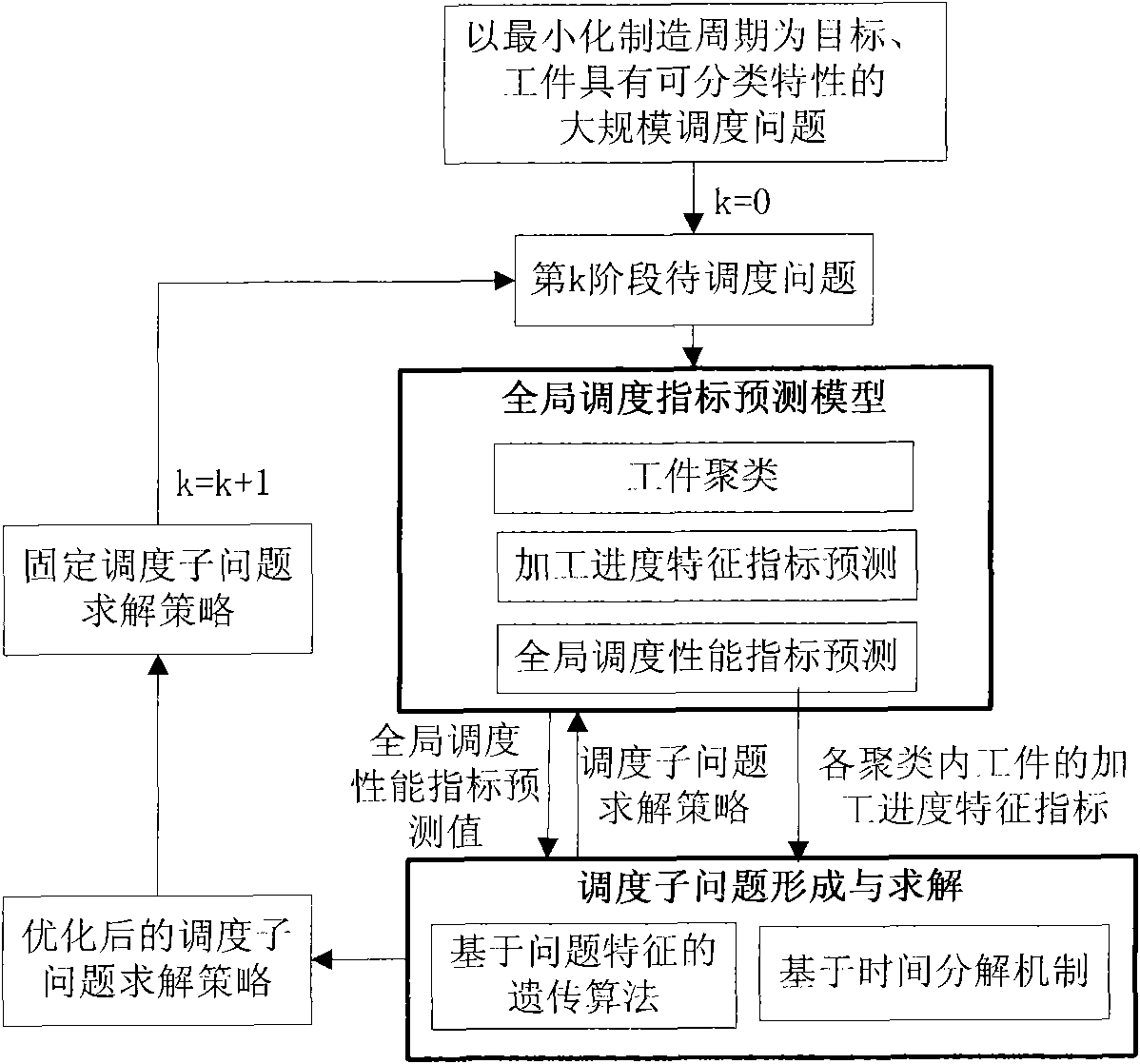

Dispatching method based on iterative decomposition and flow relaxation in large-scale production process

