Petroleum drill rod thread machining auxiliary device

A thread processing and auxiliary device technology, which is applied in chemical instruments and methods, cleaning methods and appliances, cleaning methods using liquids, etc., can solve the problems affecting the thread processing accuracy of oil drill pipes, the removal of drill pipe shafts, and the inconvenience of processing personnel Accurate positioning of thread processing stations and other issues to achieve the effect of improving mechanical utilization, improving filtration efficiency, and increasing cleaning area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

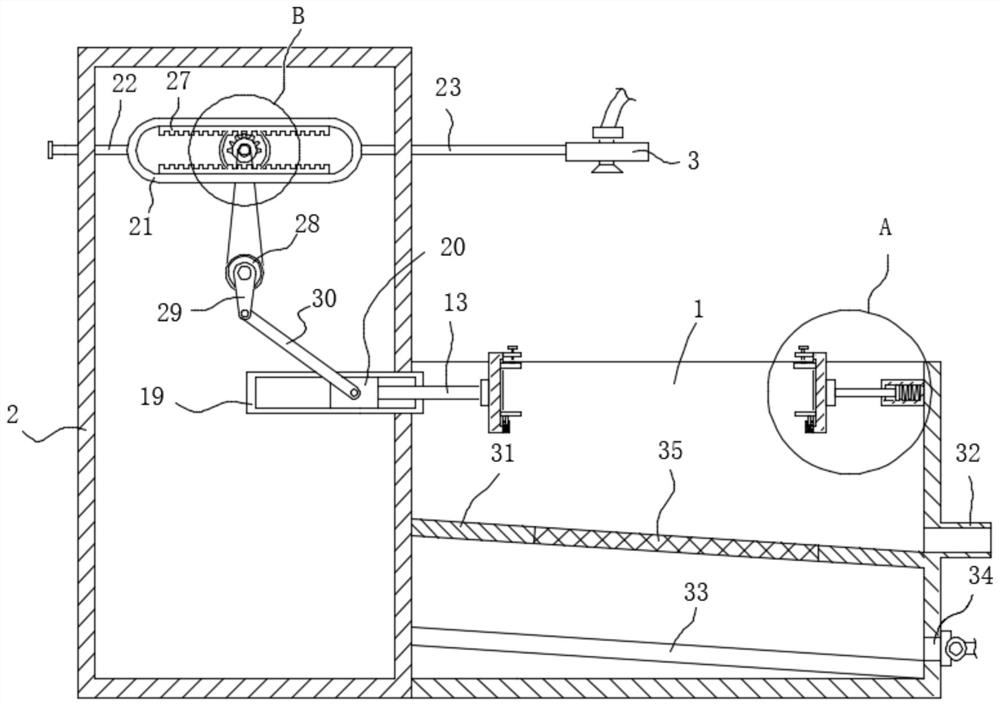

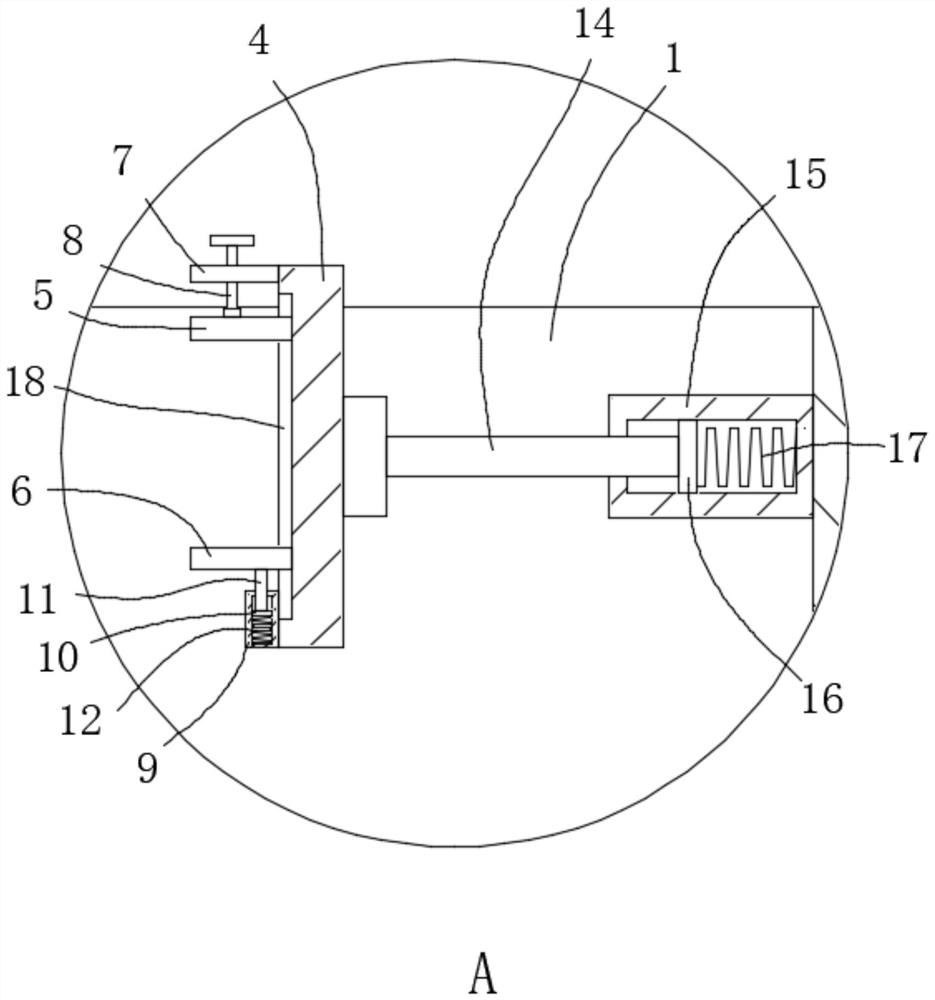

[0030] Please combine Figure 1 to Figure 3 , The auxiliary device for thread processing of oil drill pipes includes an open groove 1, a clamping mechanism arranged on the open groove 1 for fixing the drill pipe (not shown), and a spray mechanism for cleaning the drill pipe. The open groove 1 in this embodiment has a rectangular parallelepiped structure as a whole. The drill pipe in this embodiment is an oil drill pipe.

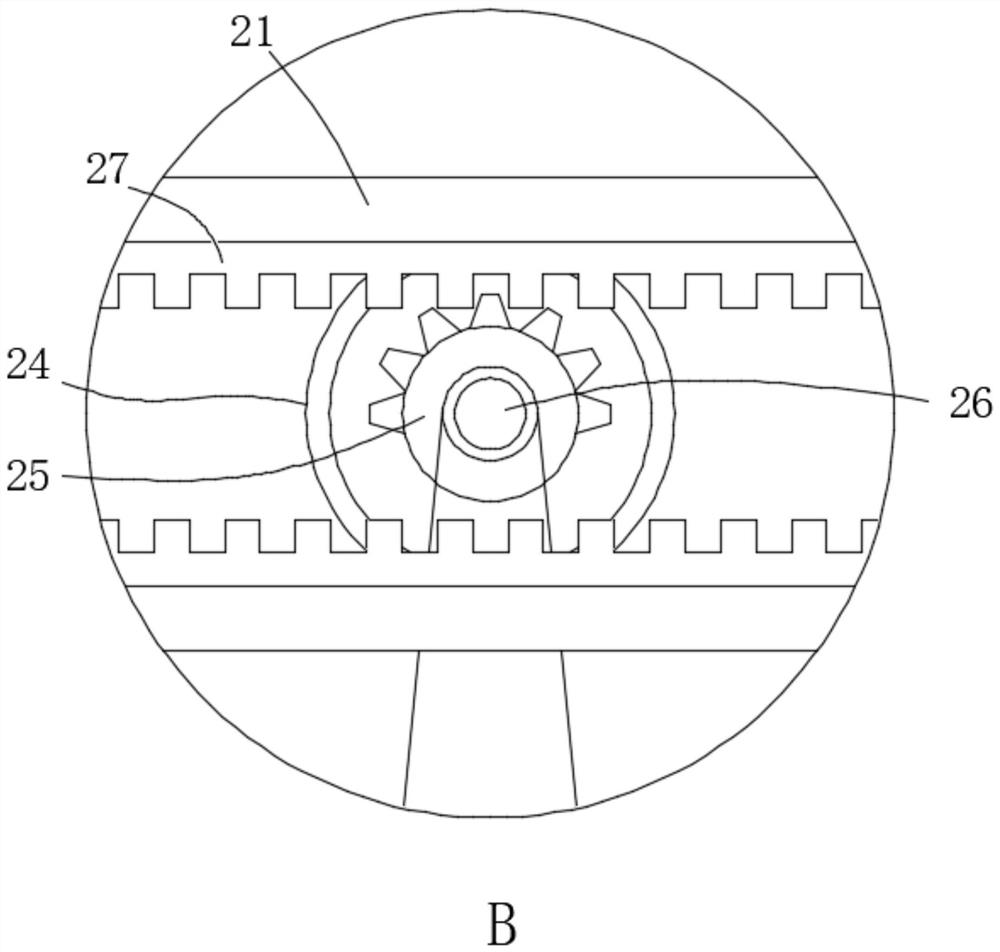

[0031] The clamping mechanism includes two clamping assemblies clamped at both ends of the drill rod and a driving mechanism for driving the drill rod to reciprocate horizontally. The spraying mechanism includes a spraying head 3 suspended above the drill pipe and a driving mechanism 2 for guiding the horizontal reciprocating movement of the spraying head 3 . The cleaning water source of the spray head 3 in this embodiment can be connected with external liquid supply equipment. Through the driving mechanism 1 and the driving mechanism 2, the spray head 3 a...

Embodiment 2

[0043] Please combine Figure 4 , this embodiment 2 is an improved solution of embodiment 1, specifically, the guide plate one 31 is connected to the corresponding groove wall of the open groove 1 at the discharge port 32 by rotation. The block body of slide block two 20 is fixed with the synchronous bar one 38 that is perpendicular to chute two 19, and the other end of synchronous bar one 38 is provided with the synchronous bar two 39 that is perpendicular to it, and synchronous bar two 39 penetrates the opening groove 1 and is connected with an inclined platform 37. The top of the ramp 37 has a slope (not shown). The bottom of one end of the guide plate one 31 away from the discharge port 32 is provided with a connecting rod three (not marked) parallel to the synchronous rod one 38, and the bottom of the connecting rod three is provided with a roller 36 matched with the inclined surface.

[0044] In the second embodiment, the second slider 20 can drive the ramp 37 to recip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com