Patents

Literature

112results about How to "Accurate capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

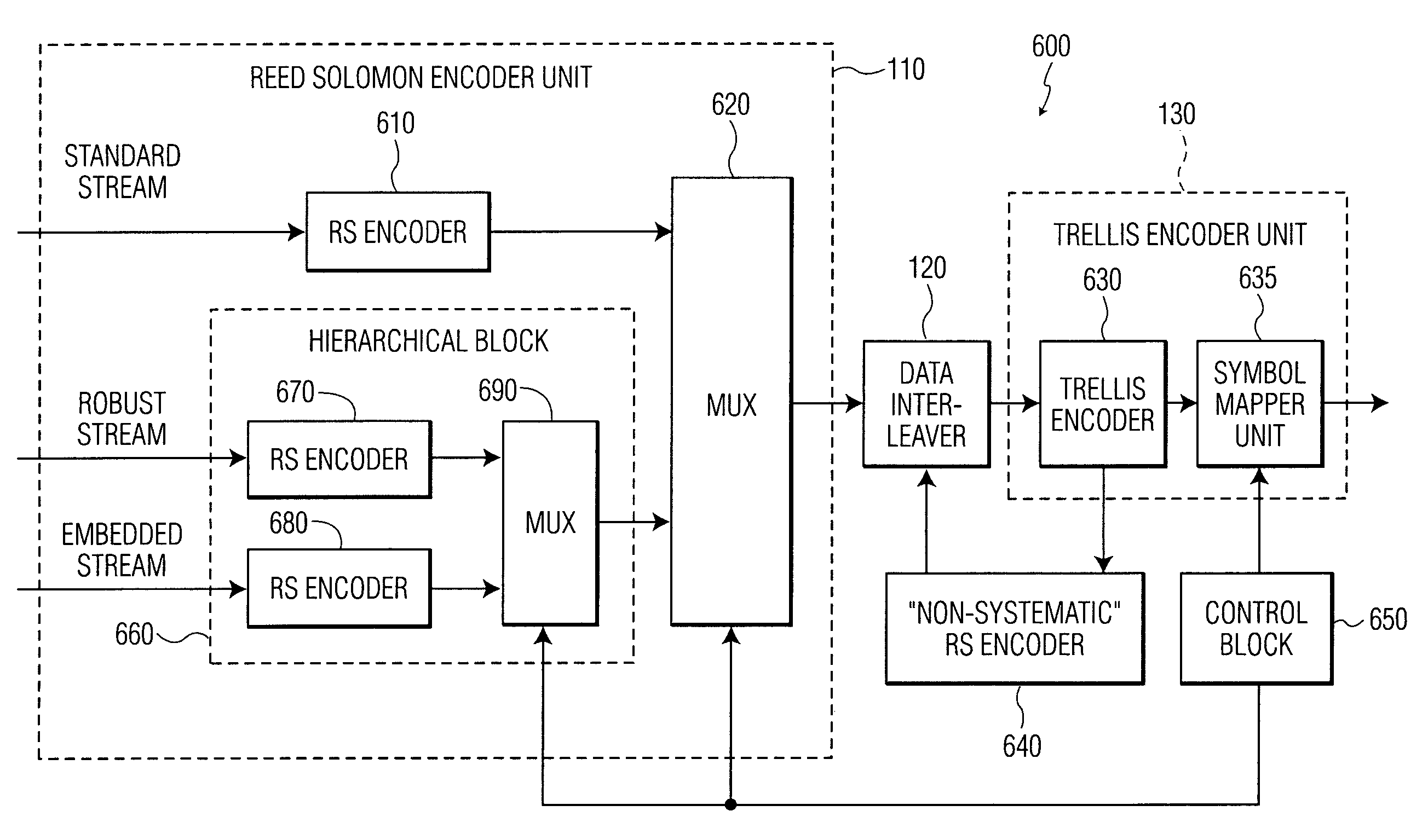

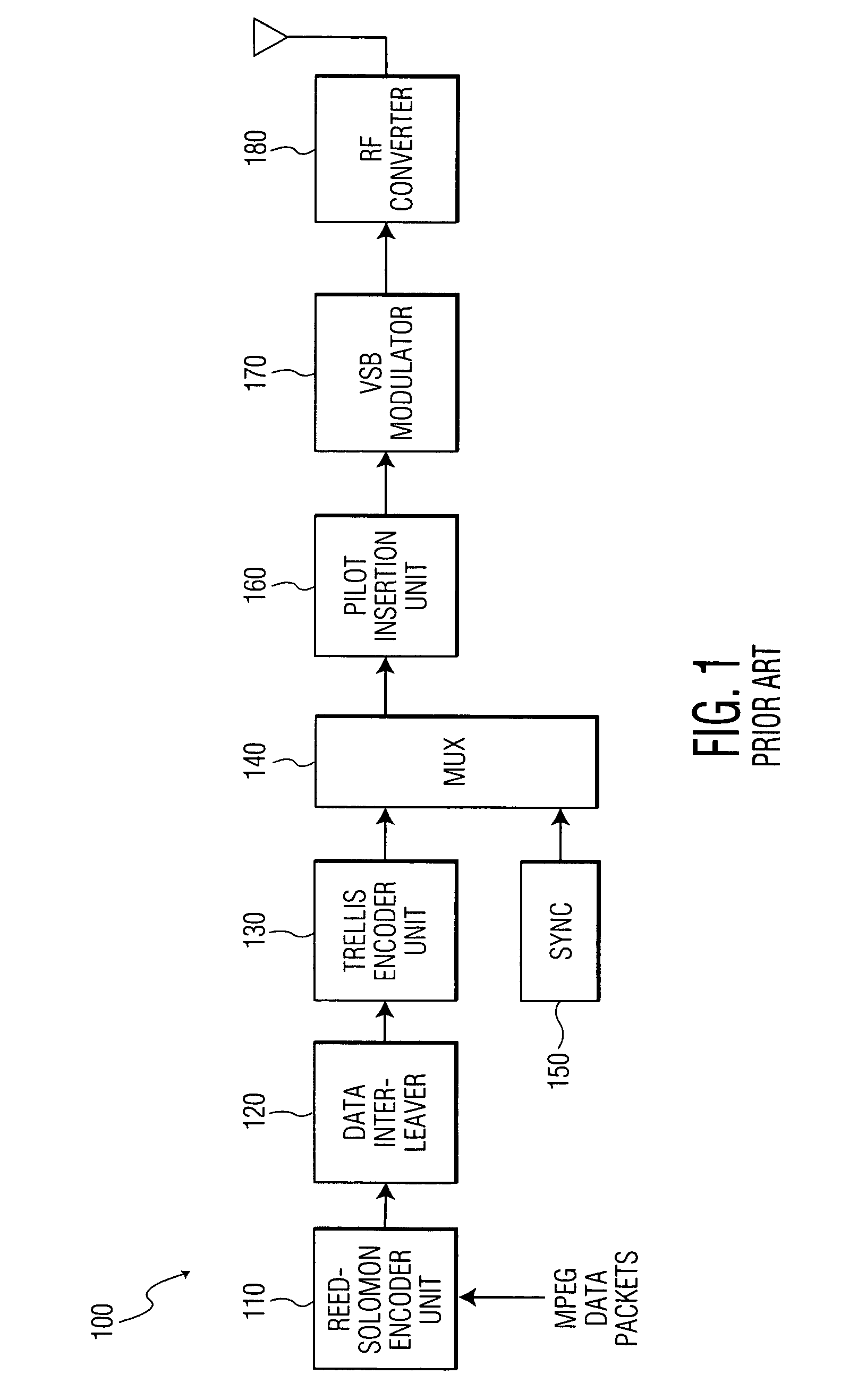

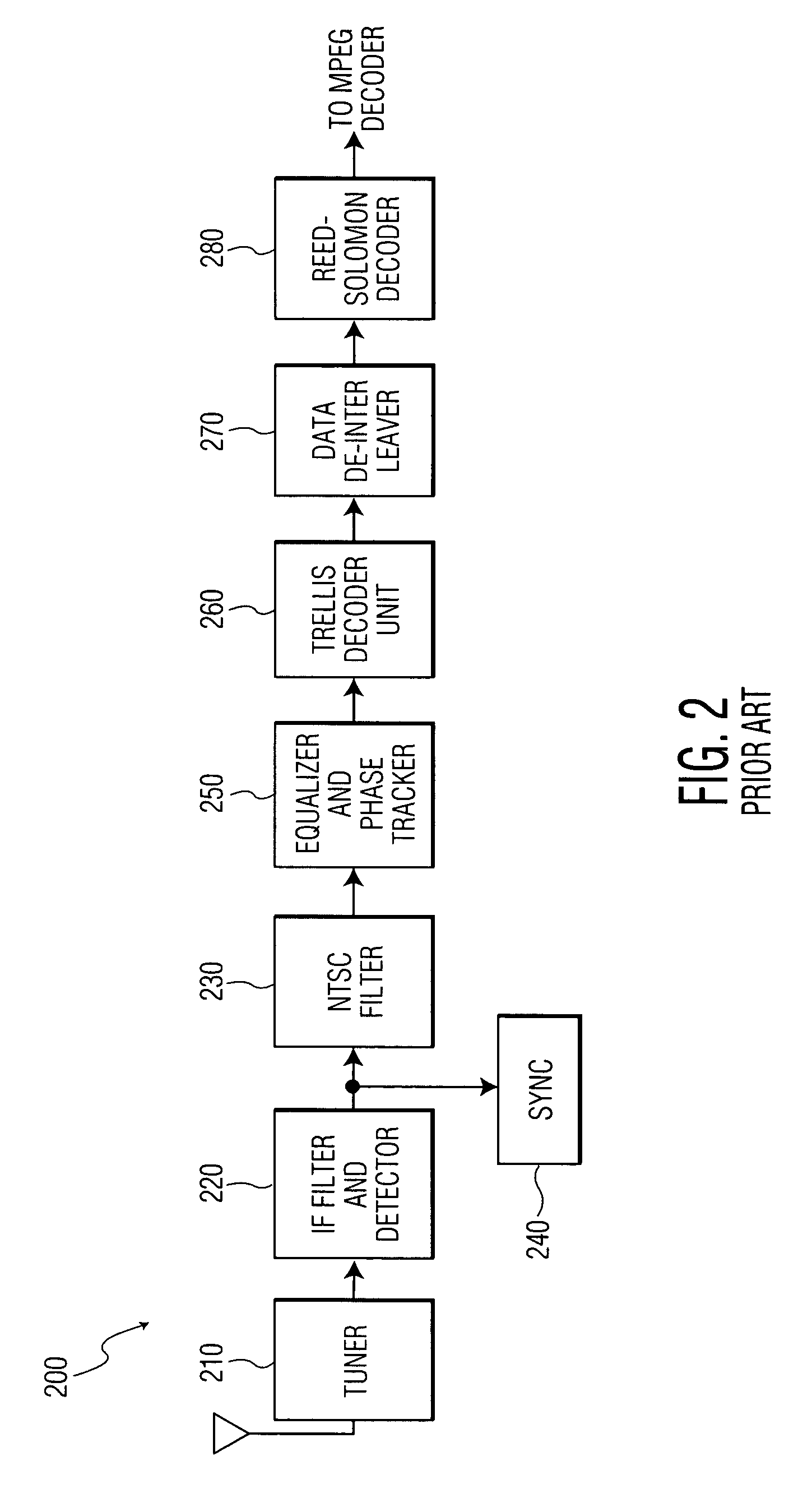

Apparatus and method for generating robust ATSC 8-VSB bit streams

ActiveUS6973137B2Accurate capacityRobust Stream is greaterCode conversionModulation with suppressed carrierDigital transmitterComputer hardware

