Patents

Literature

69results about How to "Improve machine utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Finite capacity scheduling using job prioritization and machine selection

InactiveUS20050154625A1Improve machine utilizationResourcesSpecial data processing applicationsMachine selectionMachine utilization

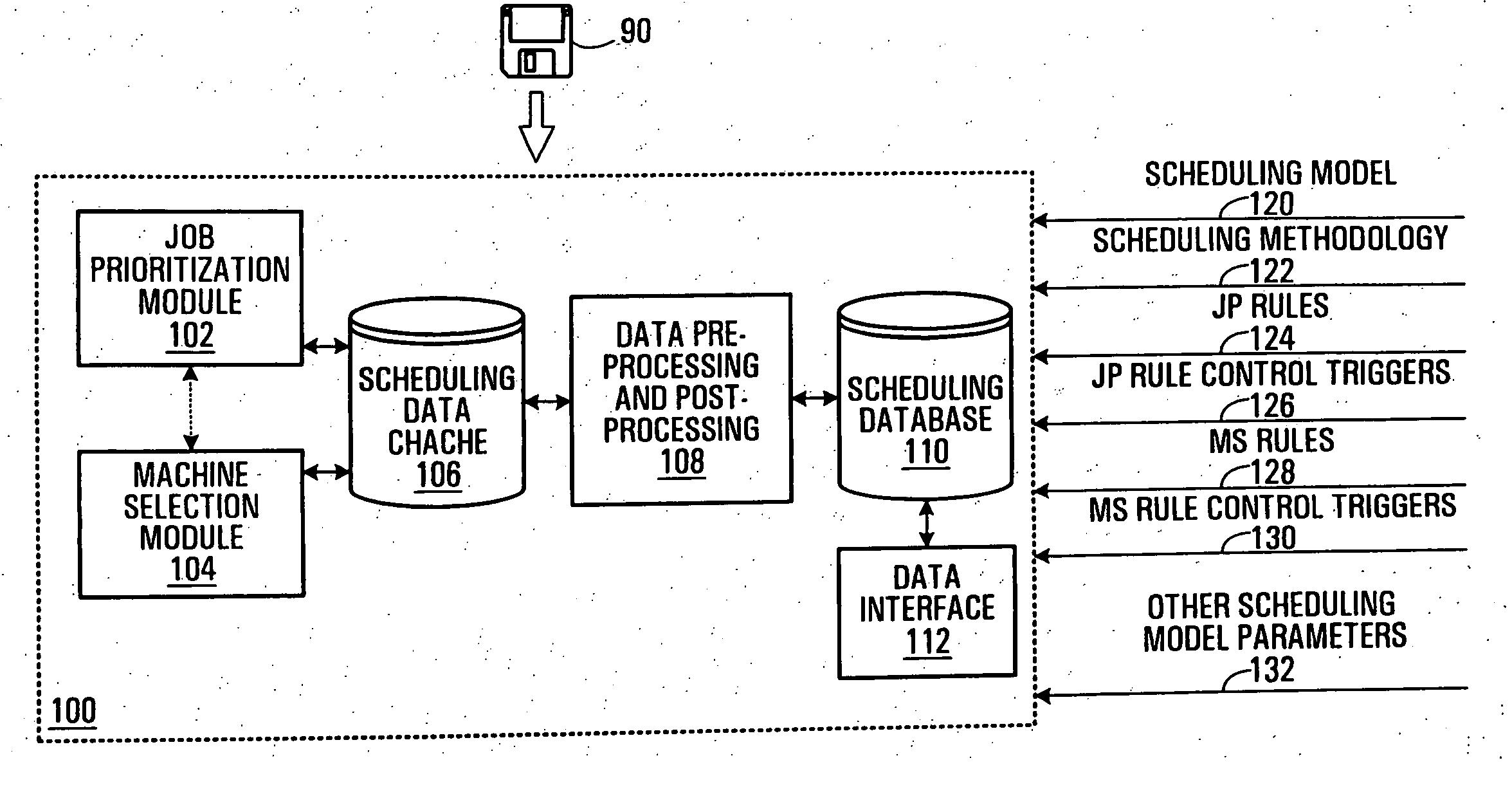

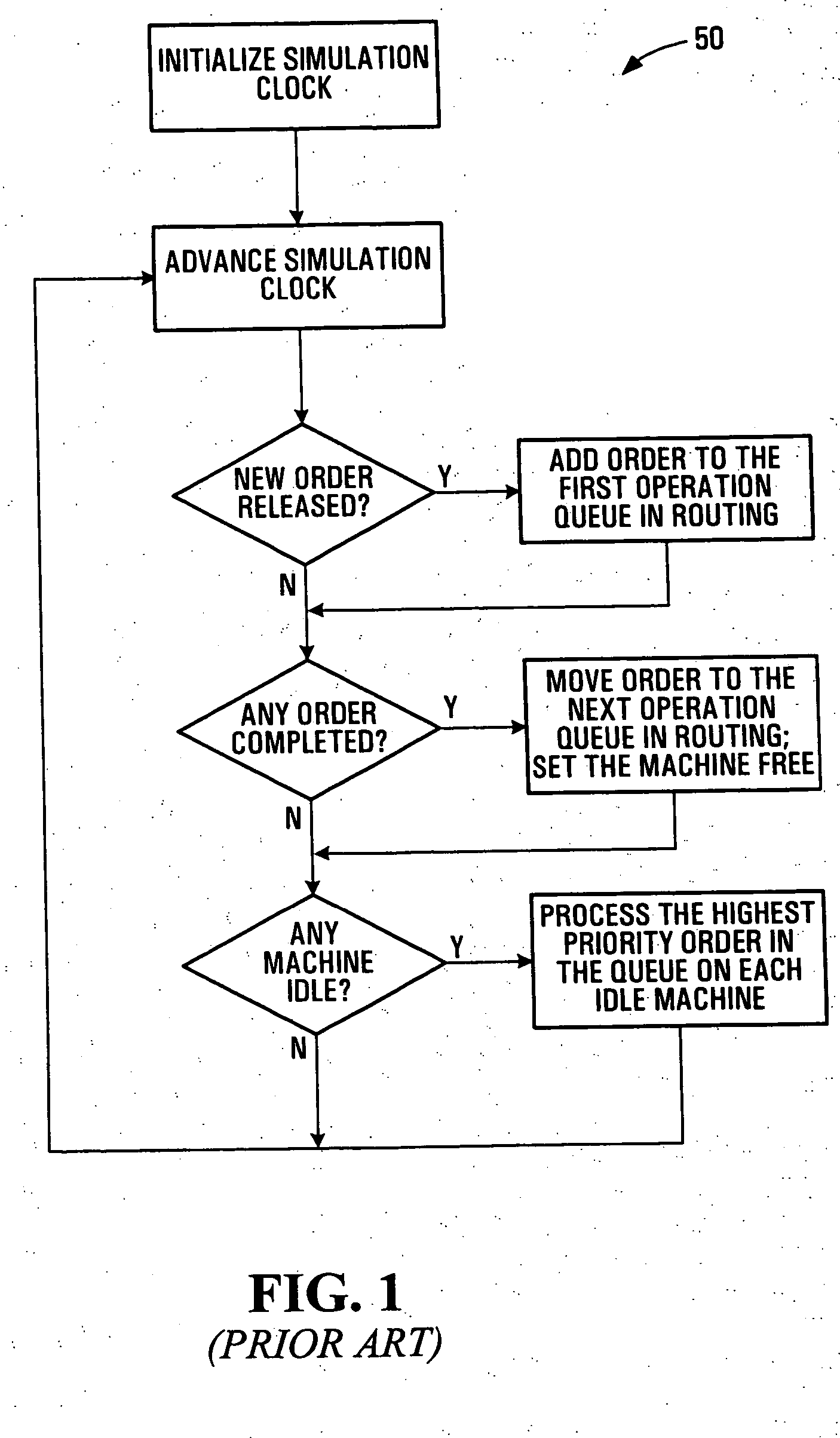

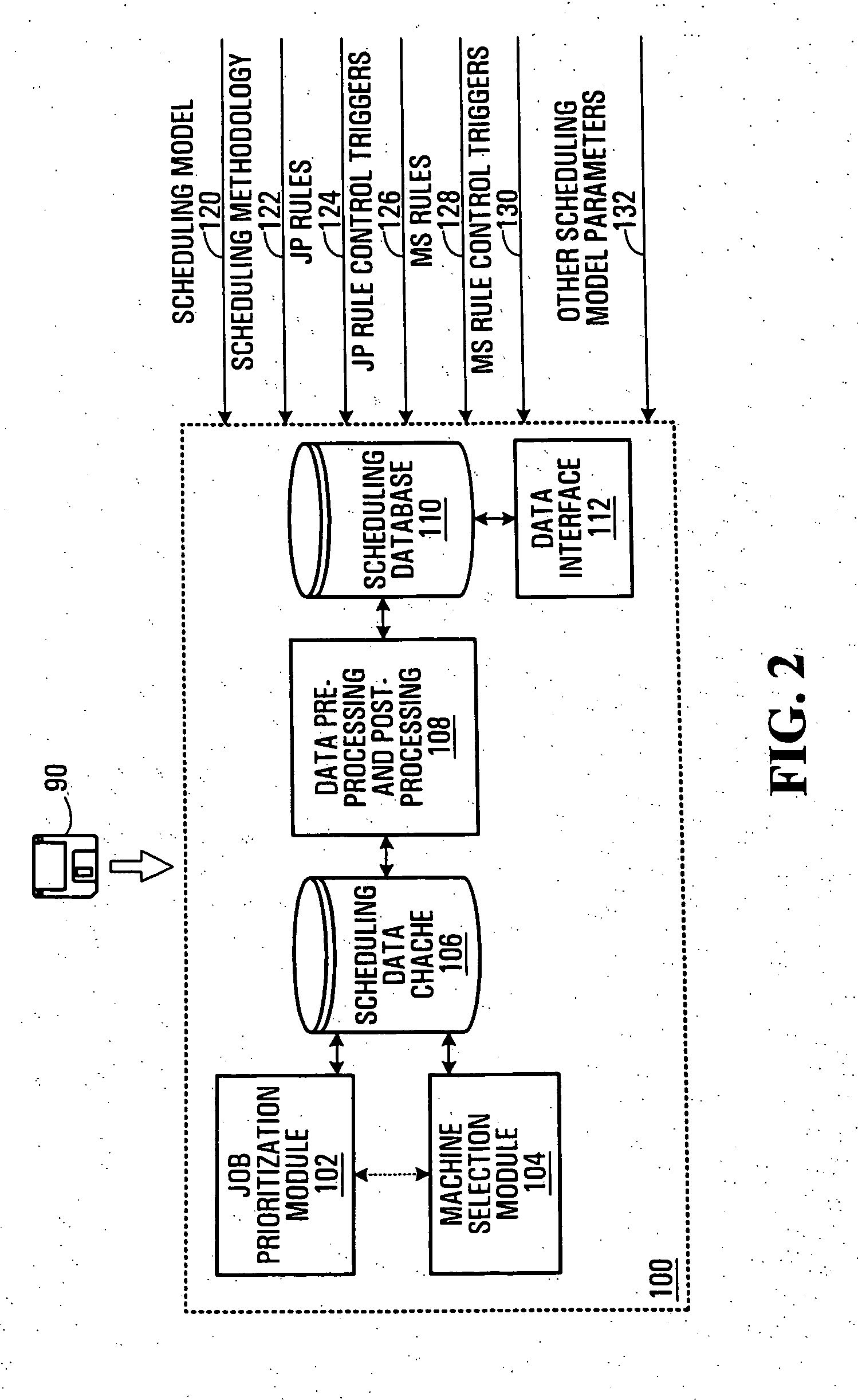

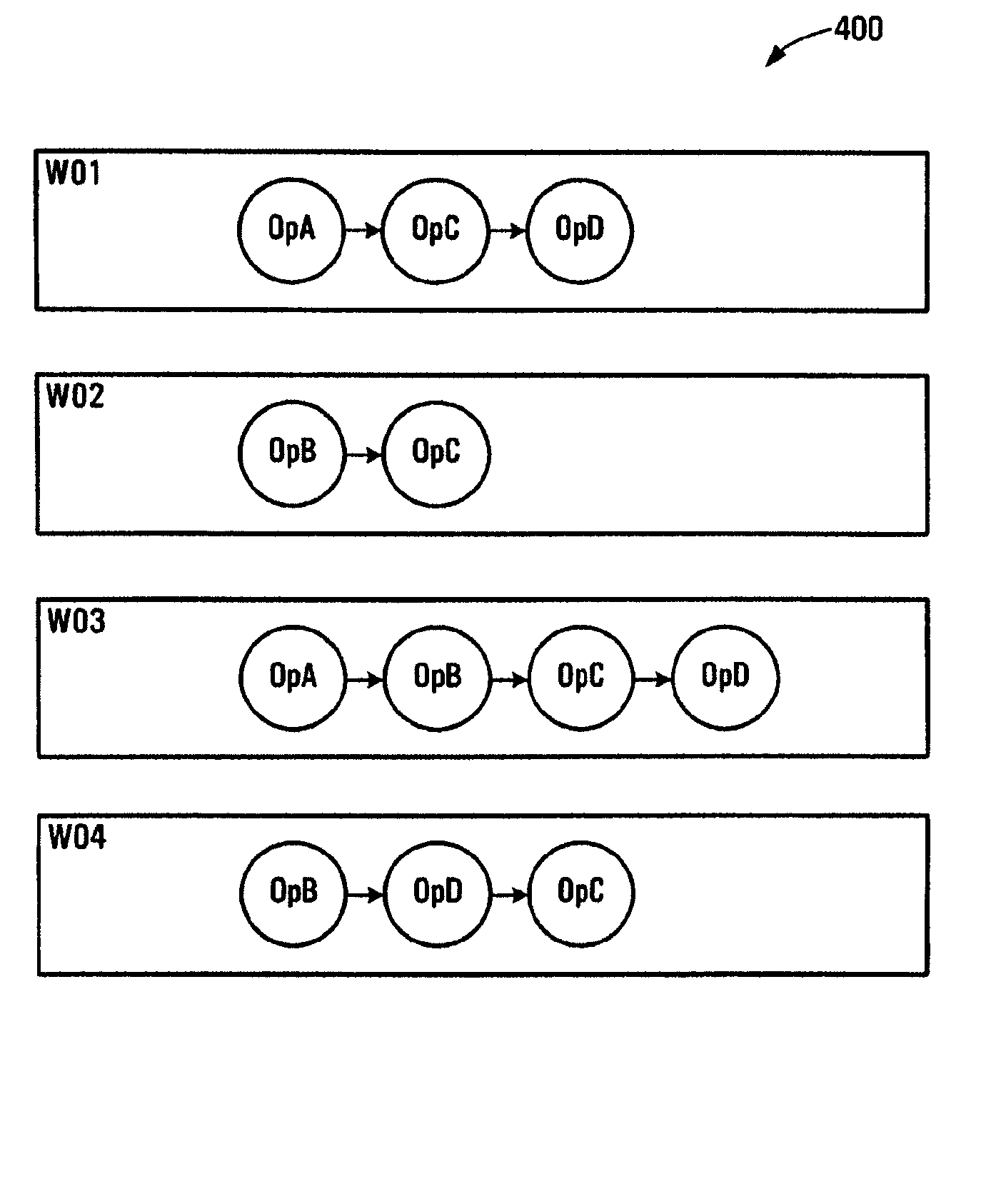

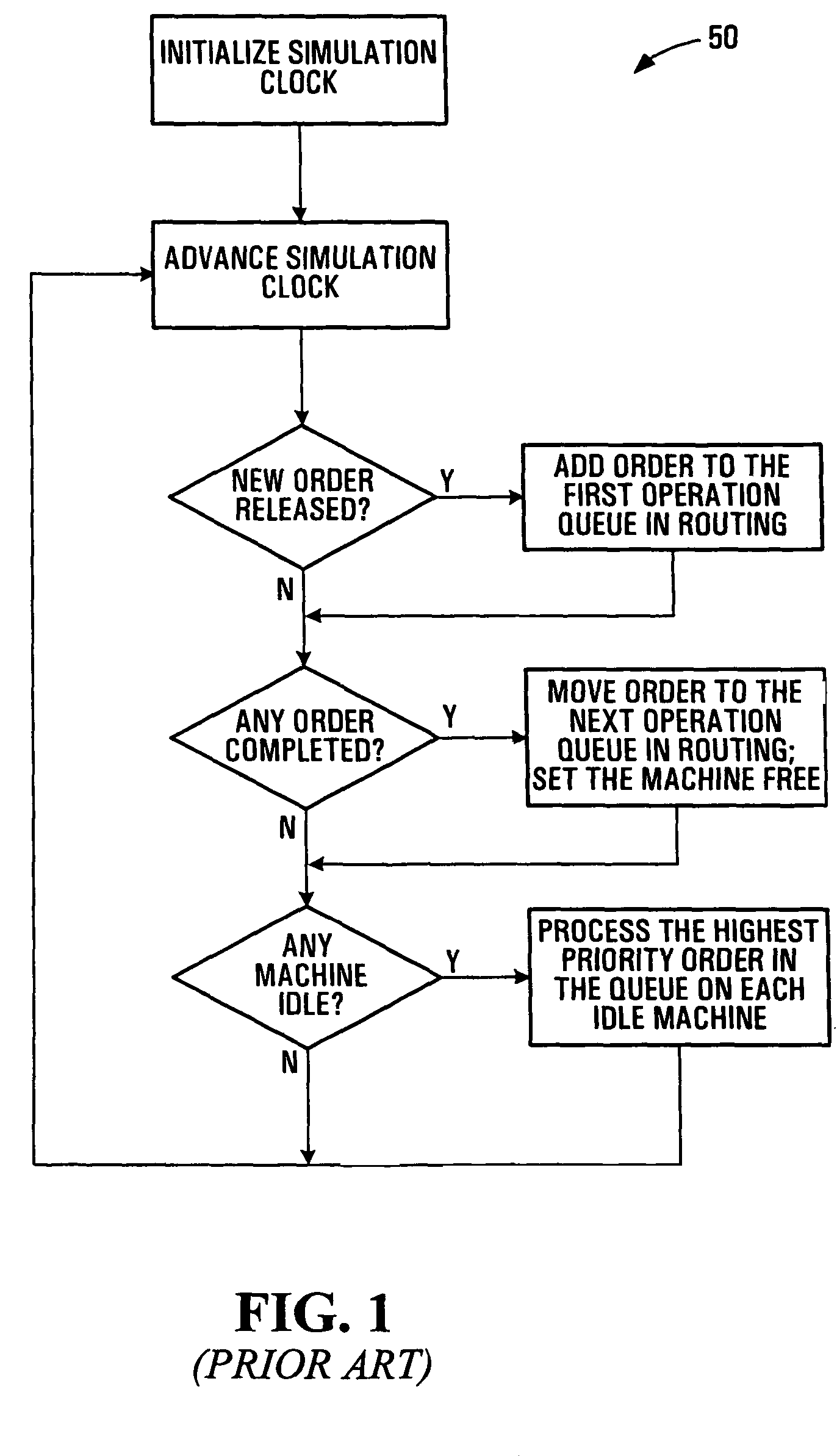

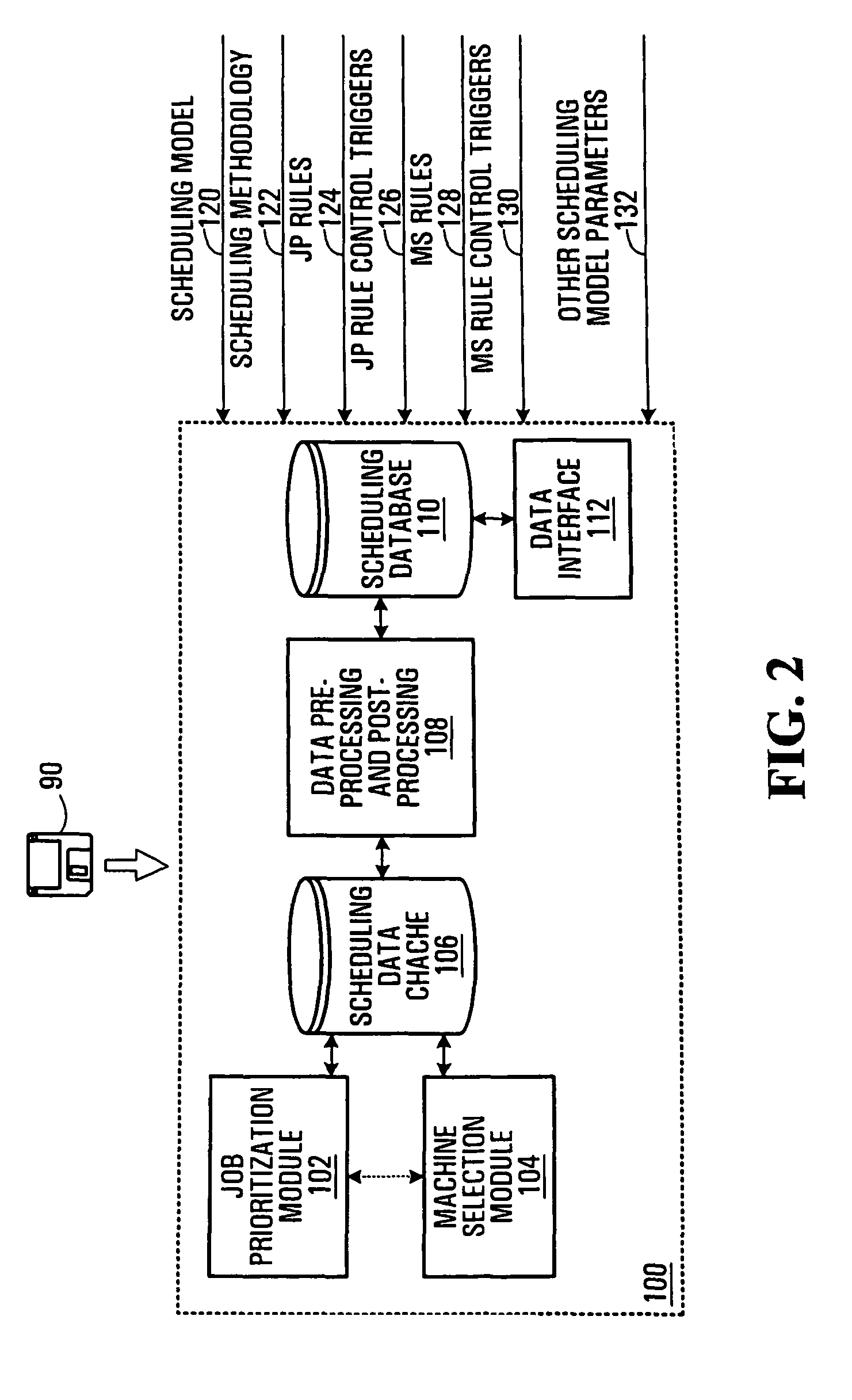

In a method, device, and computer-readable medium for finite capacity scheduling, heuristic rules are applied in two integrated stages: Job Prioritization and Machine Selection. During Job Prioritization (“JP”), jobs are prioritized based on a set of JP rules which are machine independent. During Machine Selection (“MS”), jobs are scheduled for execution at machines that are deemed to be best suited based on a set of MS rules. The two-stage approach allows scheduling goals to be achieved for performance measures relating to both jobs and machines. For example, machine utilization may be improved while product cycle time objectives are still met. Two user-configurable options, namely scheduling model (job shop or flow shop) and scheduling methodology (forward, backward, or bottleneck), govern the scheduling process. A memory may store a three-dimensional linked list data structure for use in scheduling work orders for execution at machines assigned to work centers.

Owner:AGENCY FOR SCI TECH & RES

Finite capacity scheduling using job prioritization and machine selection

InactiveUS7904192B2Improve machine utilizationMultiprogramming arrangementsResourcesMachine selectionMachine utilization

Owner:AGENCY FOR SCI TECH & RES

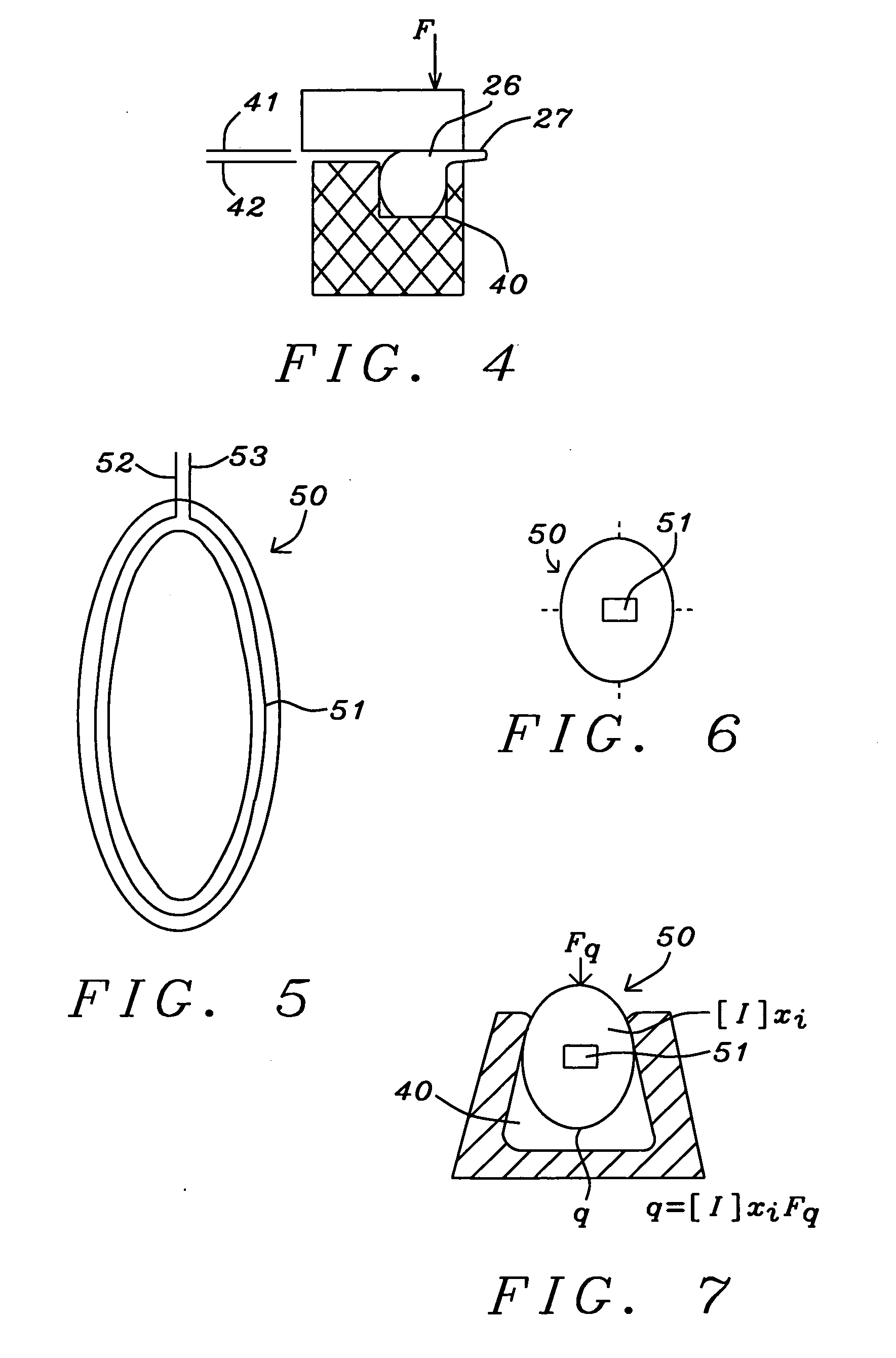

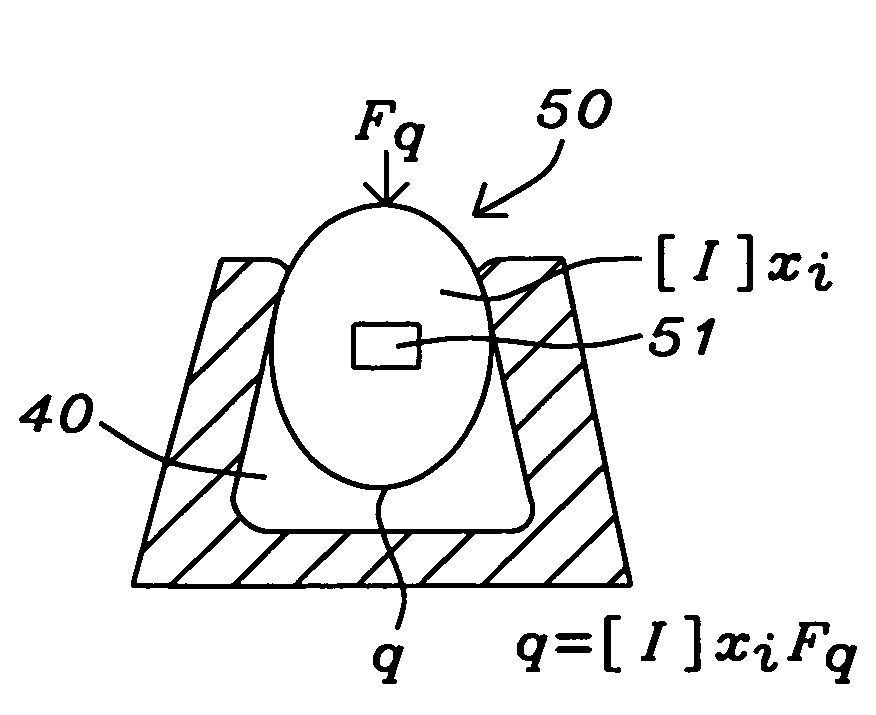

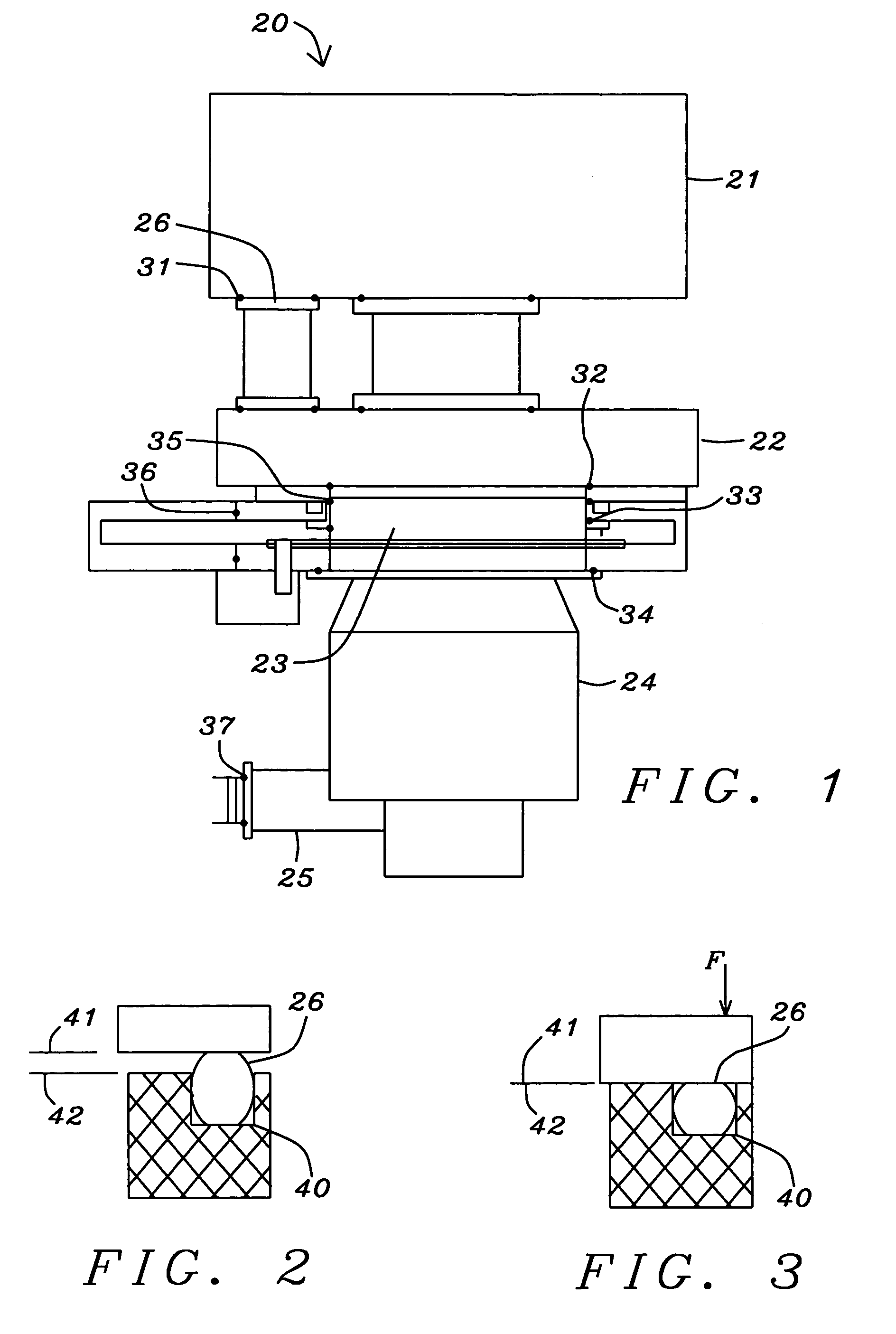

Piezoelectric o-ring transducer

InactiveUS20050156487A1Improve system utilizationTroublesome processEngine sealsPiezoelectric/electrostriction/magnetostriction machinesTransducerEngineering