A scheduling method and production process technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of complex production constraints, unsatisfactory application effects, and large number of operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

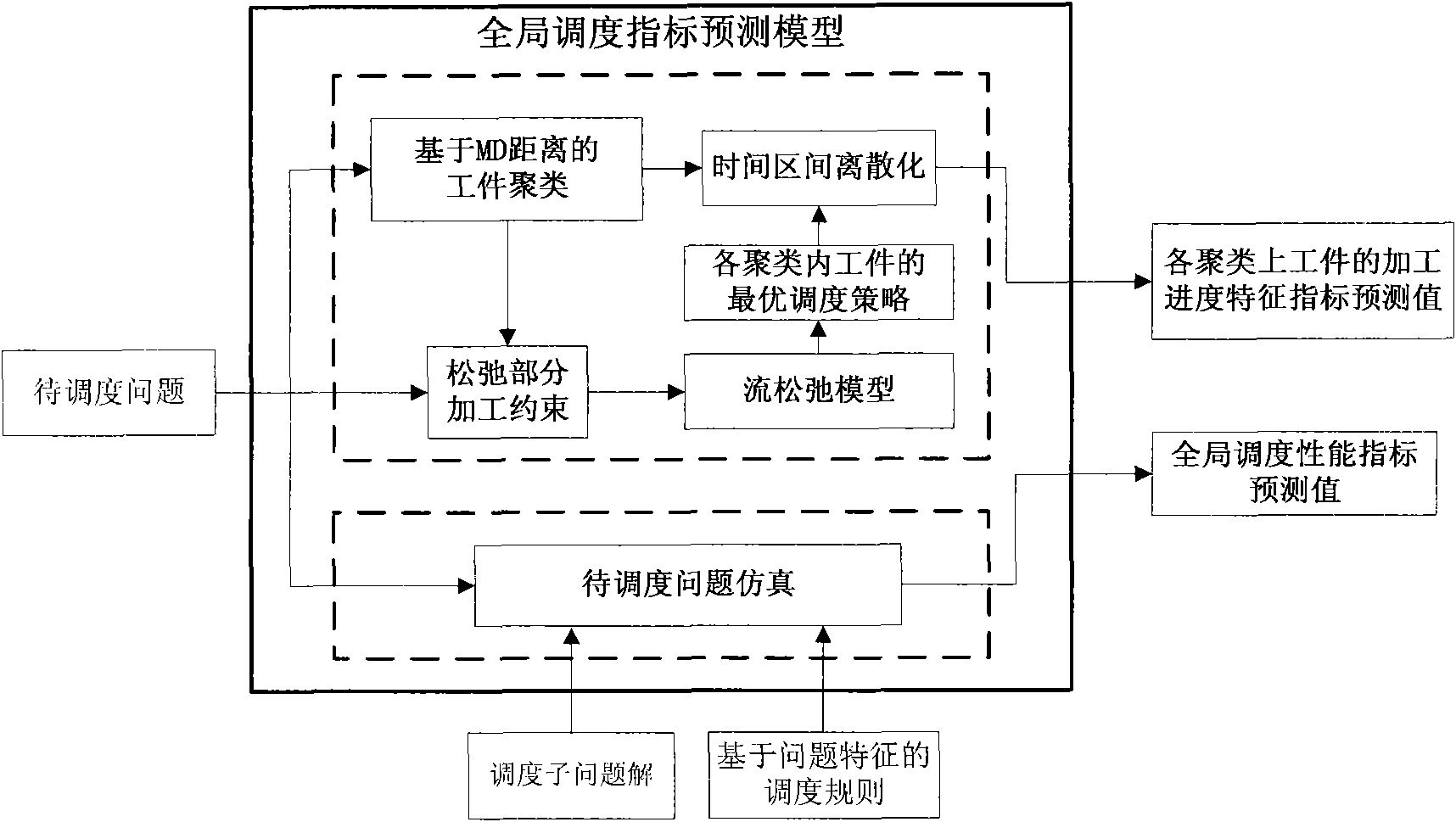

Method used

Image

Examples

Embodiment Construction

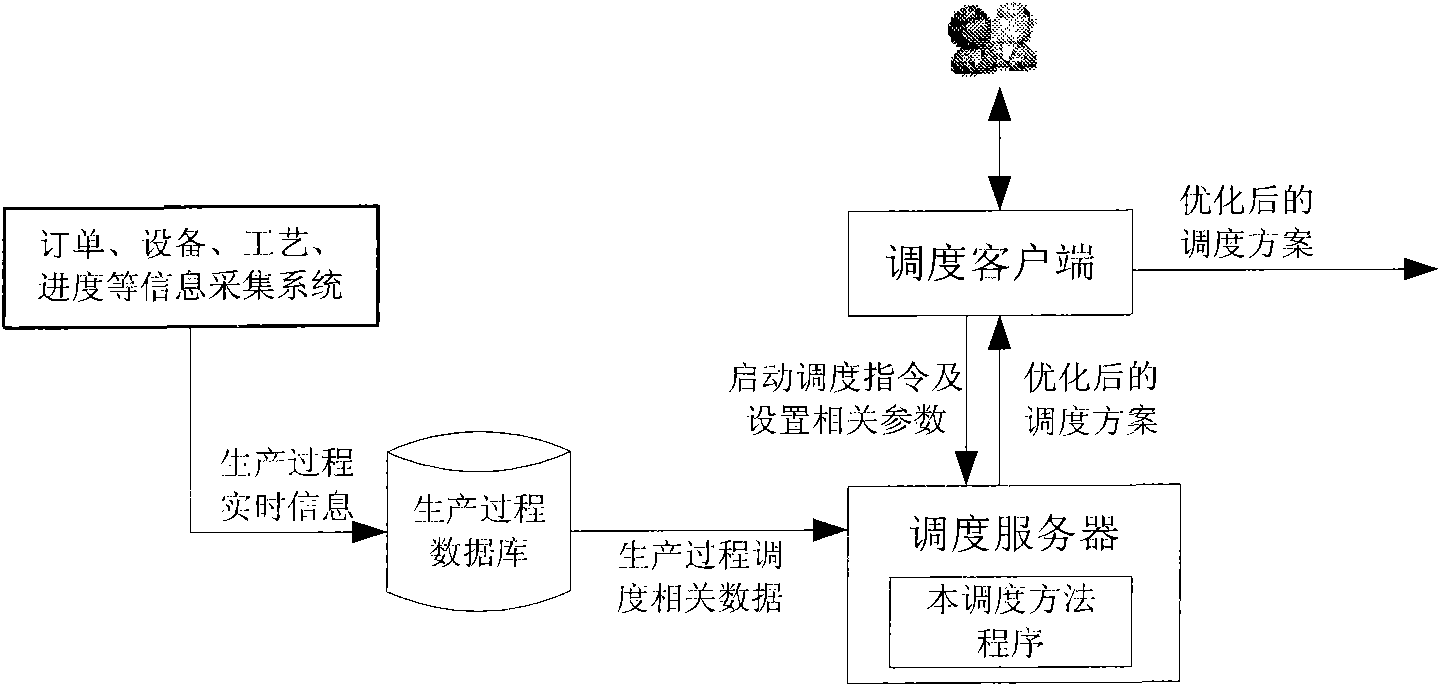

[0100] The scheduling method based on iterative decomposition and flow relaxation disclosed in the present invention depends on the related data collection system, and is realized by the scheduling system client and the scheduling server. The schematic diagram of software and hardware architecture applying the present invention in the large-scale production process scheduling of actual manufacturing enterprises is as follows: image 3 As shown, the embodiments of the present invention are as follows.

[0101] Step (1): collect the scheduling-related information such as the number of workpieces, the number of machine groups, the number of machines in each machine group, the process path of each workpiece, and the processing time of each operation, and store them in the scheduling database;

[0102] Step (2): Read scheduling-related information such as the number of workpieces, the number of machine groups, the number of machines in each machine group, the process path of each w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com