An apparatus and method is disclosed for generating robust ATSC 8-VSB bit streams for transmission by a digital transmitter. The apparatus comprises a Reed Solomon encoder unit that encodes a plurality of bit streams including bits to be encoded in a robust ATSC 8-VSB bit stream and bits to be encoded in a standard ATSC 8-VSB bit stream. The apparatus also comprises a trellis encoder unit comprising a symbol mapper unit in which an output symbol R is forced to a value of minus one minus alpha (−1−α) when R equals minus one (−1) and to a value of plus one plus alpha (+1+α) when R equals plus one (+1), where the value of alpha (α) is variable. A control block sets the value of alpha in accordance with the type of bits present within the trellis encoder unit to generate both robust and standard ATSC 8-VSB bit streams.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

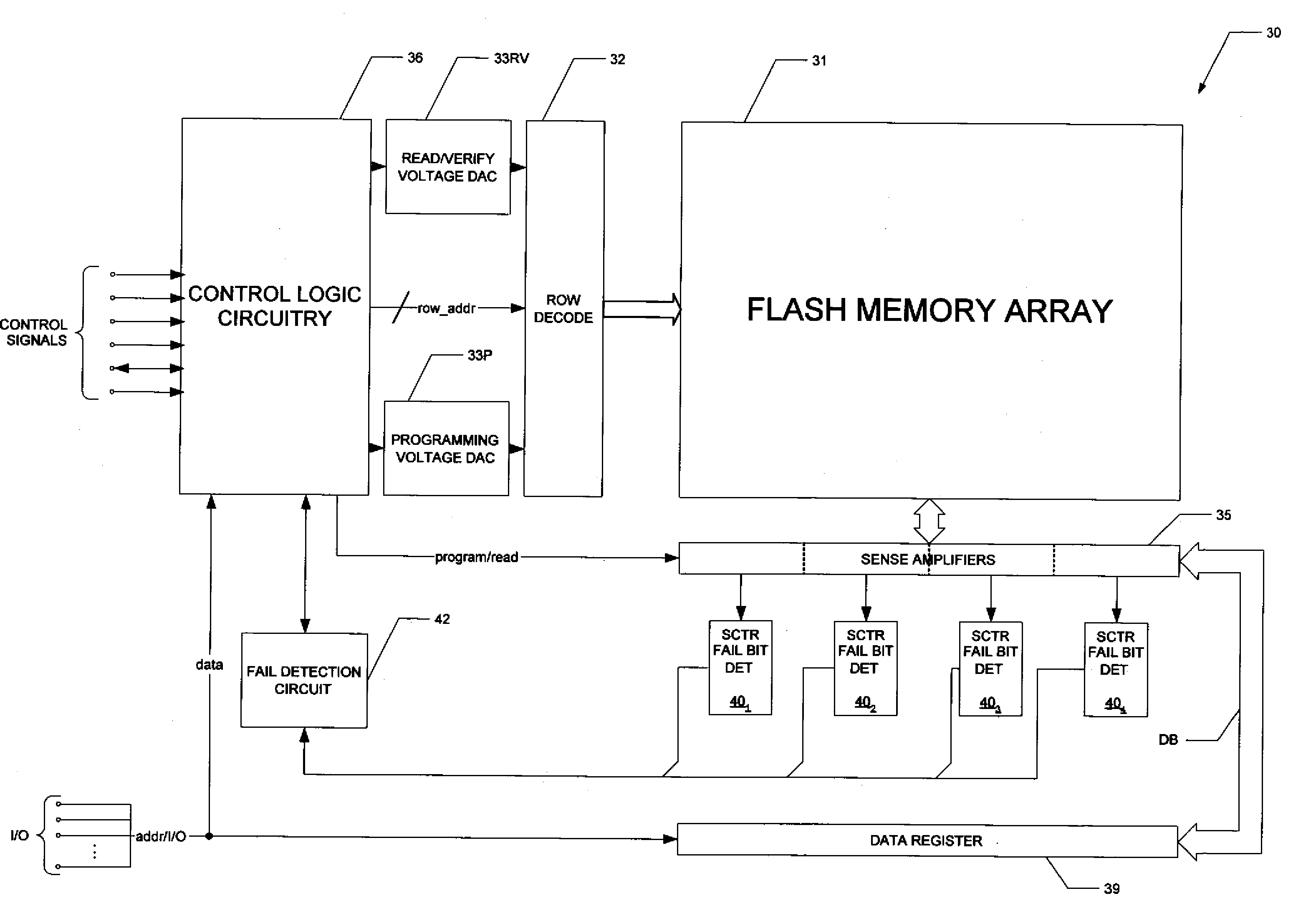

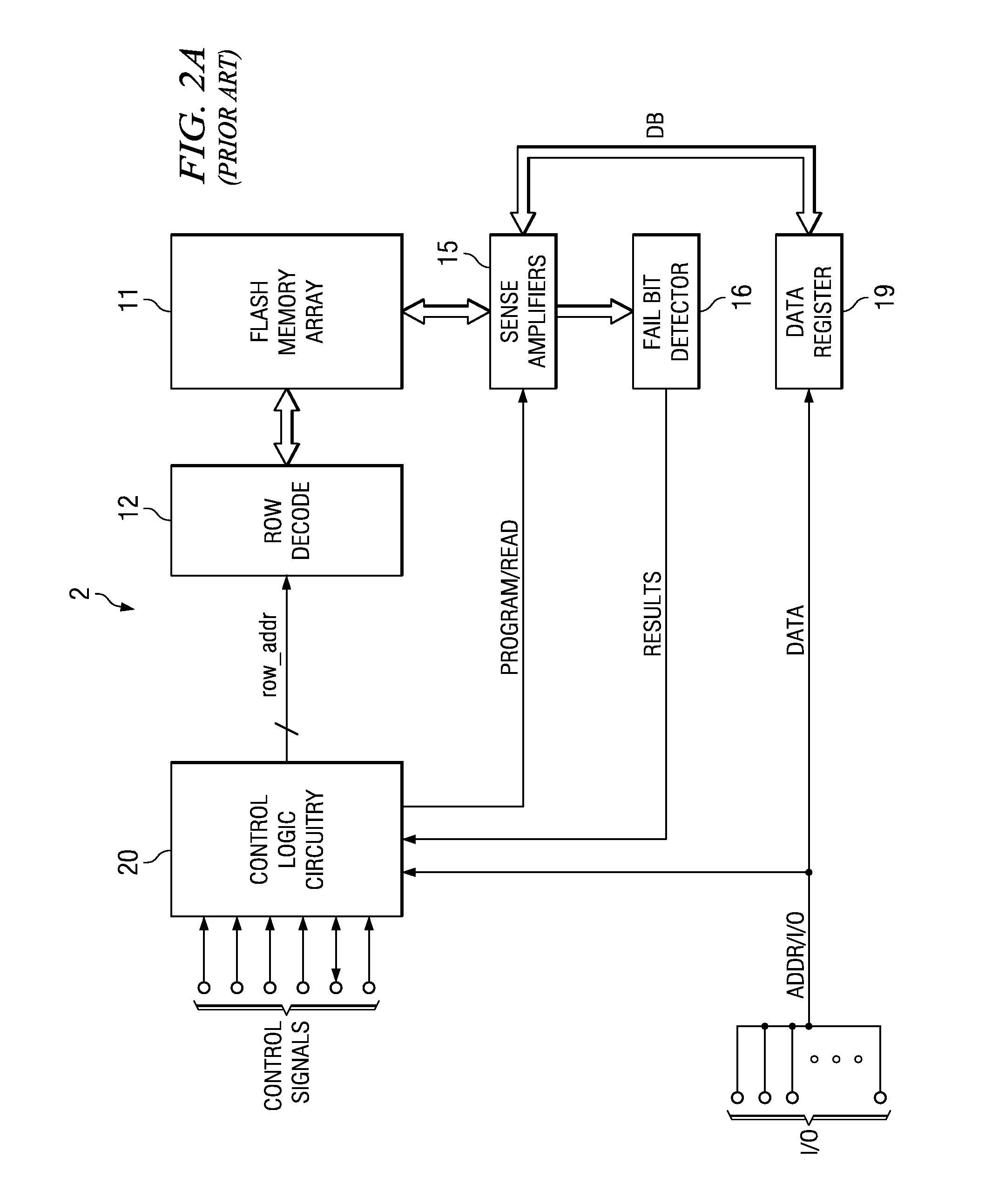

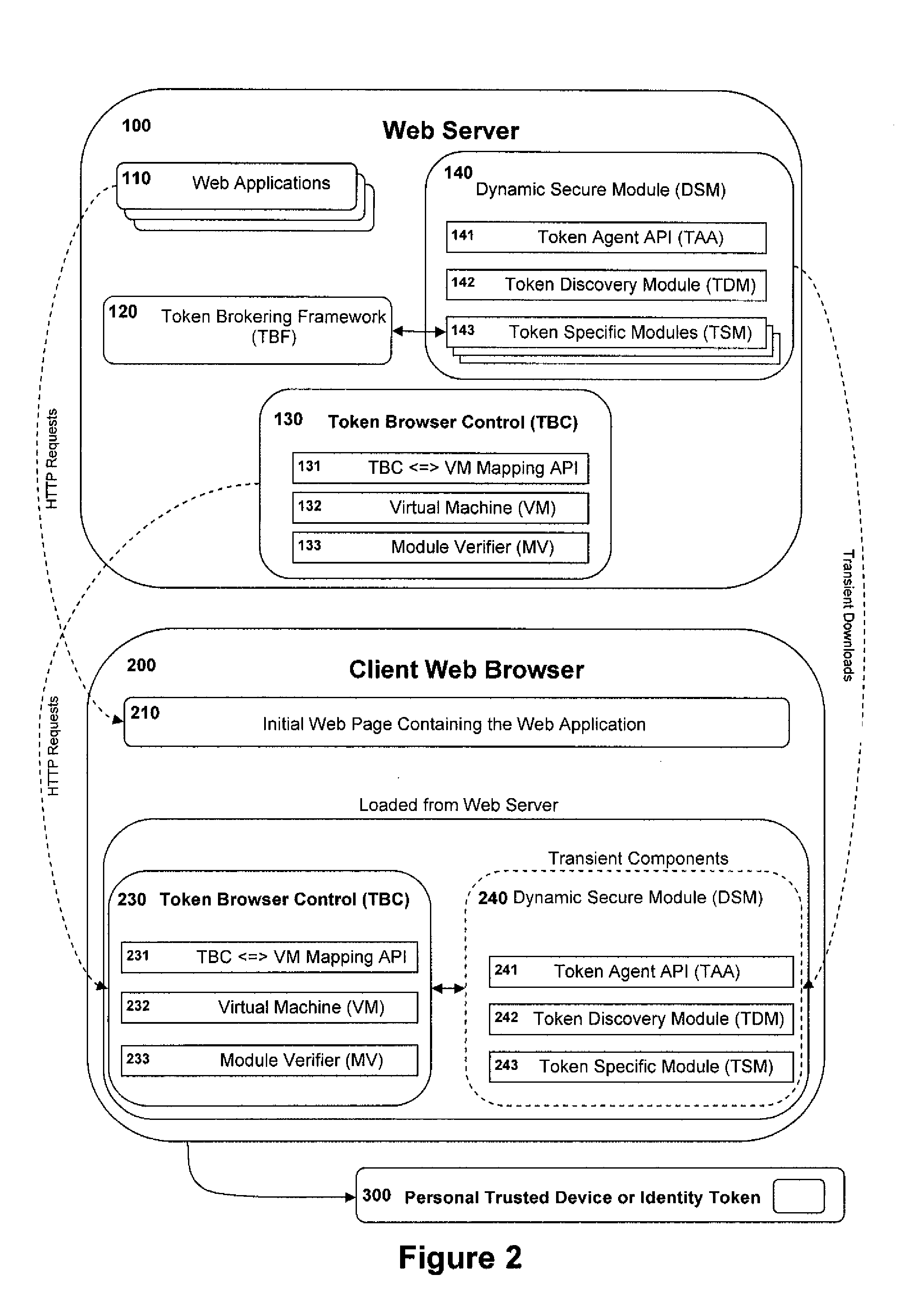

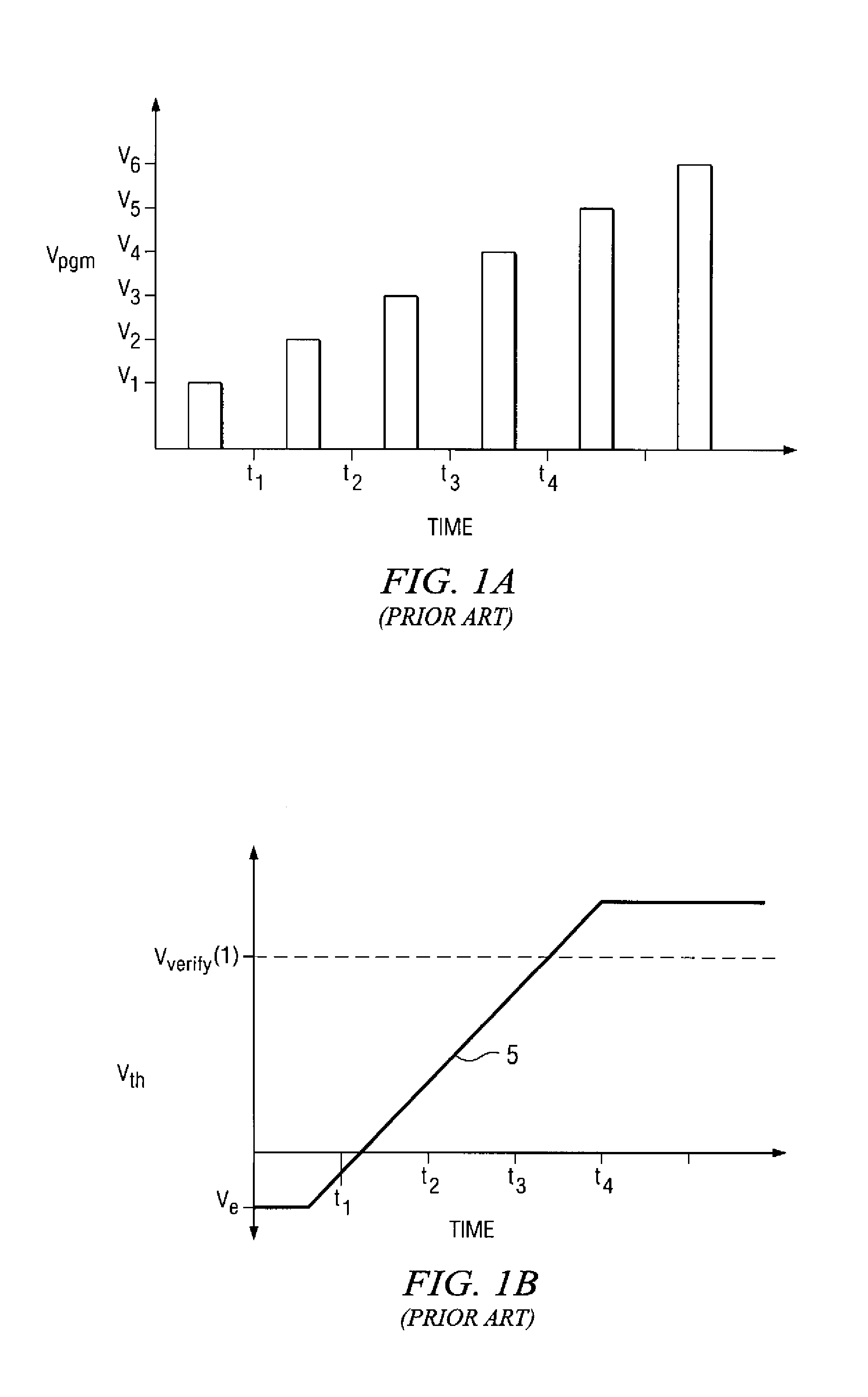

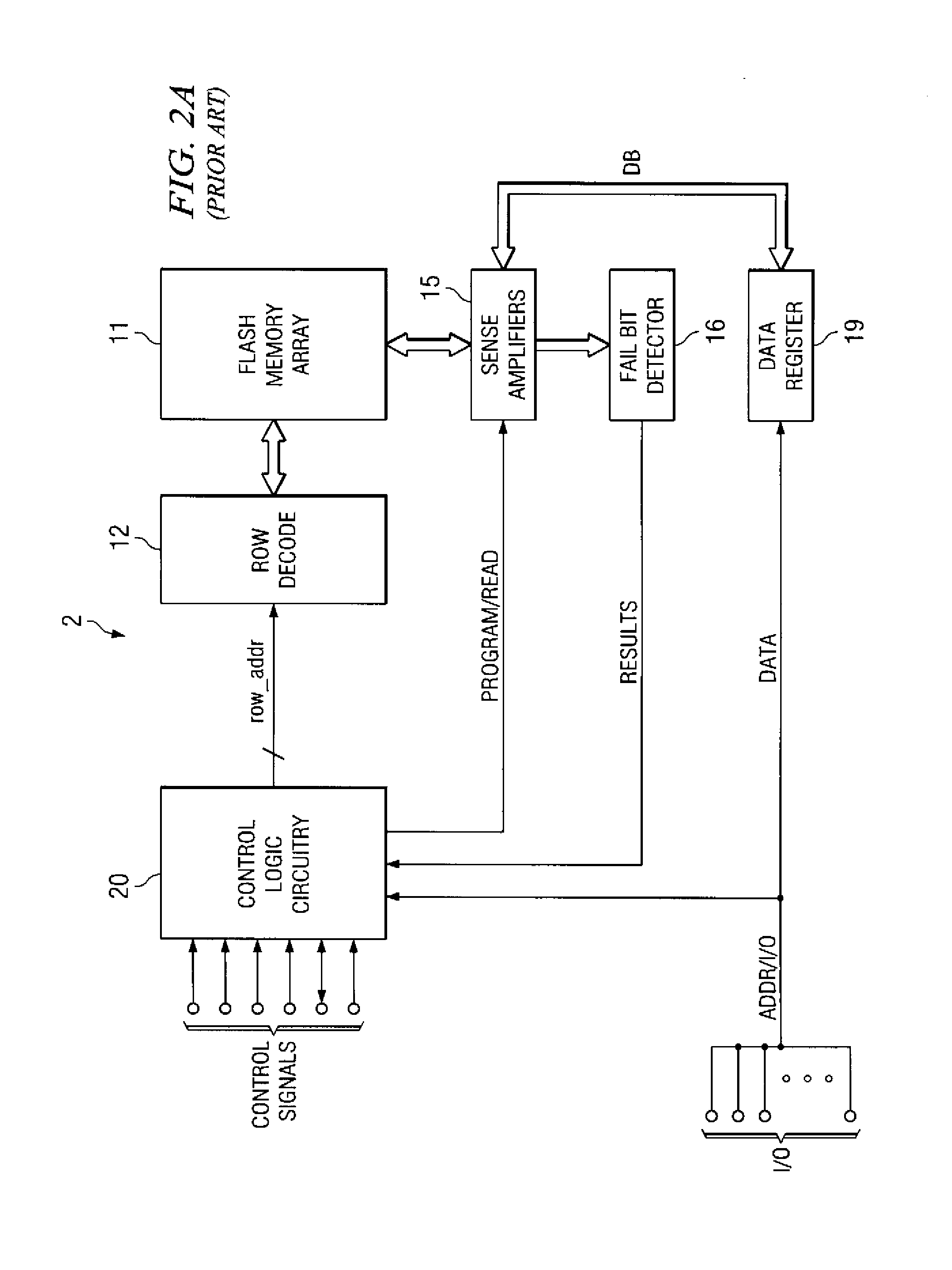

Partial Page Fail Bit Detection in Flash Memory Devices

ActiveUS20080002468A1Improve efficiencyEarly terminationError detection/correctionRead-only memoriesDetection thresholdError correction coding