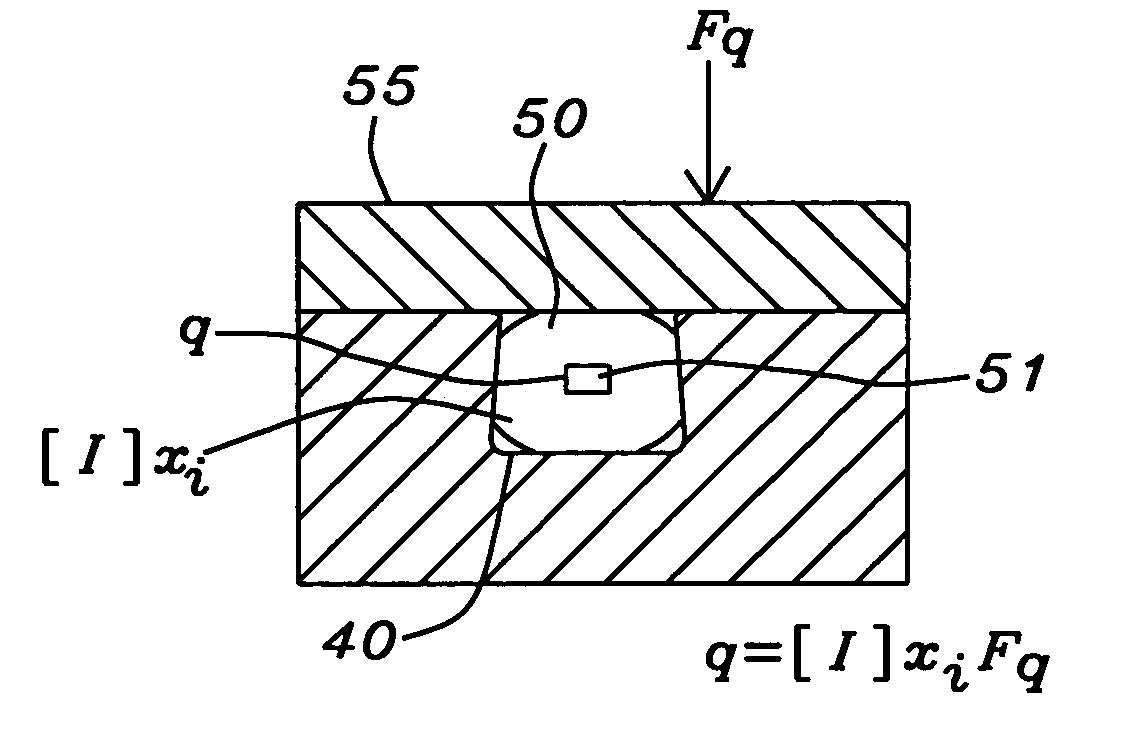

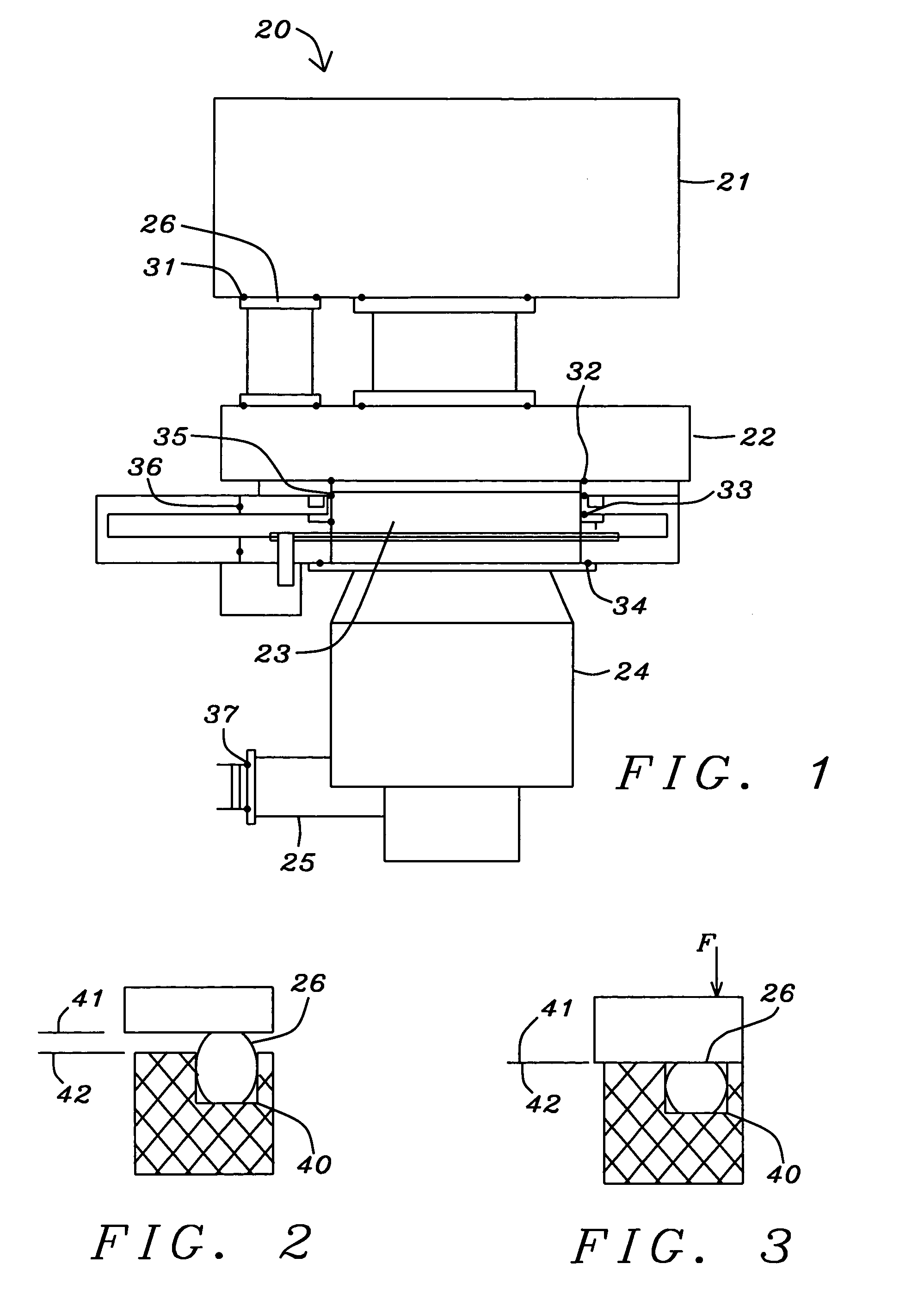

An o-ring sealing device, molded with an imbedded piezoelectric element, for use in vacuum systems. The imbedded element, of a circumferential length, has an oblong cross-sectional shape, the oblong shape having a pair of ends for externally connecting to a signal processor. The piezoelectric element is concentrically disposed and centrally placed within a mold cavity of a predetermined diameter. The cavity is filled with an elastic material fully encapsulating and insulating the piezoelectric element.

Owner:TAIWAN SEMICON MFG CO LTD

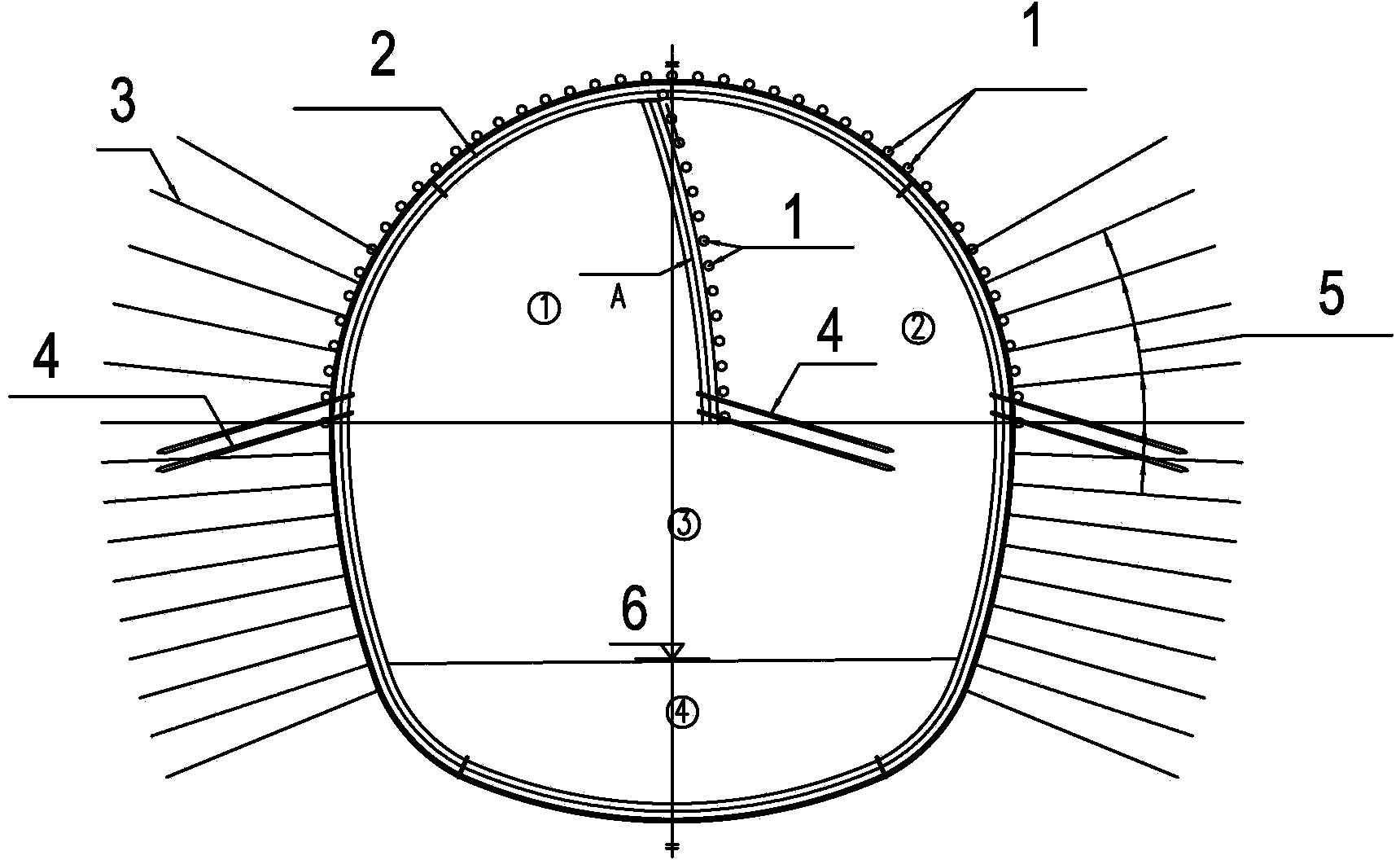

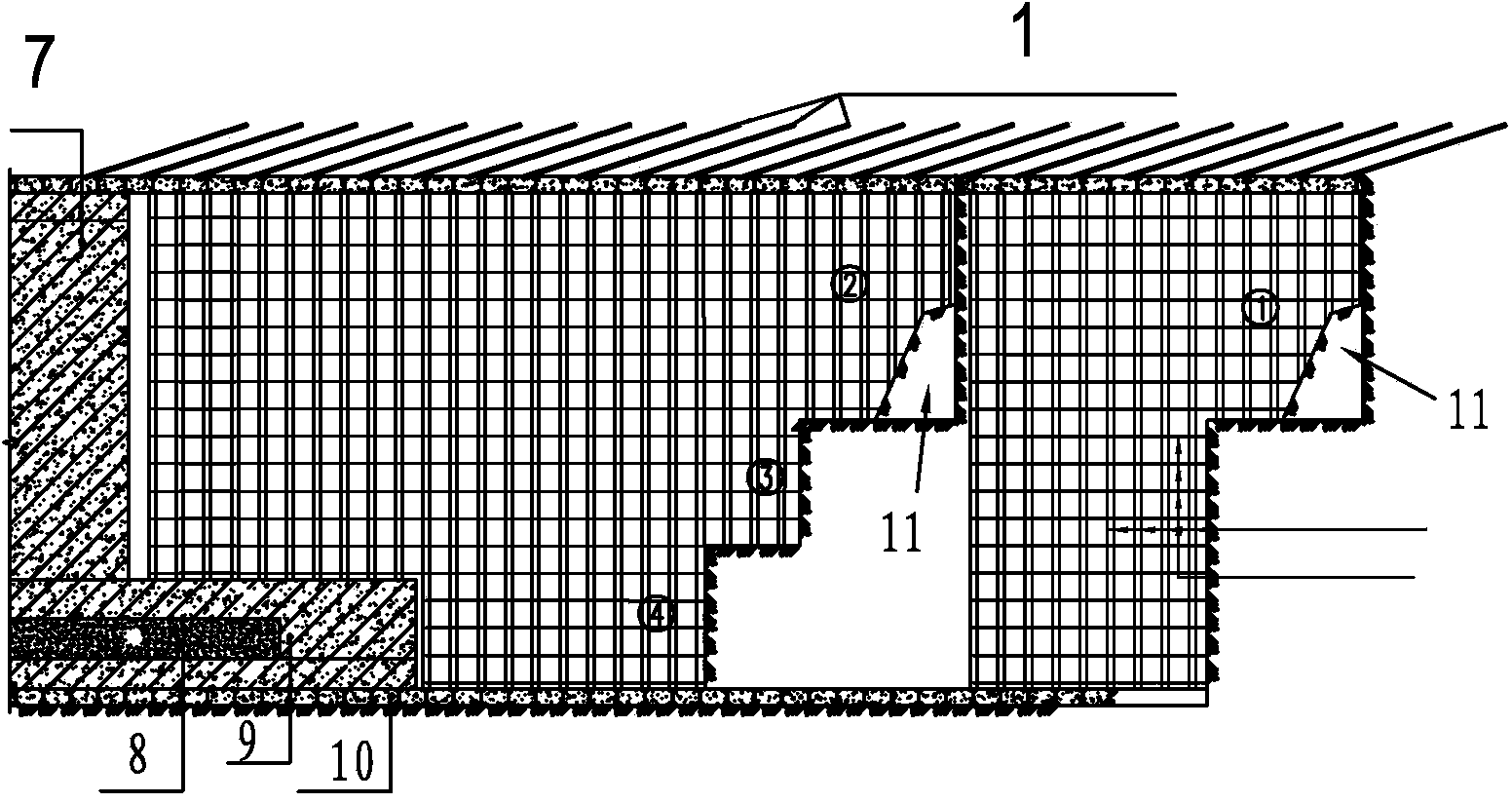

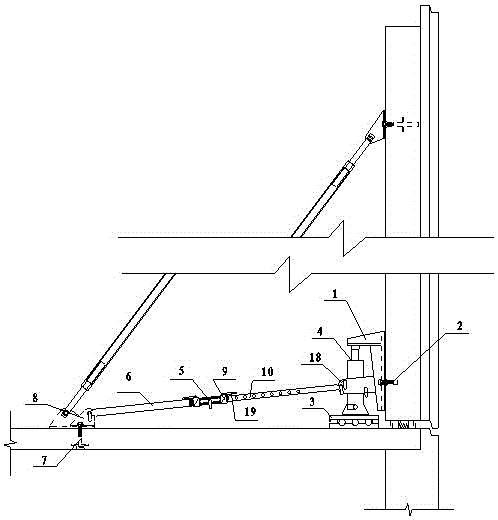

Construction method for excavating water-rich shallow underground excavation tunnel

InactiveCN104165056ASpeed up the construction progressImprove machine utilizationUnderground chambersTunnel liningTunnel constructionEngineering

The invention discloses a construction method for excavating a water-rich shallow underground excavation tunnel. The construction method includes the following steps that first, phi-42 advanced small pipes are constructed within the range of 180 degrees of the arch of the tunnel and the range of the top heading side wall through a steel frame erected in the last cycle, and advanced grouting supporting is performed; a first part is excavated; a preliminary support and a temporary support on the periphery of a heading of the first part are constructed, 4 cm thick concrete is sprayed preliminarily, a reinforcing mesh is installed, a steel frame and a temporary steel frame A are erected along with fluctuation of the rock face, and locking tremies are arranged; after holes are drilled and system anchor rods are arranged, concrete is sprayed again; second, a second part is excavated; 4 cm thick concrete is sprayed preliminarily on part of the periphery of the heading, and a reinforcing mesh is arranged; a steel frame on the periphery of a hole is lengthened through connection; after holes are drilled and system anchor rods are arranged, concrete is sprayed again; third, a third part is excavated in a blasting mode; fourth, a fourth part is excavated in a blasting mode. According to the construction method, the workloads for partition wall construction and removal are saved in construction, the tunnel construction progress is accelerated, the machine utilization rate is increased, energy waste is reduced, the construction period is short, and cost is low.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG

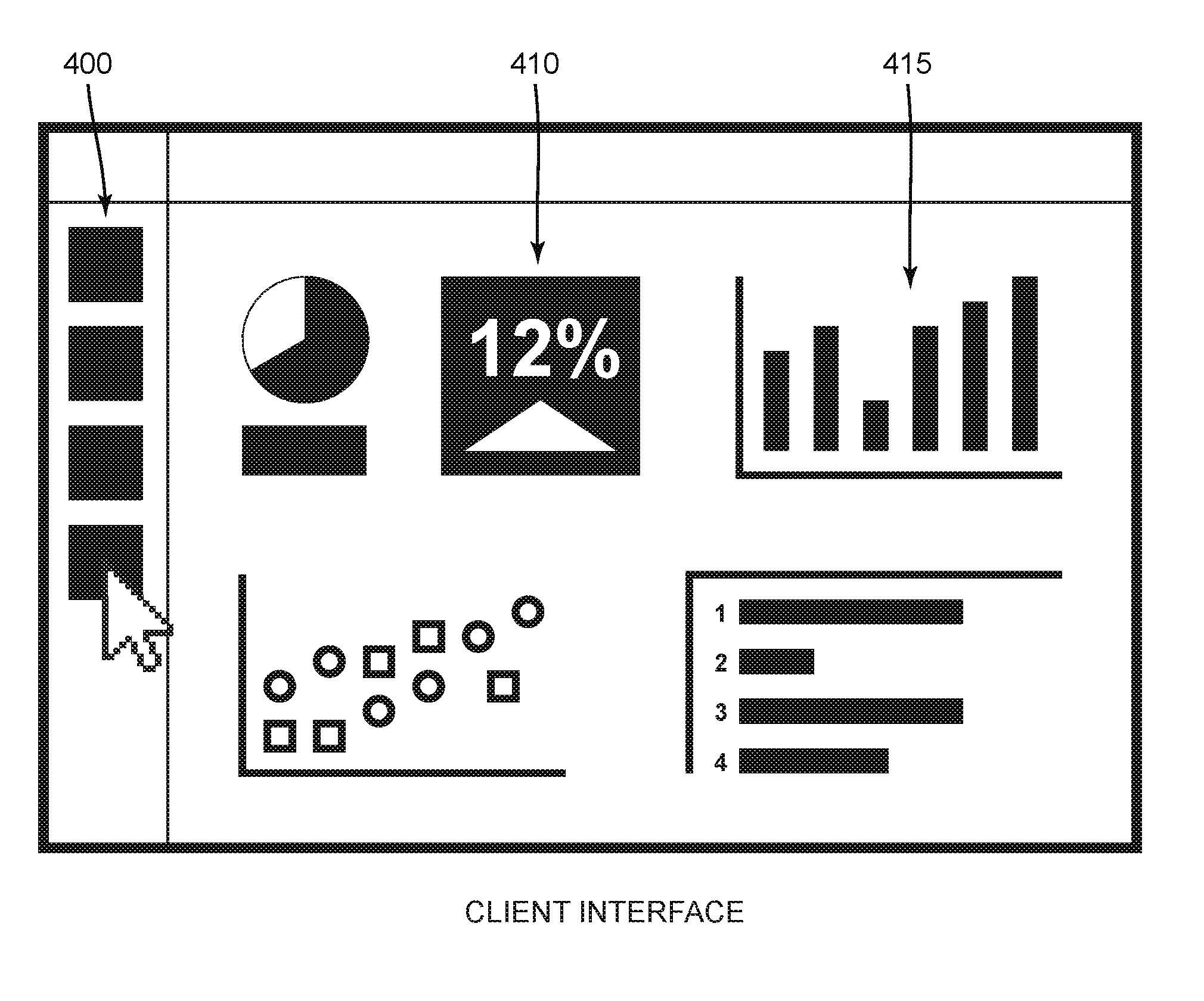

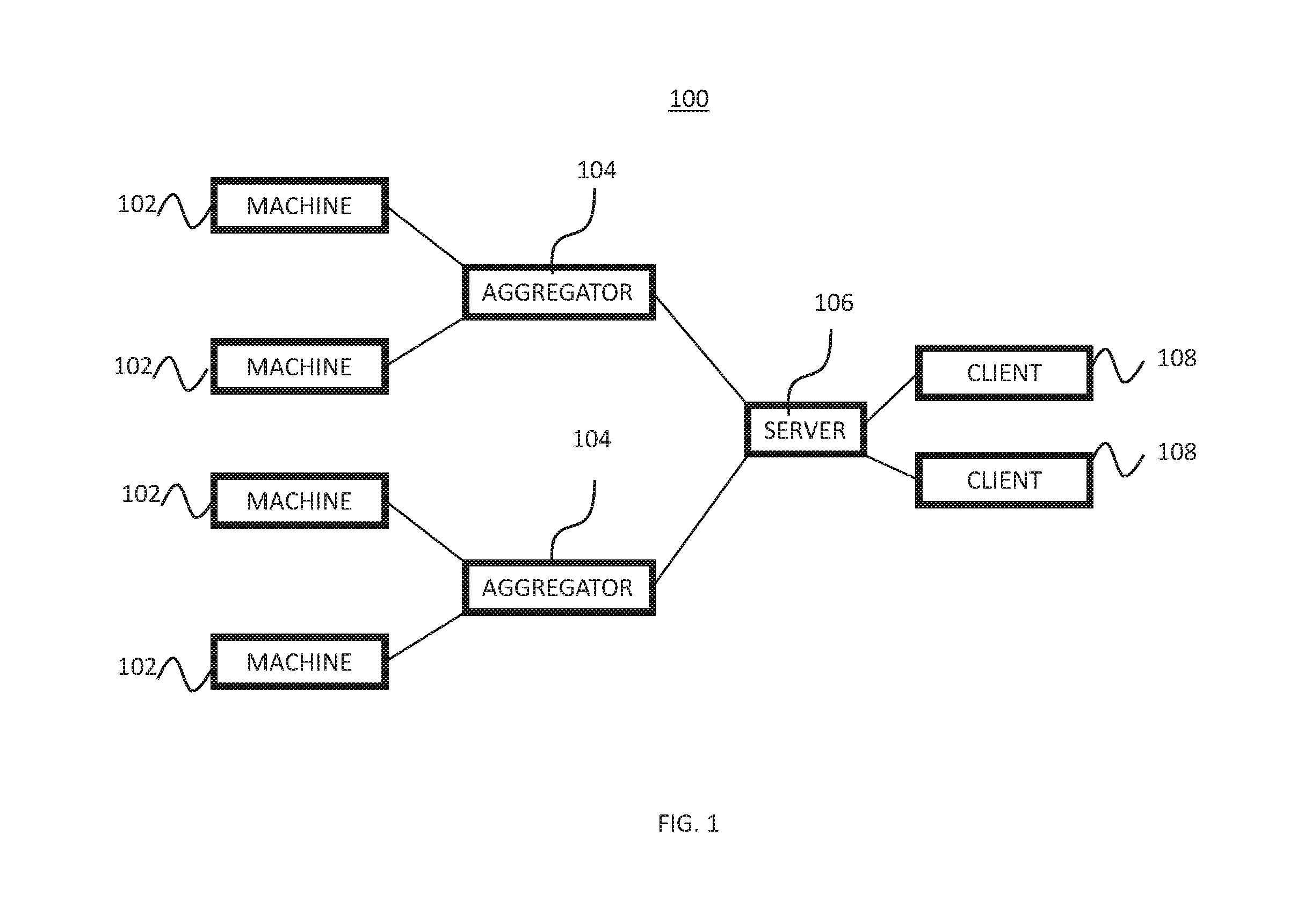

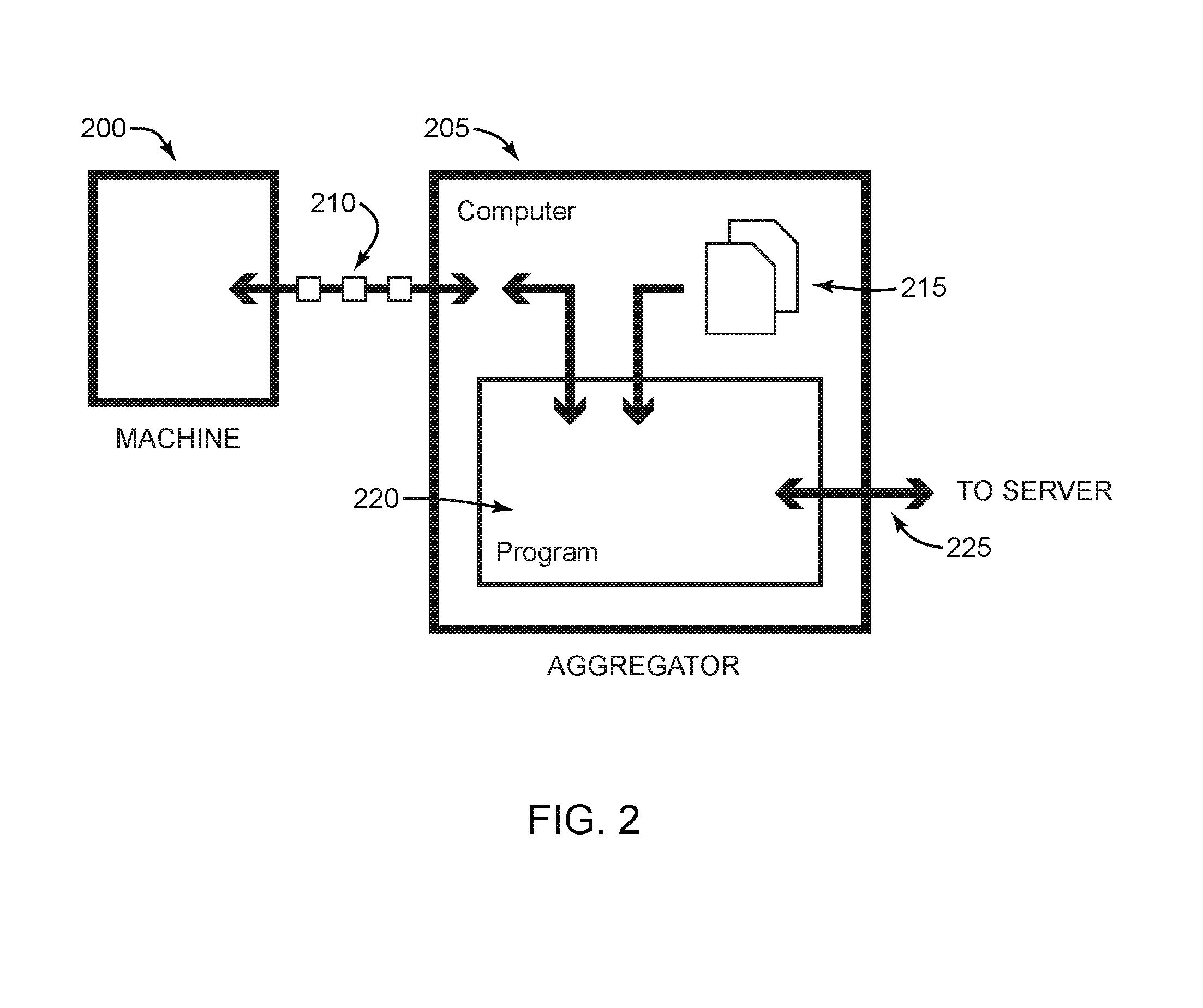

Data aggregation and analytics for digital manufacturing

InactiveUS20160328808A1Increase productivityImprove automationDigital data information retrievalResourcesData aggregatorDigital manufacturing

Systems and methods for aggregating and analyzing digital manufacturing data are disclosed. An aggregator can collect output data generated a number of digital manufacturing machines. The output data can be filtered and transmitted to a server for storage in a database. One or more clients can access the data in the database via an API.

