Online multifunctional double-station LF (Low-Frequency) furnace system and online LF furnace steelmaking method

A double-station, multi-functional technology, applied in furnaces, crucible furnaces, furnace types, etc., can solve problems such as insufficient flexibility and reduced operating rate of LF furnaces, and achieve the effects of easy layout, shortened production cycle, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

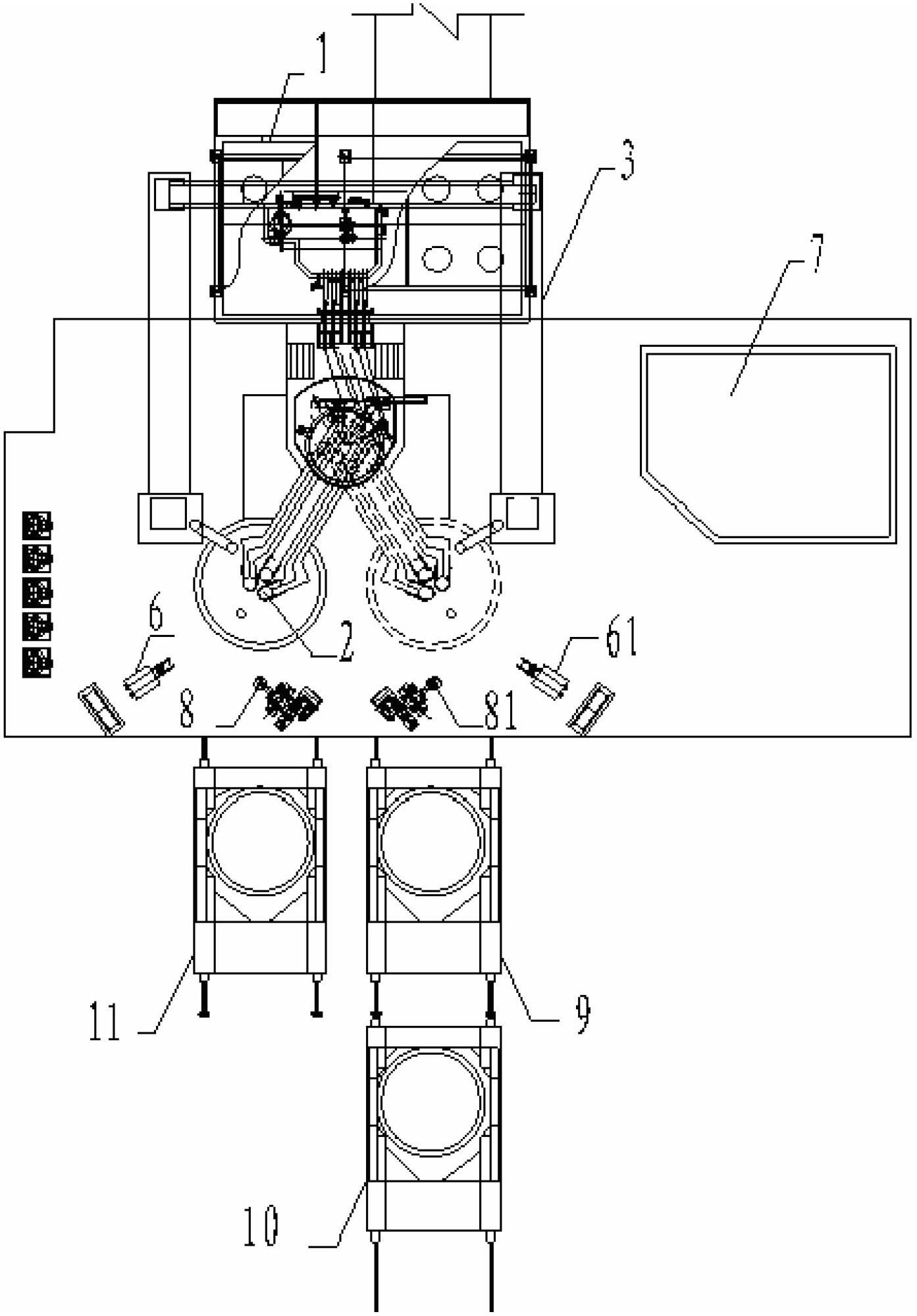

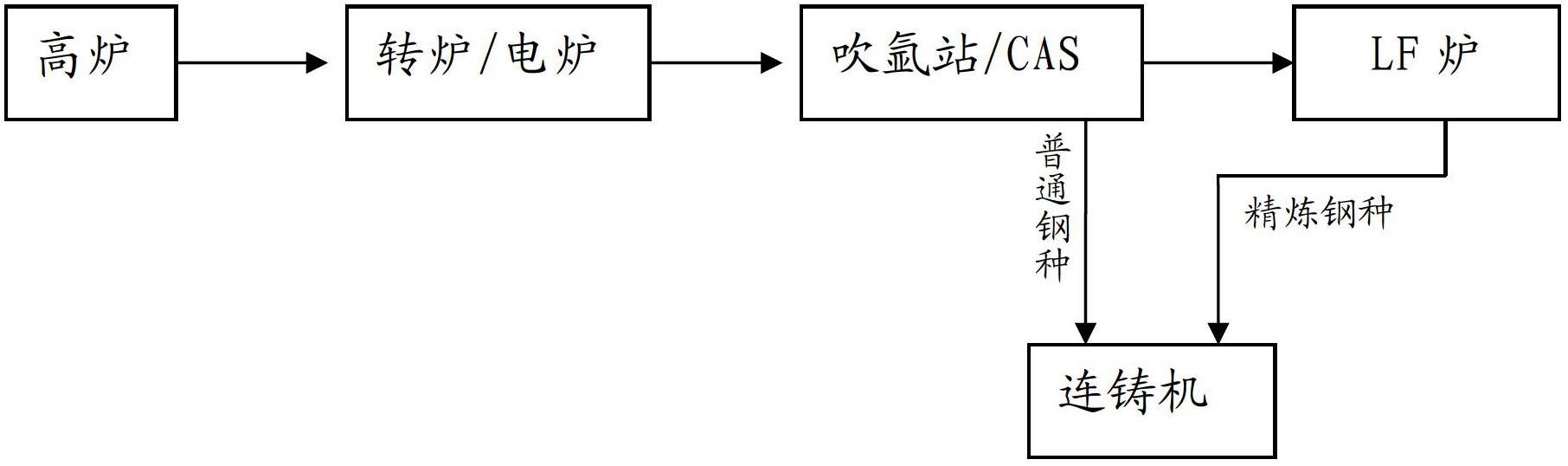

[0028] Such as figure 1 , image 3 As shown, the online multifunctional double station LF furnace system in this embodiment includes an LF furnace, and the LF furnace includes a rotating electrode 2 that can move back and forth between the main processing position and the secondary processing position, and a ladle for steelmaking and a crane for transferring ladles; argon blowing devices, wire feeders, and temperature-measuring and sampling devices are installed on the main processing position and the secondary processing position, and the LF furnace is horizontally arranged on two parallel stations. The processing position is set on the tapping line of the steelmaking furnace in the front section; there are two ladle cars on the main processing position, which are respectively a ladle car 9 and a ladle car 10; there is one ladle car on the secondary processing position for ladle car 11

[0029] in,

[0030] When refining ordinary steel grades, the wire feeder at the main ...

