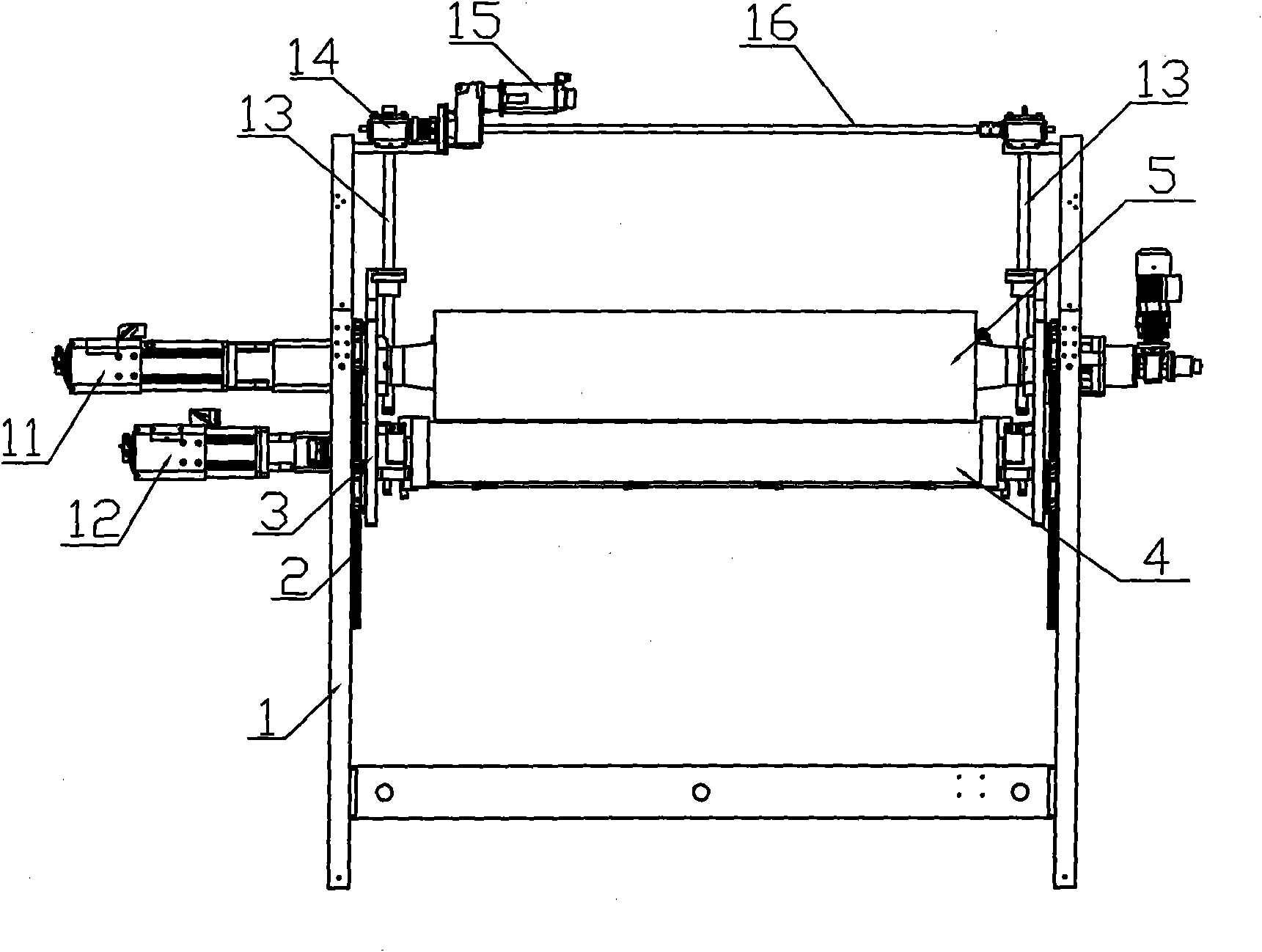

[0011] See figure 1 ~As shown in Figure 6, an energy-saving and high-efficiency servo-driven carton printing mechanism is composed of several printing units, each printing unit includes a frame with left and right side panels 1, linear guide rail pairs 2, left and right inner mounting panels 3, Inking anilox roller 4, printing plate roller 5, printing vacuum paper feeding transmission box 6, transitional vacuum paper feeding transmission box 7, paper feeding wheel shaft 8, paper feeding wheel 9, paper feeding transmission servo drive motor 10, printing plate roller servo drive Motor 11, inking anilox roller servo drive motor 12, screw mandrel 13, screw lifter 14, reduction motor 15, transmission shaft 16. The left and right inner mounting plates 3 are respectively installed on the left and right side plates 1 of the frame by sliding up and down through the linear guide pair 2; the printing plate roller 5 and the ink anilox roller 4 are respectively installed on the left and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com