Owner:KEMEERA INC

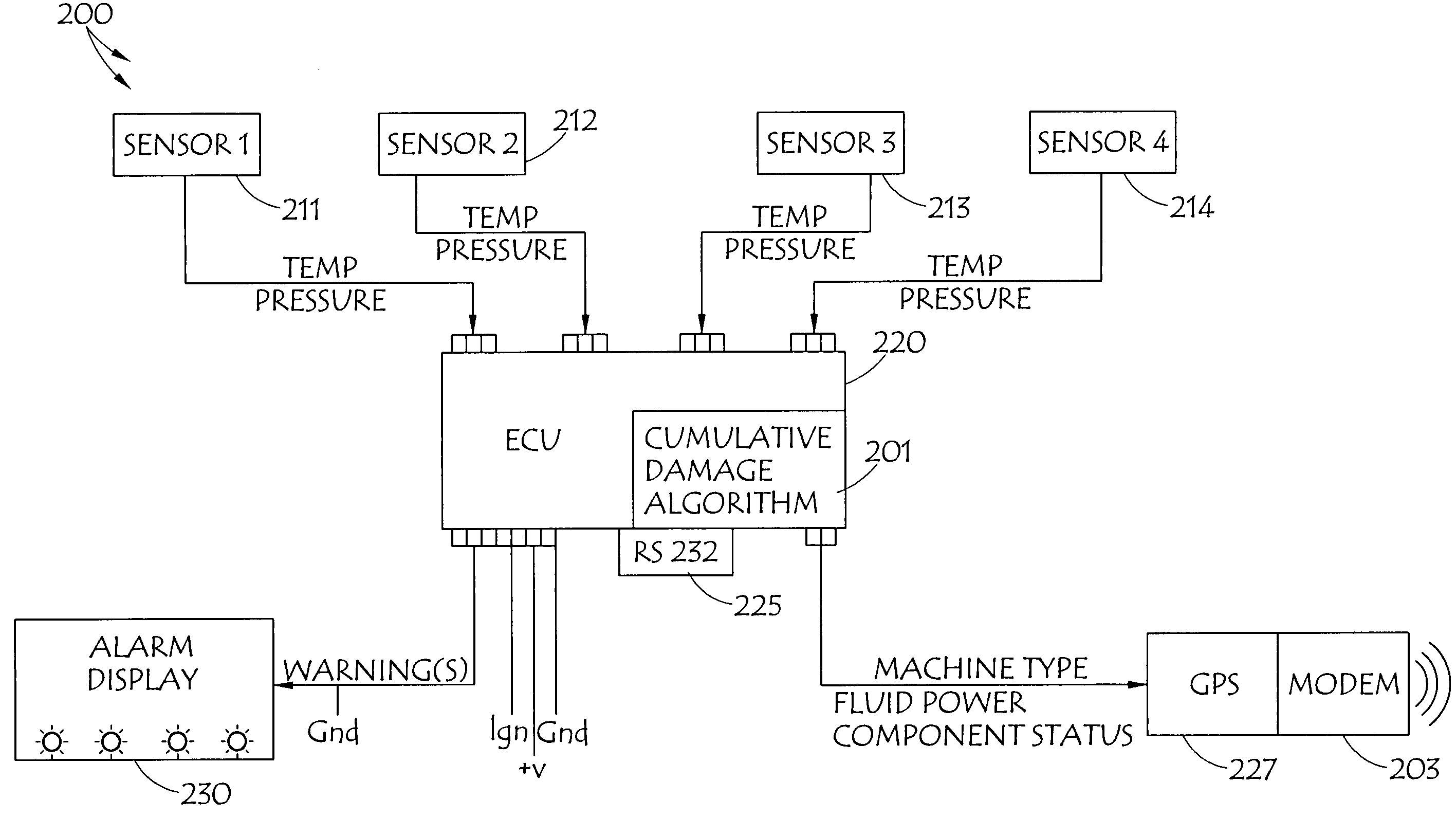

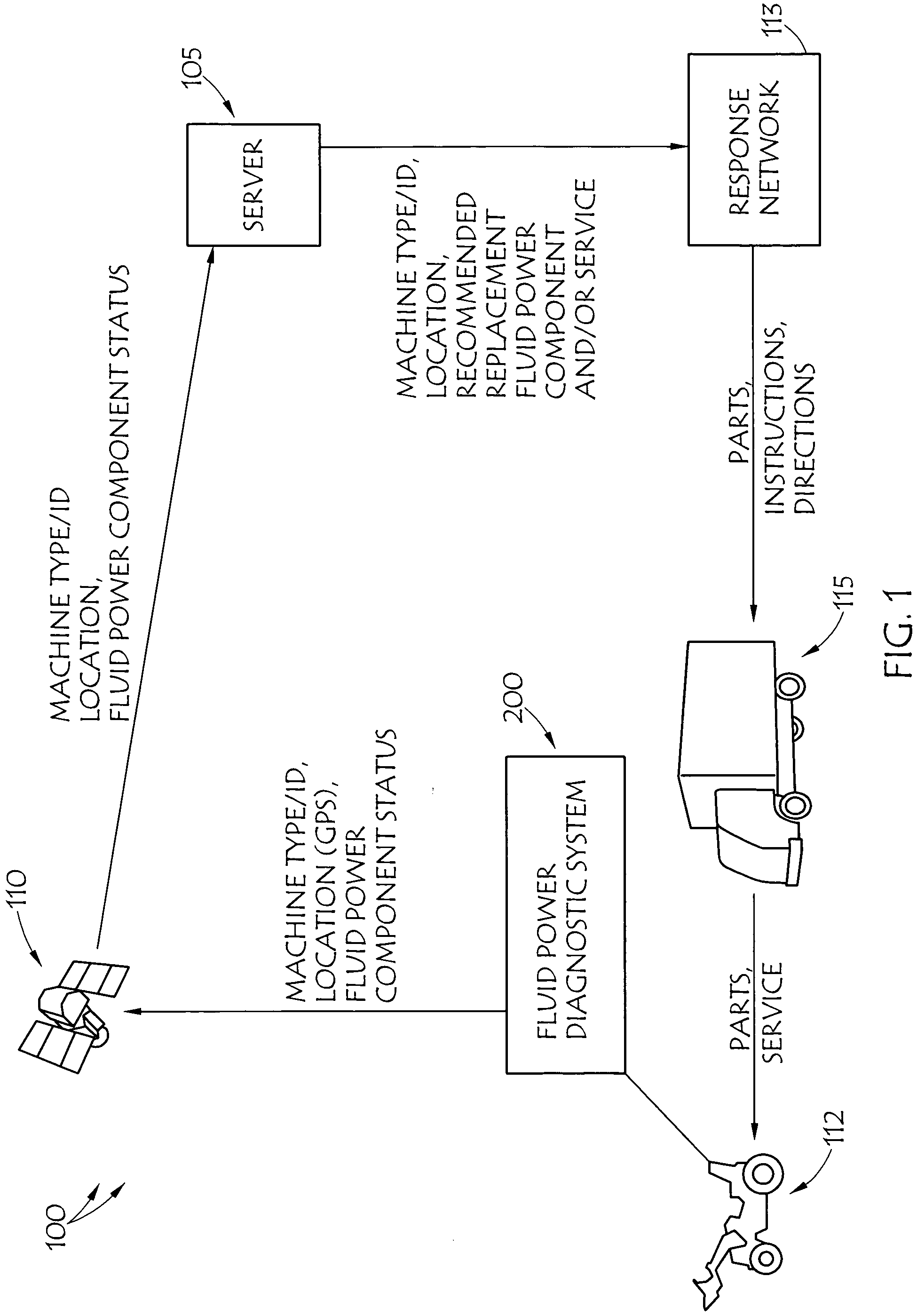

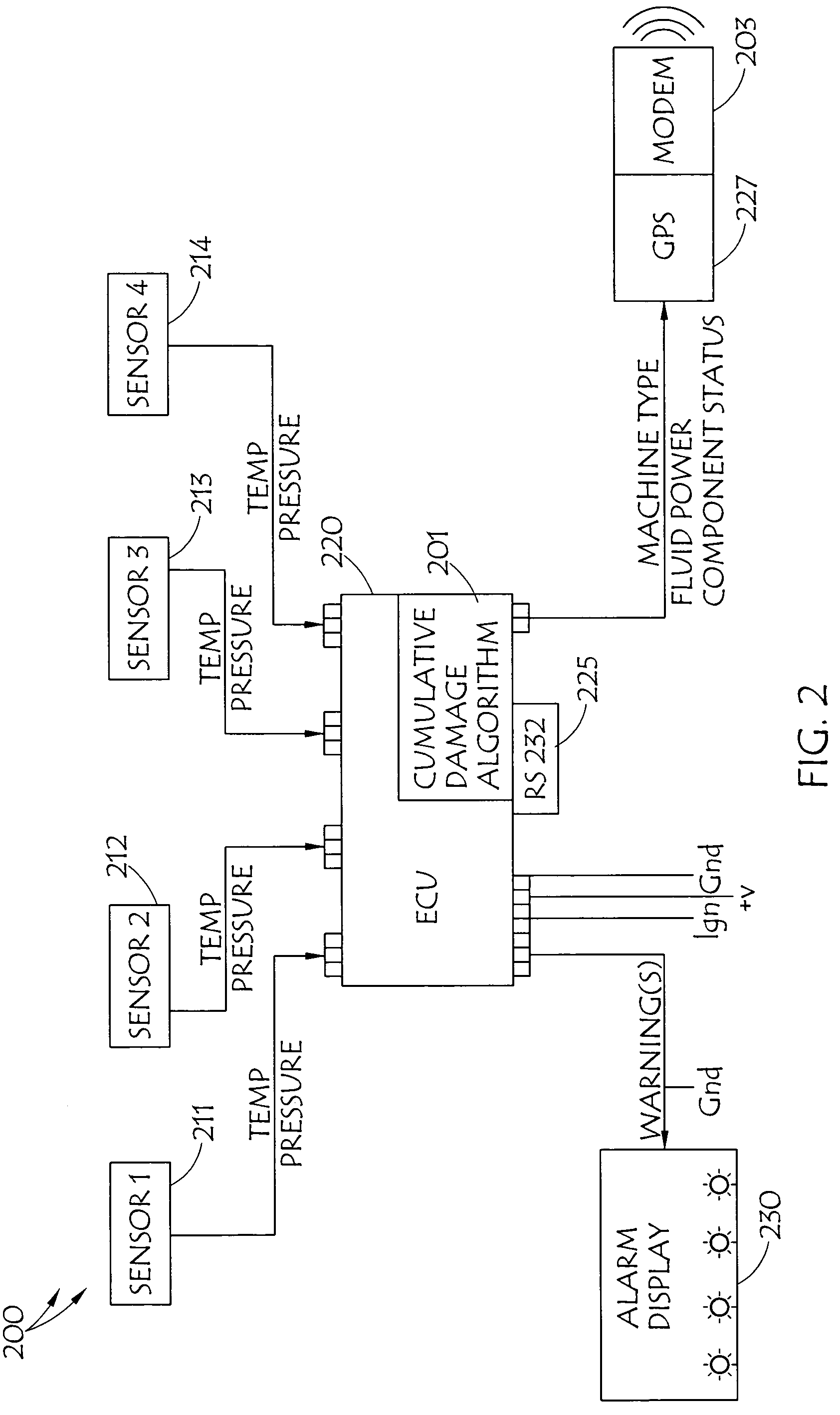

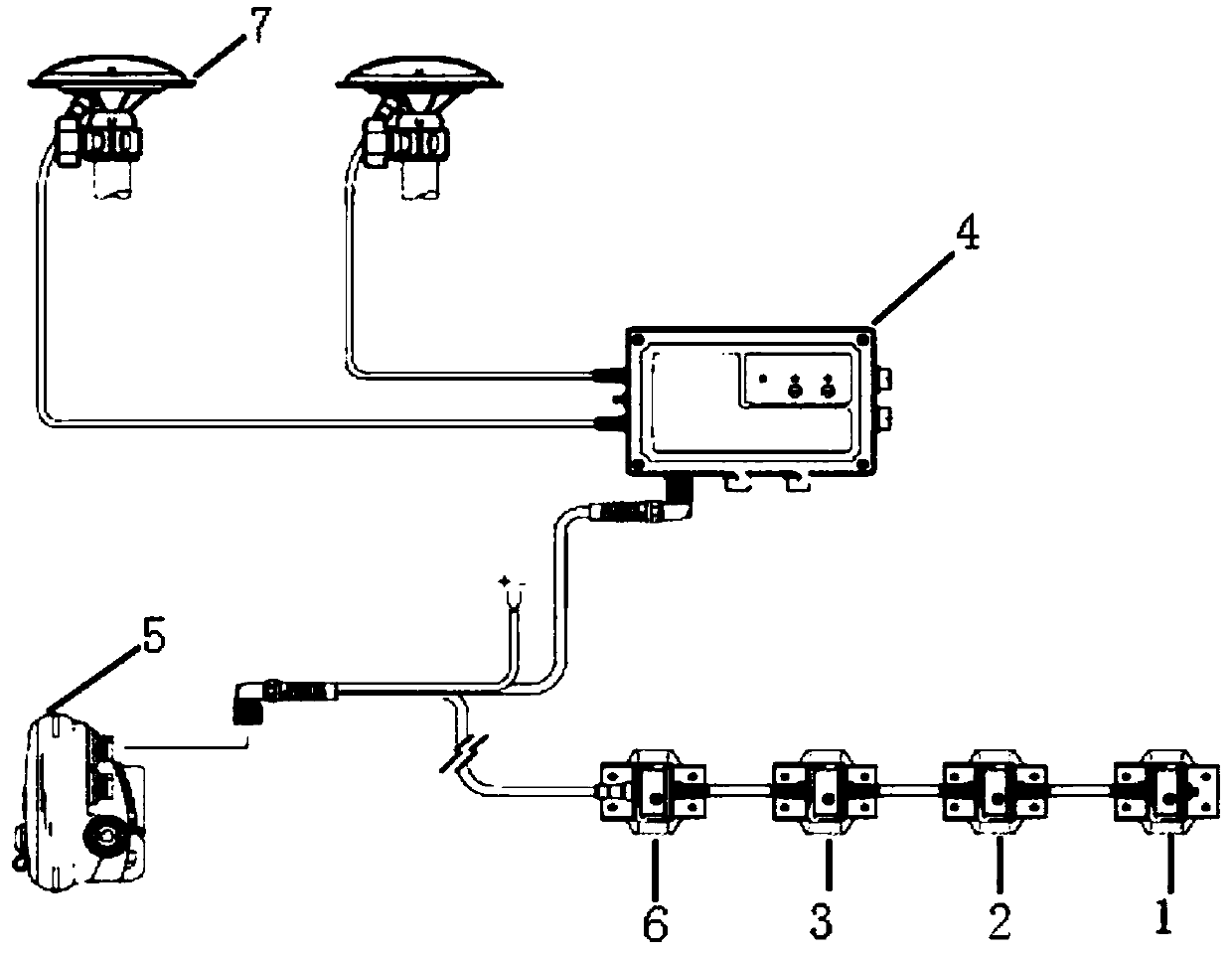

Diagnostic and response systems and methods for fluid power systems

InactiveUS20100106461A1Expand coverageNew revenue streamProgramme controlTesting/monitoring control systemsRapid response systemAnalysis center

Diagnostic and response systems and methods for a fluid power system acquire data from pressure and temperature sensors disposed in the fluid power system, analyze the data in a failure algorithm to build a history of cumulative damage to hoses in the fluid power system, communicates an indication of potential imminent hose failure to a central location when a level of the cumulative damage indicates imminent failure of a hose, analyze the information at the central location to determine an appropriate response, and transmit information about the fluid power system, including location, and identification of the hose about to fail to a response unit. The response unit responds to the location and replaces the component prior to failure, or the communication might include information that the hose has failed, such that the response unit replaces the failed hose to return the fluid power system to normal operation.

Owner:THE GATES CORP

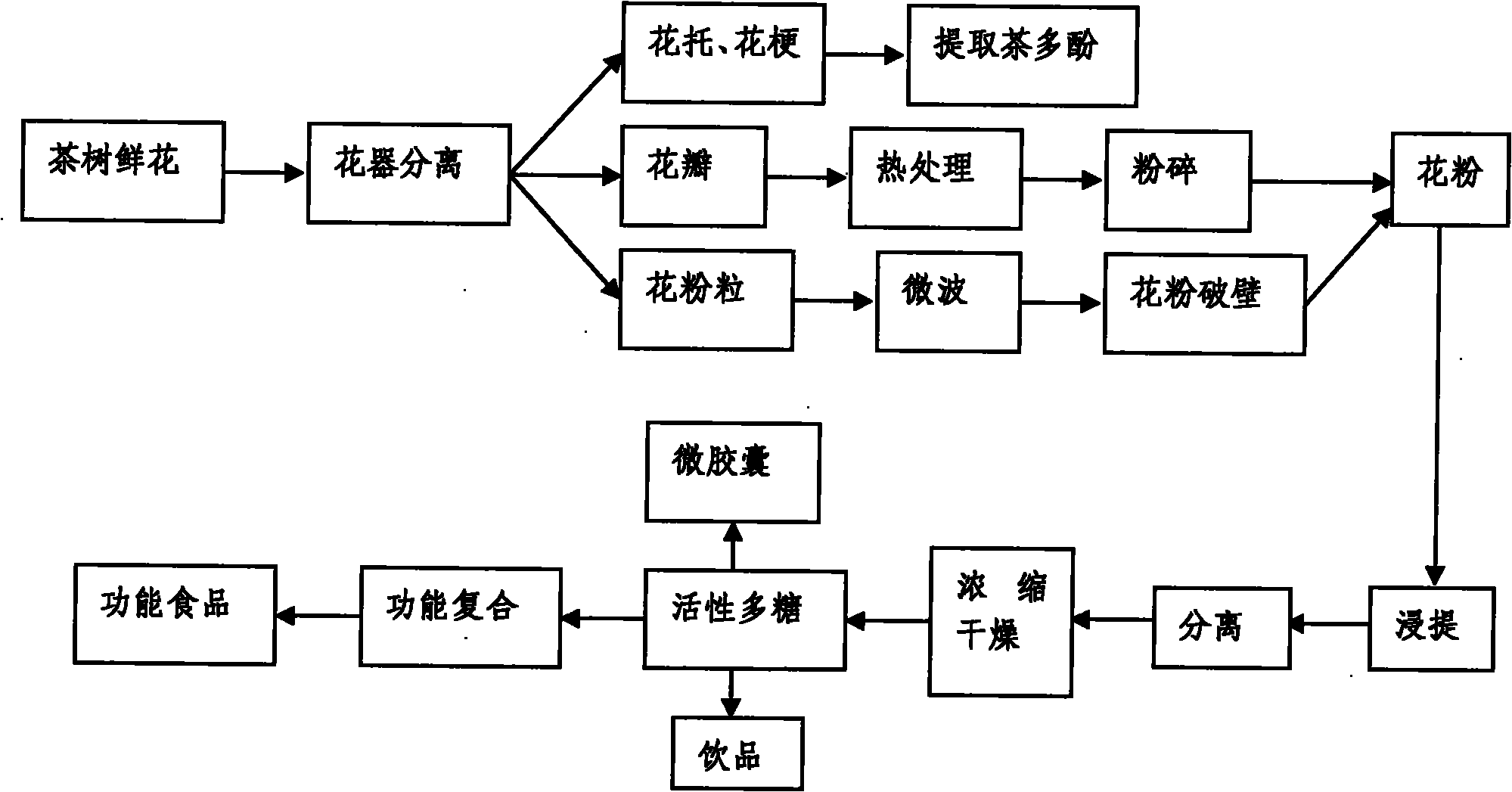

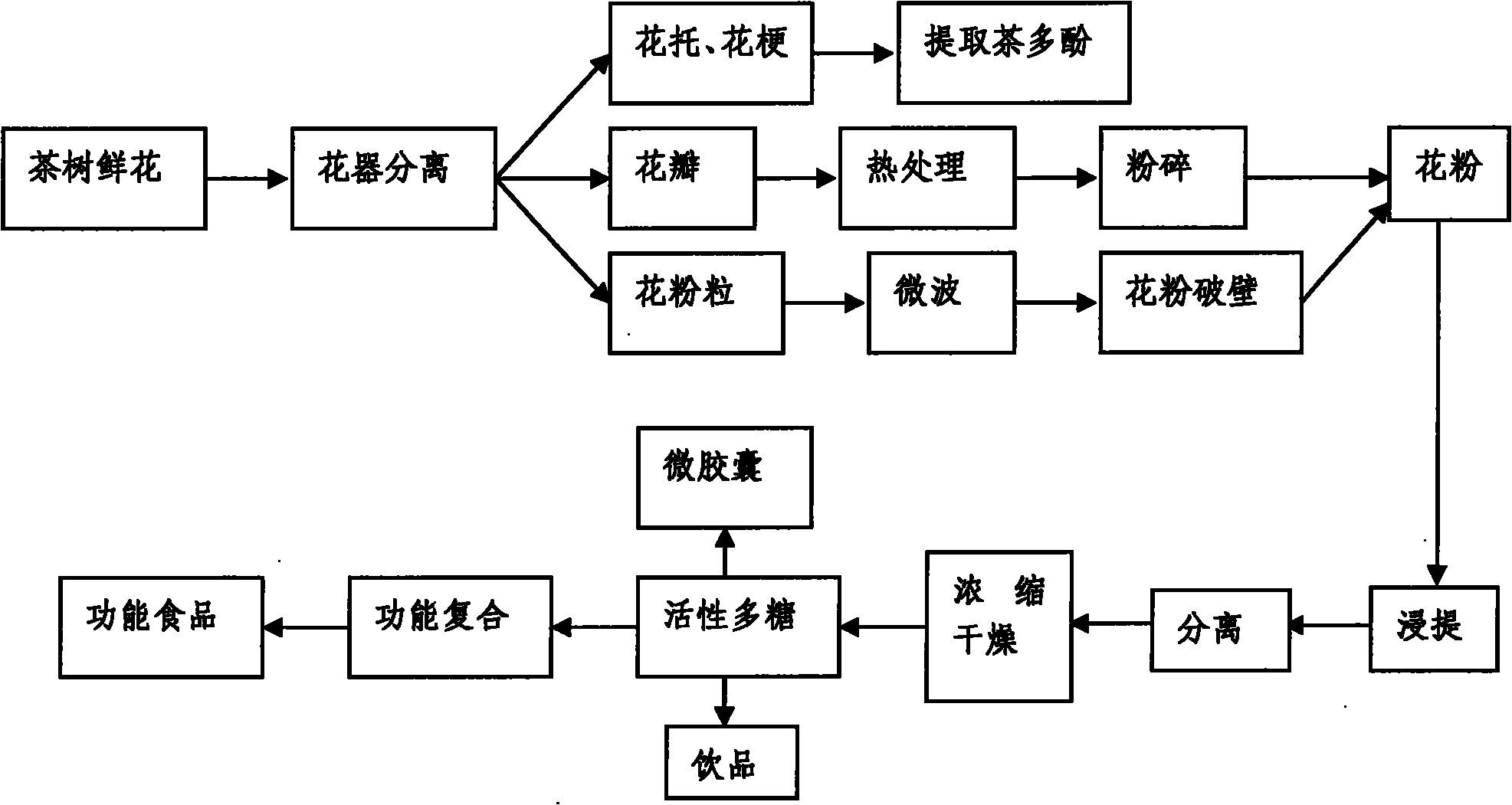

Tea plant nutrient comprehensive utilization technology

InactiveCN101849666AImprove machine utilizationIncrease productionFood preparationNatural resourceSkin protection

The invention discloses the tea plant nutrient comprehensive utilization technology, which comprises the tea plant flower form separation processing technology, the tea plant pollen wall breaking technology, the tea plant flower polyhexose efficient extraction technology (refering to the polygahatous plysaccharides efficient extraction process) and the tea plant flower polyhexose functional food development. The invention utilizes natural resources at low cost and high efficiency, improves the machinery utilization rate of factory buildings of tea factories, improves the work production efficiency, controls the reproductive growth of the tea plants, promotes the nutritive growth of the tea plants, and improves the yield of tea gardens and the quality of the tea. Tea plant flower polyhexose products have the obvious effect on beautification, beauty treatment, skin protection and prostate protection.

Owner:ANHUI TIANPINTANG ECOLOGICAL TECH CO LTD

Piezoelectric o-ring transducer

An o-ring sealing device, molded with an imbedded piezoelectric element, for use in vacuum systems. The imbedded element, of a circumferential length, has an oblong cross-sectional shape, the oblong shape having a pair of ends for externally connecting to a signal processor. The piezoelectric element is concentrically disposed and centrally placed within a mold cavity of a predetermined diameter. The cavity is filled with an elastic material fully encapsulating and insulating the piezoelectric element.

Owner:TAIWAN SEMICON MFG CO LTD

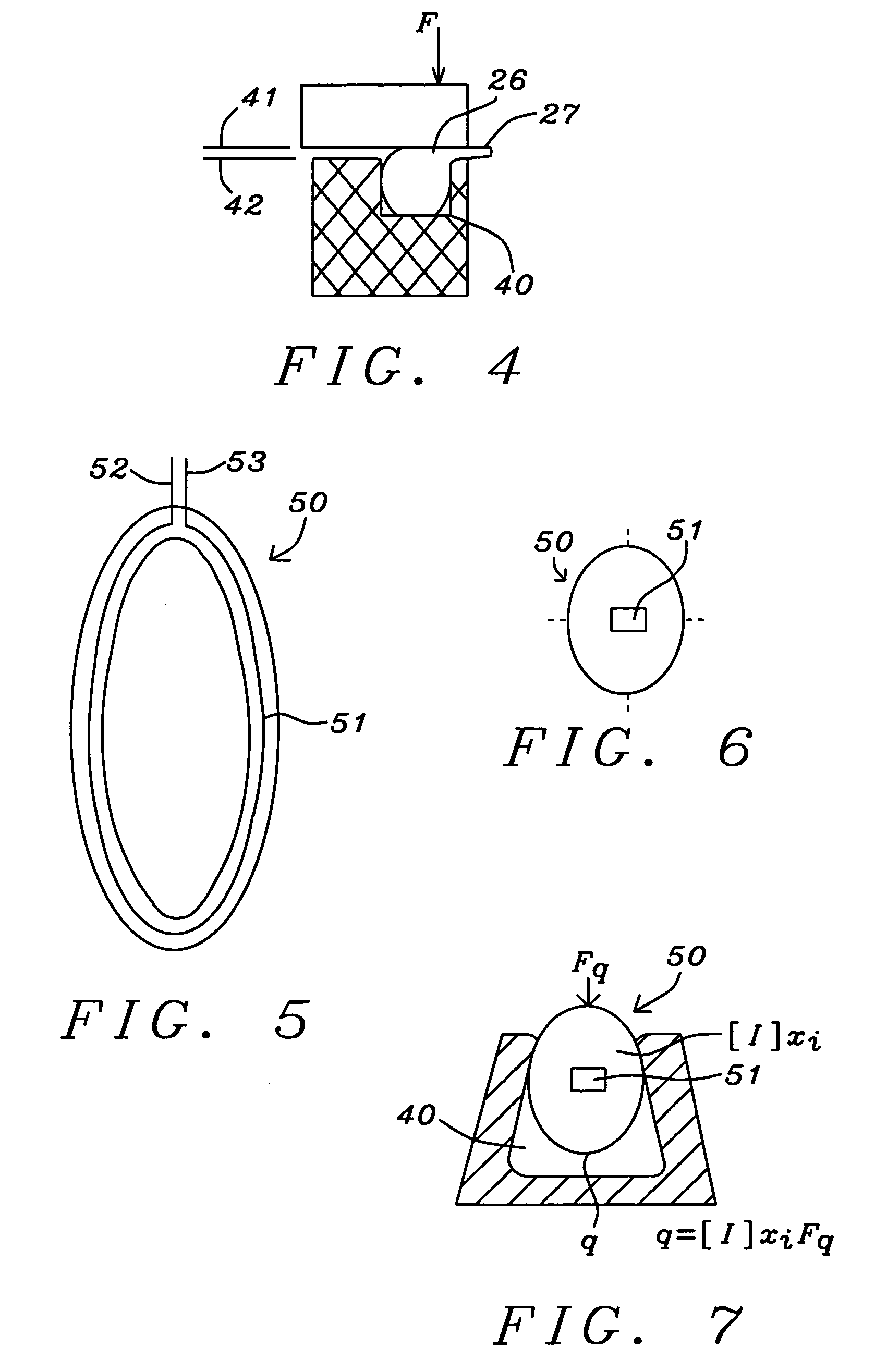

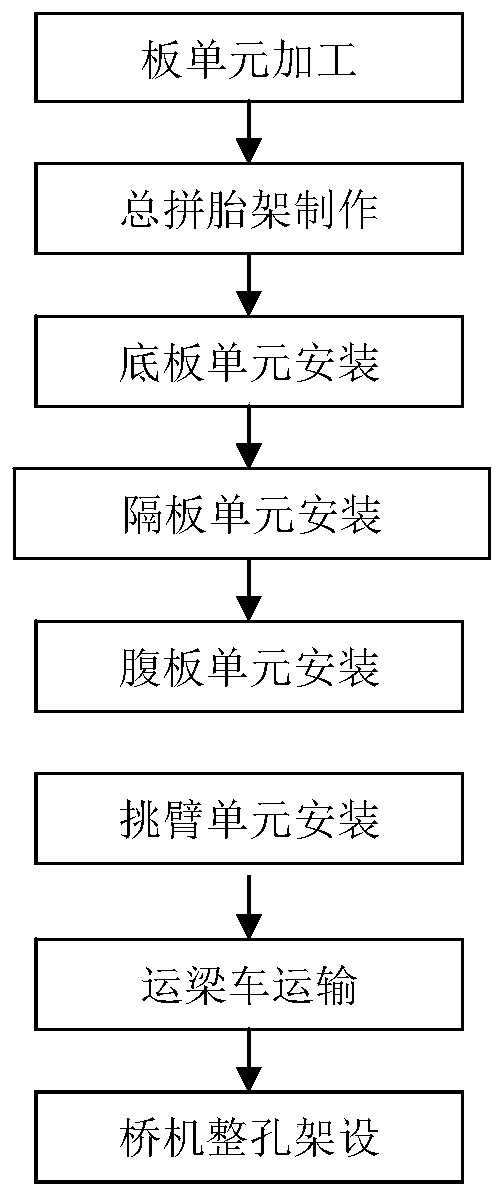

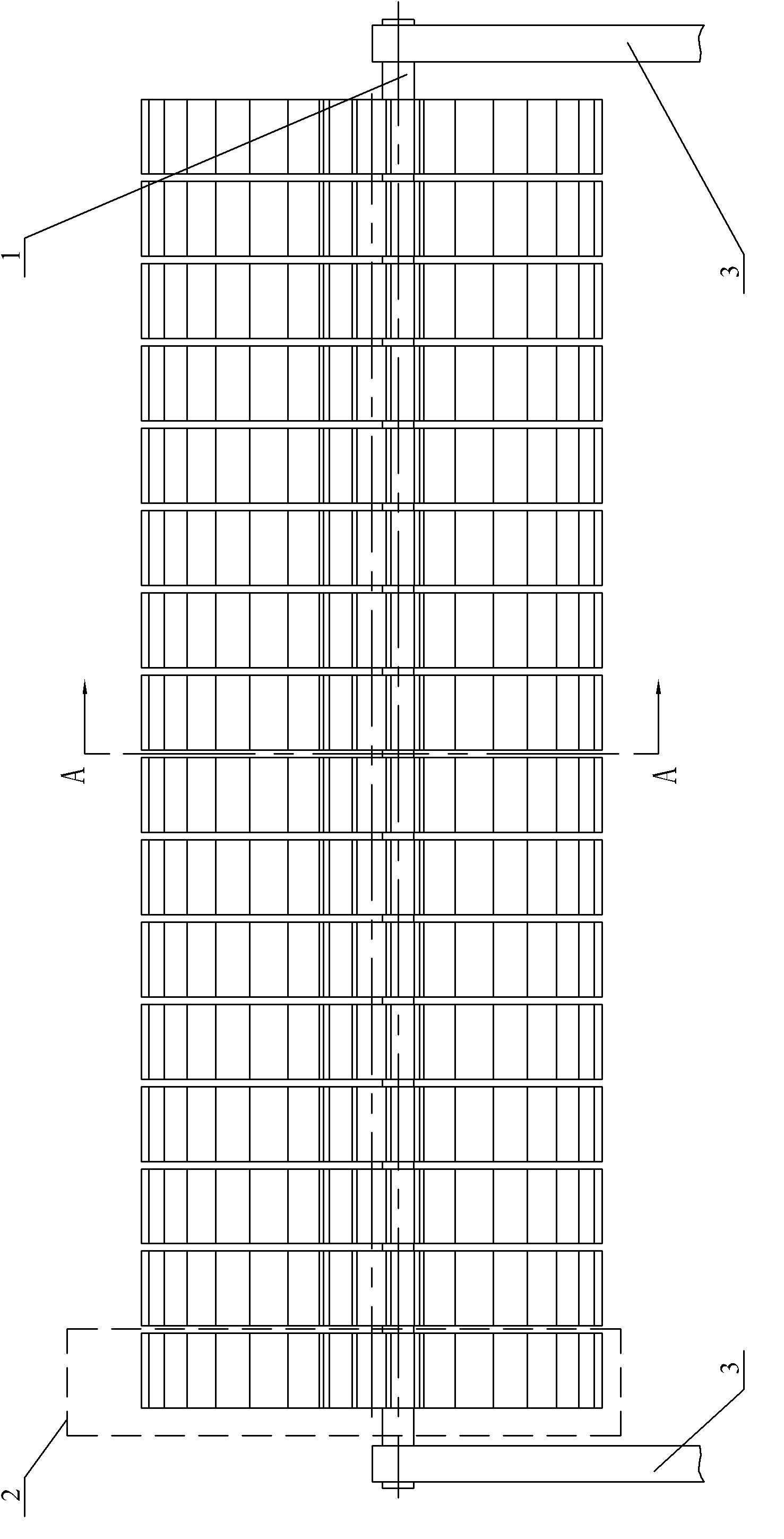

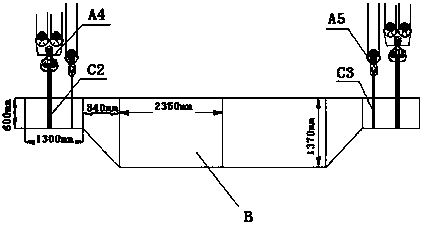

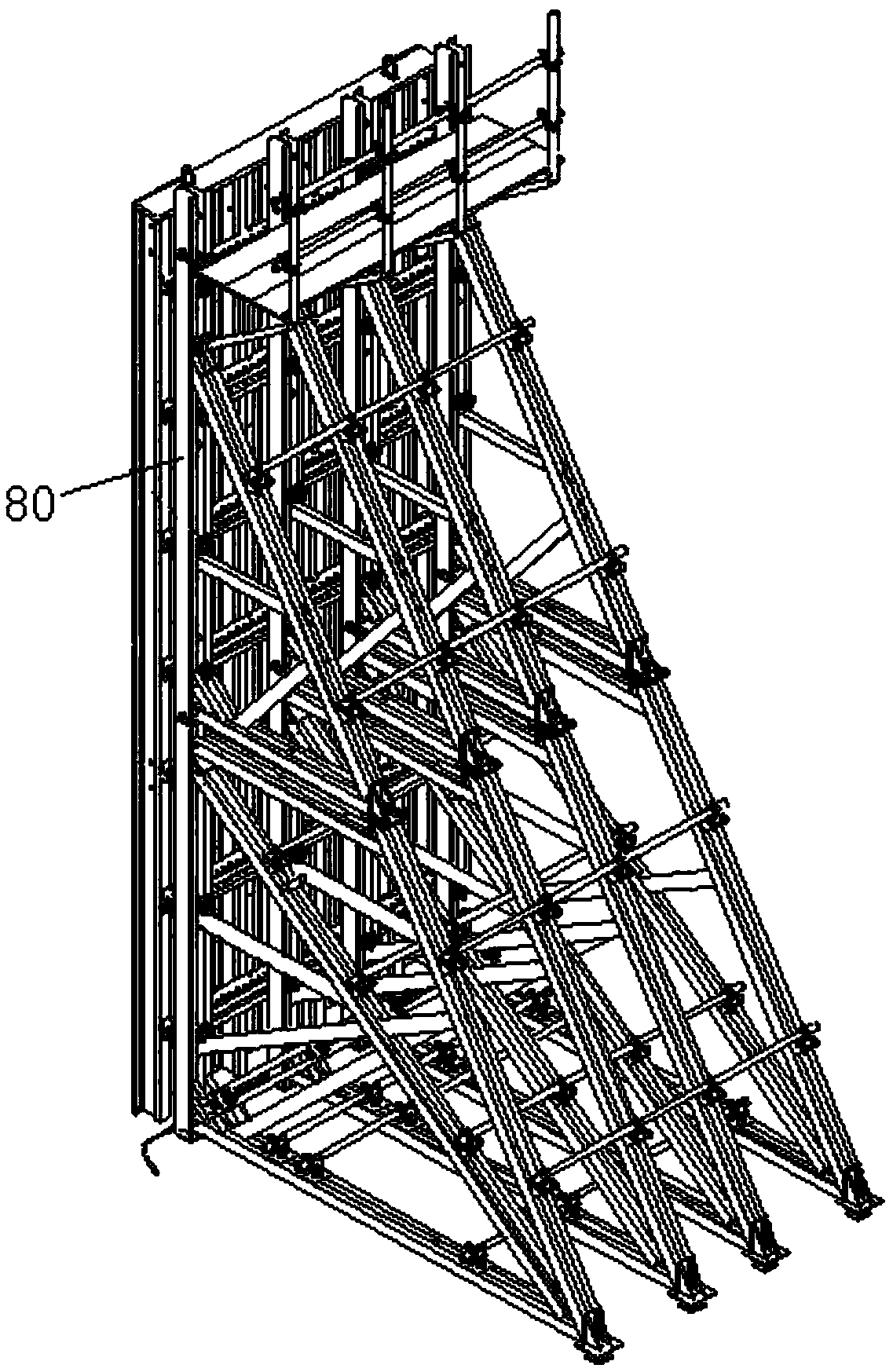

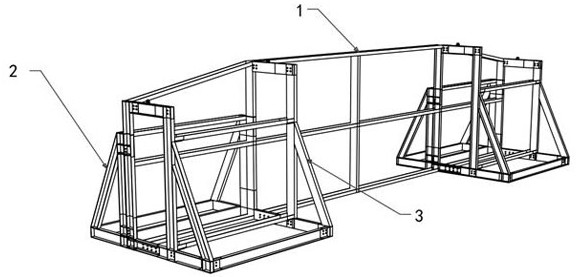

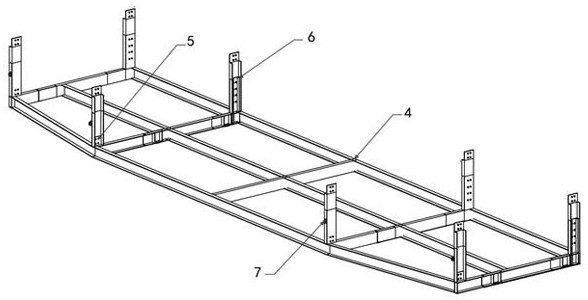

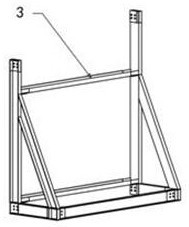

80-meter-span width steel box girder in-plant full-span assembly double-width erecting construction method

InactiveCN110847062AImprove machine utilizationReduce pollutionBridge erection/assemblyT-beamAgricultural engineering

The invention provides an 80-meter-span width steel box girder in-plant full-span assembly double-width erecting construction method. The 80-meter-span width steel box girder in-plant full-span assembly double-width erecting construction method comprises the following steps that first, a bottom plate unit (2), a partition plate unit (3), an inclined web T beam unit (4) and a cantilever unit (5) are machined by applying a BIM technology; second, a steel box girder general-assembly bed jig (1) is arranged in a general-assembly area of a beam plant; third, the bottom plate unit (2), the partitionplate unit (3), the inclined web T beam unit (4) and the cantilever unit (5) are machined, and all components are assembled; fourth, acceptance inspection is conducted after general assembly of an 80-meter steel box girder (6) is completed; fifth, the steel box girder (6) is transported through a combined modular beam transporting vehicle (7); sixth, beam feeding is conducted; seven, beam fallingis conducted; and eight, the left and right widths of the full-span steel box girder are erected. The 80-meter-span width steel box girder in-plant full-span assembly double-width erecting construction method can be suitable for inland areas and can also be suitable for coastal areas, the field workload is decreased, human input is reduced under the current broad environment of high labor cost, and the cost is saved.