Embodiment 2

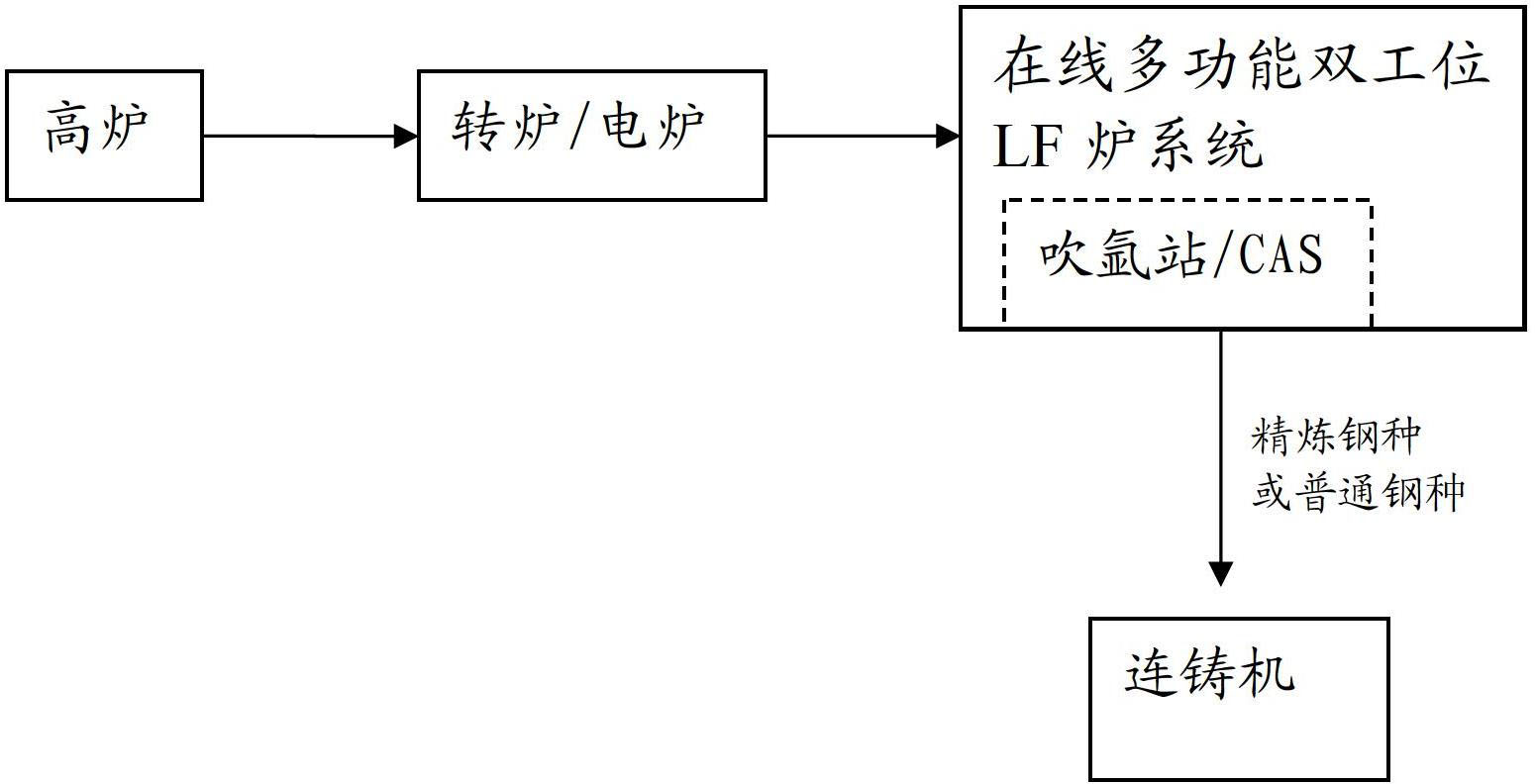

[0042] The online LF furnace steelmaking method of this embodiment is that the above-mentioned online multi-functional double-station LF furnace system performs temperature measurement and sampling, wire feeding and argon blowing on the molten steel after primary smelting.

[0043] In this embodiment, the on-line multi-functional double-station LF furnace system is used to realize the functions of temperature measurement and sampling, wire feeding and argon blowing of the molten steel after primary smelting, which are realized by the argon blowing station when refining common steel types.

Embodiment 3

[0045] The online LF furnace steelmaking method of this embodiment is the above-mentioned online multi-functional double-station LF furnace system for temperature measurement and sampling of the molten steel after primary smelting, wire feeding machine, argon blowing and alloy addition to fine-tune the composition.

[0046] The use of the LF furnace in this embodiment to realize the CAS function has fully improved the utilization rate of the LF furnace. Because the LF furnace of the present invention has two wire feeders, two argon blowing devices, and two feeding systems to form two For an argon blowing station, when any mechanical problem occurs at one of the processing positions, you only need to select the selection electrode 2 to this processing position, and then the normal operation can be carried out at the other processing position without interruption.

[0047] The steelmaking system of this embodiment adopts the LF furnace of the present invention, fully utilizes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com