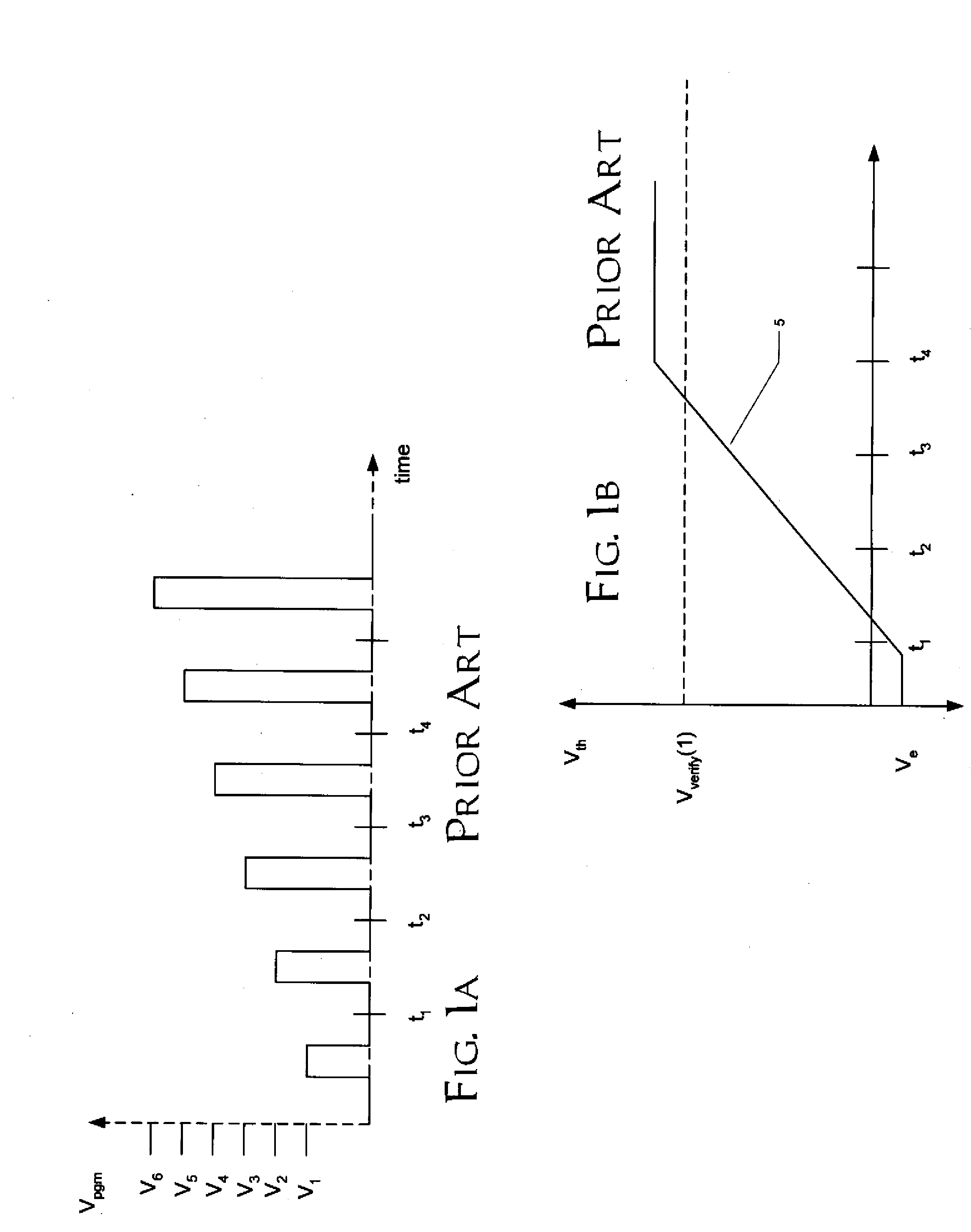

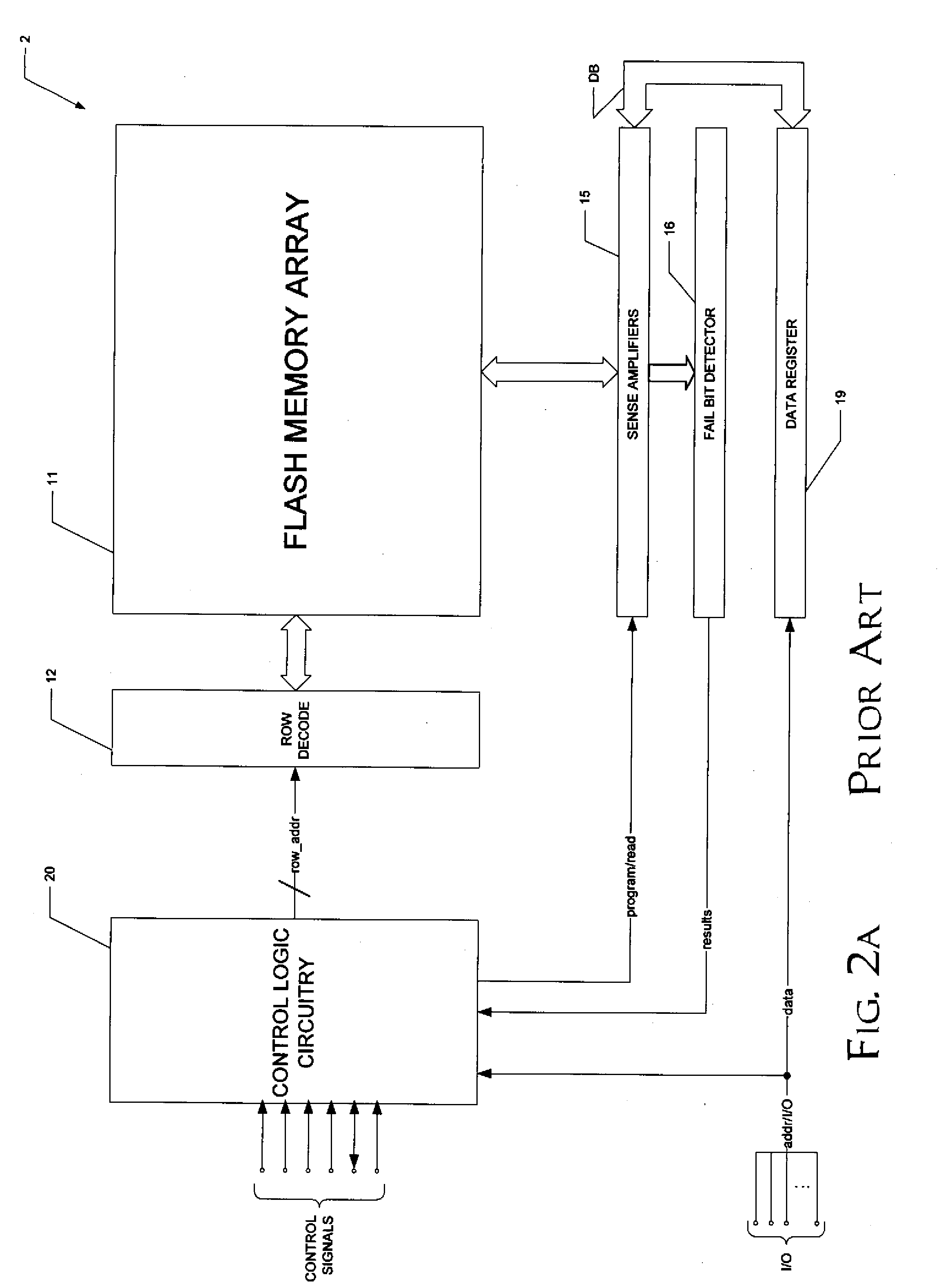

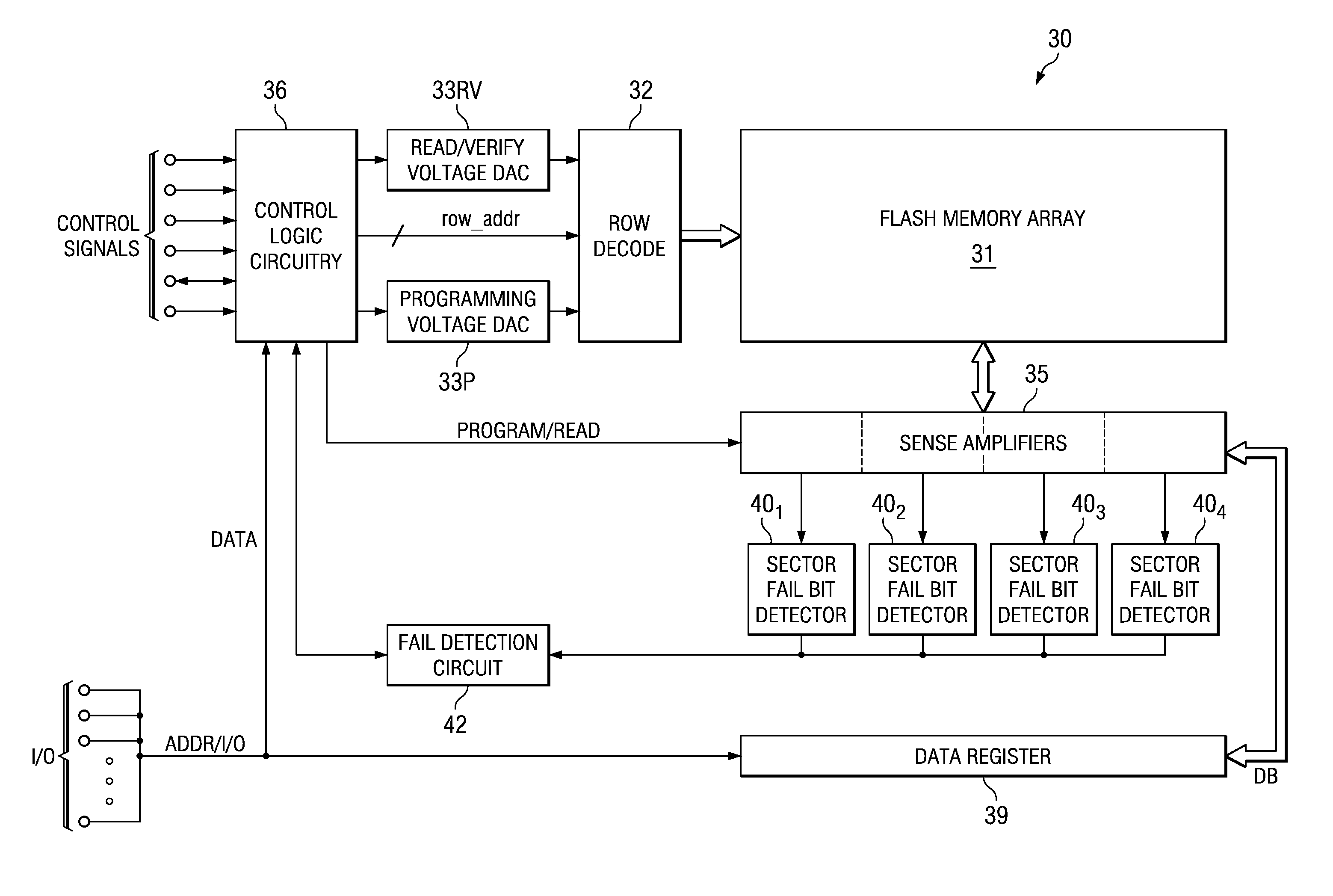

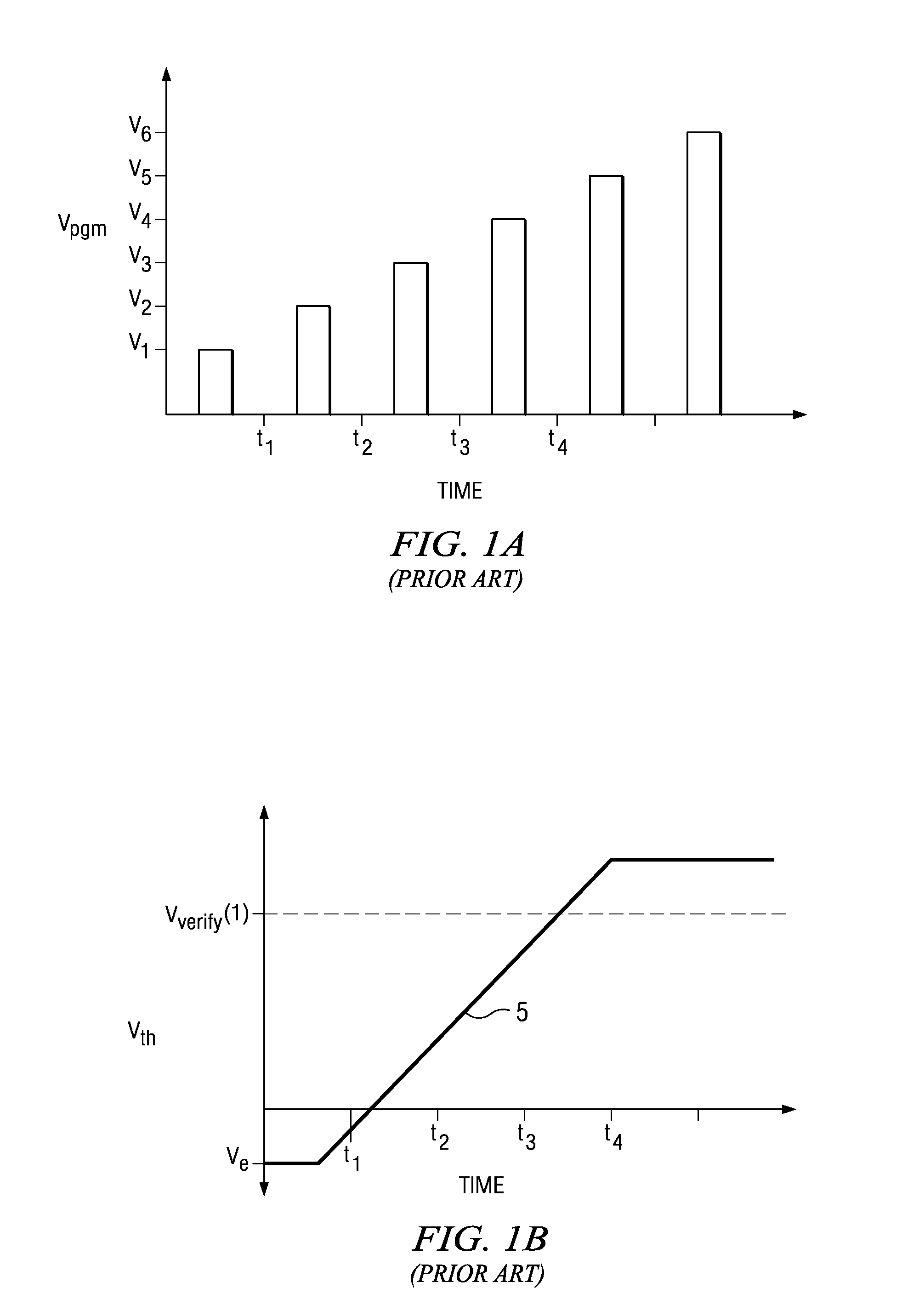

A flash memory device, and a method of operating the same, is disclosed. The array of the flash memory device is arranged in pages of memory cells, each page having memory cells associated into groups of memory cells within the page for purposes of fail bit detection in program verification. For example, these groups may correspond to sectors within the page. In a programming operation, the verify process determines whether each group of memory cells within the page has fewer than a selected ignore bit limit for the sector. If not, additional programming is required for the insufficiently programmed cells in the page. By applying a fail bit detection threshold for each of multiple groups within the page, the efficiency of error correction coding in the flash memory is improved. A similar verify and fail bit detection approach may be used in erase and soft programming operations.

Owner:SANDISK TECH LLC

Method of partial page fail bit detection in flash memory devices

ActiveUS7304893B1Improve efficiencyEarly terminationRead-only memoriesDigital storageDetection thresholdCorrection code

A flash memory device, and a method of operating the same, is disclosed. The array of the flash memory device is arranged in pages of memory cells, each page having memory cells associated into groups of memory cells within the page for purposes of fail bit detection in program verification. For example, these groups may correspond to sectors within the page. In a programming operation, the verify process determines whether each group of memory cells within the page has fewer than a selected ignore bit limit for the sector. If not, additional programming is required for the insufficiently programmed cells in the page. By applying a fail bit detection threshold for each of multiple groups within the page, the efficiency of error correction coding in the flash memory is improved. A similar verify and fail bit detection approach may be used in erase and soft programming operations.