Owner:NO 6 ENG CO LTD OF CCCC FIRST HIGHWAY ENG

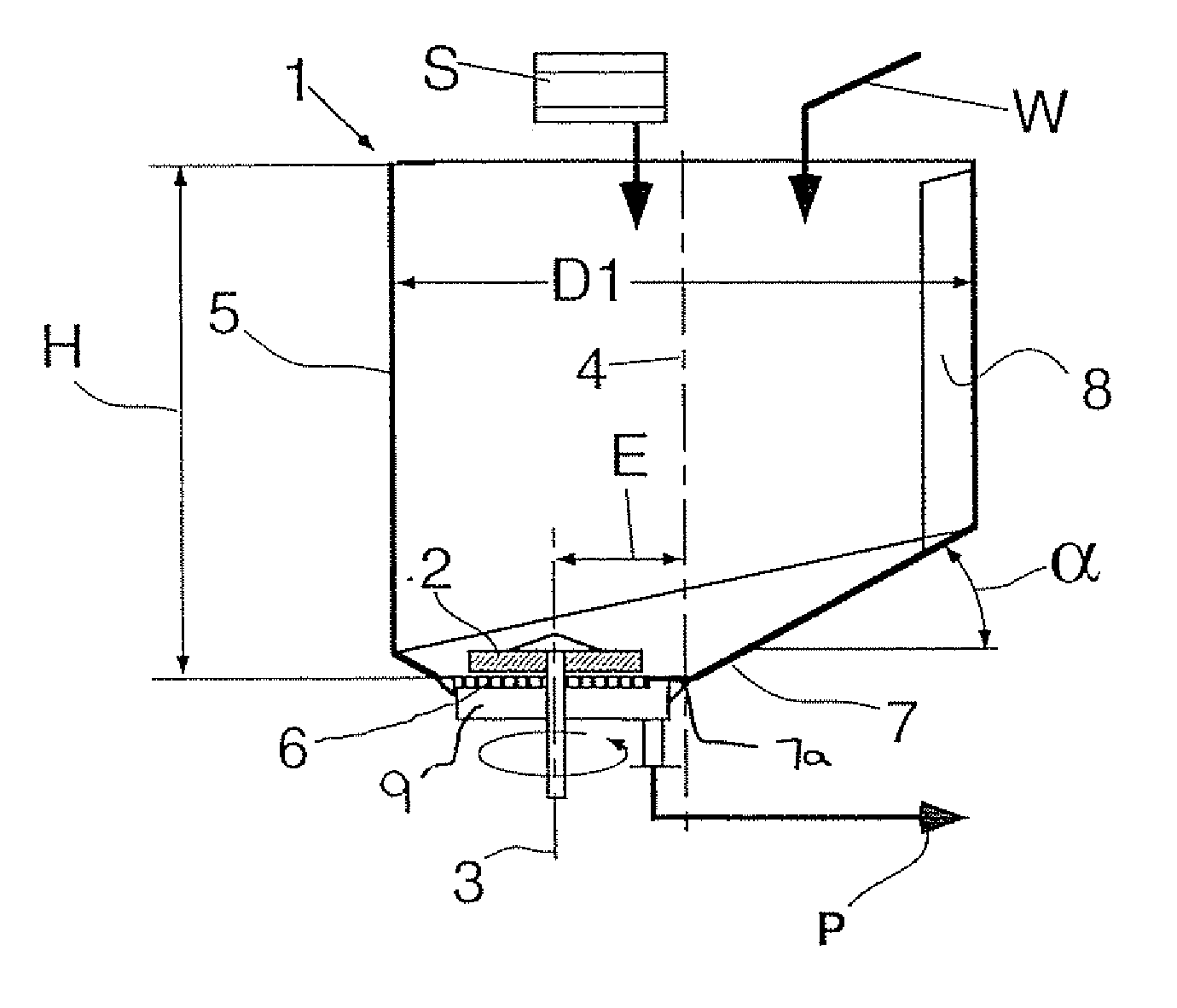

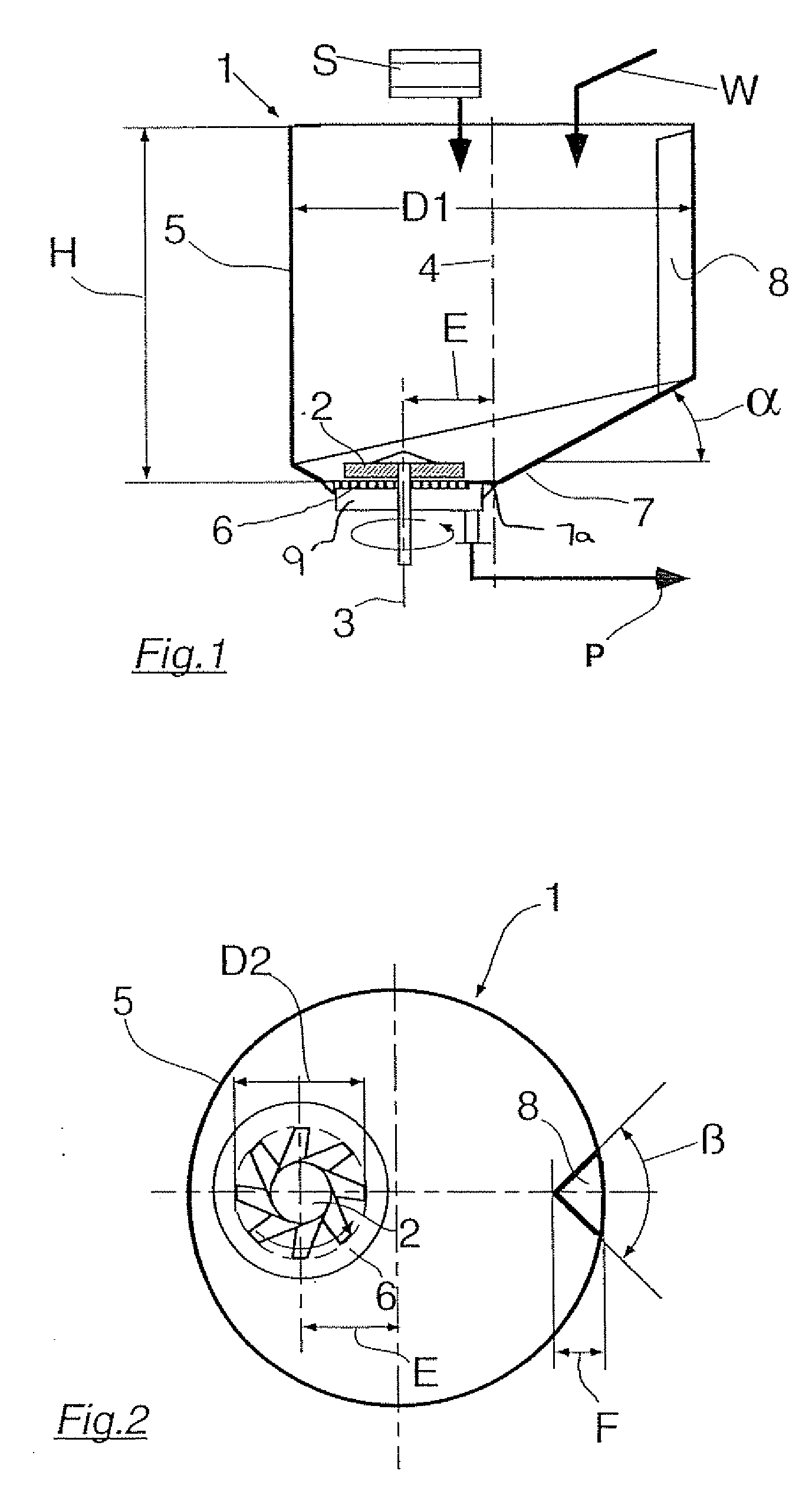

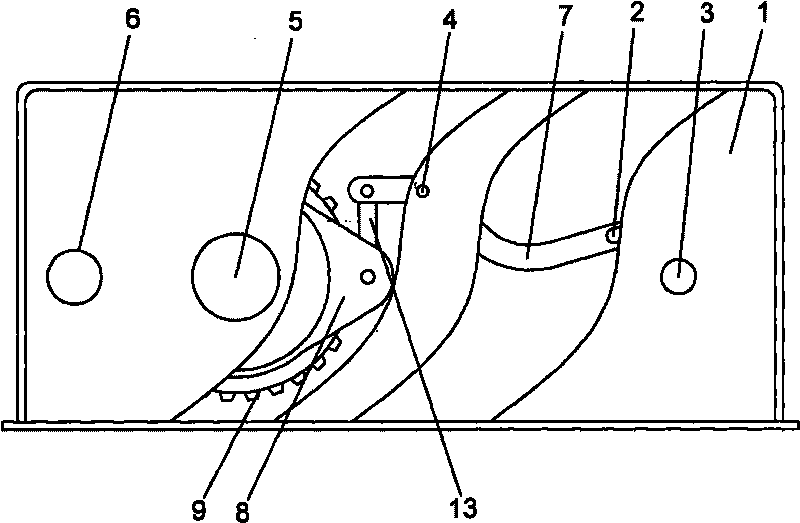

Pulper for pulverizing and suspending paper stock

InactiveUS20060273208A1Easy to optimizeSimple materialGas current separationFibrous raw materialsEngineeringMechanical engineering

Owner:VOITH PATENT GMBH

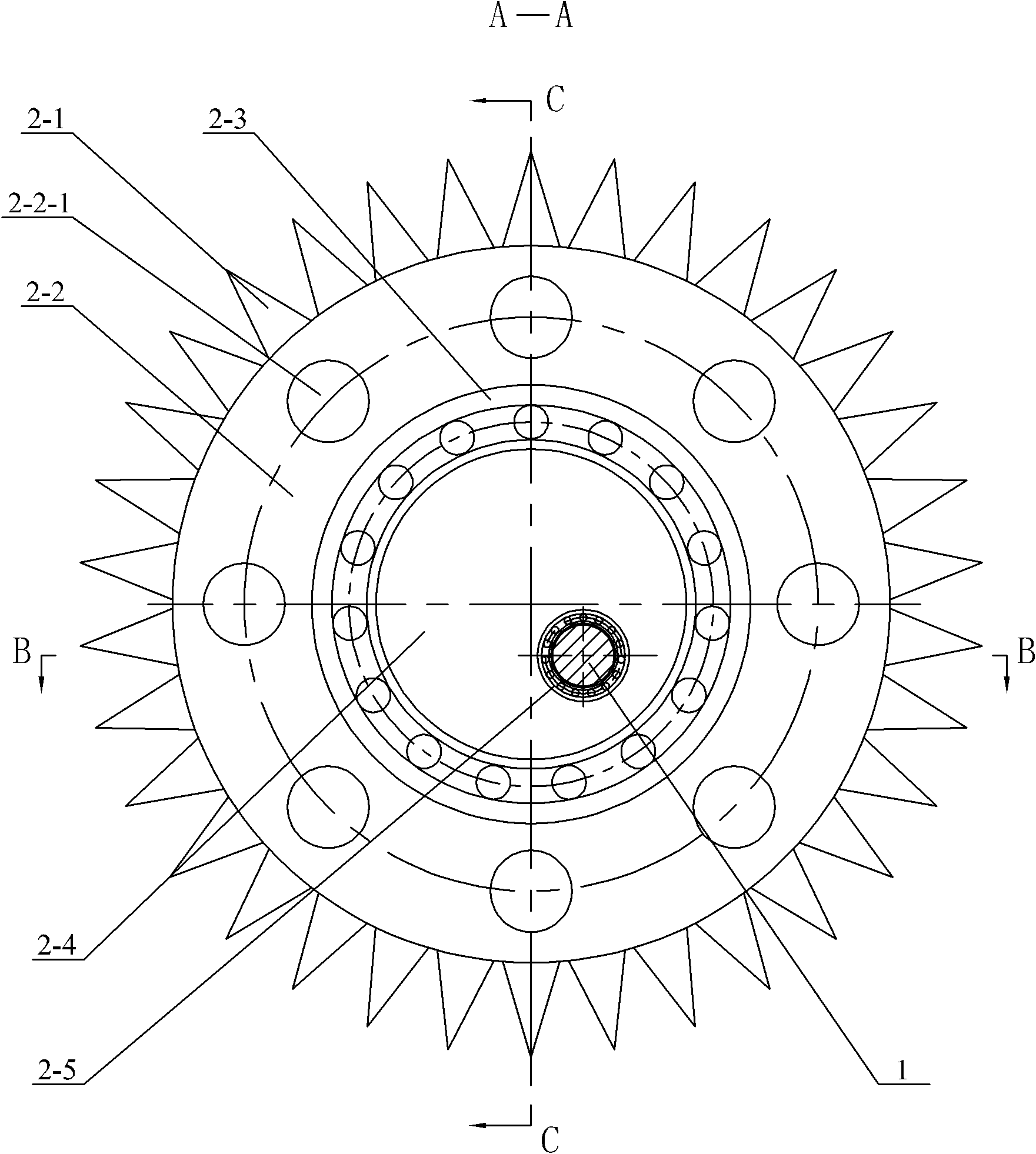

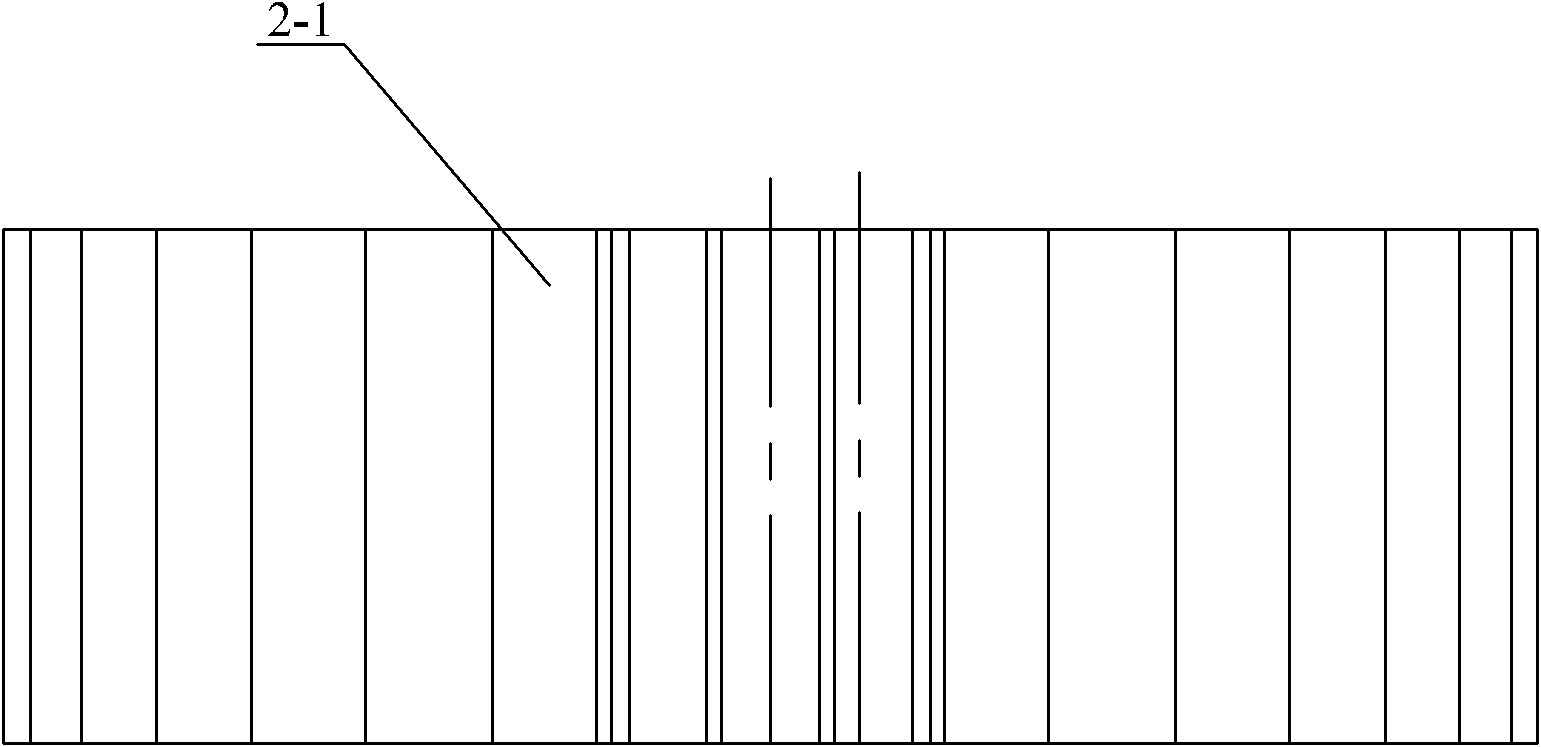

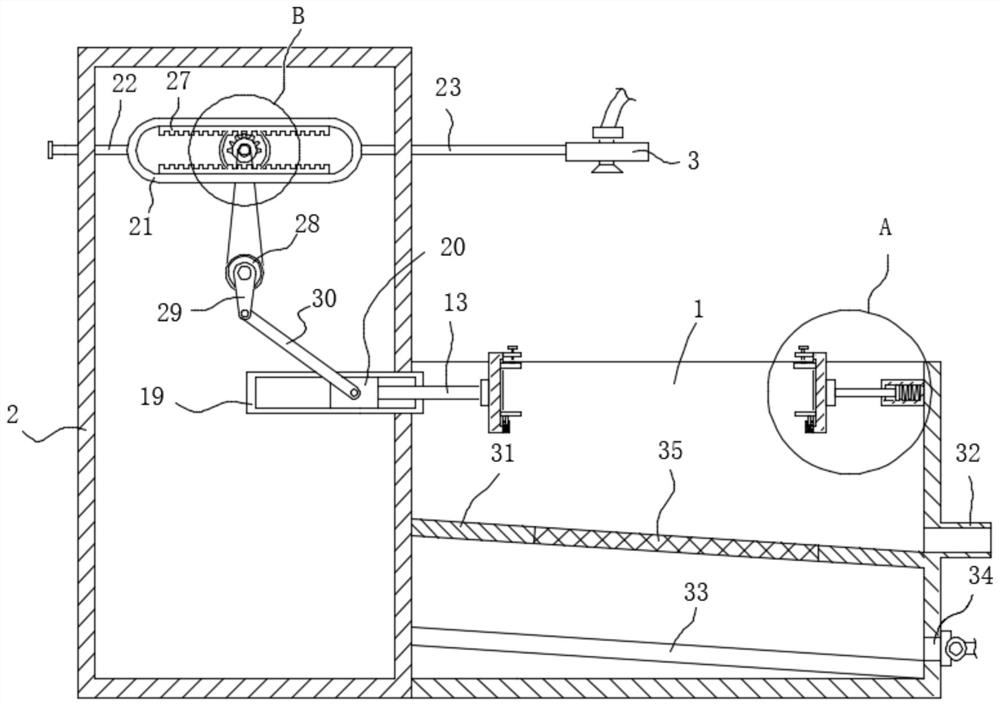

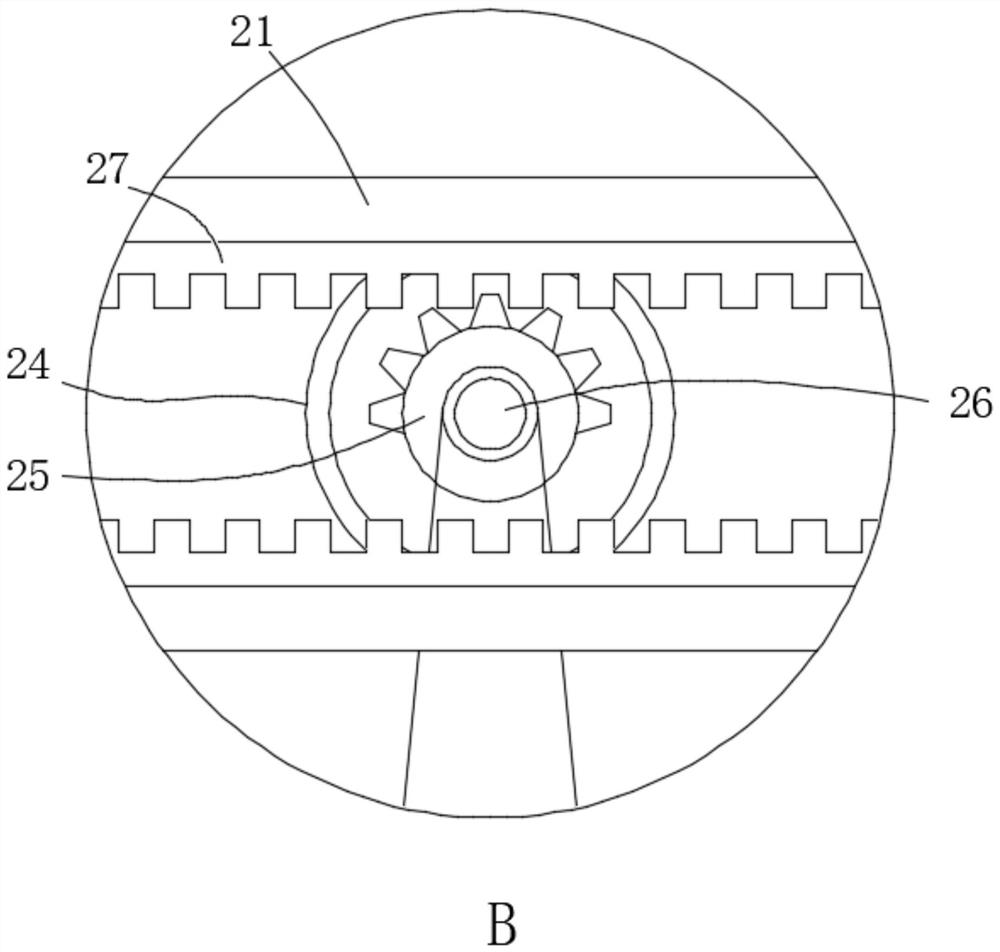

Boosting lever and gear combination mechanism

InactiveCN101701621AImprove machine utilizationReduce mechanical wear and tearGearingDrive wheelMachine utilization

The invention relates to a boosting lever and gear combination structure which belongs to the technical field of transmission machines. The boosting lever and gear combination structure comprises an input shaft and an output shaft, wherein the input shaft and the output shaft are arranged at a gear box casing, the input shaft is linked with the output shaft by boosting levers, a stage tooth rotating shaft, a speed regulation driving wheel and a speed regulation driven wheel which are sequentially arranged, the boosting levers are arranged at the gear box casing in a matching way by fulcrum shafts on the boosting levers, one end of a long rod of the boosting levers is connected to the input shaft, one end of a short rod is connected to a connection arm wheel of a unidirectional movable tooth arranged on the stage tooth rotating shaft in a matching way, the stage tooth rotating shaft and the output shaft are respectively connected with the speed regulation driving wheel and the speed regulation driven wheel in a matching way, and the speed regulation driving wheel and the speed regulation driven wheel are engaged for transmission. The invention audaciously and skillfully combines levers and gear transmission together, utilizes a group of boosting levers which are arranged side by side to work alternately by turns and enables the transmission of each time to push the stage tooth rotating shaft by maximum force after being reinforced; by the structure with reasonable design, higher machine utilization rate is realized, the mechanical wear is lowered, and energy resources are saved.

Owner:陈周林

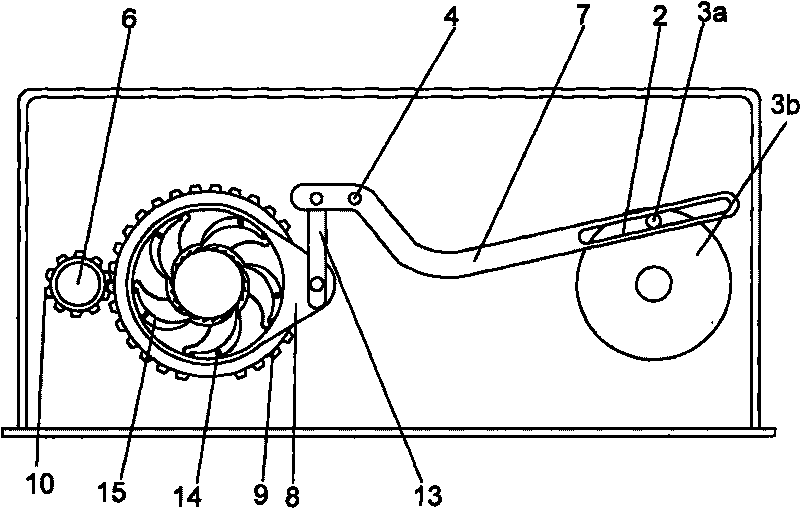

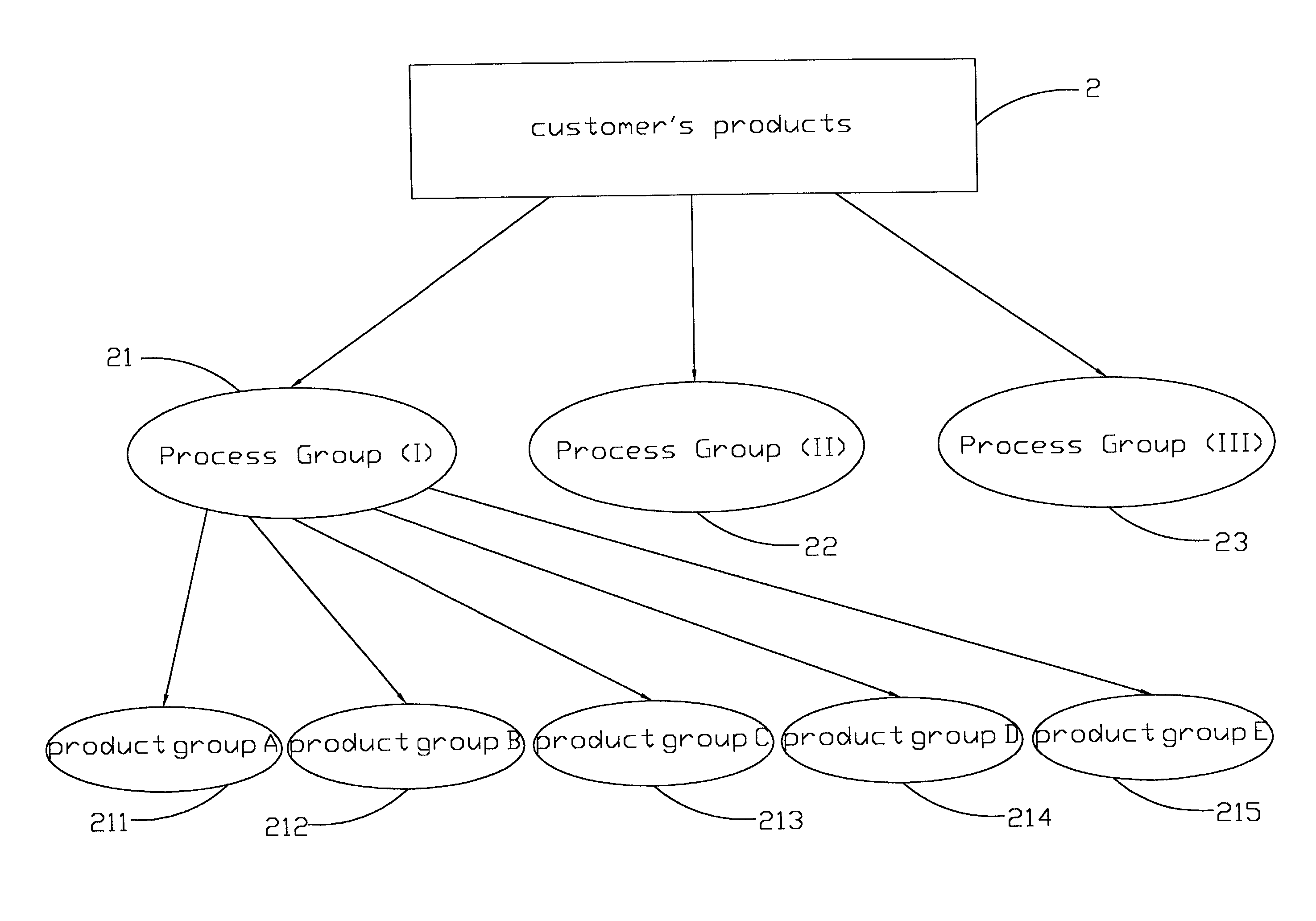

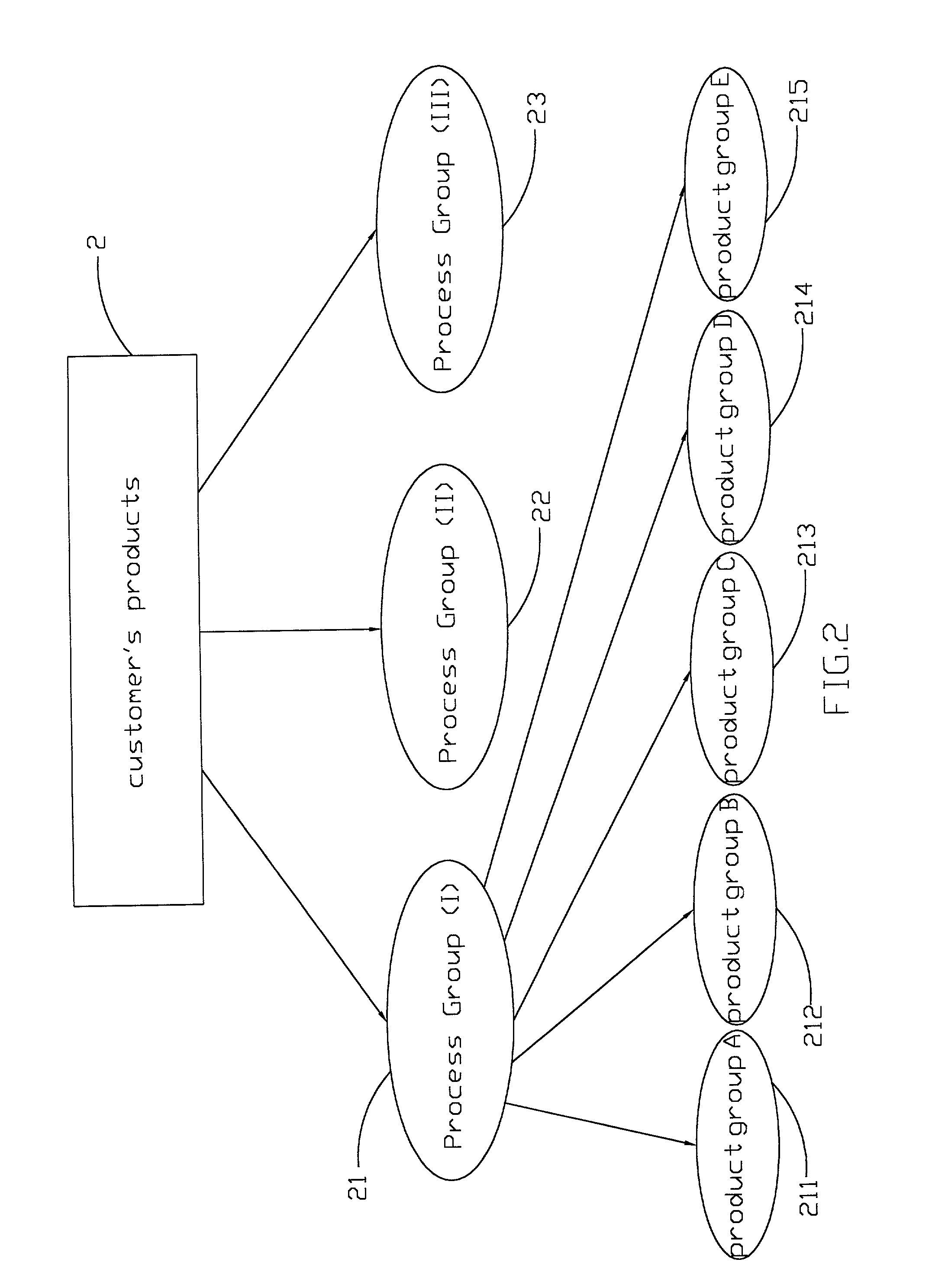

Method for planning product groups

InactiveUS20020184074A1Accurate capacityImprove machine utilizationResourcesSpecial data processing applicationsPresent methodProduct group

A method for planning product groups is provided. The present method is characterized in that selecting processes from a process group according to the rule of the sum of production capacities of the processes in proportion to the total production capacity of the process group not less than a predetermined ratio and the demand production capacity per month of the processes not less than a predetermined value. Then, defining each of selected processes as a product group. Finally, incorporating the unselected processes of the process group into the product groups according to process resemblance.

