Thick-bed sintering feed surface-spraying covering agent and spraying method thereof

A technology of covering agent and thick material layer is applied in the field of spraying covering agent and spraying on the sintered material surface of thick material layer, which can solve the problem of uneven heat, and achieve the effects of reducing carbon content, improving strength and reducing thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

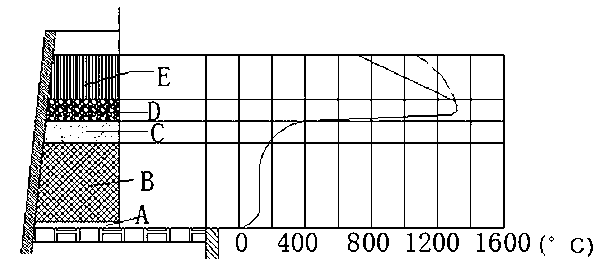

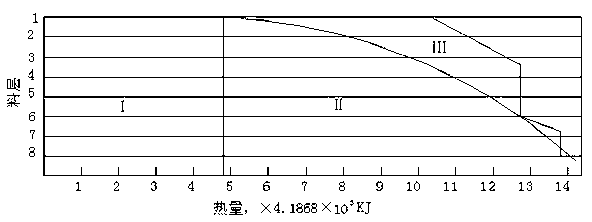

[0023] Embodiments 1 to 3: The specific preparation steps of spraying the covering agent on the sintered material surface of the thick material layer are as follows:

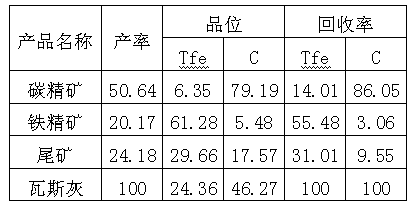

[0024] (1) Analysis of blast furnace gas ash TFe, C and analysis of iron concentrate, carbon concentrate and tailings after screening, the results are shown in Table 1.

[0025] Table 1: Iron and carbon composition of each ore

[0026]

[0027] It can be seen from Table 1 that after beneficiation of gas ash, iron concentrate with iron grade of 61.28% and recovery rate of 55.48% can be obtained, and carbon concentrate with carbon content of 79.19% and recovery rate of 86.05%. Table 2 is the particle size composition table of the gas ash in the embodiment. It can be seen from Table 2 that the particle size of the gas ash is relatively coarse. After mineral processing, the coarse particles contain high carbon, and the fine particles contain high iron; this embodiment selects carbon fine particles with particle s...

Embodiment 4

[0033] Embodiment 4: The covering agent is sprayed on the sintered material surface of the thick material layer using the following raw material ratio and preparation method.

[0034] Raw material weight percentage distribution: carbon content 45wt%, carbon concentrate ≥100 mesh 70%, sintered ore with a particle size 1-3mm 22%, and expanded beads with a particle size 1-2mm 8%.

[0035] The preparation method is the same as in Examples 1-3.

[0036] The average specific gravity of the covering agent that present embodiment obtains is 0.704t / m 3 .

Embodiment 5

[0037] Embodiment 5: The covering agent is sprayed on the sintered material surface of the thick material layer using the following raw material ratio and preparation method.

[0038] Raw material weight distribution ratio: carbon content 80wt%, carbon concentrate ≥100 mesh 55%, sintered ore with a particle size 1-3mm 30%, expanded beads 15%.

[0039] The preparation method is the same as in Examples 1-3.

[0040] The average specific gravity of the covering agent that present embodiment obtains is 0.77t / m 3 .

[0041] The spraying method of spraying the covering agent on the sintered material surface of the thick material layer is as follows:

[0042] (1) Use a concrete wet spraying machine, model PZS3000, to spray the covering agent into water, and control the mixing moisture to be equal to that of the mixing material, 6.5-7.5wt% moisture.

[0043] (2) Determine the spray flow rate according to the thickness of the spray covering agent:

[0044] The characteristics of he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com