Owner:SANDISK TECH LLC

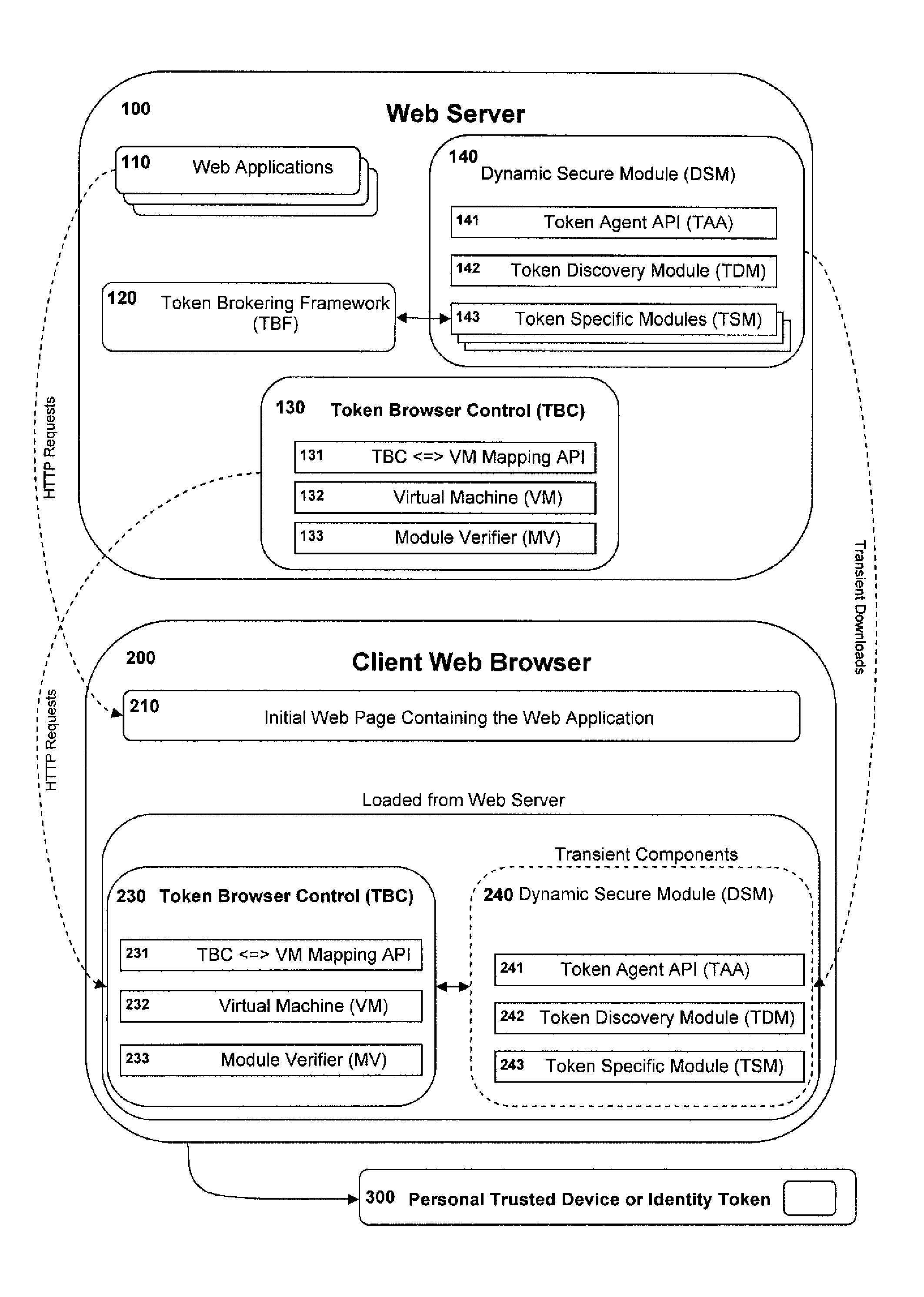

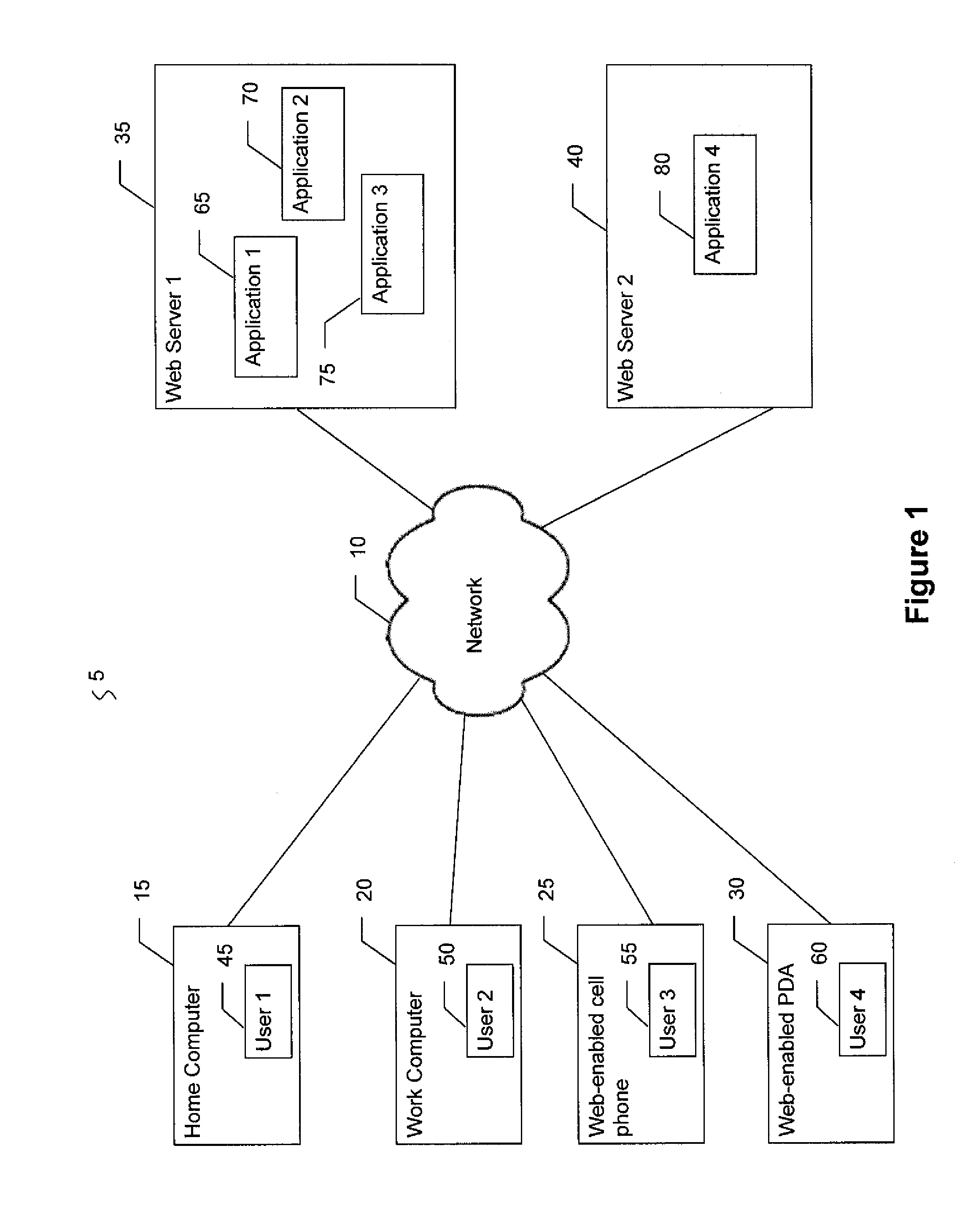

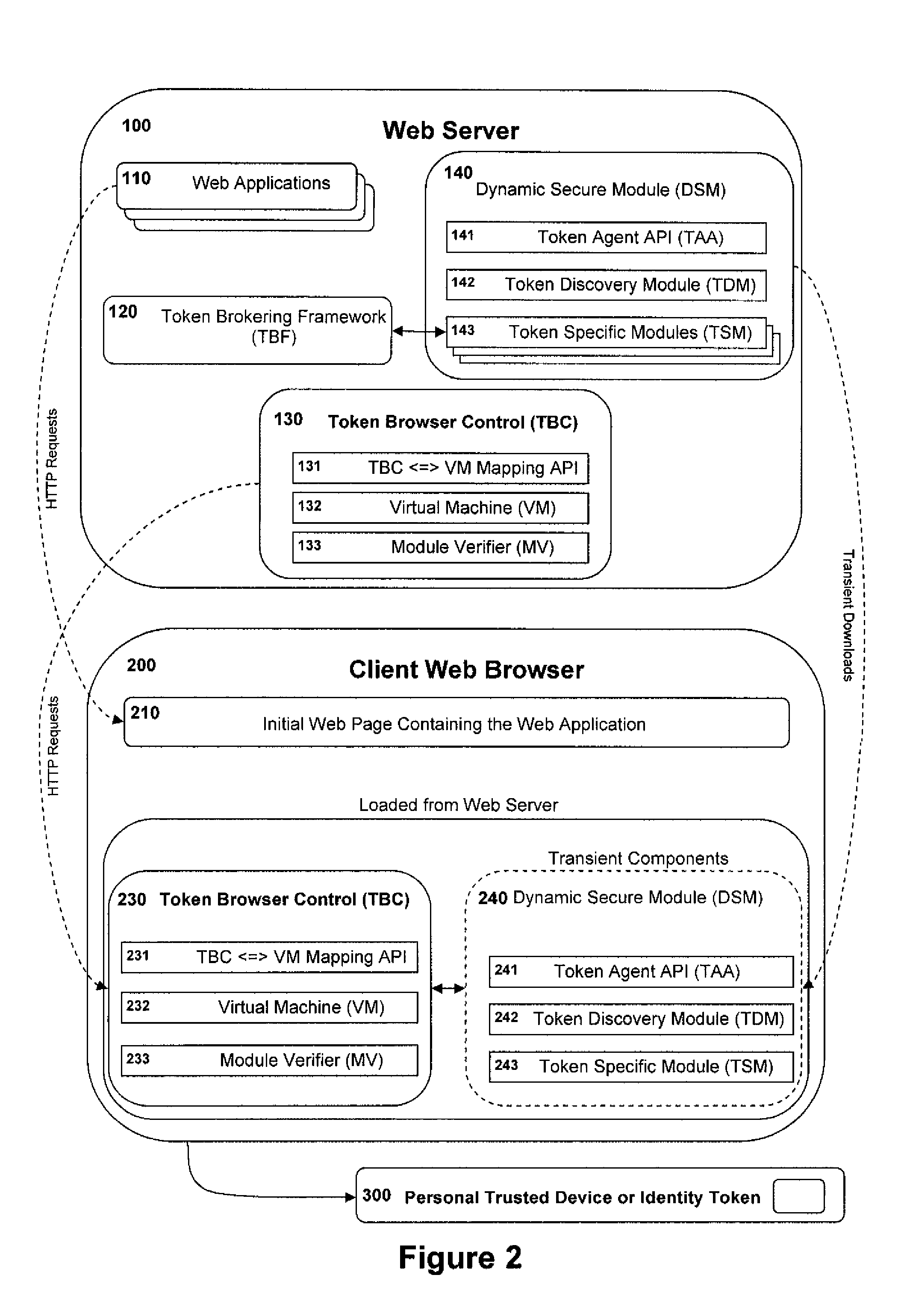