Owner:UNITED MICROELECTRONICS CORP

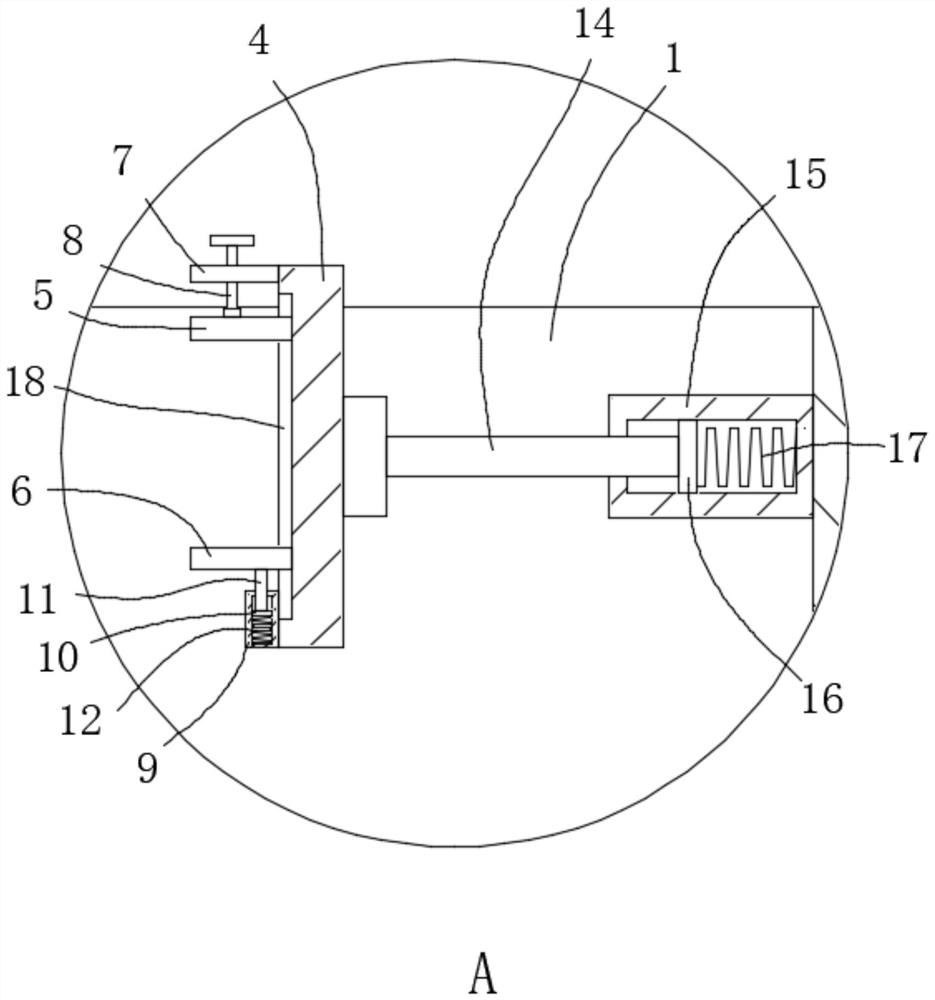

Position-adjusting device for precast concrete wall panel

The invention discloses a position-adjusting device for a precast concrete wall panel. The position-adjusting device comprises the precast concrete wall panel, a jacking device, a roller support and an adjusting device. The precast concrete wall panel and the jacking device are connected by means of a fixing bolt. The lower portion of a horizontal connecting plate of the jacking device is provided with a jack. The jack is mounted onto the upper surface of the roller support. A vertical connecting plate of the jacking device is fixedly connected with a pull rod connecting plate. The pull rod connecting plate is connected with a movable rod by means of a pin rod. The movable rod is arranged in an adjustable bracing pull rod in a sleeving mode. The front end of the adjustable bracing pull rod is provided with an adjusting device. The tail end of the adjustable bracing pull rod is hinged onto a support by means of the pin rod. The support is connected with the ground by means of a foundation bolt. The position-adjusting device for the precast concrete wall panel has following advantages: position adjustments in two directions can be made to a wall plate; and with no large hoisting equipment required for cooperation during installation, utilization rate of machinery is increased and damage to the wall plate is avoided so that high installation efficiency is obtained.

Owner:CHINA MCC17 GRP

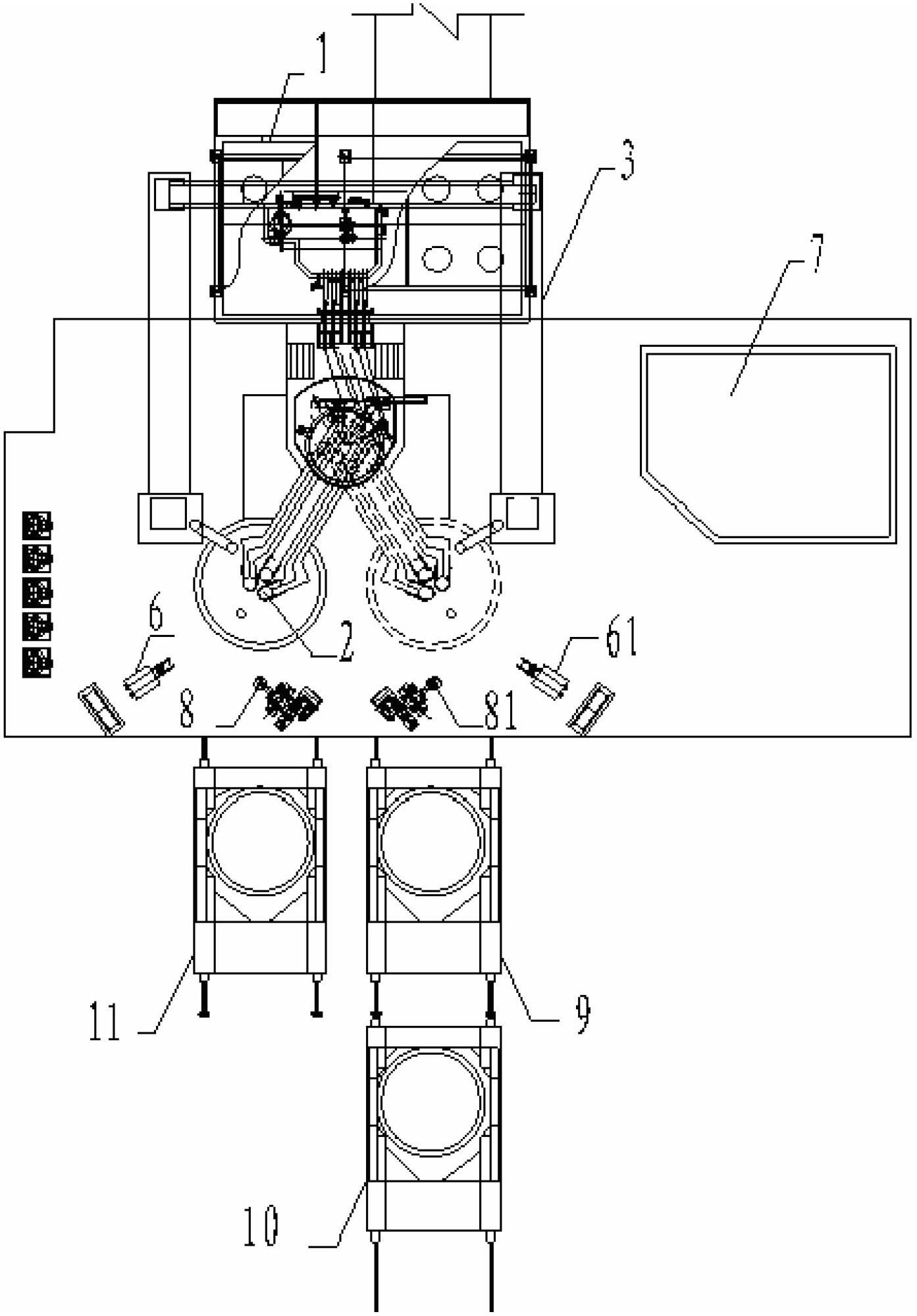

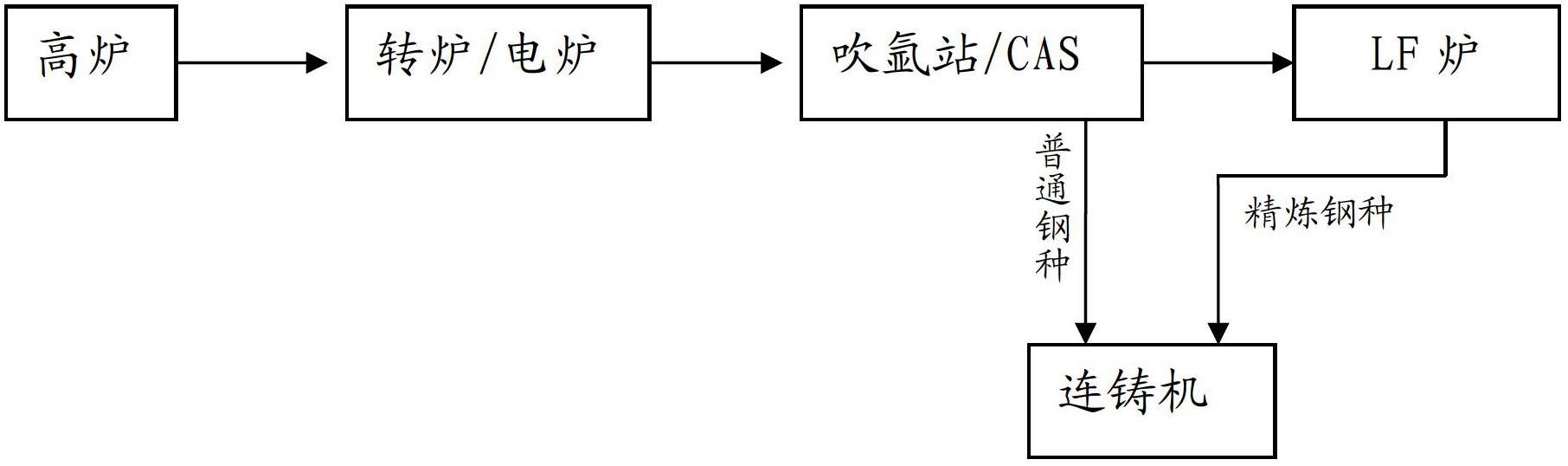

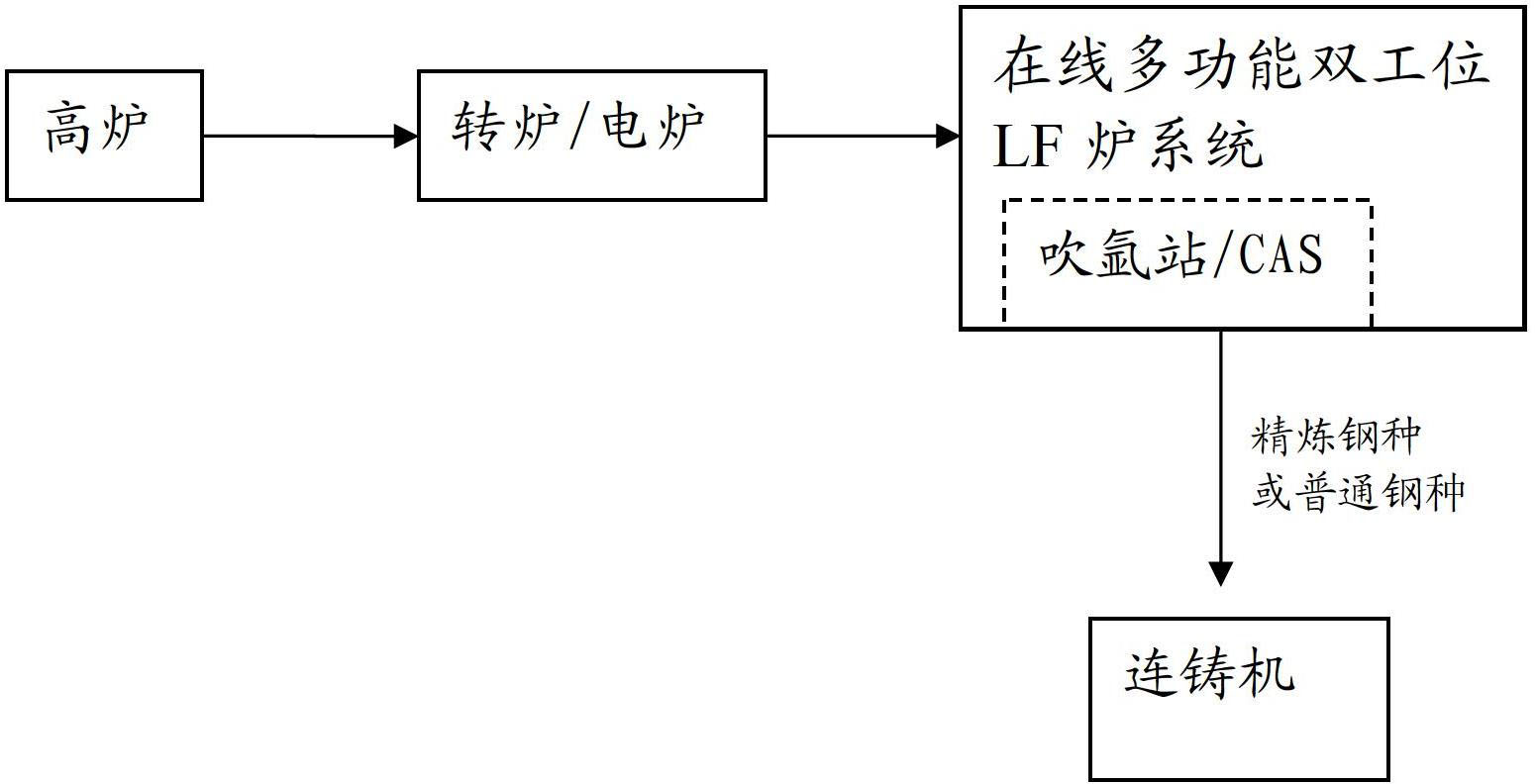

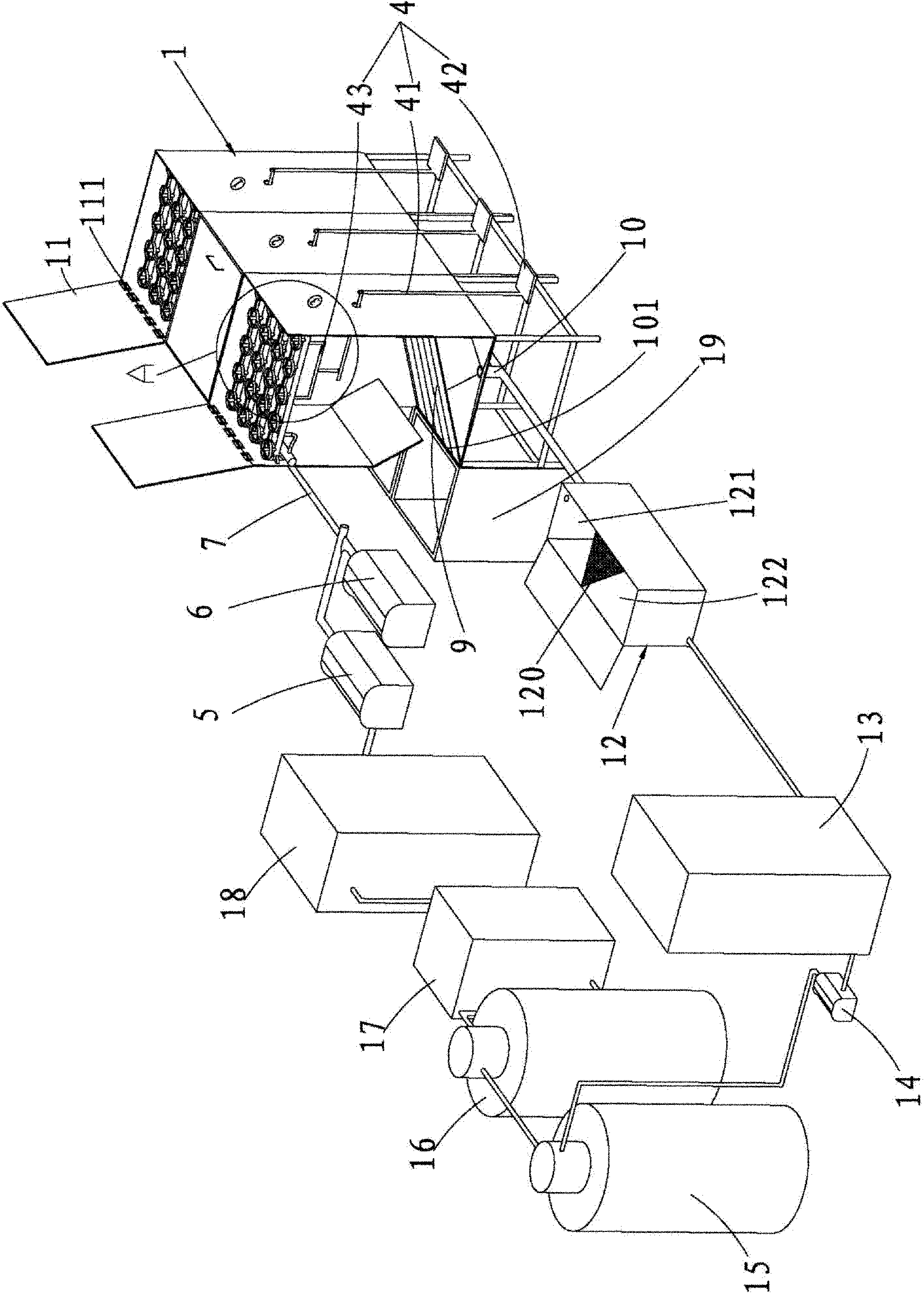

Online multifunctional double-station LF (Low-Frequency) furnace system and online LF furnace steelmaking method

InactiveCN102660661AReduce distanceShorten the production cycleCrucible furnacesSteelmakingMetallurgy

The invention discloses an online multifunctional double-station LF (Low-Frequency) furnace system and an online LF furnace steelmaking method and aims to solve the problems that the conventional LF furnace can be used in a steel refining process only and has low utilization efficiency and slight resource waste, a large area is occupied as an area is required to be independently arranged for accommodating the LF furnace and the like. The online multifunctional double-station LF furnace system comprises an LF furnace which is transversely arranged on two parallel stations. The functions of the traditional argon flushing station are realized by equipment in the LF furnace; or the functions of CAS (Control Automatic System) are realized by the equipment in the LF furnace, and the LF furnace is used for refining molten steel in the process of making refined steel. The online LF furnace steelmaking method comprises the following steps of: performing treatments of blowing argon, measuring the temperature and sampling, feeding wires and the like on the molten steel subjected to primary steelmaking by directly using the online multifunctional double-station LF furnace system. The online multifunctional double-station LF furnace system and the online LF furnace steelmaking method have the characteristics of low investment, small occupied land, high efficiency and the like, and are particularly suitable for improvement of old plants and old equipment.

Owner:HUATIAN ENG & TECH CORP MCC

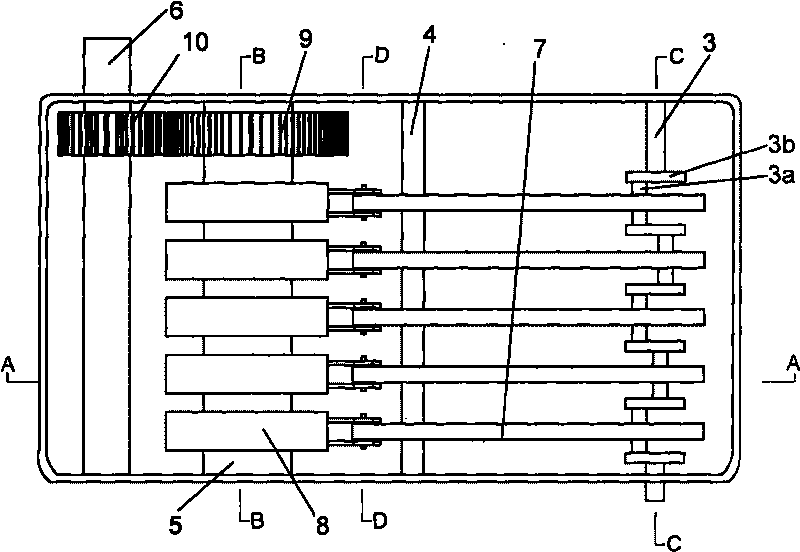

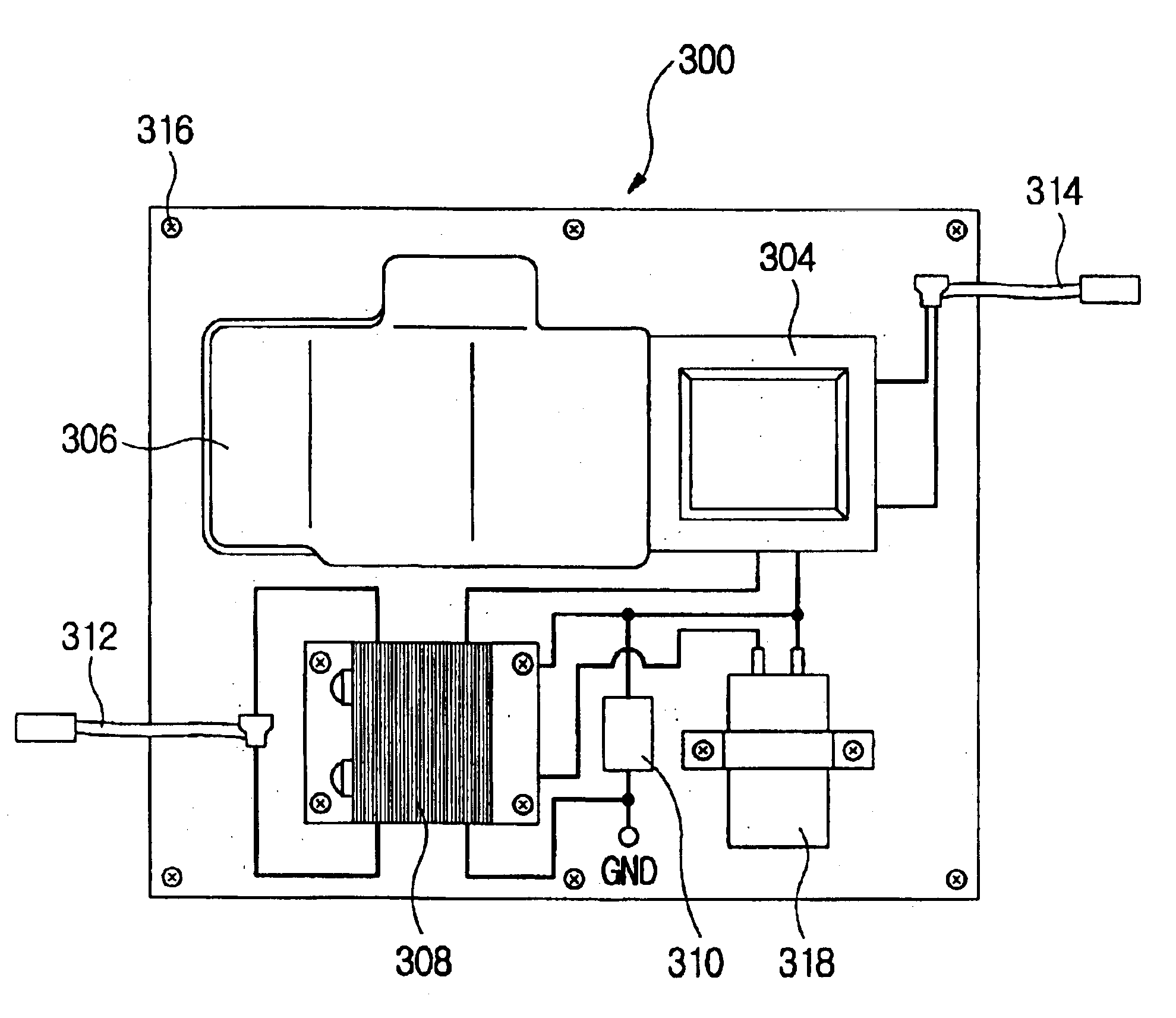

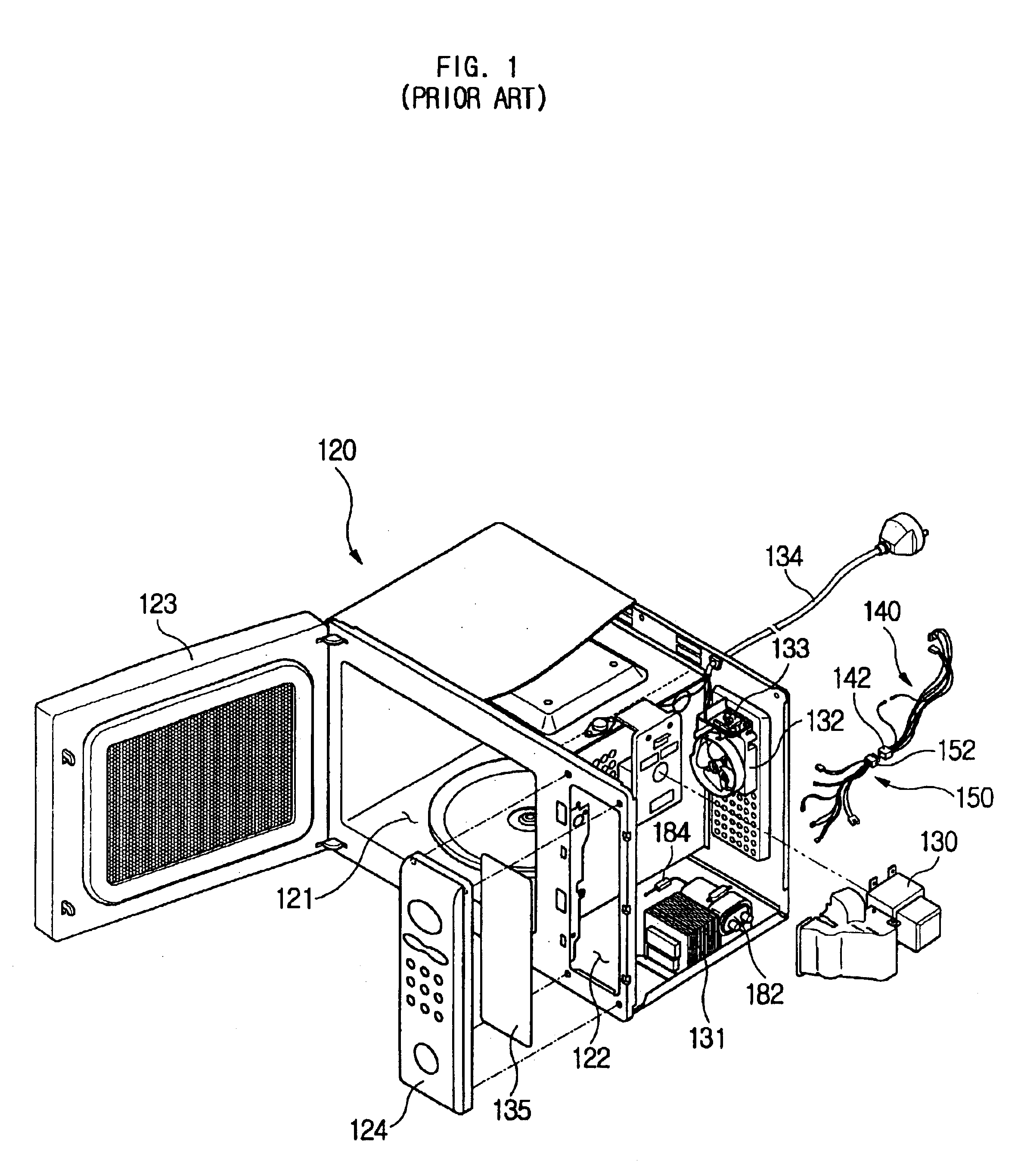

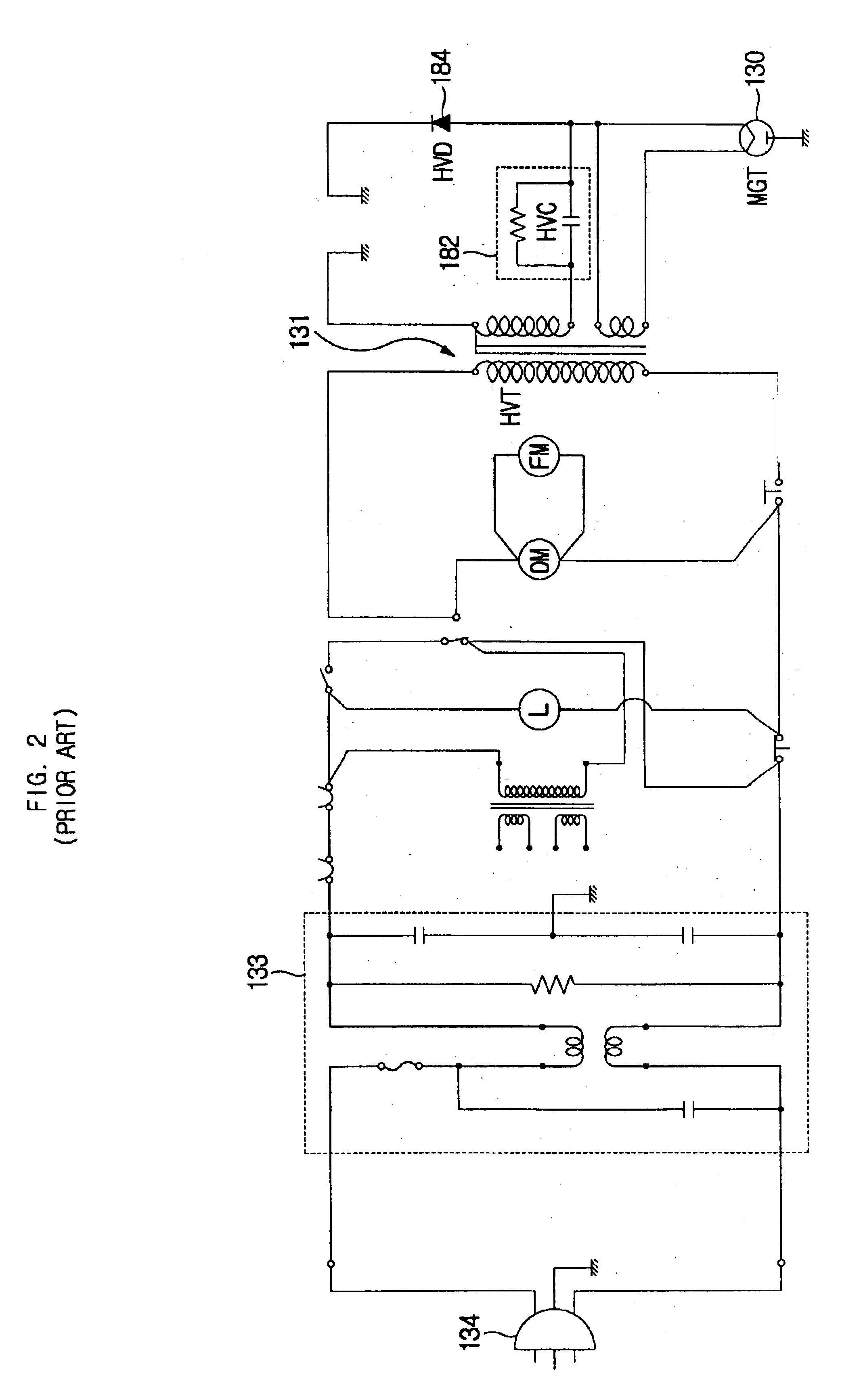

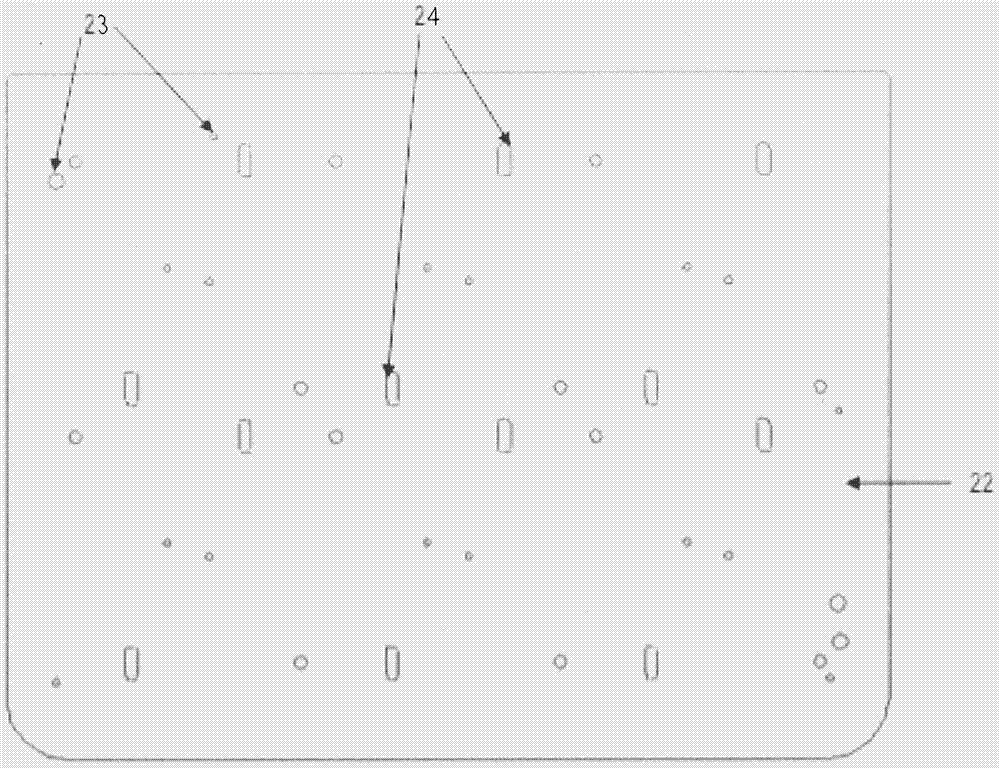

Magnetron driving circuit board for microwave oven

InactiveUS6906298B2Improve machine utilizationSmall sizeDomestic stoves or rangesLighting and heating apparatusMicrowave ovenEngineering

A microwave oven having a magnetron that generates microwaves, a magnetron driving circuit that supplies high voltage power to the magnetron and a machine room that accommodates the magnetron and the magnetron driving circuit. The microwave oven includes a single magnetron driving circuit board in which the magnetron and the electronic devices of the magnetron driving circuit are mounted thereon. The single magnetron driving circuit board is fixedly attached to the machine room by mounting members.

