Regulating type pouring formwork used in one-time-forming construction process of basement floor

A basement, adjustable technology, applied in the direction of construction, building structure, etc., can solve the problems of easy generation of hollowing on the ground, low wear resistance, long construction period, etc., to achieve the effect of convenient transportation, shorten construction period, and improve wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The applicant of this patent takes Minnan Construction Engineering Group Headquarters Building as the specific implementation location, and provides the following specific examples:

[0036] The adjustable pouring formwork used in the one-time molding construction process of the basement floor is composed of a side wall mechanism A and a corner stop mechanism B, and is characterized in that,

[0037] Such as Figure 7 , Figure 8 As shown, the four groups of side enclosure mechanisms A can form a square frame mechanism, and the four corners of the square frame mechanism can be fastened to a corner stop mechanism B, and the square frame mechanism is fastened and connected through the four corner stop mechanisms B; Each corner stop mechanism B can realize fastening connection with the vertical ruler column A2 in the side wall mechanism A through the U-shaped buckle bar B2;

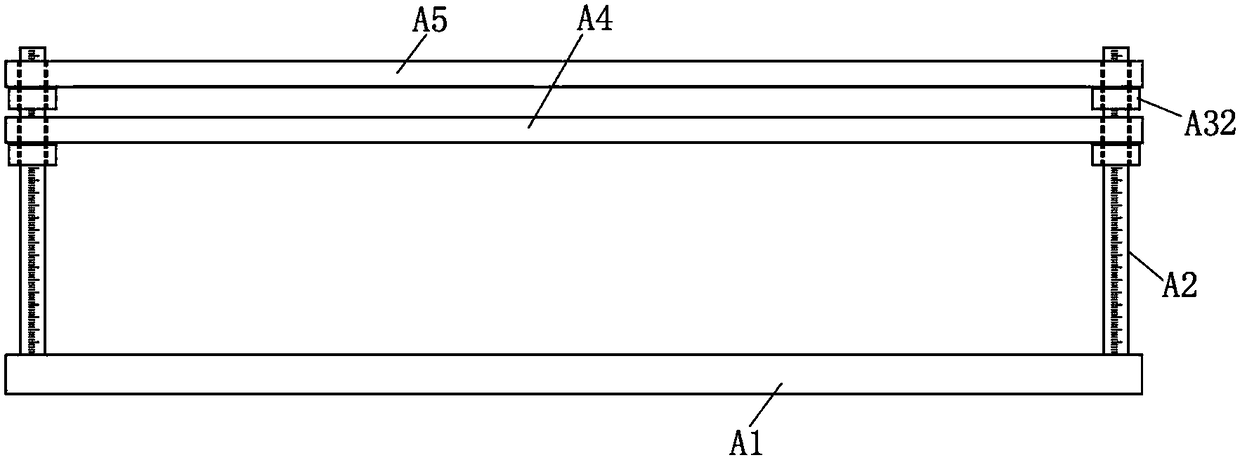

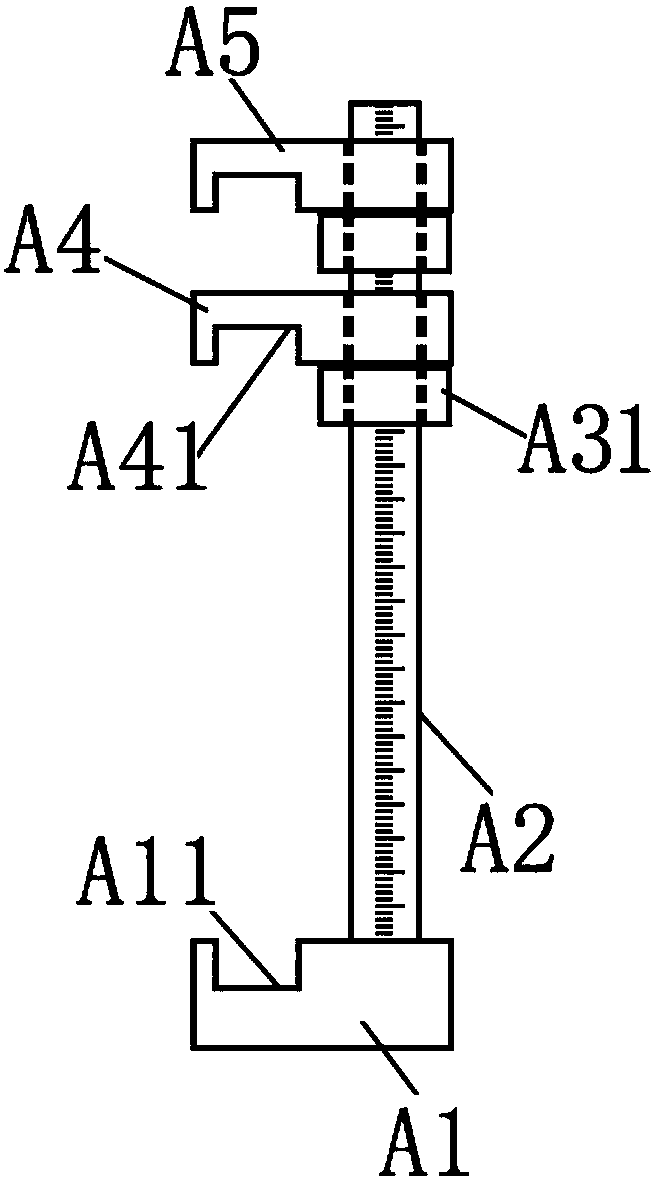

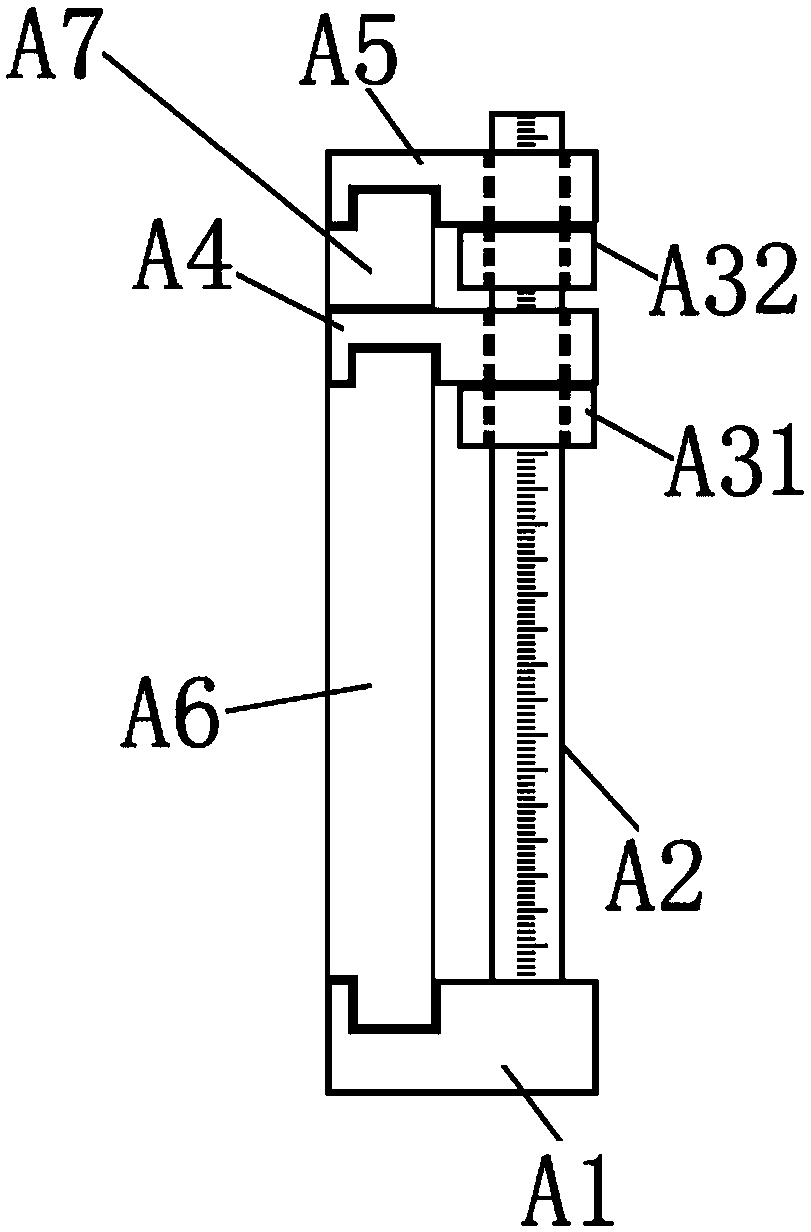

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com