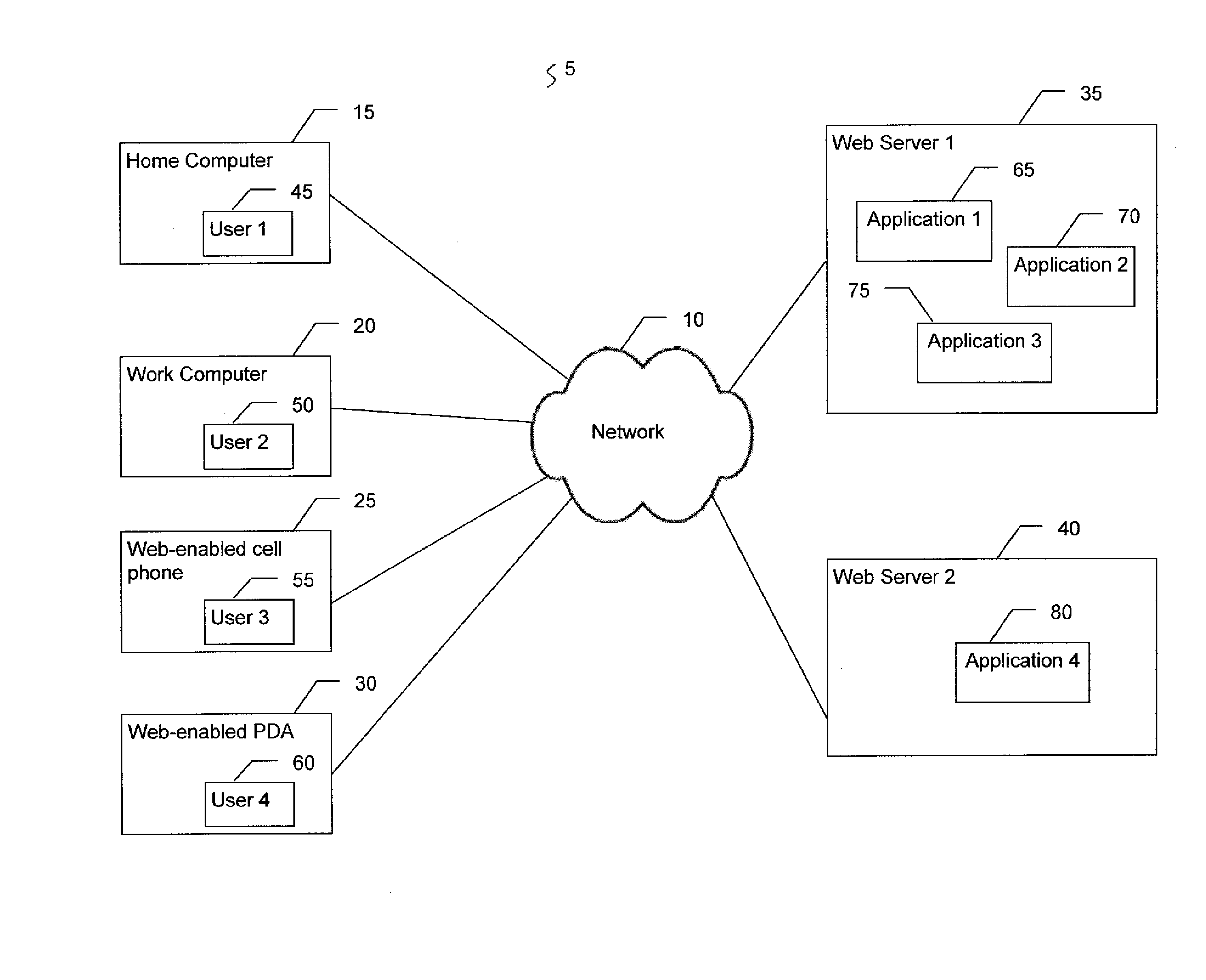

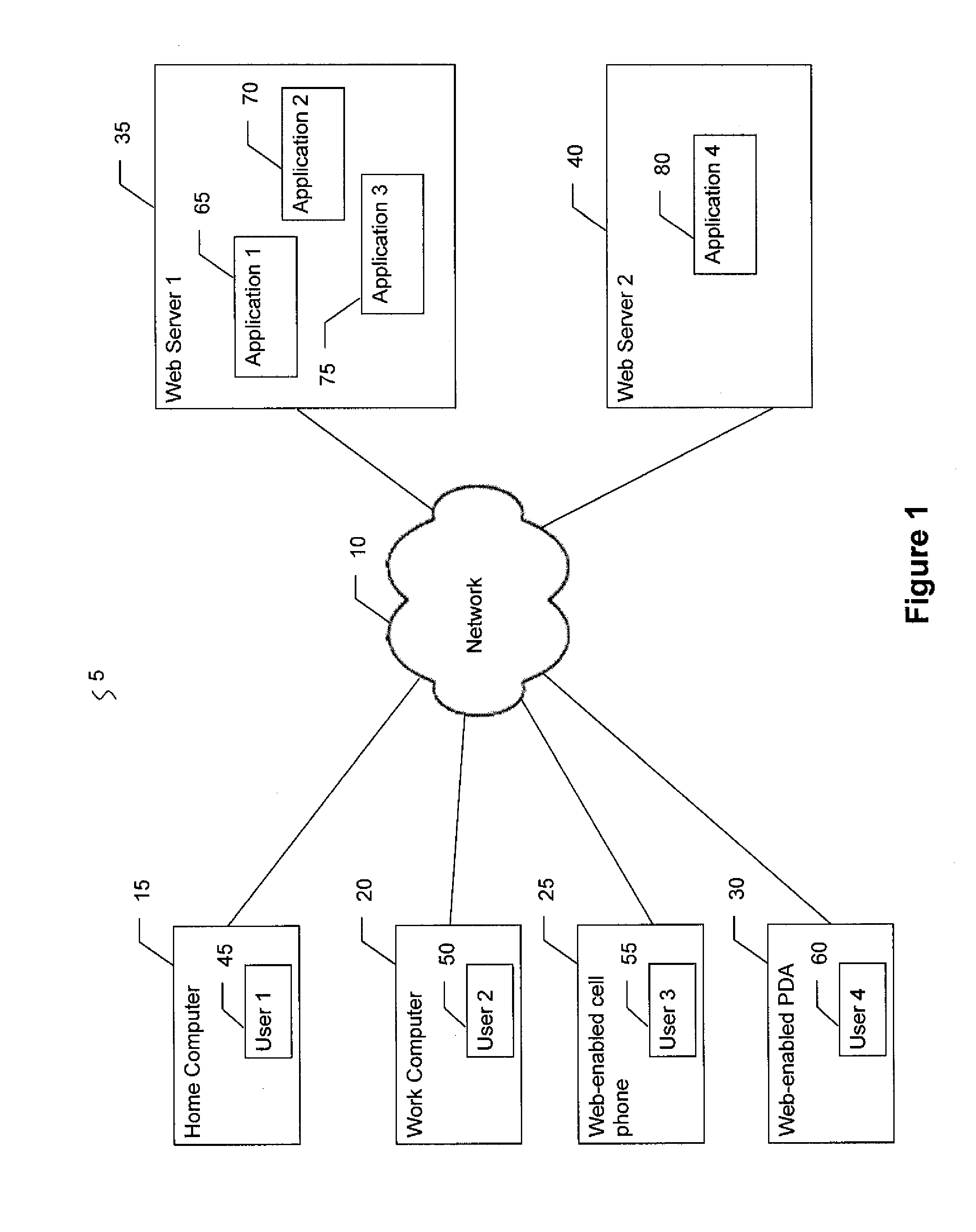

Dynamic web services systems and method for use of personal trusted devices and identity tokens