Owner:SAMSUNG ELECTRONICS CO LTD

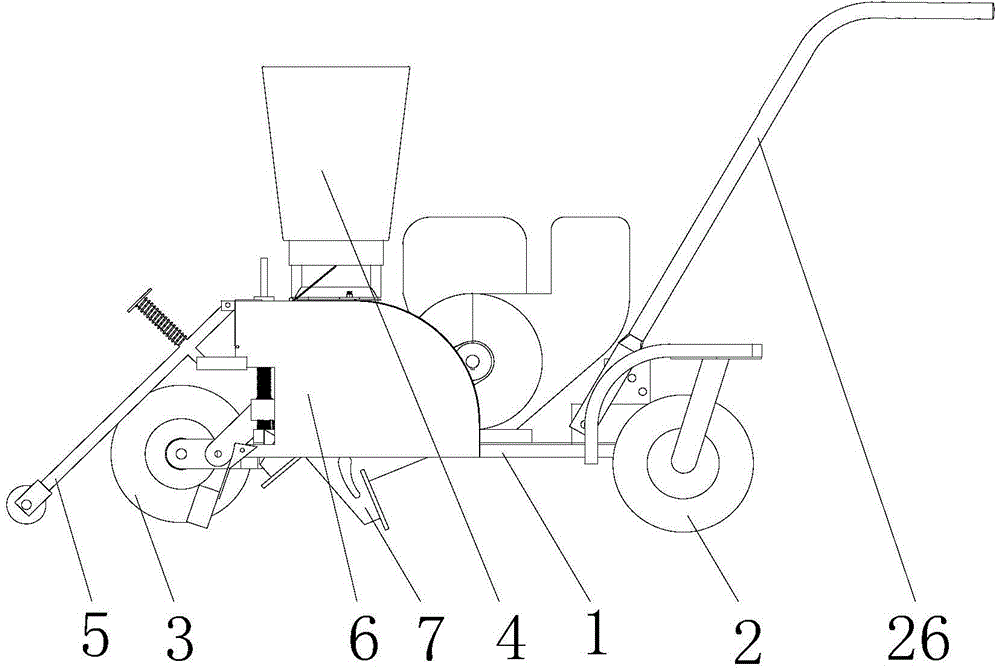

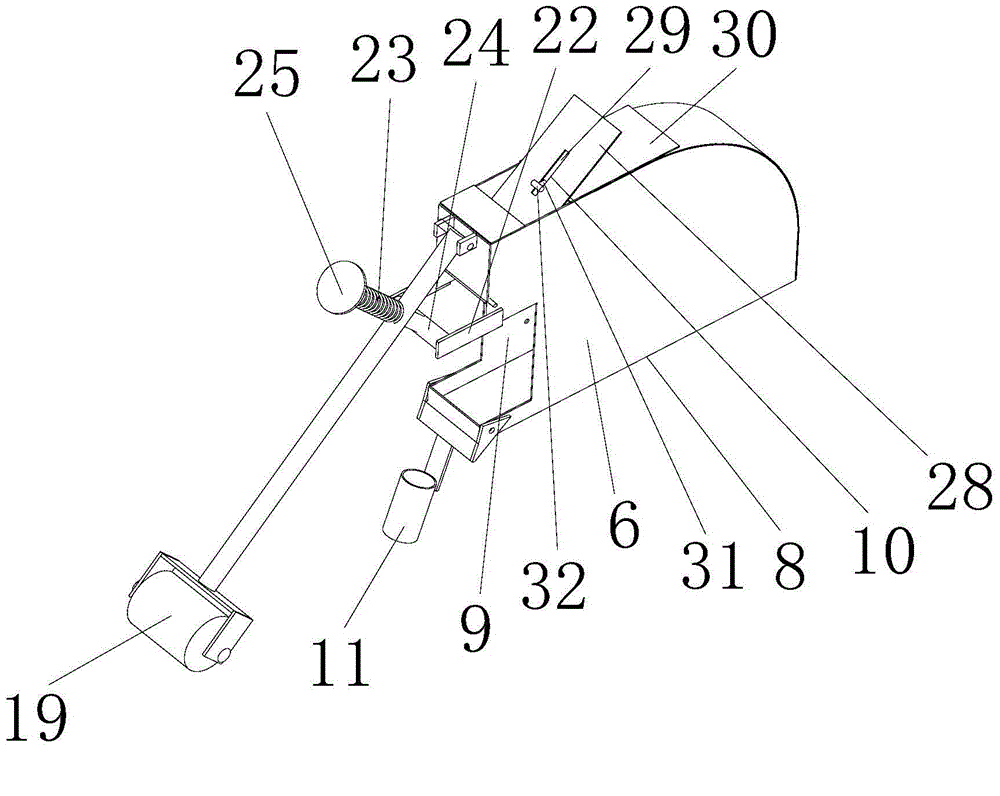

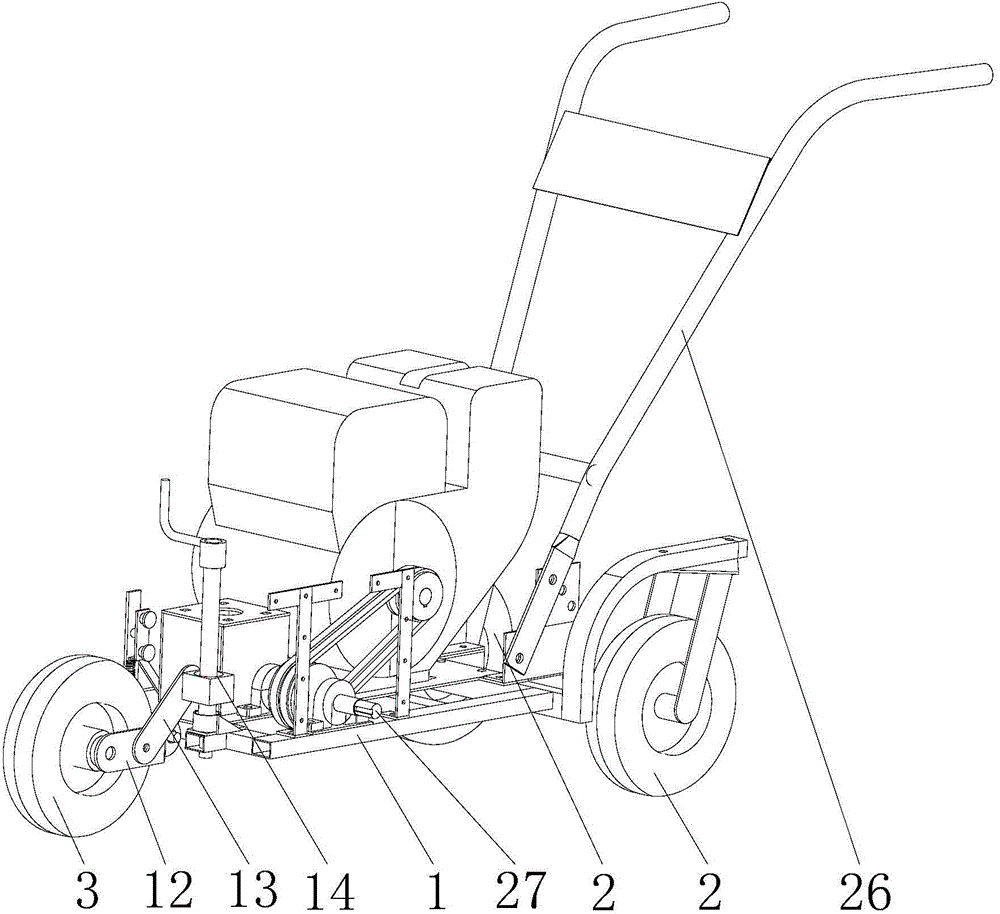

Multifunctional ditching and soil covering integrated machine

ActiveCN104303645AReduce labor intensityImprove work efficiencyPlantingAgricultural rollersEngineeringUltimate tensile strength

The invention discloses a multifunctional ditching and soil covering integrated machine. The multifunctional ditching and soil covering integrated machine comprises a supporting frame, and a rear walking wheel, a front walking wheel, a soil covering box, a material discharging device and a power device which are mounted on the supporting frame; the soil covering box comprises a box body and a ditching knife; the box body is provided with a soil inlet and a soil outlet; the soil inlet is formed at the bottom of the box body; the soil outlet is formed at the rear side of the forwarding direction of the box body; the ditching knife is arranged in the box body and partially extends out of the soil inlet; the ditching knife is driven to rotate by the power device; the output opening of the material discharging device is formed between the soil inlet and the soil falling position. According to the multifunctional ditching and soil covering integrated machine, soil return operation can be performed automatically after ditching, fertilizing or sowing are completed. The process of performing backfill finishing operation at the cost of manpower and resources after the ditching by a ditching machine is avoided, so that the labor intensity of operating personnel is reduced, and the work efficiency is improved. The multifunctional ditching and soil covering integrated machine can be applied to farmland field fertilization and can also be applied to field sowing; one machine has multiple functions and the mechanical utilization rate is improved.

Owner:SOUTH CHINA AGRI UNIV

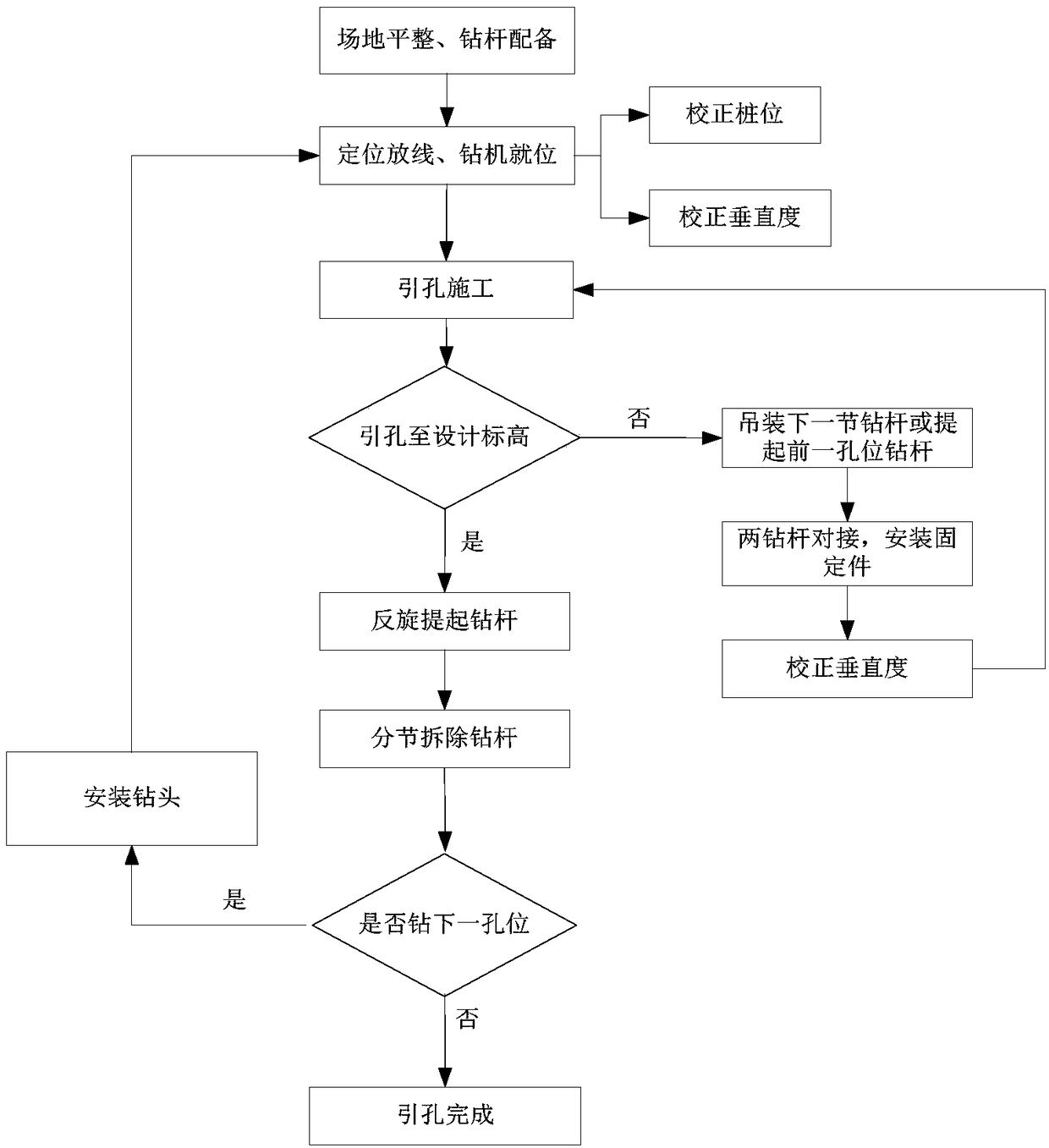

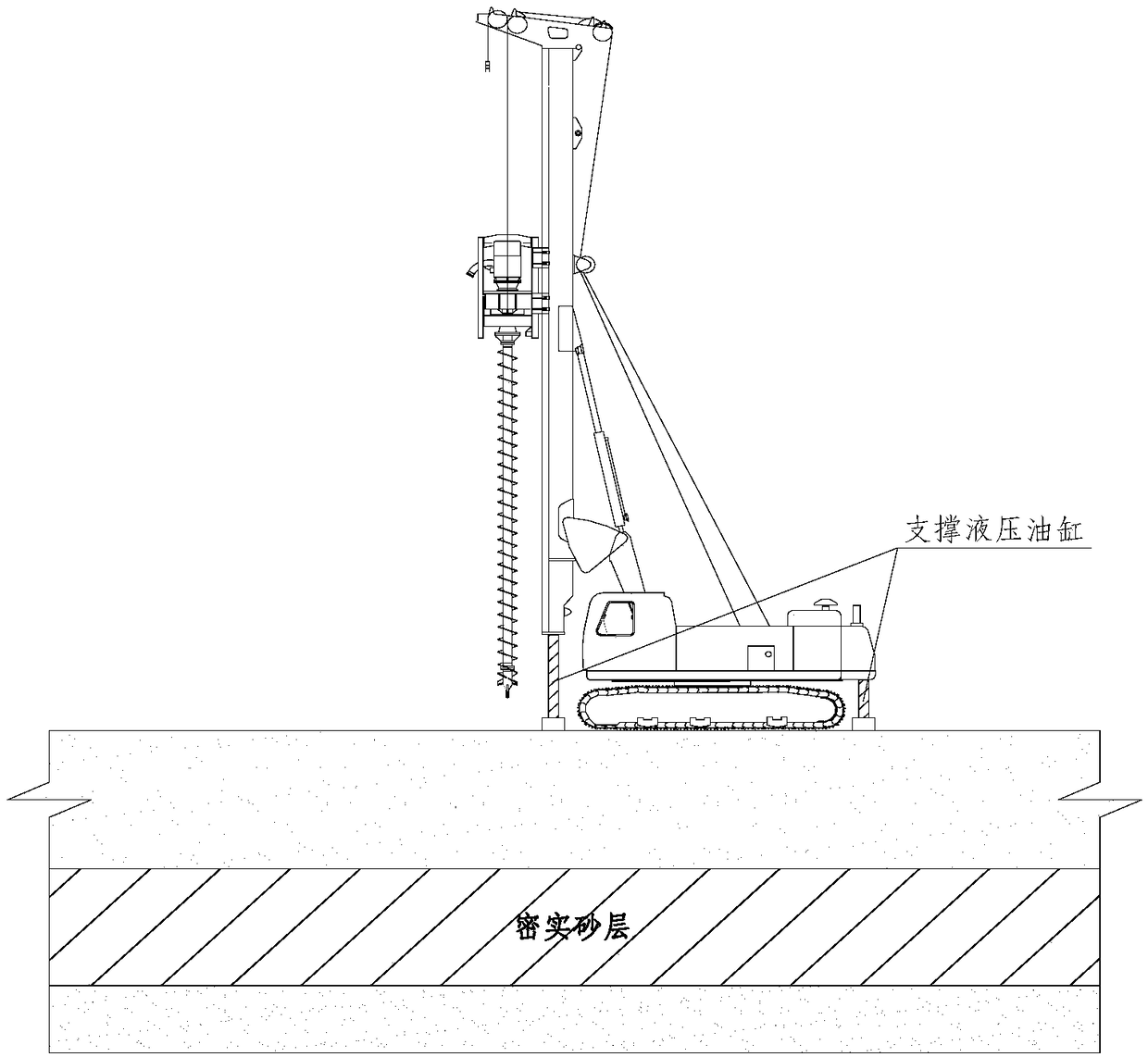

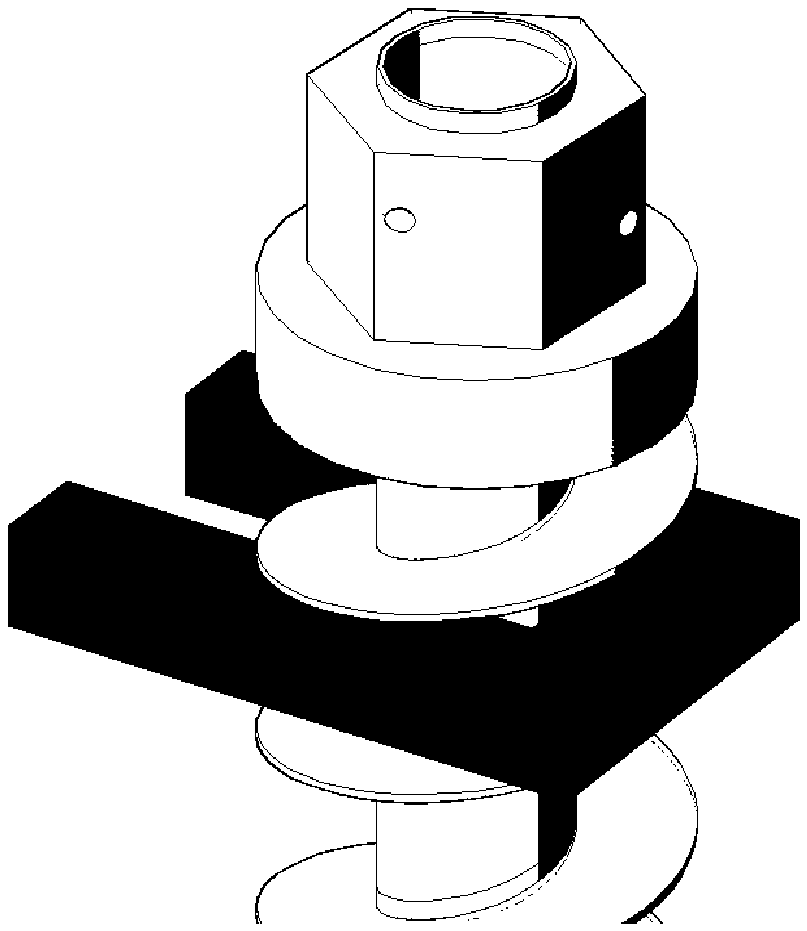

Ultra-deep and extra-thick dense sand stratum prestressed pipe pile long spiral lead hole construction method

ActiveCN109025816AFirmly connectedMeet the constructionDrilling rodsDirectional drillingTotal stationEngineering

The present invention discloses an ultra-deep and extra-thick dense sand stratum prestressed pipe pile long spiral lead hole construction method. The method comprises the following steps of: S1: siteformation and drill stem equipping: performing leveling and compaction for a site prior to place taking, or bedding a steel plate to facilitate place taking of a pile machine, and regulating equippingof the corresponding quantity of drill stems according to the depth of the lead holes to ensure the lead hole operation flow construction, wherein two lead hole drills are arranged on the site; and S2: location, paying-off and place taking of the pile machine: employing a total station to perform laying-off for preset lead hole stake positions, taking a drill machine in place to complete correction of the vertical degree of the drill stem and the centering of the center of the drill, and after location, putting down a support oil cylinder at the lower portion of a front-end mast and two support oil cylinders at the tail portion of the machine body of the drill machine. The ultra-deep and extra-thick dense sand stratum prestressed pipe pile long spiral lead hole construction method can extend the drill stem at will through connection according to pore-forming demands by employing a design of the hexagonal joint of the drill stem, can effectively ensure the reliable connection of the drill stem by only using a dual-way fixed plug pin after the drill stem is inserted when being connected and can meet the construction of an overlength pile hole.

Owner:SHENZHEN GONGKAN GEOTECHN GRP

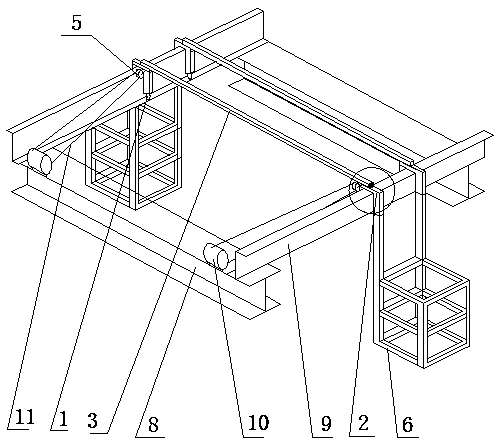

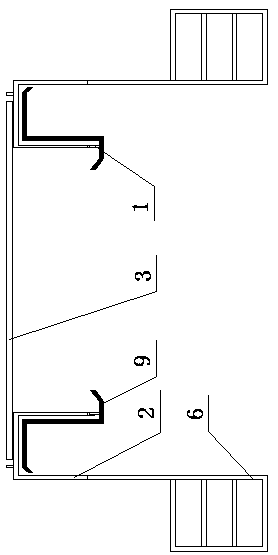

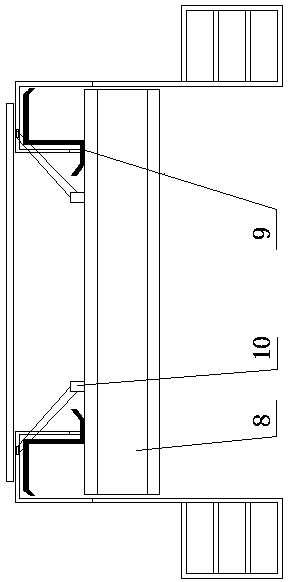

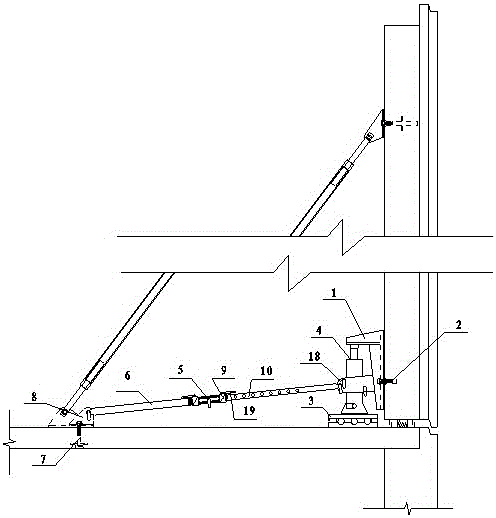

Color plate reverse ceiling upper-air sliding device and reverse ceiling construction method

PendingCN108190808ASave spaceOptimize the construction processLifting devicesBuilding material handlingEngineeringProtection KIT

The invention provides a color plate reverse ceiling upper-air sliding device and a reverse ceiling construction method. As for a traditional roof color plate inner plate, mounting work procedures arecomplex, needed environment factors are many, and consumption in the aspects of manpower, funds and machines is over large. The color plate reverse ceiling upper-air sliding device comprises two hanging baskets (6), the hanging baskets are connected with idler wheels (1) through U-shaped connecting devices (2), and the two hanging baskets are connected together through the U-shaped connecting devices, bolts (4) and connecting square steel (3). The outer ends of the U-shaped connecting devices are provided with protecting sleeves, the side edges of the U-shaped connecting devices are providedwith fixed pulley sets A (5), and the U-shaped connecting devices are placed on Z-shaped purlines (9). The two ends of the Z-shaped purlines are welded to I-shaped steel (8). The invention discloses the color plate reverse ceiling sliding device and a using method.

Owner:黑龙江省建筑安装集团有限公司

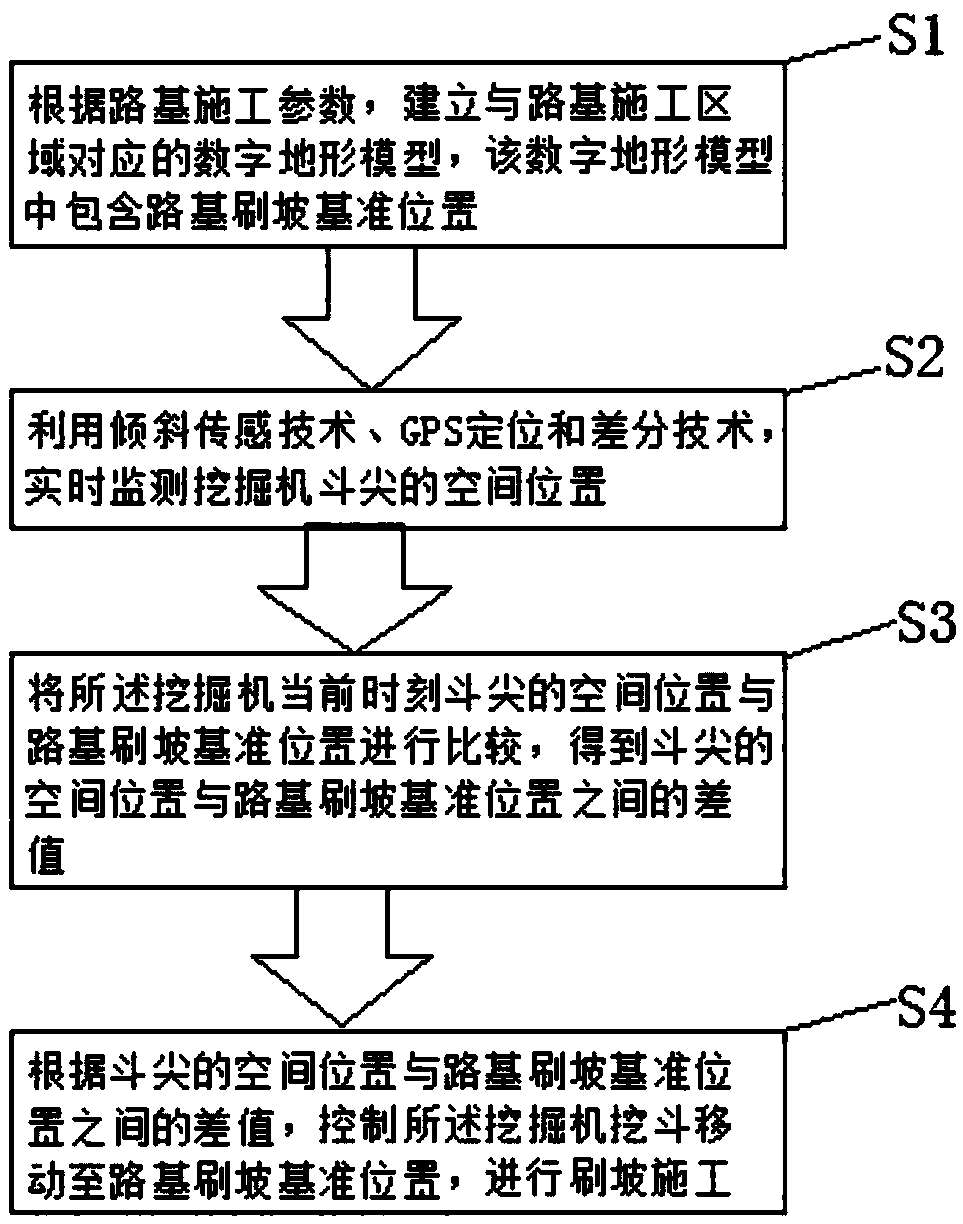

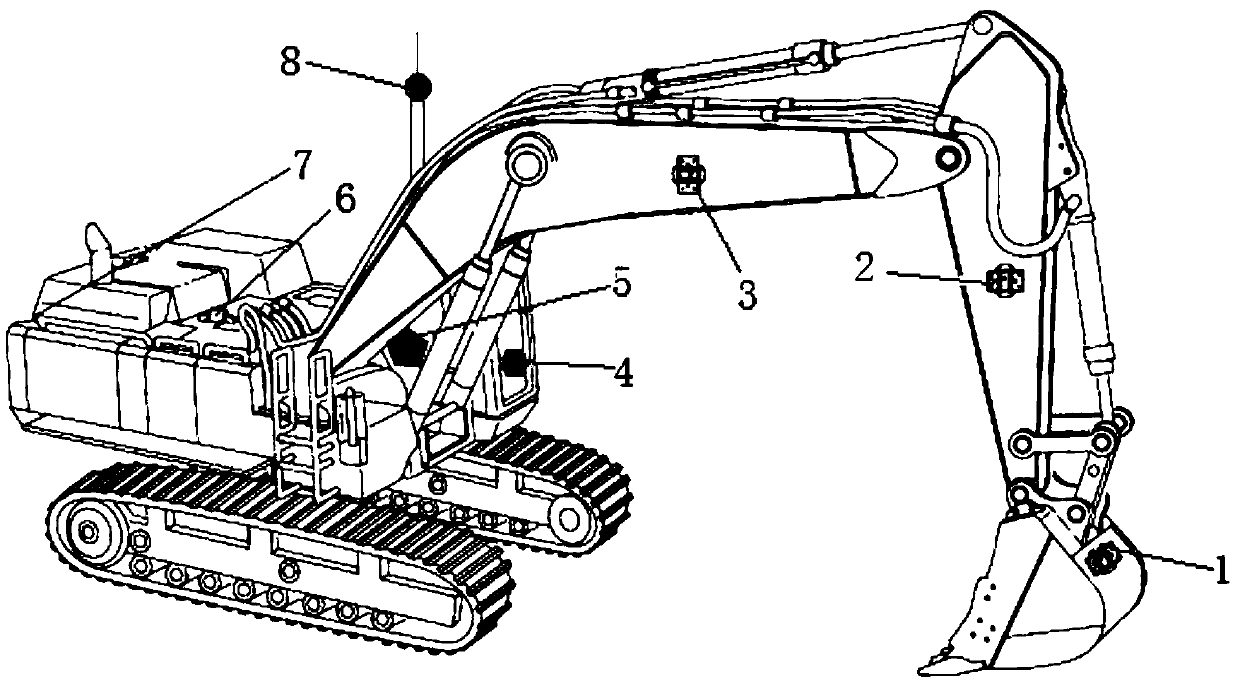

Construction method and system of roadbed brush slope

InactiveCN109577413ASave the heavy work of measuring and setting outReduce labor inputSoil-shifting machines/dredgersEngineeringExcavator

The invention discloses a construction method and a system of a roadbed brush slope. The construction method of the roadbed brush slope comprises the following steps of digitally modeling, obtaining spatial positions of tips, comparing the positions, and constructing the brush slope; the construction system of the roadbed brush slope comprises an excavator body, an inclined sensor, a GPS (Global Positioning System) receiving device and a data processor, wherein the inclined sensor, the GPS receiving device and the data processor are installed on the excavator body, the inclined sensor and theGPS receiving device are respectively connected with the data processor, and the data processor is connected with the power output end of the excavator body. According to the construction method and the construction system, an excavator bucket is controlled to move to the reference position of the roadbed brush slope according to the difference between the spatial positions of the tips and the reference position of the roadbed brush slope so as to construct the brush slope, heavy measuring and lofting work and a large amount of labor input in a traditional brush slope method are saved, additionally, the utilization rate of machinery is greatly increased, the construction efficiency is improved, and the construction period is shortened.

