Improved pouring formwork for primary molding construction process of basement floor

A basement and improved technology, which is applied in the direction of construction and building construction, can solve the problems of inaccurate adjustment of pouring thickness, easy hollowing of the ground, and low wear resistance, so as to shorten the construction period, increase the headroom size, and reduce the construction cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The applicant of this patent takes the headquarters building of Minnan Construction Engineering Group as the specific implementation site, and provides the following specific examples:

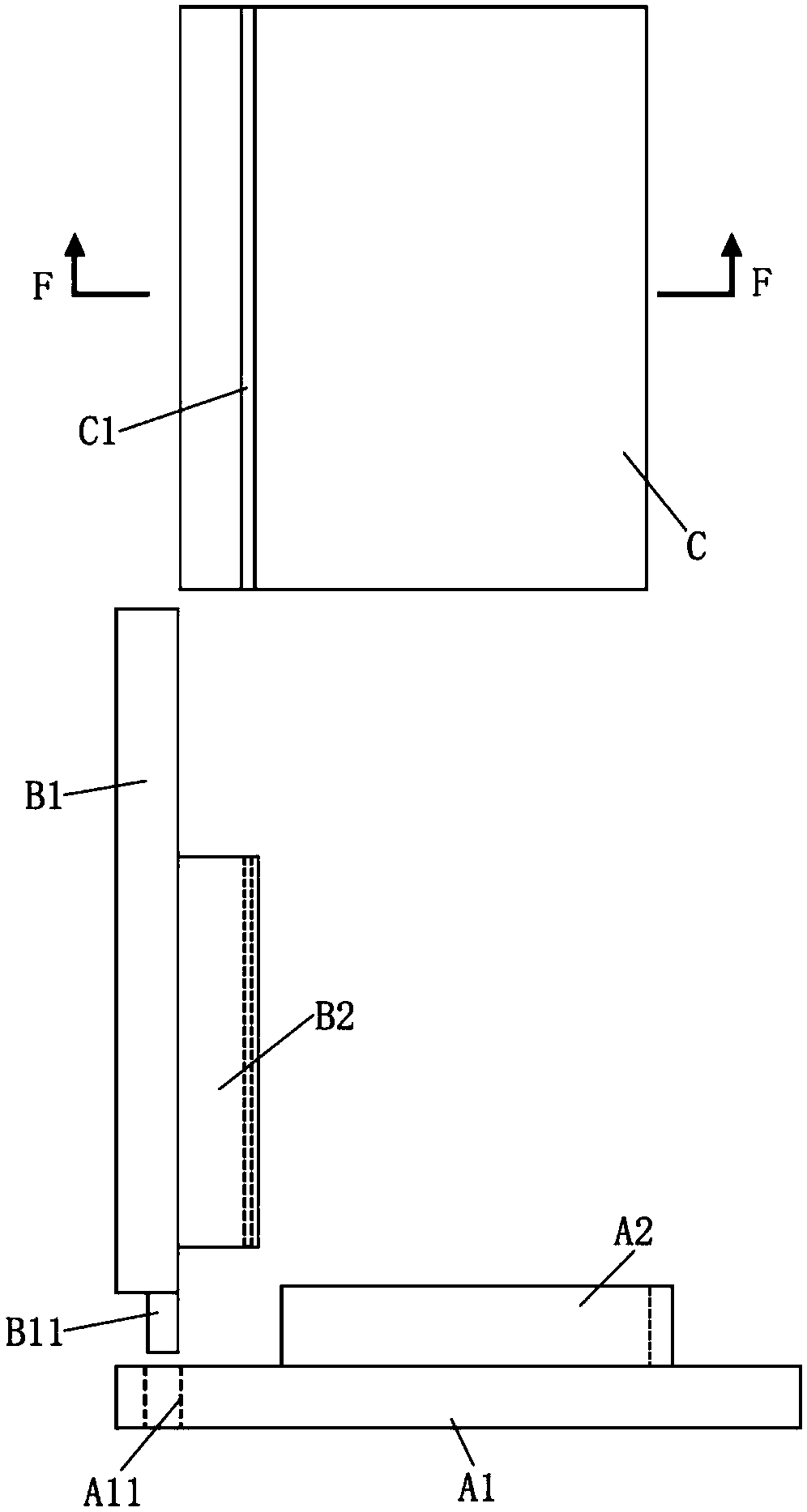

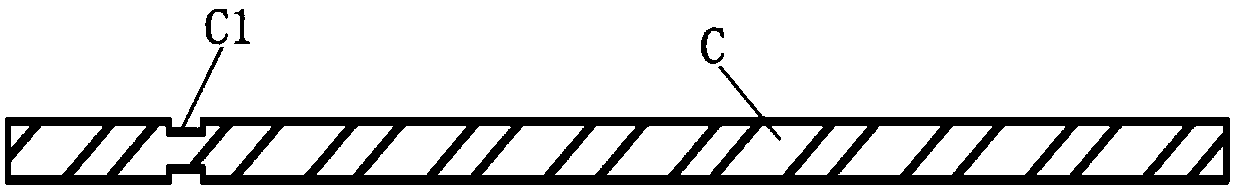

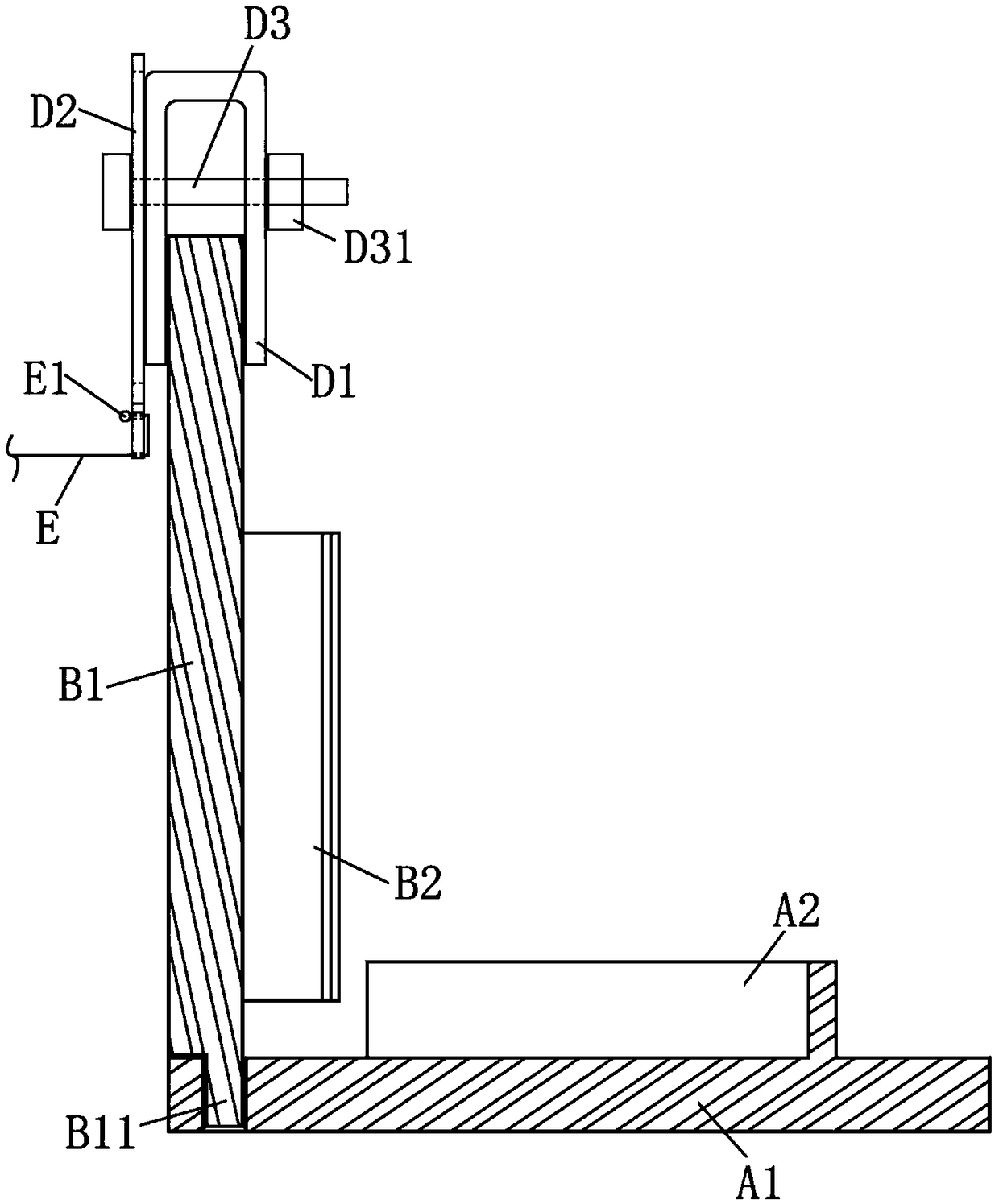

[0038] like figure 1 , image 3 , Figure 4 , Figure 5 As shown in the figure, the improved pouring formwork used in the one-step forming construction process of the basement floor is used for the improved pouring formwork in the one-step forming construction process of the basement floor. , a vertical insert C, a calibration adjustment mechanism, and a calibration rope E, characterized in that,

[0039] The horizontal base plate A1 has a left and right length of 150 cm, a front and rear width of 40 cm, and a thickness of 10 cm. The rear side of the horizontal base plate A1 is integrally formed with three vertical rectangular sockets A11 on the left, middle and right, and each vertical rectangular socket is formed. The size of A11 is 25cm×5cm×10cm;

[0040] The top surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com