Multifunctional ditching and soil covering integrated machine

A multi-functional, all-in-one technology, applied in the direction of excavation/covering trenches, planting methods, agricultural machinery and implements, etc., can solve the problems of increasing labor intensity, reducing work efficiency, inconvenient manual operation, etc. The effect of improving the utilization rate of machinery and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

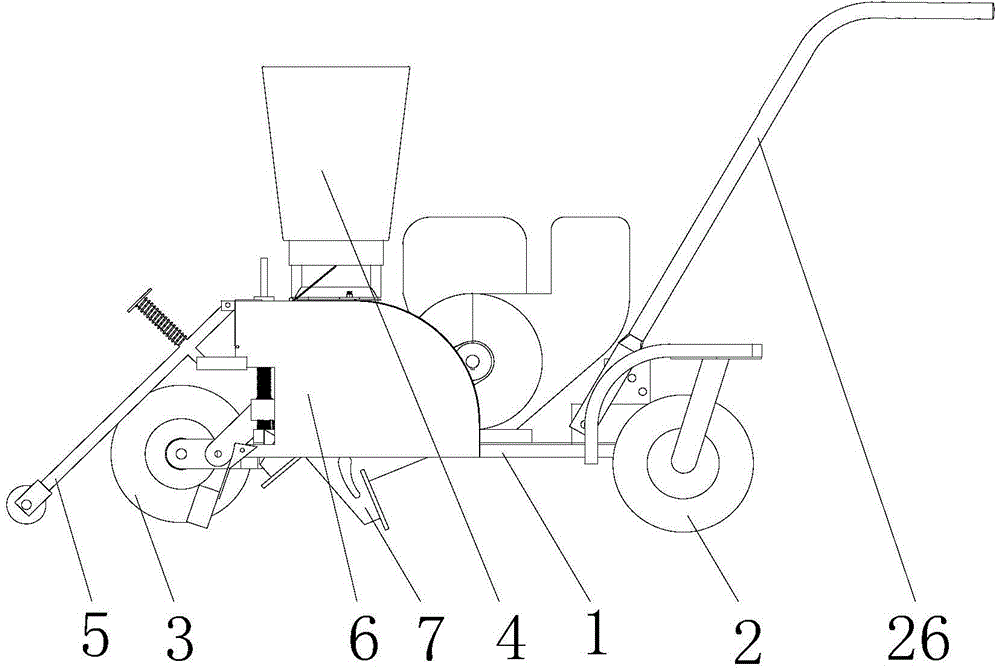

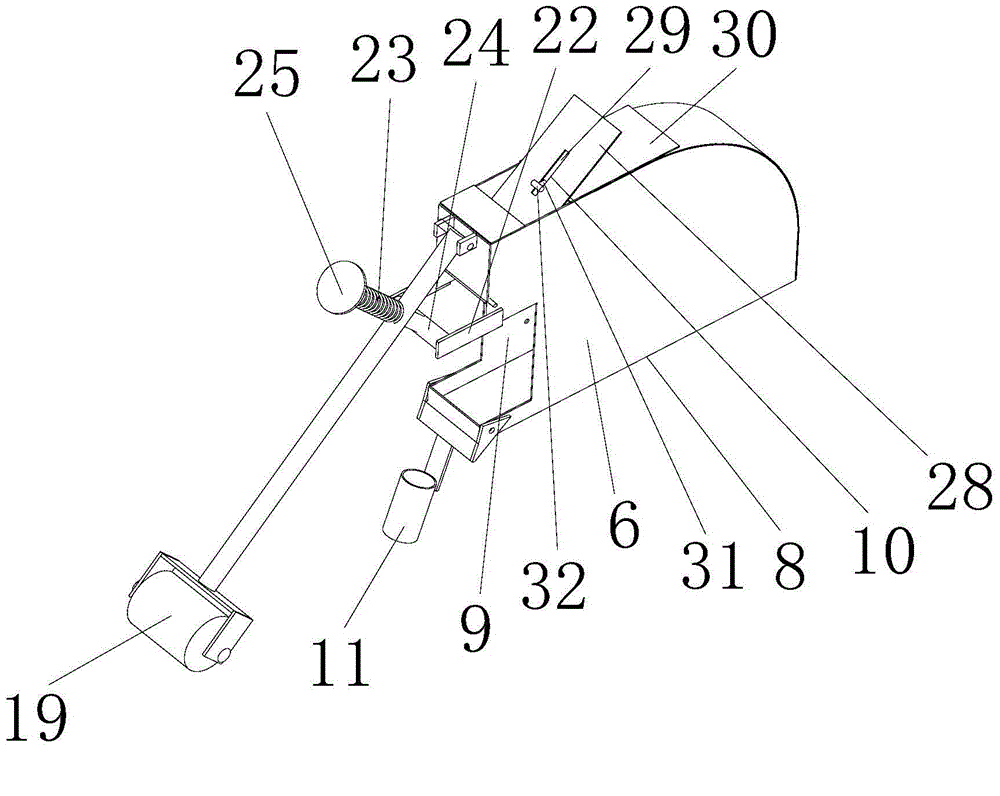

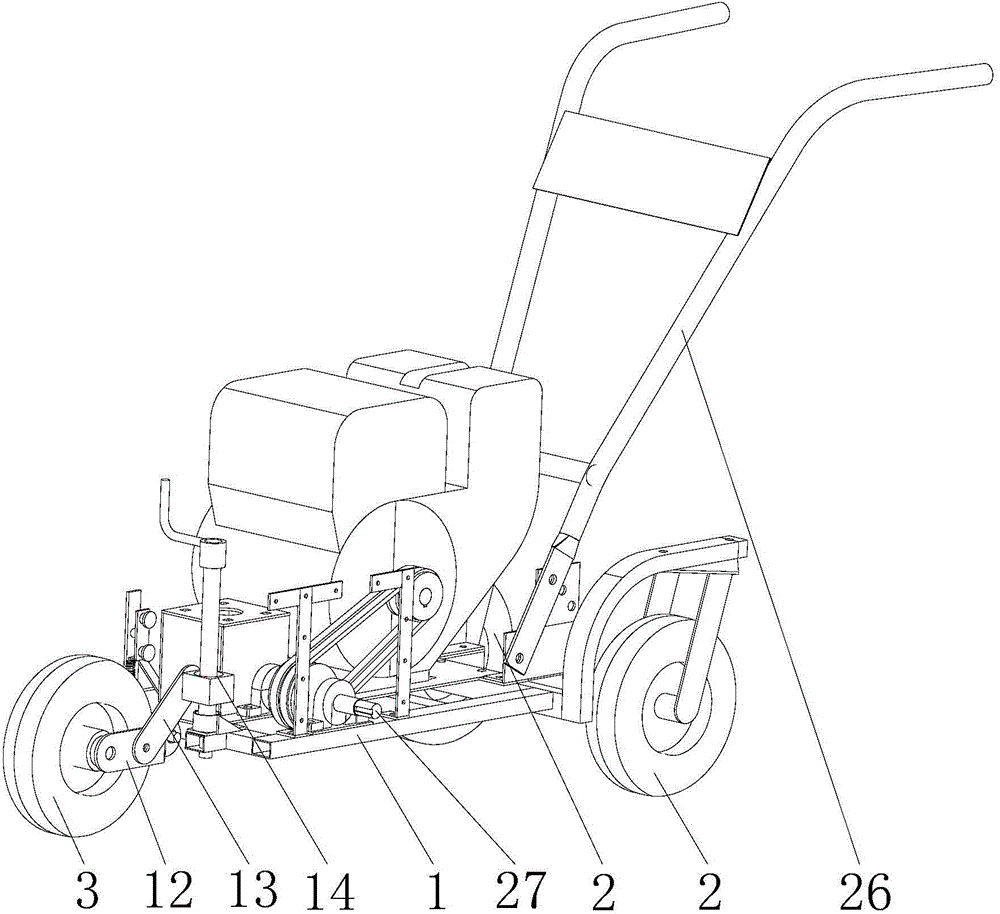

[0026] A multi-functional machine for ditching and soil covering, comprising a bracket 1 and a rear traveling wheel 2, a front traveling wheel 3, a soil covering box, a discharge device 4, a suppression mechanism 5 and a power unit 27 installed on the bracket 1, The discharge device 4 is a fertilizer discharger or a seed metering device, and the soil covering box includes a casing 6 and a ditching knife 7. The casing 6 has a soil inlet 8, a soil outlet 9, and is used to respond to the ditching knife. The guide adjusting plate 10 of the earth, described earth inlet 8 is arranged on casing 6 bottoms, and described earth outlet 9 is arranged on the back upper part of casing 6 advance direction, and guide adjusting plate 10 is hinged on the top of the earth covering box. The ditching knife 7 is arranged in the casing 6 and partly protrudes from the soil inlet 8, the ditching knife 7 is driven and rotated by the power unit 27, and the output port of the discharge device 4 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com