Owner:THE FIRST ENG CO LTD OF CTCE GRP +1

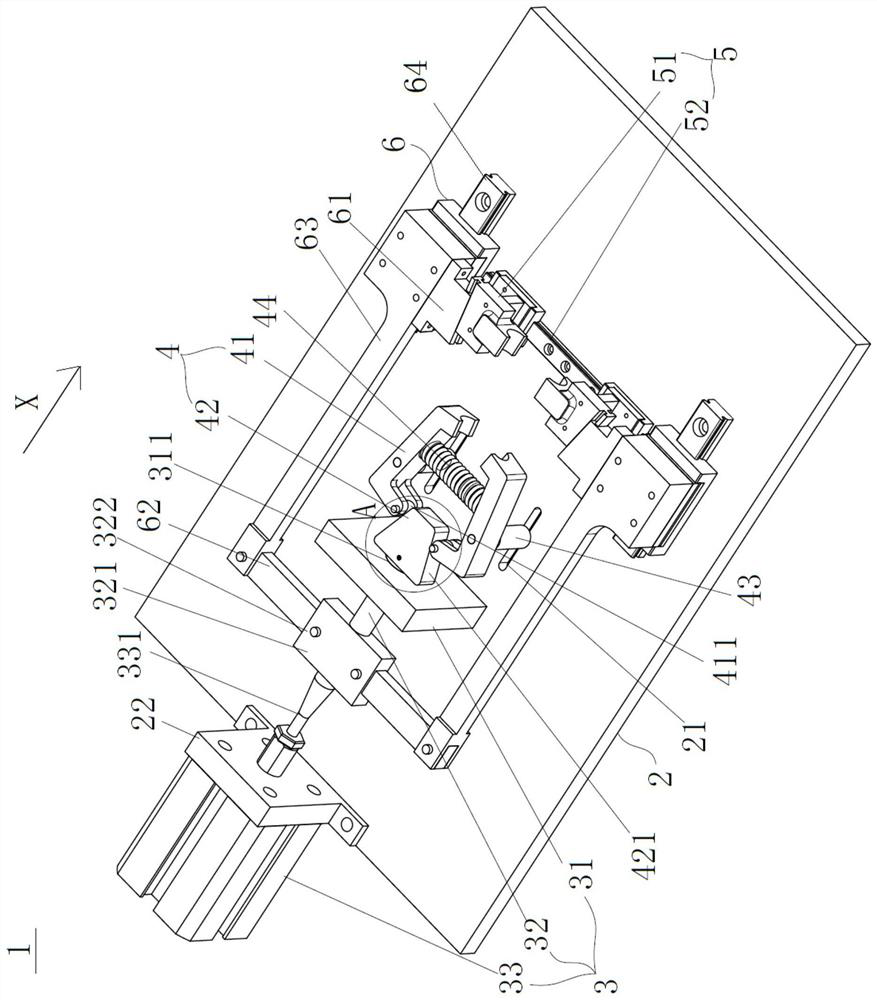

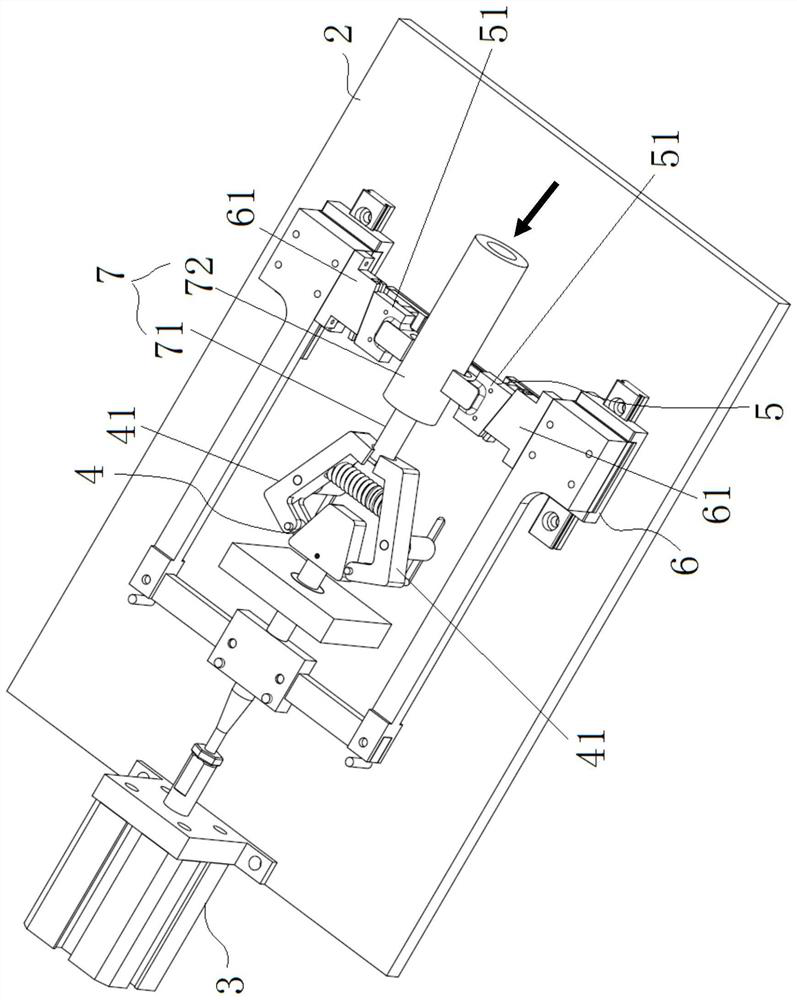

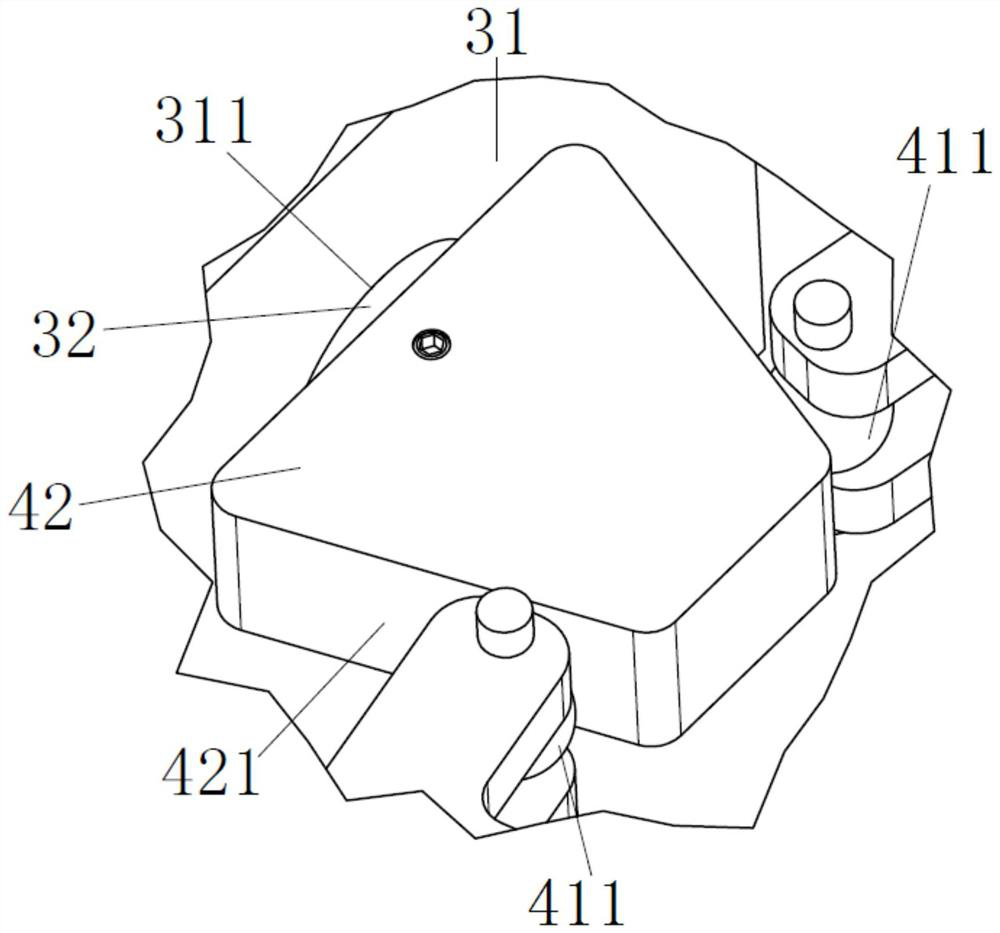

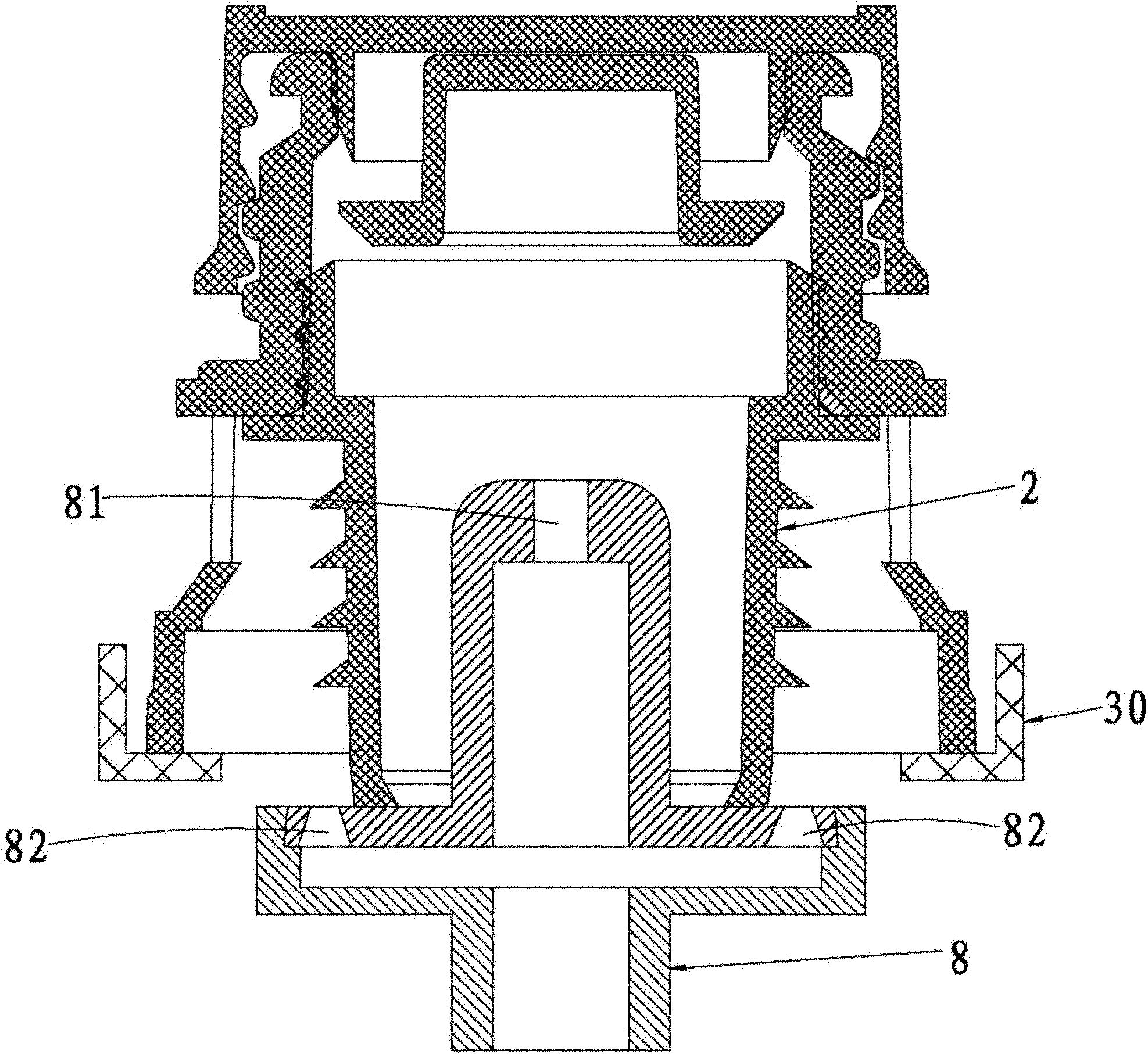

Clamping device

ActiveCN111922960AImprove assembly yieldImprove machine utilizationWork holdersLinkage (mechanical)Engineering

The invention discloses a clamping device. The clamping device comprises a bearing table, a driving assembly, a first clamping assembly, a second clamping assembly and a linkage assembly; the first clamping assembly is connected with the driving assembly, the first clamping assembly comprises two clamping jaws which are symmetrically arranged, and the two clamping jaws are movably connected with the bearing table; the second clamping assembly is arranged on the bearing table, the first clamping assembly is located between the driving assembly and the second clamping assembly, and the second clamping assembly comprises two clamping blocks which are symmetrically arranged; and one end of the linkage assembly is connected with the driving assembly, two linkage blocks which are symmetrically arranged are arranged at the end, far away from the driving assembly, of the linkage assembly, and the two linkage blocks are movably connected with the corresponding clamping blocks. According to theclamping device, two workpieces of a workpiece assembly are clamped and positioned at the same time, so that the problem that the two workpieces are prone to happen relative position deviation, collision, scratch and other adverse conditions in the assembling or carrying process is solved, and the assembling yield is increased; and the clamping device adopts one driving assembly to drive the two clamping jaws and the two clamping blocks to move at the same time, so that the mechanical utilization rate is increased.

Owner:LUXSHARE ITECH(ZHEJIANG) CO LTD

Ice breaking and snow removing device detachably arranged on driving machine

The invention discloses an ice breaking and snow removing device detachably arranged on a driving machine and relates to an ice breaking and snow removing device, aiming to solve the problems that the ice breaking effect on a sunk part of the road surface by additionally arranging ice breaking teeth on a grinding roller of a road roller is poor, and meanwhile, zebra stripes on the road surface can be cut with indentations and even damaged. In the invention, the centers of a plurality of eccentric ice breaking and snow removing wheels are on the same axis, and each eccentric ice breaking and snow removing wheel comprises an outer shaft head, an outer bearing, an inner shaft head, an inner bearing and a plurality of ice breaking teeth, wherein a plurality of ice breaking teeth are distributed and fixedly connected to the outer peripheral wall of each outer shaft head, and each inner shaft head is arranged in a central shoulder through hole of each outer shaft head; each outer bearing is arranged in the central shoulder through hole of each outer shaft head and between each inner shaft head and each outer shaft head; an eccentric shoulder through hole of each inner shaft head is internally provided with the inner bearing; the inner bearings are fixedly sleeved on a wheel shaft; and two ends of the wheel shaft are detachably connected with two vertical beams of a driving machine. The device is matched with power machines such as the road roller, a loader, a forklift, a grader, a large tractor, and the like to remove ice and snow on the road surface.

Owner:HARBIN ZHONGCHENG TECH DEV

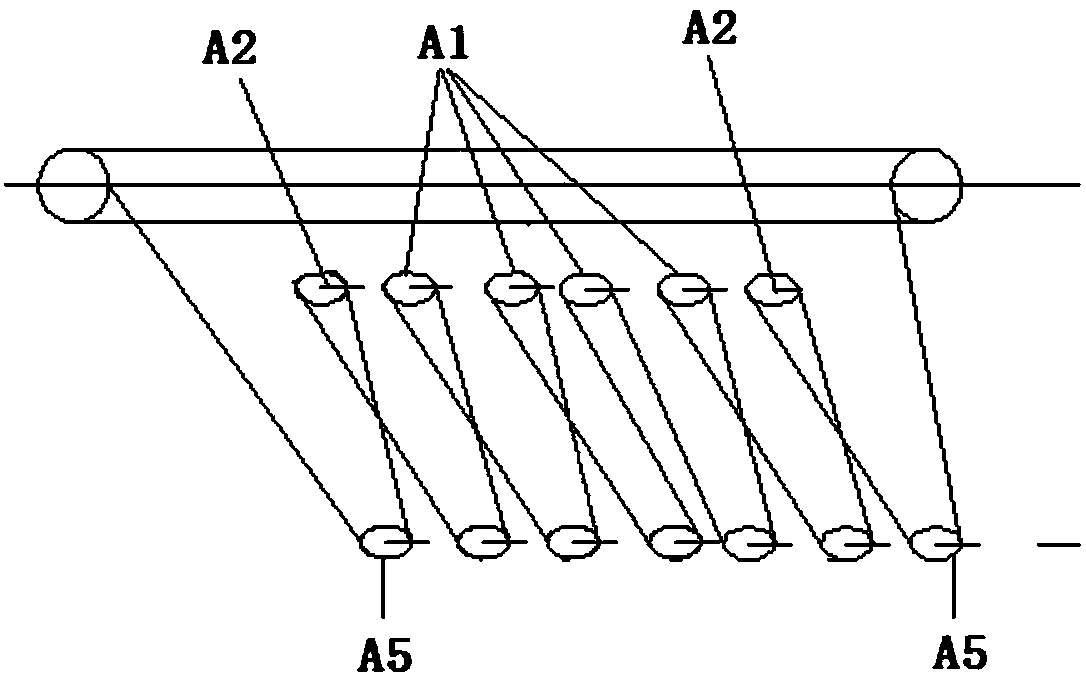

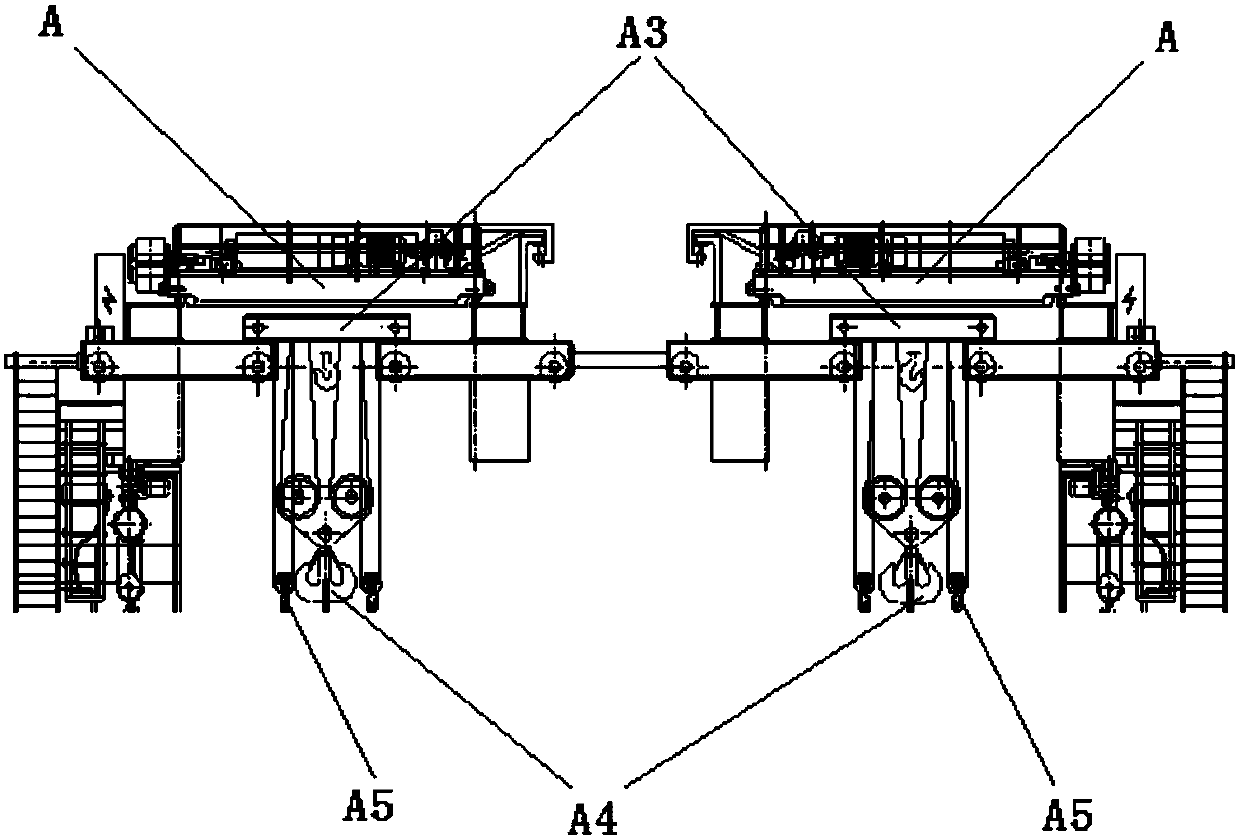

Generator stator hoisting steering system and method thereof

InactiveCN107804785AIncrease headroom sizeSolving the Steering DilemmaTravelling cranesLoad-engaging elementsPull forceBeam steering

The invention discloses a generator stator hoisting and steering system and a method thereof. The generator stator hoisting and steering system includes two bridge-type double-girder cranes (A) that are flexibly connected, and a special-purpose self-made hoisting pole beam (B). , a fixed pulley assembly, a movable pulley assembly, a steel wire rope assembly and a set of lifting and steering auxiliary equipment, the fixed pulley assembly includes the original fixed pulley (A1) next to the main hoisting mechanism of each bridge-type double-girder crane and its two sides 2 additional fixed pulleys (A2) are added each, and the movable pulley assembly includes the original movable pulley and 2 additional movable pulleys ( A5); the steel wire rope assembly includes re-threaded main hoisting mechanism steel wire ropes and newly added hoisting steel wire ropes, and the magnification of the main hoisting mechanism steel wire ropes is refitted from the original "five-five to ten" to "seven to seven to fourteen" "magnification, reduce the traction force of the head end of the main hoisting mechanism.

Owner:JIANGXI THERMAL POWER CONSTR CORP

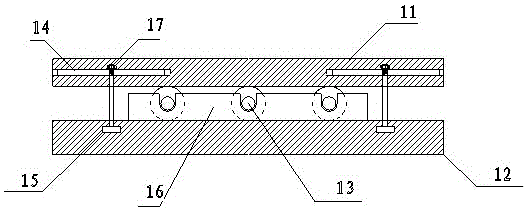

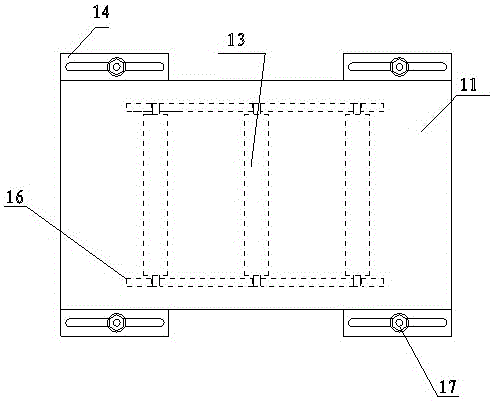

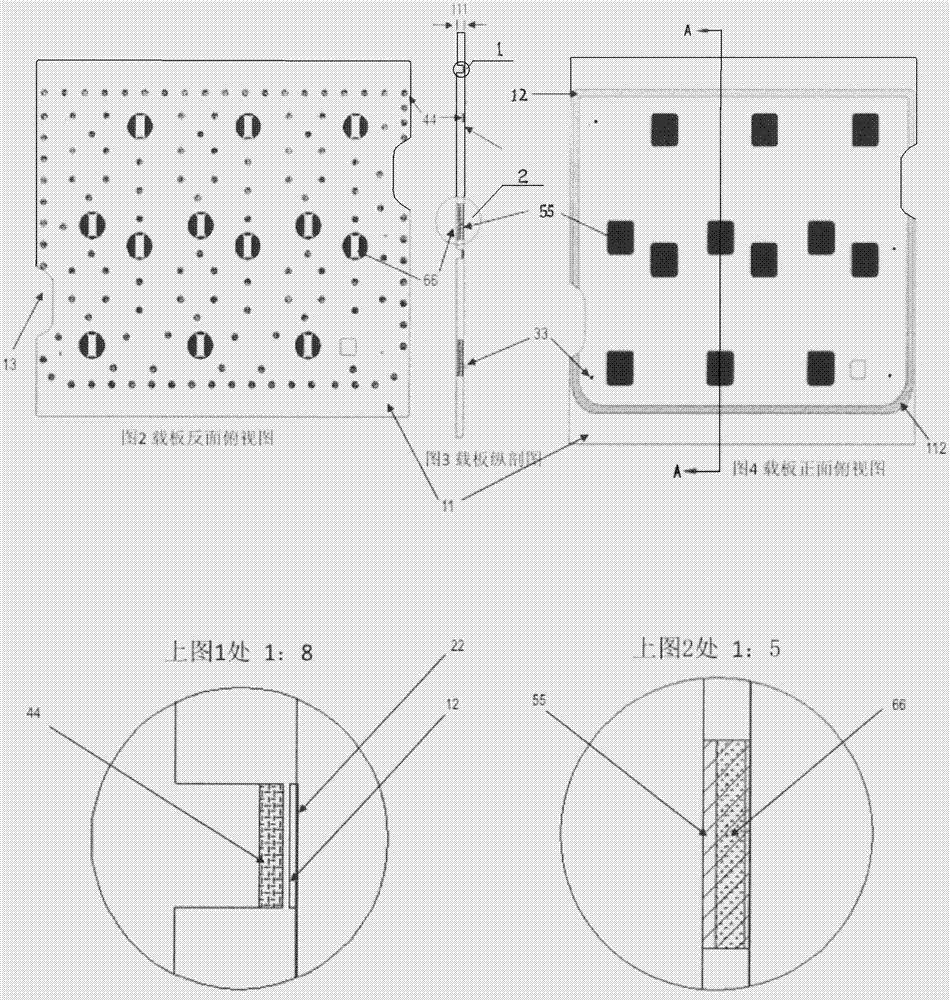

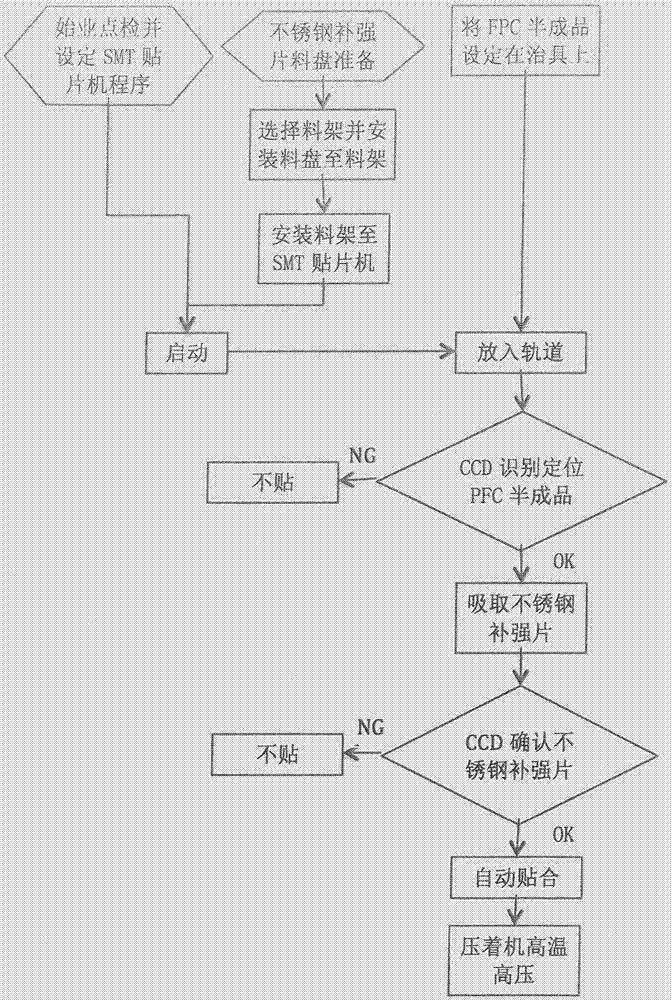

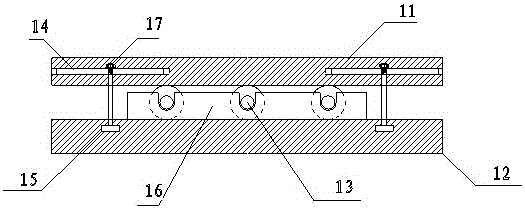

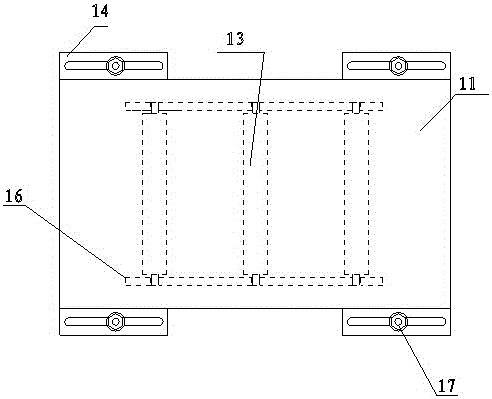

Method for performing stainless steel reinforcing plate automatic fitting on FPC through SMT chip mounter and jig thereof

ActiveCN107105581AImprove work efficiencyImprove pass ratePrinted circuit assemblingPrinted circuit aspectsBonding processEngineering

The invention provides a method for performing stainless steel reinforcing plate automatic fitting through a SMT chip mounter and a matching jig thereof The jig comprises a rigid support plate, a cover plate, multiple positioning pins, multiple magnets and a synthetic stone. A stainless steel reinforcing plate pre-fit by the SMT chip mounter can be accurately positioned, and back glue melting time can be shortened in the high temperature and high pressure bonding process. Therefore, the stainless steel reinforcing plate can be full-automatically, accurately and efficiently fit without purchasing new equipment, the production efficiency can be enhanced and the production cost can be reduced.

