Generator stator hoisting steering system and method thereof

A generator stator and steering system technology, applied to cranes, transportation and packaging, load hanging components, etc., can solve problems such as long preparation period, difficulty in meeting hoisting and steering requirements, and reduced clearance of lifting height, etc., to achieve Save the cost of mechanical shifts, solve the problem of stator steering, and reduce the weight of the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings.

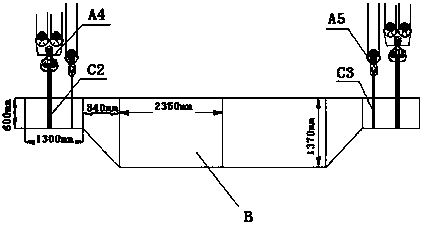

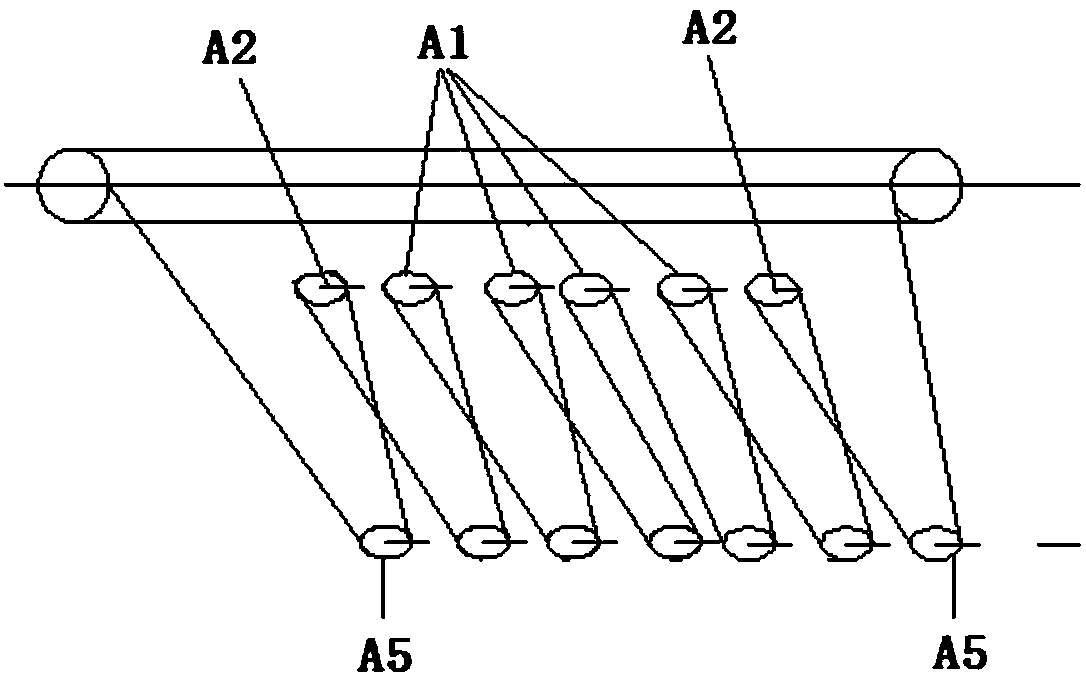

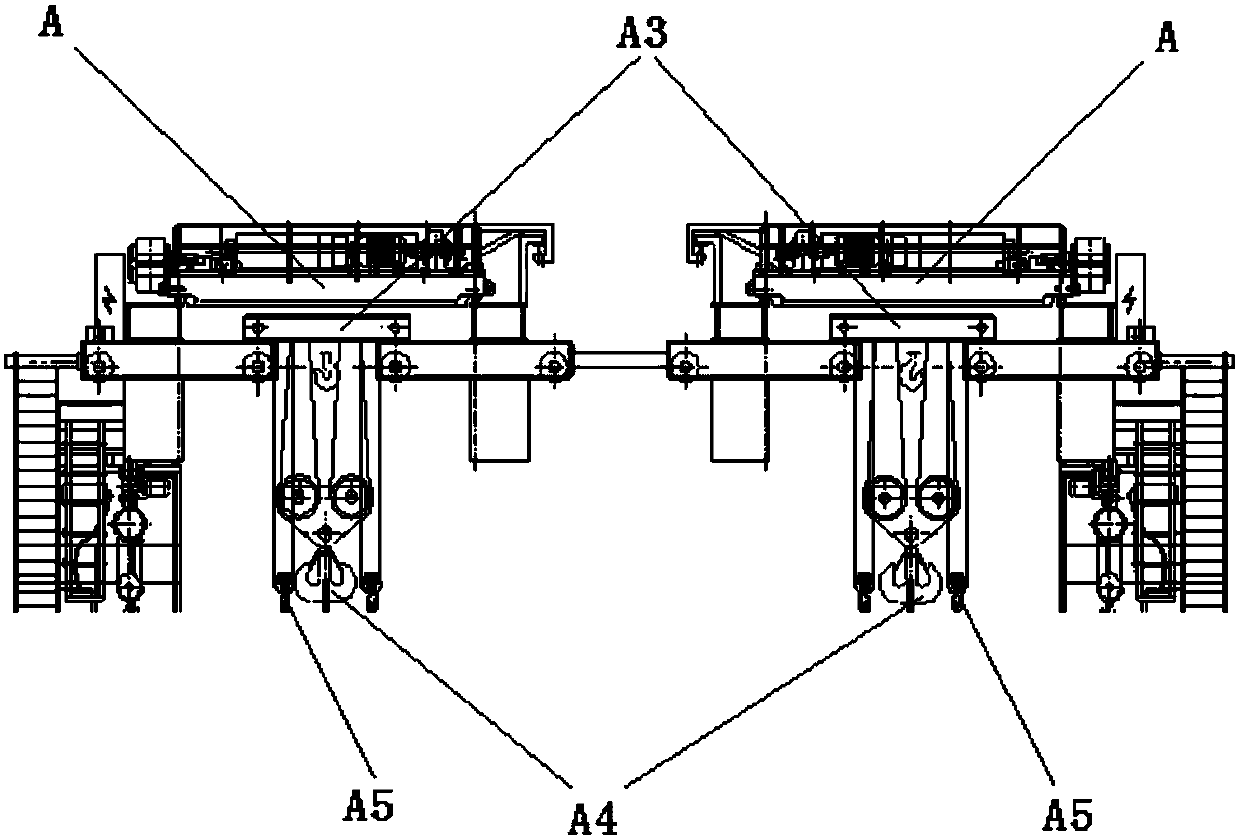

[0023] A generator stator hoisting and steering system, including two bridge-type double-girder cranes A with flexible connection, a special self-made hoisting shoulder beam B, fixed pulley assembly, movable pulley assembly, wire rope assembly and a set of lifting and steering auxiliary equipment, The fixed pulley assembly includes the original fixed pulley A1 next to the main hoisting mechanism (main winch) of each bridge type double-girder crane and 2 additional fixed pulleys A2 respectively increased on both sides thereof, and the movable pulley assembly includes the original fixed pulley A1 There are movable pulleys and 2 additional movable pulleys A5 beside the main hook A4 connected under the trolley A3 of each bridge-type double-girder crane; the wire rope componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com