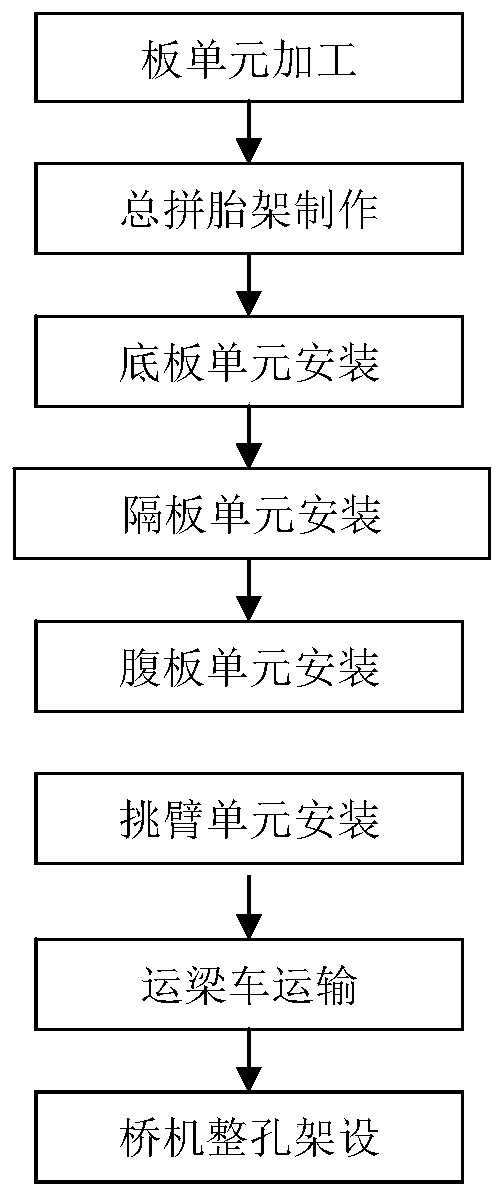

80-meter-span width steel box girder in-plant full-span assembly double-width erecting construction method

A construction method and wide-width steel technology, applied in bridge construction, erection/assembly of bridges, bridges, etc., can solve problems such as limited transportation conditions, high requirements for bridge cranes, and many restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

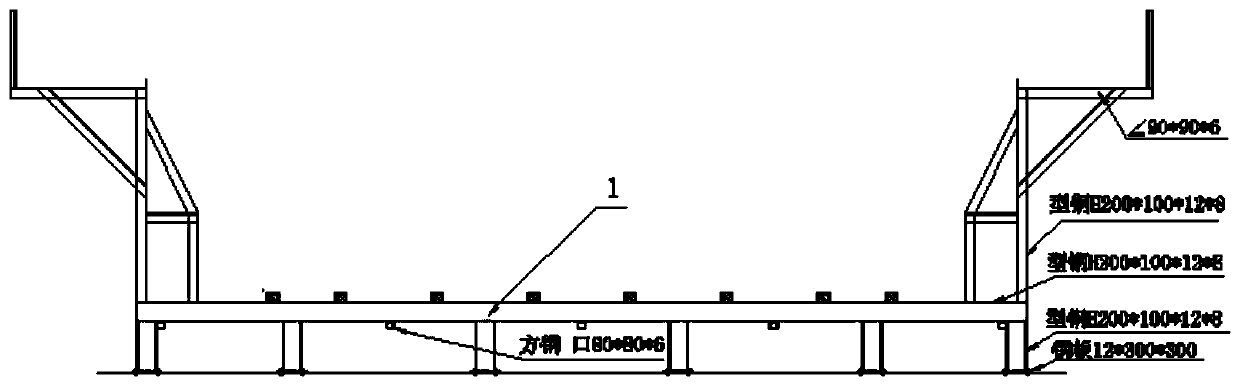

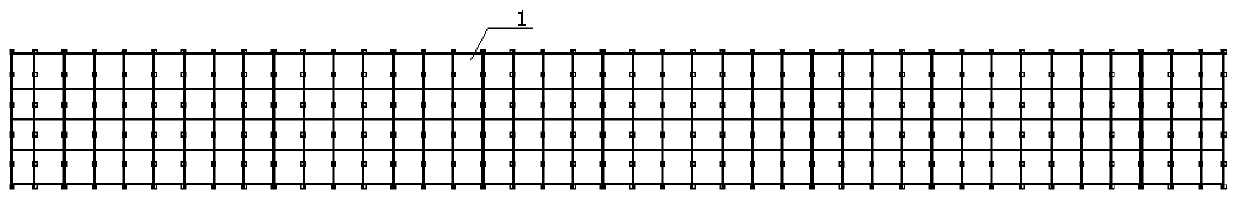

[0059] The technical solutions of the present application will be described in detail below in conjunction with the accompanying drawings and specific implementation methods of the application, but the following embodiments are only used to understand the present invention, and the embodiments in the application and the features in the embodiments can be combined with each other , the application can be practiced in a multitude of different ways as defined and covered by the claims.

[0060] A national highway project is two-way six-lane, and the main control project of the Yellow River Super Bridge is divided into 11 bridges. The direction from the small pile number to the large pile number is 30 meters T beam for the north approach bridge, and 50+80+50 for the cross protection embankment bridge. Meter steel-concrete composite girders, 50-meter corrugated steel web girders for the north approach bridge inside the dike, 80-meter steel-concrete composite girders for the main bri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com