Owner:苏州紫翔电子科技有限公司

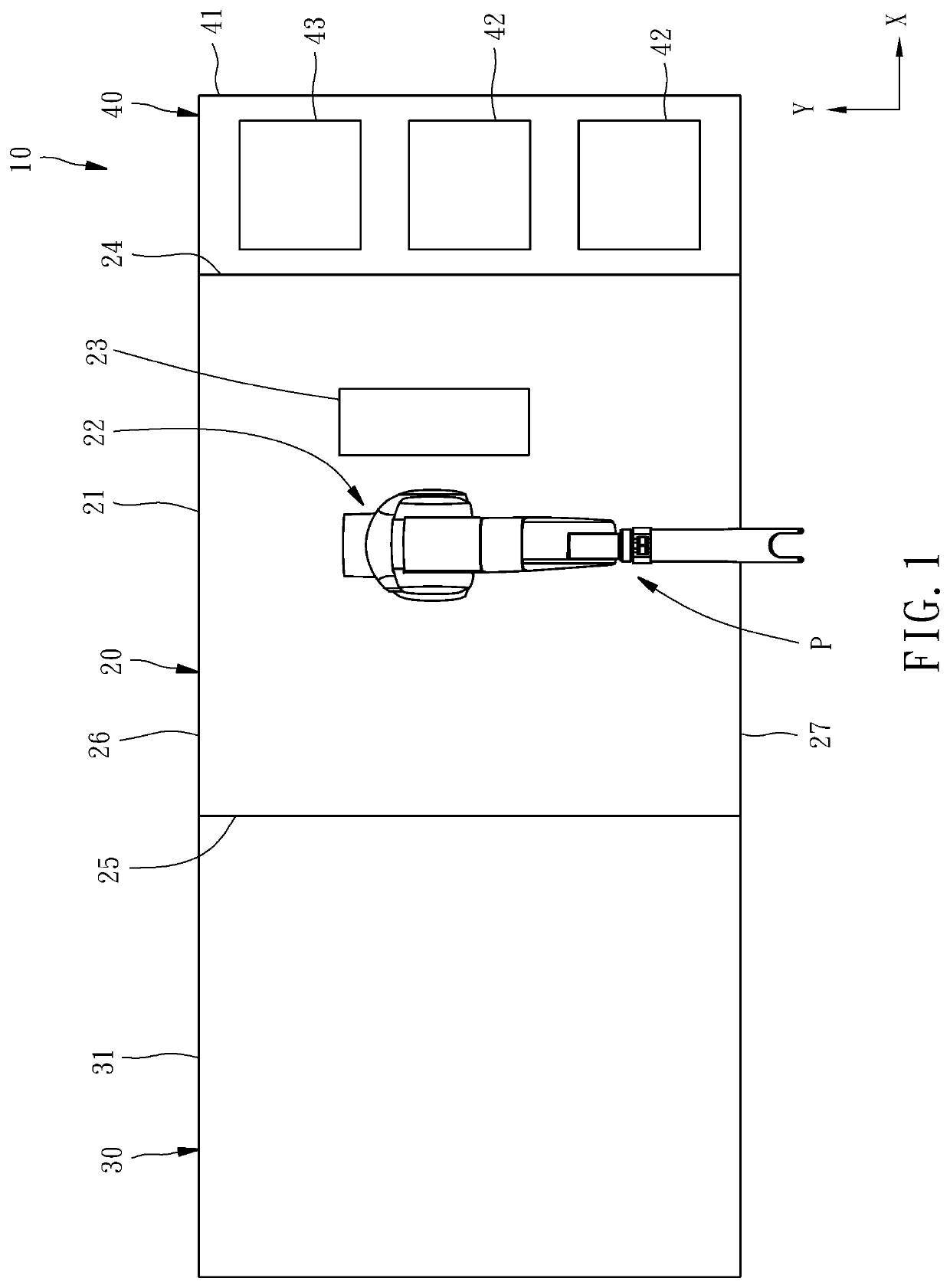

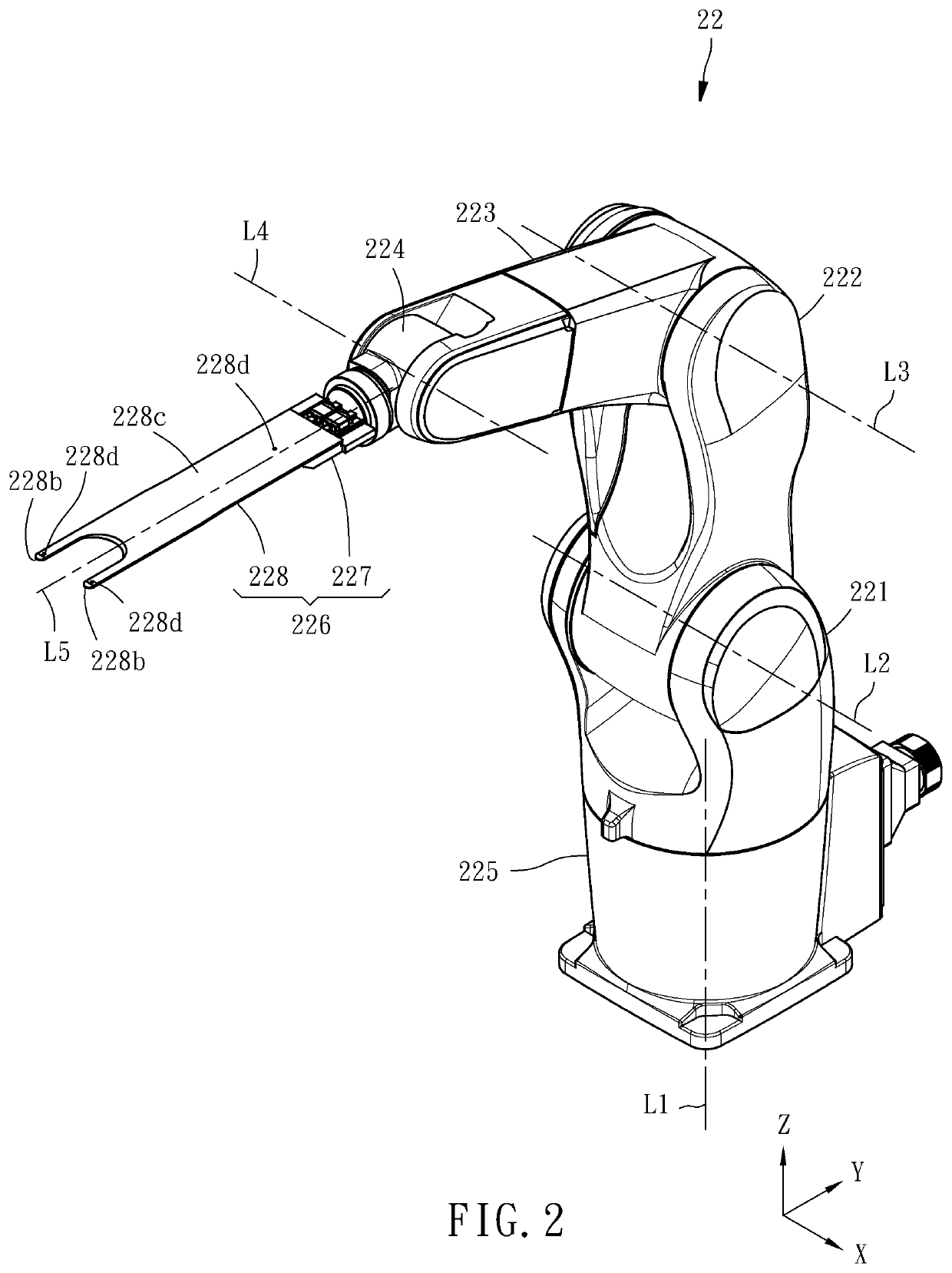

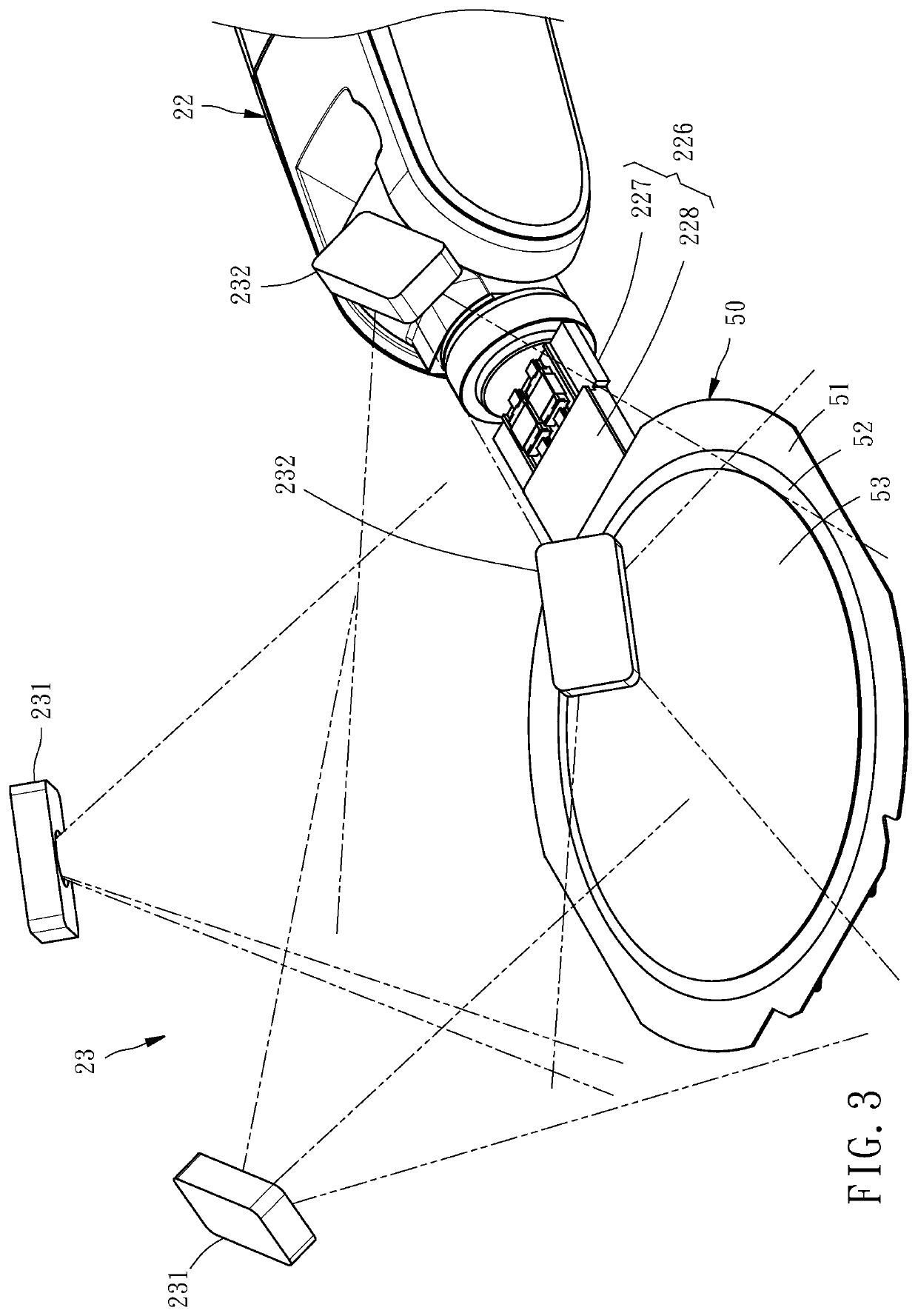

Macro and micro inspection apparatus and inspection method

PendingUS20220074866A1Improve efficiencySimple in structure and space-savingTelevision system detailsGripping headsEquipment under testEngineering

A macro and micro inspection apparatus includes a macro inspection station including a housing, a robot arm and a visual recognition system, and a device under test storage station and a micro inspection station disposed on two sides of the macro inspection station, respectively. The robot arm including an end effector adapted for carrying and turning over a device under test is disposed in the housing in a way that the end effector enables to enter the device under test storage station and the micro inspection station. The visual recognition system includes at least one image capturing device disposed in the housing for shooting toward the end effector for capturing the image of the device under test. The invention, which also provides an inspection method using the inspection apparatus, is structurally simple, space-saving, avoids problems caused by manual inspection, and brings high inspection efficiency.

Owner:MICROELECTRONICS TECH INC

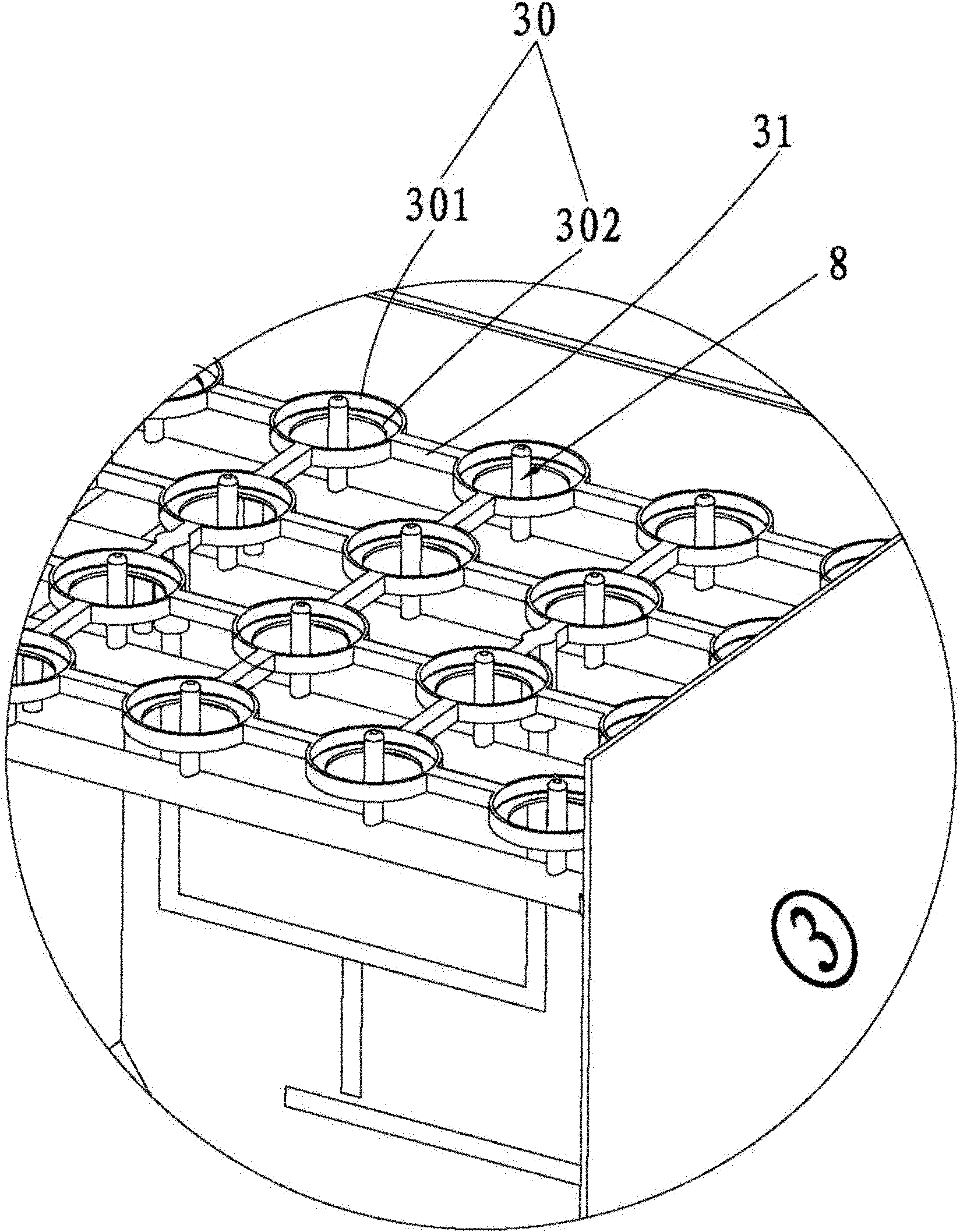

Container cleaning machine

The invention is applicable to the technical field of container cleaning equipment, and discloses a container cleaning machine, which comprises at least one box body, wherein a feed plate is arranged in the box body, a tray for bearing a container is fixedly arranged on the feed plate, the feed plate is in a grid shape, and the tray is arrayed on the feed plate in a matrix way and is positioned at the intersecting points of the grids; a spray nozzle which can flush the container is arranged at the center of the tray in a penetrating way, a water inlet pipe and a high pressure pulse pump are fixedly connected onto the spray nozzle, and the spray nozzle is higher than the bottom of the tray; a cover plate is arranged at the upper end of the box body, and a clearance is left between the cover plate and the container on the tray; a water outlet pipe and a discharge device are also arranged on the box body; a discharge port is arranged on the box body too; and a grid guide plate is fixedly arranged below the feed plate, and is obliquely arranged below the feed plate and toward the discharge port. The container cleaning machine provided in the invention has a simple and reliable structure, clean flushing, good flushing effect, saved manpower and material resources, high flushing efficiency and a low flushing cost.

Owner:泗洪金之彩包装有限公司

Petroleum drill rod thread machining auxiliary device

InactiveCN113042442AGuaranteed thread processing accuracyIncrease the cleaning areaCleaning using liquidsStructural engineeringMachining

The invention relates to the technical field of petroleum drill rod machining, and discloses a petroleum drill rod thread machining auxiliary device. The device comprises an open groove, a clamping mechanism arranged on the open groove and used for fixing a drill rod and a spraying mechanism used for cleaning the drill rod. The clamping mechanism comprises two clamping assemblies clamped at the two ends of the drill rod and a first driving mechanism used for driving the drill rod to horizontally move in a reciprocating mode. The spraying mechanism comprises a spraying head arranged above the drill rod in a suspended mode and a second driving mechanism used for guiding the spraying head to horizontally move in a reciprocating mode. By means of the clamping mechanism and the spraying mechanism which are arranged on the open groove, the drill rod can be rapidly clamped and fixed before thread machining of the drill rod, then dirt attached to a rod body of the drill rod is removed, a needed thread machining station can be accurately positioned on the rod body of the drill rod by machining personnel, and the thread machining precision of the petroleum drill rod is guaranteed.

Owner:安徽宝立华机械设备有限公司

Precast concrete wall panel position adjustment device

The invention discloses a position-adjusting device for a precast concrete wall panel. The position-adjusting device comprises the precast concrete wall panel, a jacking device, a roller support and an adjusting device. The precast concrete wall panel and the jacking device are connected by means of a fixing bolt. The lower portion of a horizontal connecting plate of the jacking device is provided with a jack. The jack is mounted onto the upper surface of the roller support. A vertical connecting plate of the jacking device is fixedly connected with a pull rod connecting plate. The pull rod connecting plate is connected with a movable rod by means of a pin rod. The movable rod is arranged in an adjustable bracing pull rod in a sleeving mode. The front end of the adjustable bracing pull rod is provided with an adjusting device. The tail end of the adjustable bracing pull rod is hinged onto a support by means of the pin rod. The support is connected with the ground by means of a foundation bolt. The position-adjusting device for the precast concrete wall panel has following advantages: position adjustments in two directions can be made to a wall plate; and with no large hoisting equipment required for cooperation during installation, utilization rate of machinery is increased and damage to the wall plate is avoided so that high installation efficiency is obtained.

Owner:CHINA MCC17 GRP

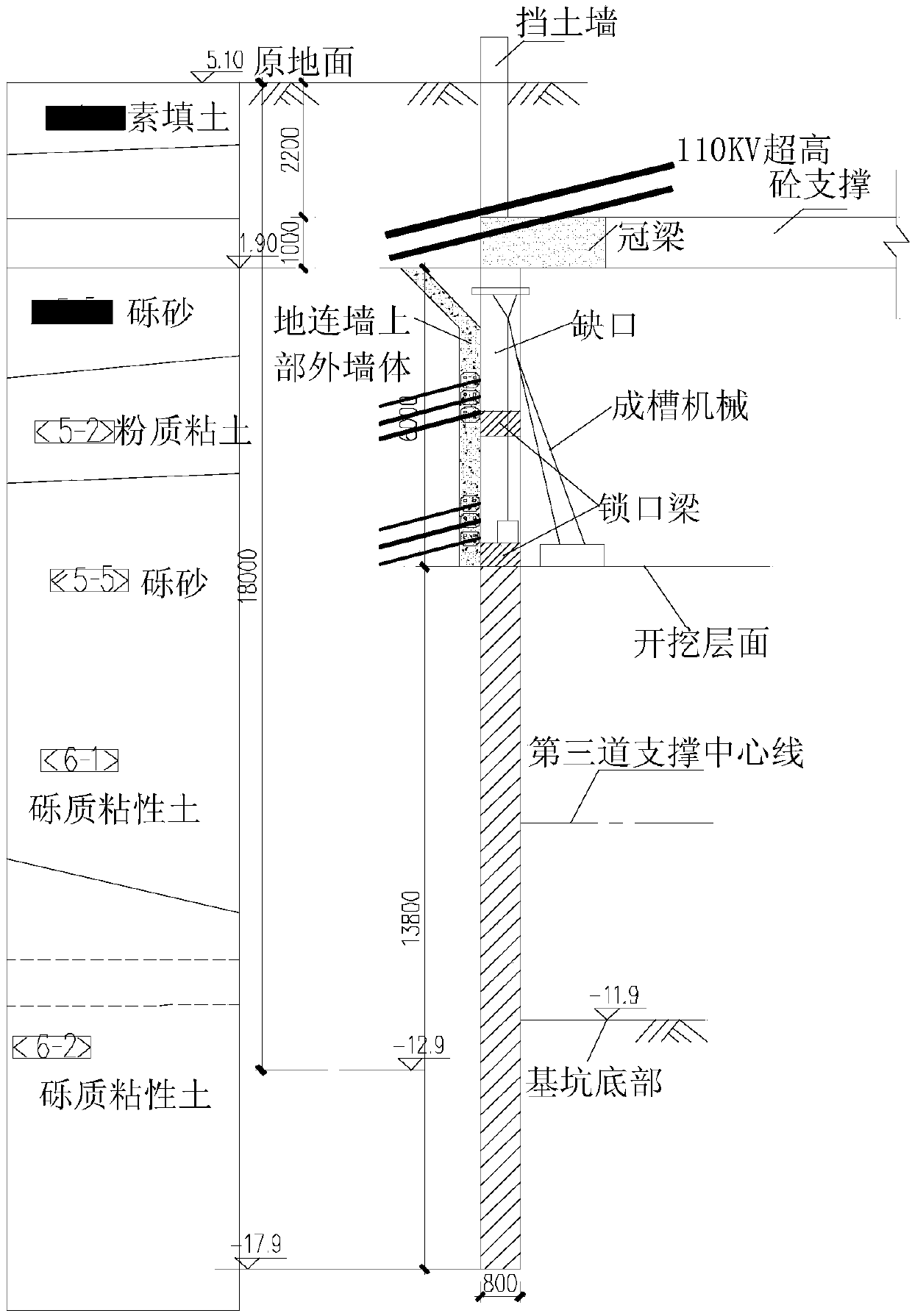

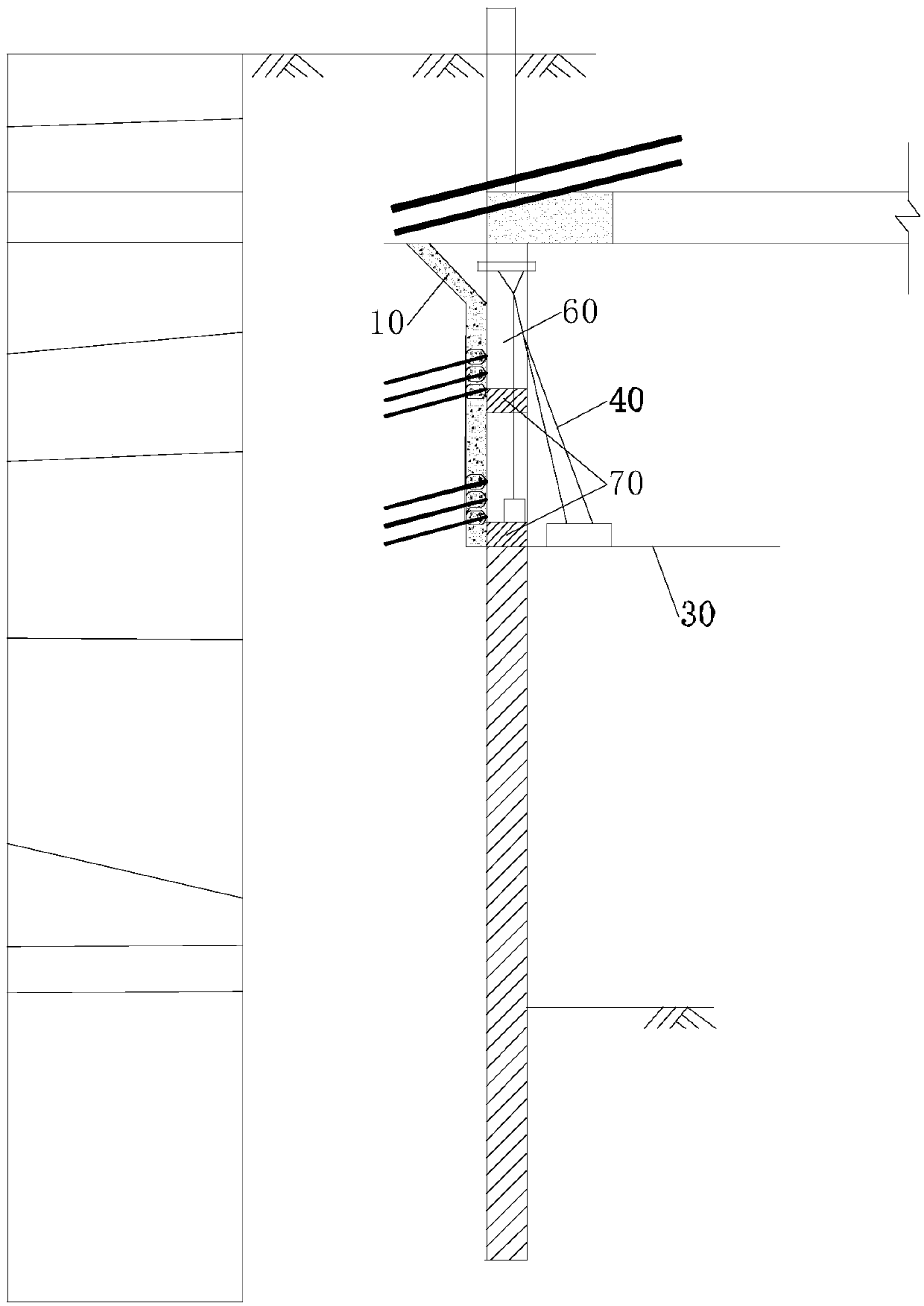

Reverse underground continuous wall construction method

ActiveCN109653193AEnhancing the enclosure effectPrevent leakageSoil-shifting machines/dredgersBulkheads/pilesSlurry wallWater leakage

The invention discloses a reverse underground continuous wall construction method which includes the steps: constructing an upper outer wall body of a concrete diaphragm wall on a continuous wall soilbody by a manual excavation reverse construction method; forming a groove for forming a lower wall body of the concrete diaphragm wall at the upper outer wall body of the concrete diaphragm wall by agrooving machine, and enabling the groove to be positioned on the inner side of the upper outer wall body of the concrete diaphragm wall; pouring concrete into the groove to form the lower wall bodyof the concrete diaphragm wall; pouring concrete into a notch formed by the lower wall body of the concrete diaphragm wall and the upper outer wall body of the concrete diaphragm wall to form an upperinner wall body of the concrete diaphragm wall, and enabling the upper outer wall body of the concrete diaphragm wall, the upper inner wall body of the concrete diaphragm wall and the lower wall bodyof the concrete diaphragm wall to form an underground continuous wall to be constructed. According to the reverse underground continuous wall construction method, by the aid of a 'manual reverse construction + machinery grooving' mode, safety of excavation construction is ensured, construction schedule requirements are ensured, water leakage cannot be easily generated, later foundation pit excavation construction is greatly facilitated.

Owner:ZHONGJIAN SUIDAO CONSTR CO LTD

Efficient roof truss turnover system

PendingCN111749477AReduce the risk of turning overFirmly connectedBuilding material handlingArchitectural engineeringSupport plane

The invention relates to the technical field of building construction, and particularly relates to an efficient roof truss turnover system. The efficient roof truss turnover system comprises a turnover underframe used for clamping a roof truss, a right supporting frame used for supporting the right side of the turnover underframe and a left supporting frame used for supporting the left side of theturnover underframe, and the right supporting frame and the left supporting frame are right-angle supporting frames; the turnover underframe is composed of a net-shaped frame and one or more connecting devices; the connecting devices are welded and fixed to the right side face of the net-shaped frame and used for clamping the roof truss; one right-angle face of the right supporting frame is detachably connected with the connecting device to form a closed body and then clamps the roof truss, and the other right-angle face of the right supporting frame is flush with the bottom face of the net-shaped frame; after the roof truss is turned over, one right-angle face of the left supporting frame is detachably connected to the left side face of the net-shaped frame, and the other right-angle face of the left supporting frame is flush with the bottom face of the net-shaped frame. The efficient roof truss turnover system is reliable in connection, convenient to use and convenient to transfer,reduces the roof truss turnover risk during construction, saves the site, and achieves the purposes of shortening the construction period and improving the mechanical utilization rate through overallturnover.

Owner:THE THIRD CONSTR & ENG OF CCFED

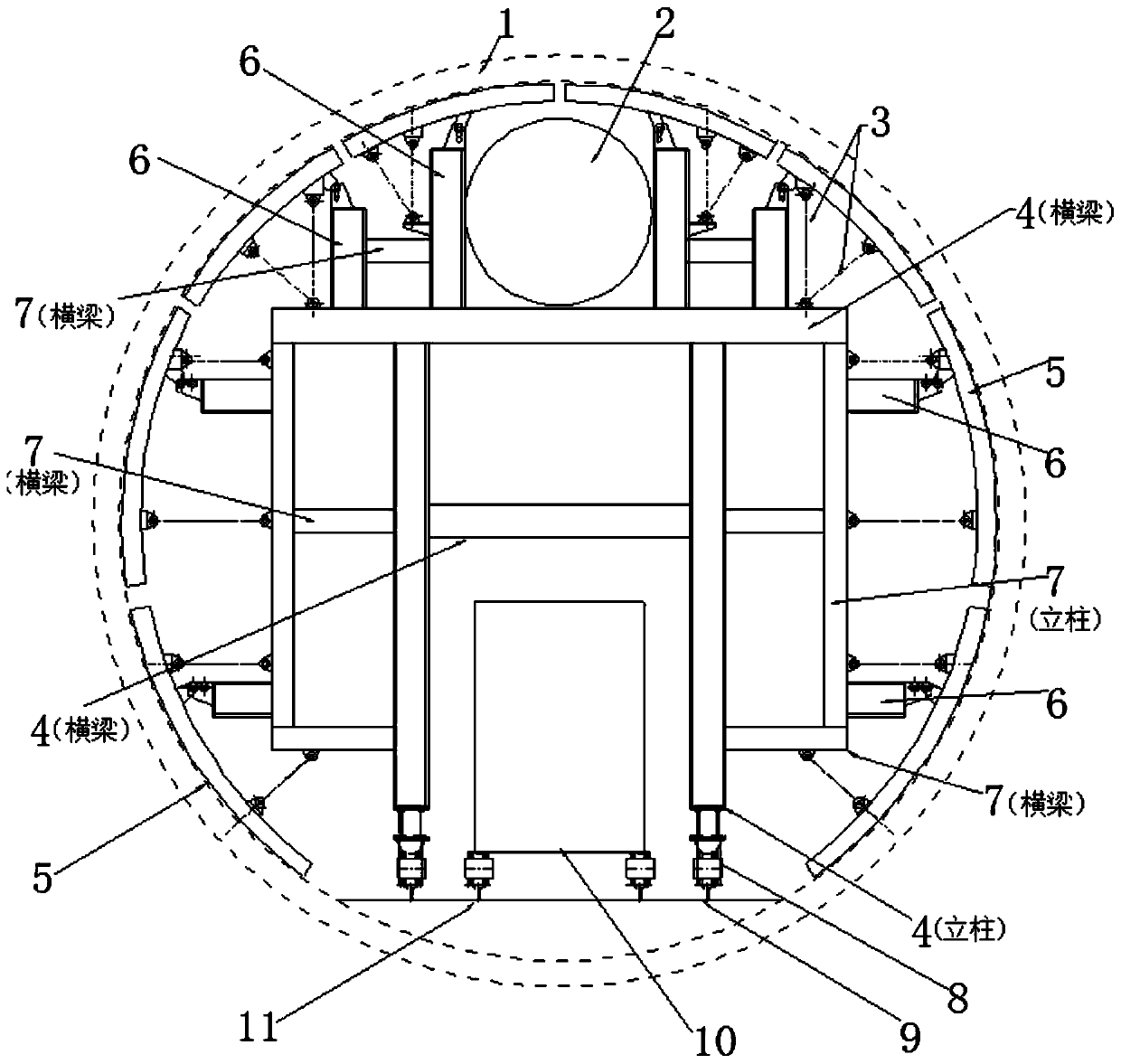

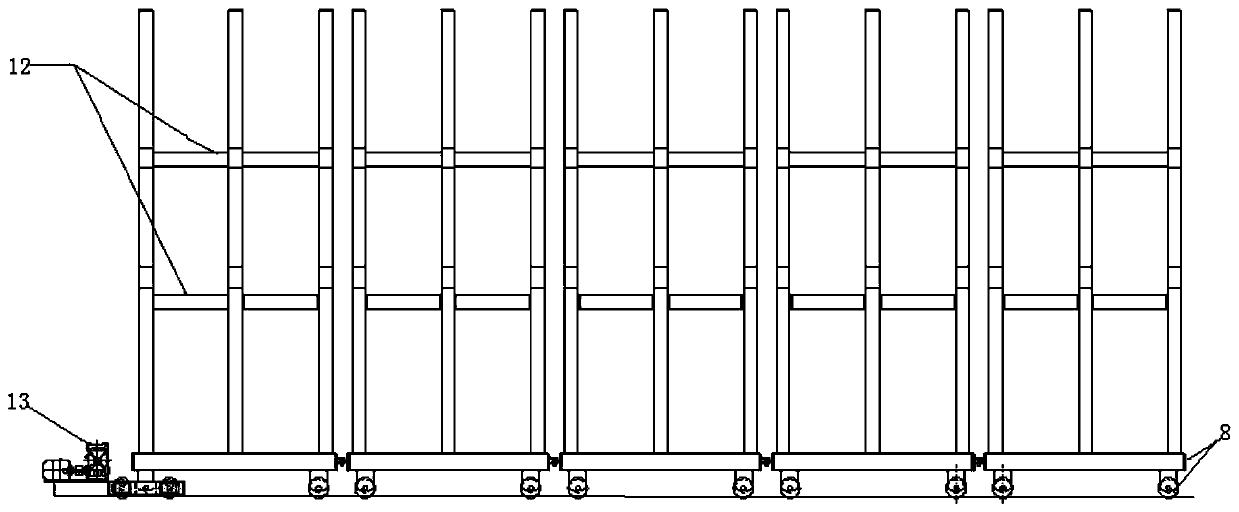

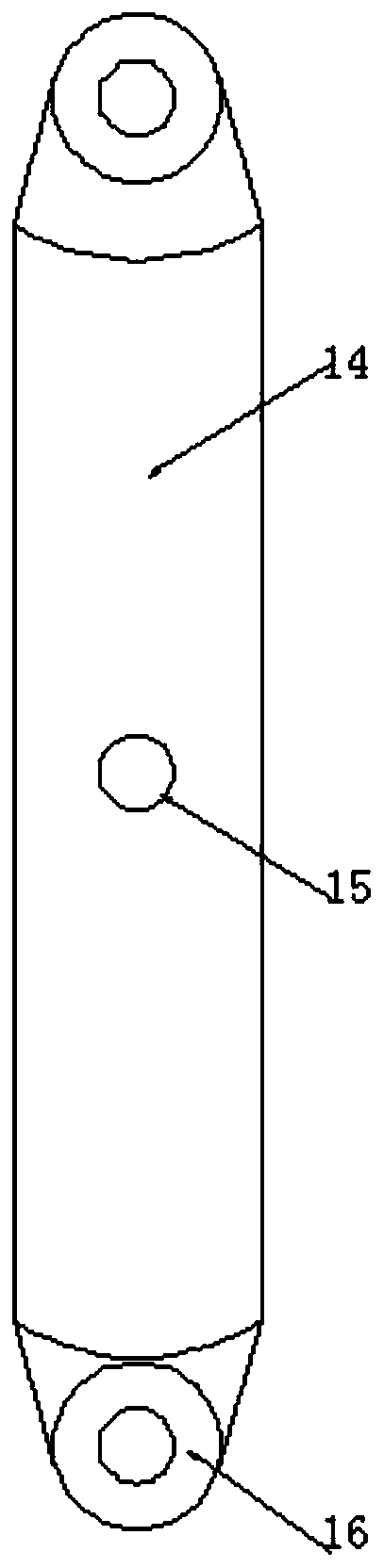

Shield tunnel internal supporting trolley system under small spacing, shallow soil covering and small radius conditions

ActiveCN111236990AReduce the impact of settlementReduce construction riskUnderground chambersTunnel liningVehicle frameGeotechnical engineering

The invention discloses a shield tunnel internal supporting trolley system under small spacing, shallow soil covering and small radius conditions. The shield tunnel internal supporting trolley systemcomprises a trolley track, a muck vehicle track, a trolley and a muck vehicle, wherein the trolley track and the muck vehicle track are arranged at the bottom of a tunnel, the trolley is matched withthe trolley track, and the muck vehicle is matched with the muck vehicle track; the trolley track adopts an original track on which a shield trolley walks; and the trolley comprises a frame, a walkingmechanism and a supporting mechanism, the upper portion of the frame can contain a ventilation pipeline, the lower portion of the frame stretches across the muck vehicle and does not interfere with the muck vehicle, the supporting mechanism comprises arc-shaped plate supports, sliding hinge pieces and telescopic jacking pieces, the arc-shaped plate supports are distributed on the upper portion and the two sides of the tunnel, gaps exist between the adjacent arc-shaped plate supports, the arc-shaped plate supports are slidably hinged to the frame through the sliding hinge parts, the arc-shapedplate supports are telescopically connected with the frame through the telescopic jacking pieces, and when the telescopic jacking pieces drive the arc-shaped plate supports to be ejected out and retracted back, the sliding hinge parts play a role in guiding and limiting. According to the system, duct pieces are prevented from being damaged, advancing spaces of the ventilation pipeline and muck isreserved, and the influence on the first-departure line tunnel is reduced to the minimum.

Owner:CHINA RAILWAY 11TH BUREAU GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com