ActiveUS8364968B2Accurate capacityEnhancing efficiency and effectivenessDigital data authenticationSecuring communicationWeb browserWeb application

Owner:GEN DIGITAL INC

Dynamic Web Services Systems and Method For Use of Personal Trusted Devices and Identity Tokens

ActiveUS20070300057A1Thwart phishing style attackStrong authenticationDigital data authenticationSecuring communicationWeb applicationWeb browser

The present invention involves one or more computers that provide software controls to enable a web application to interface with a personal trusted device. The server side of the computer system comprises: a server-based framework process; a device for receiving requests from the client computer and determining which software controls to send in response; and a device for digitally signing and encrypting the software controls before sending them to the client computer so that their authenticity can be verified. The client side of the computer system comprises: a client web browser that runs on a computer; a device for transmitting requests to the server computer and for receiving responses from those requests; a device for decrypting software controls so that the authenticity of their digital signature can be verified; and a connection to one or more personal trusted devices. An authentication proxy may be used to mutually authenticate a client user and server process using personal trusted devices.

Owner:GEN DIGITAL INC

Partial page fail bit detection in flash memory devices

ActiveUS7355892B2Improve efficiencyEarly terminationError detection/correctionRead-only memoriesDetection thresholdCorrection code

Owner:SANDISK TECH LLC

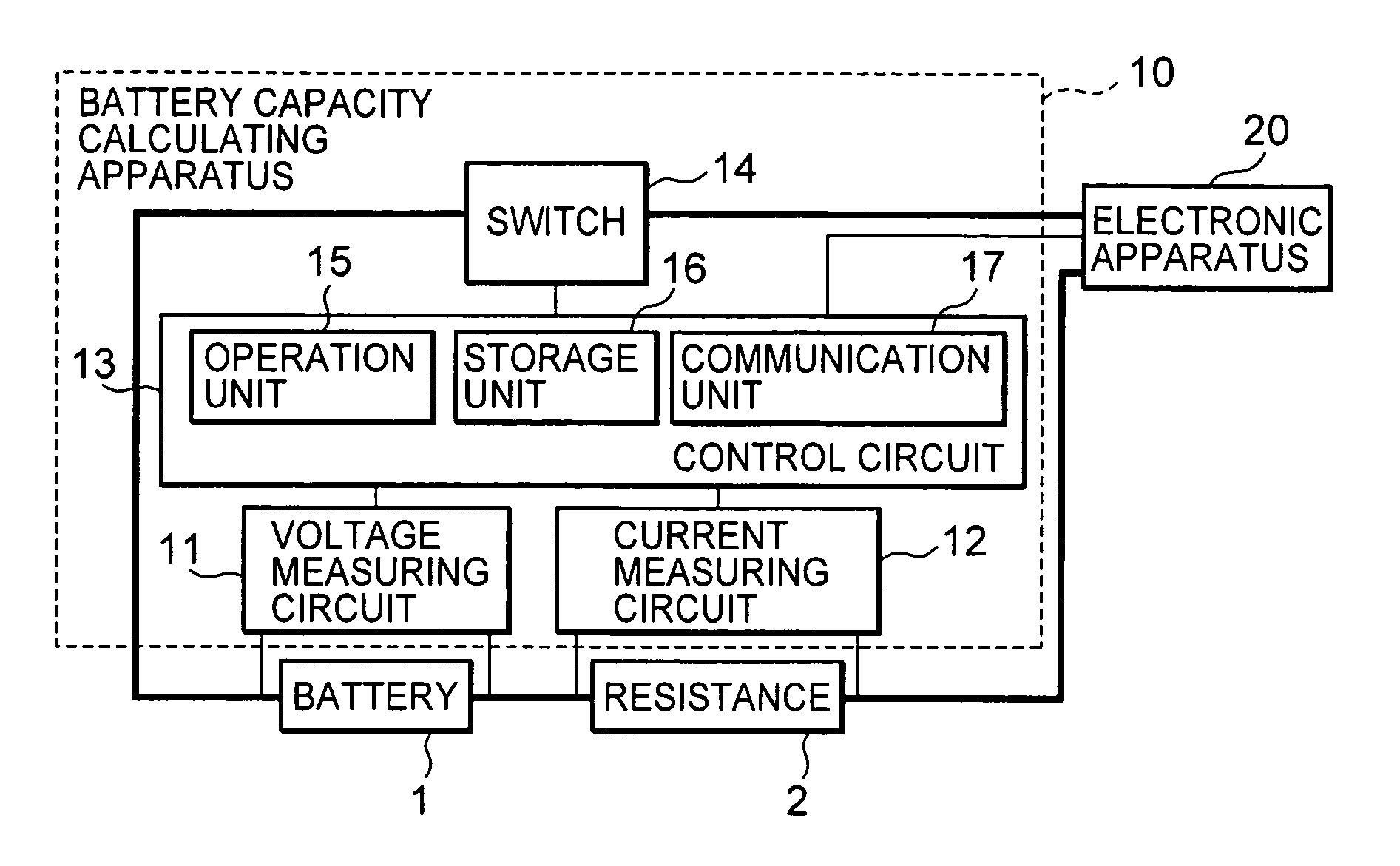

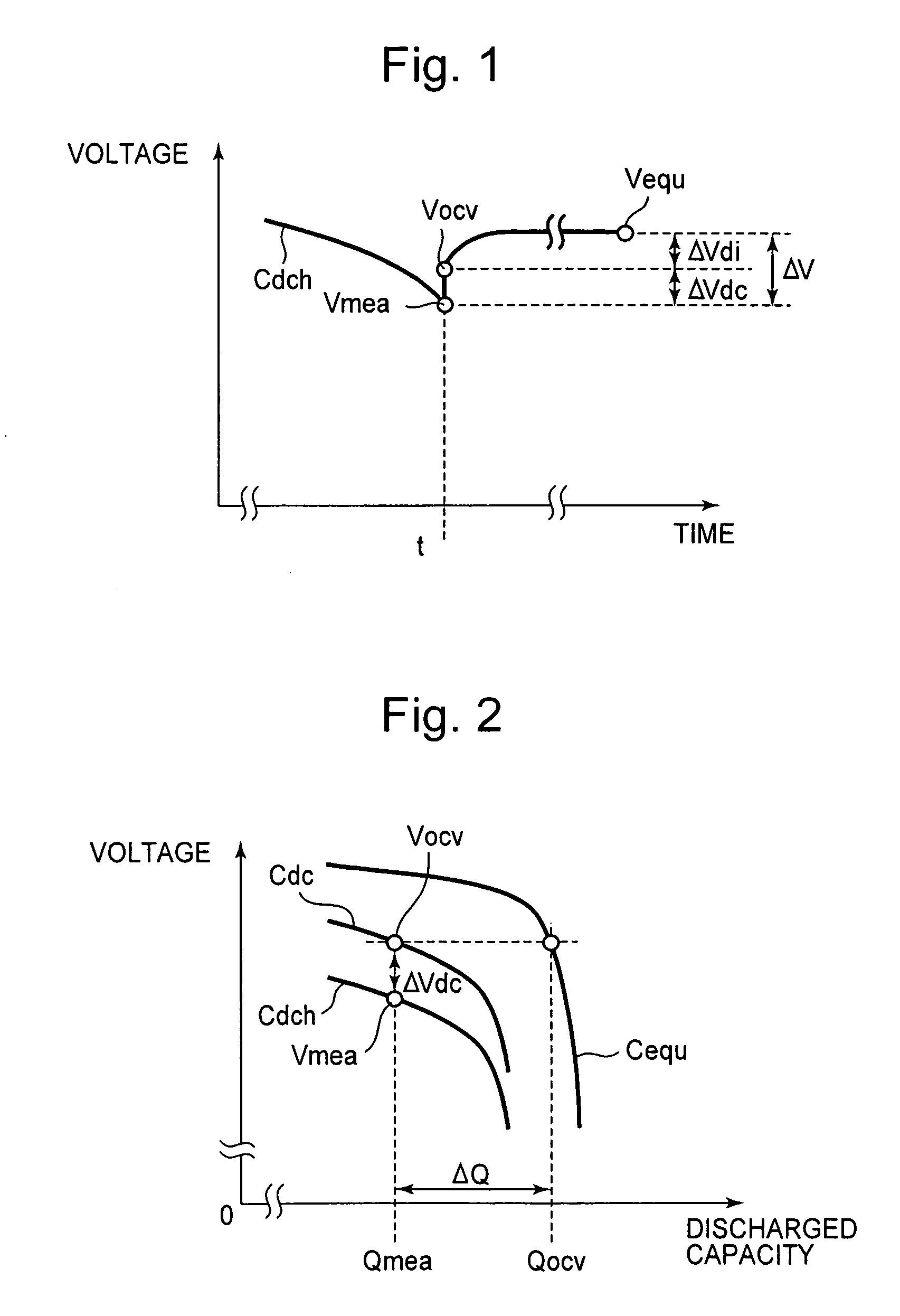

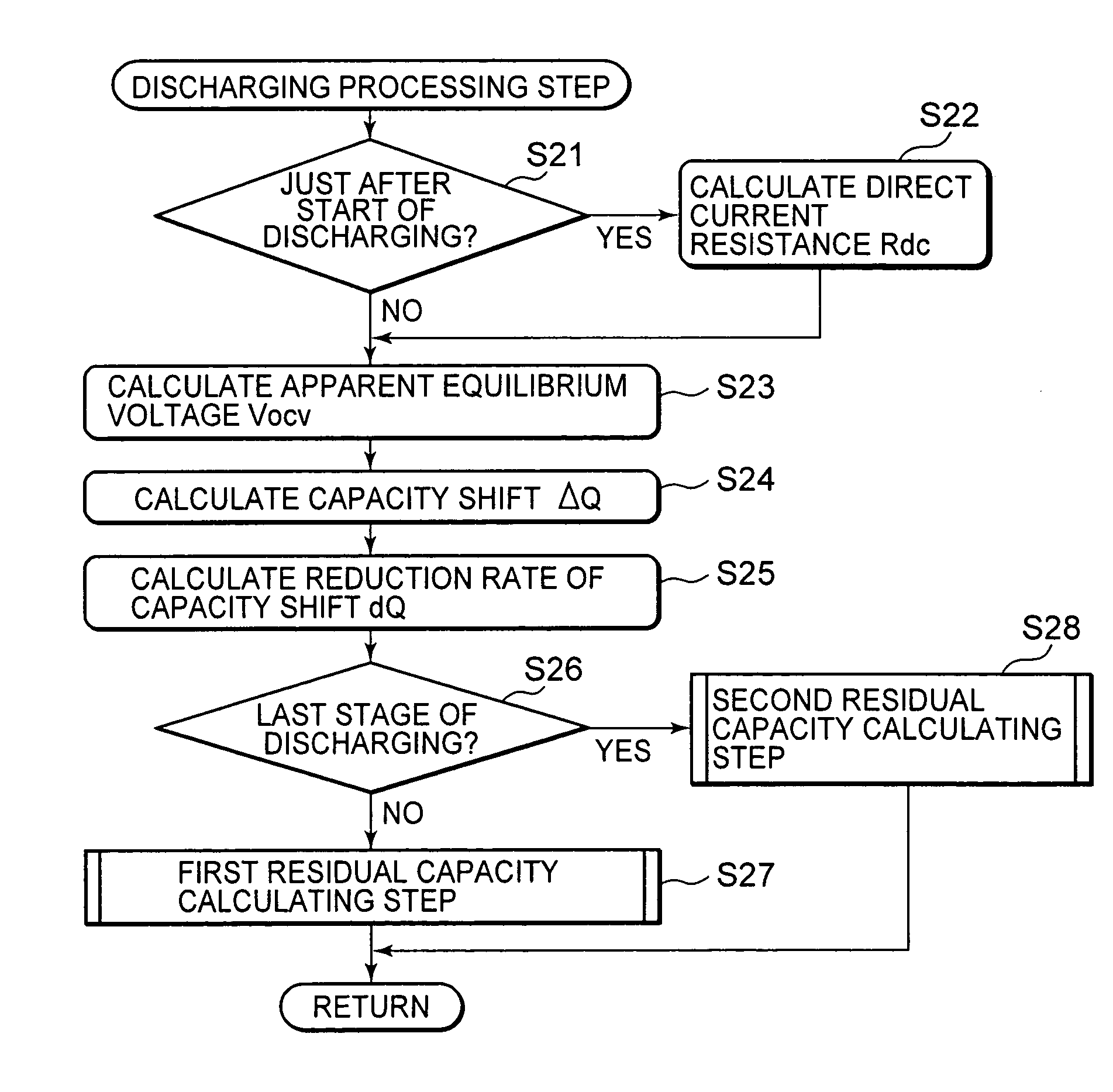

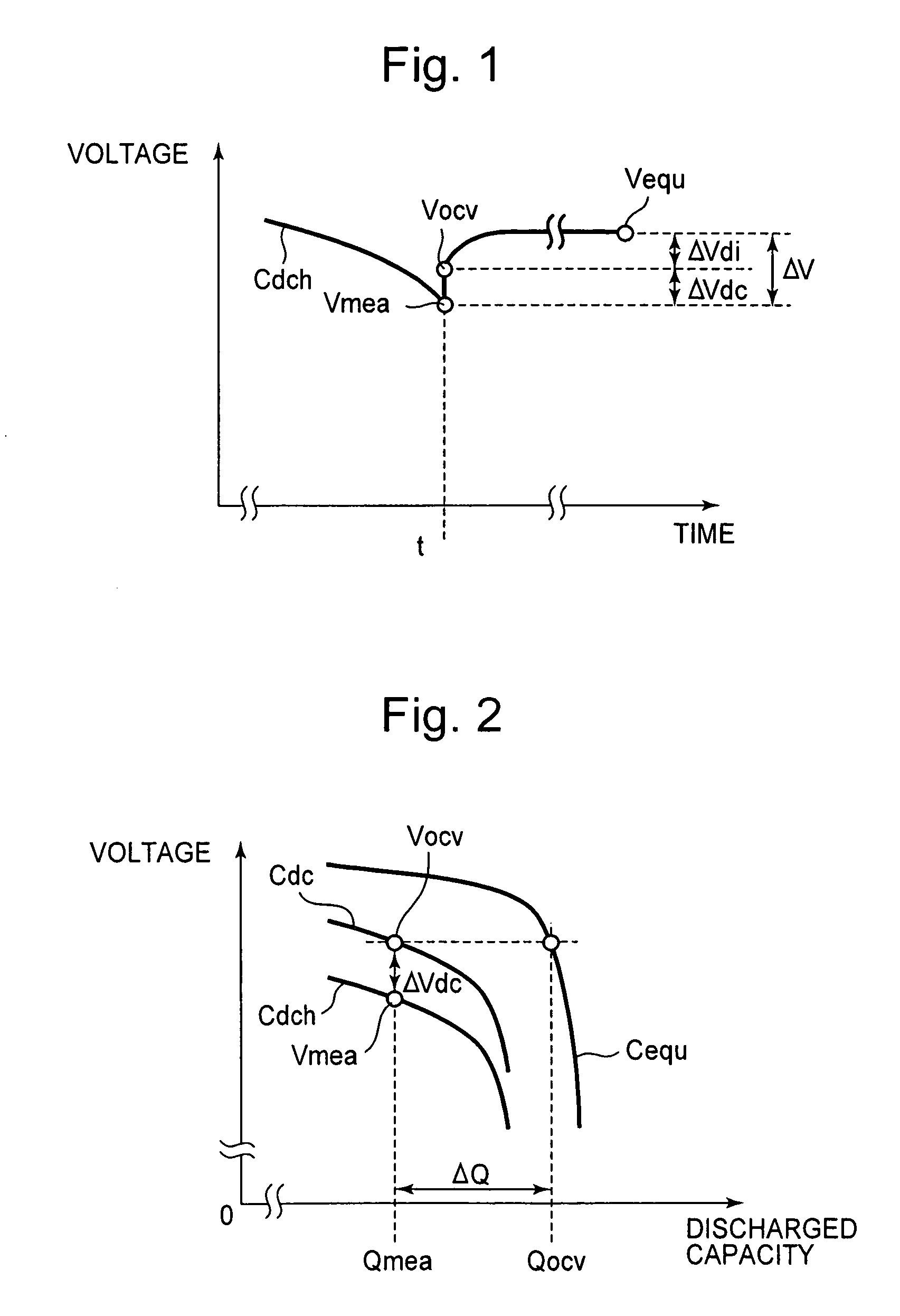

Battery capacity calculating method, battery capacity calculating apparatus and battery capacity calculating program

ActiveUS20060022676A1Accurate residual capacity residualAccurate residual residual powerBatteries circuit arrangementsMaterial analysis by electric/magnetic meansTerminal voltageControl circuit

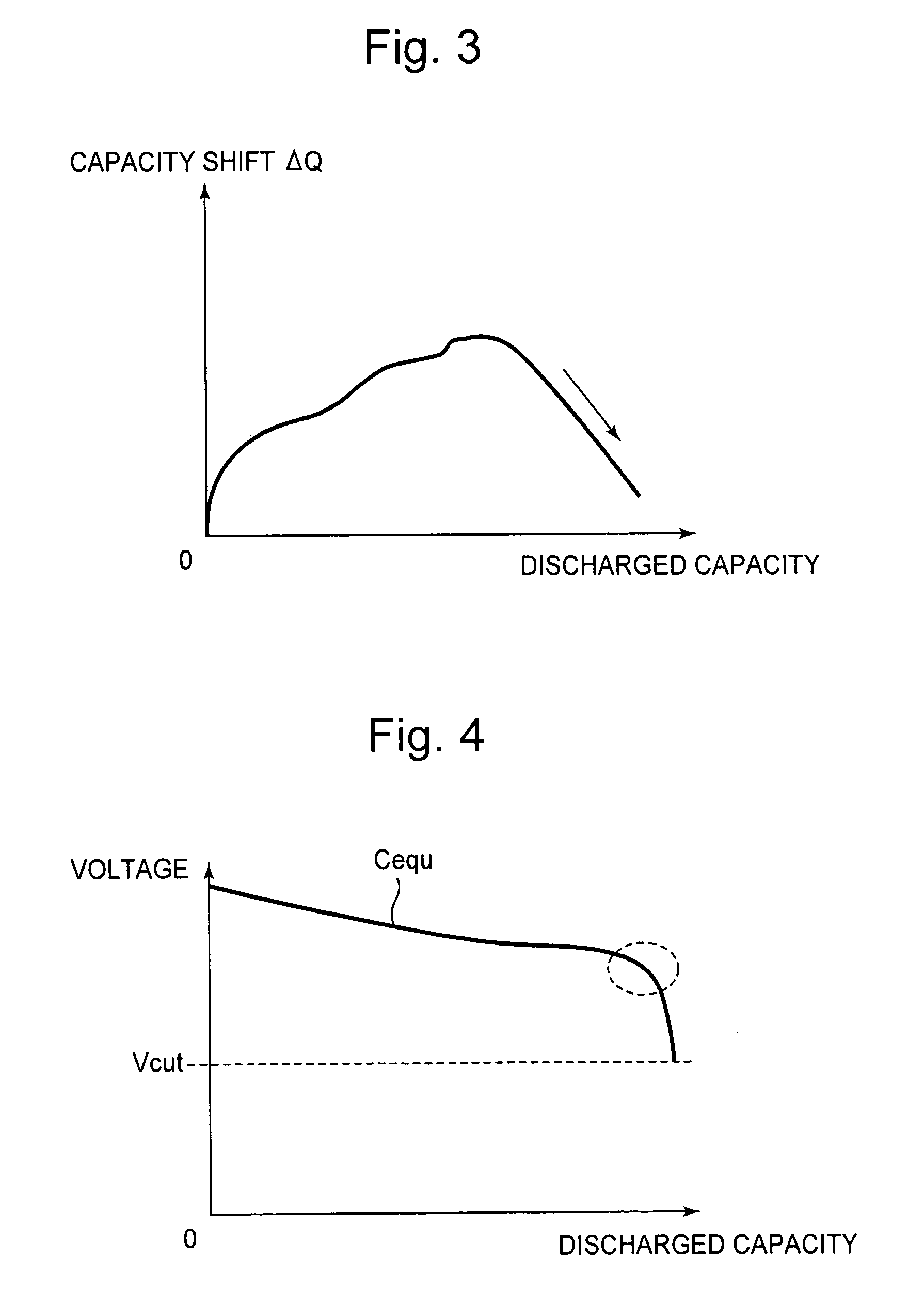

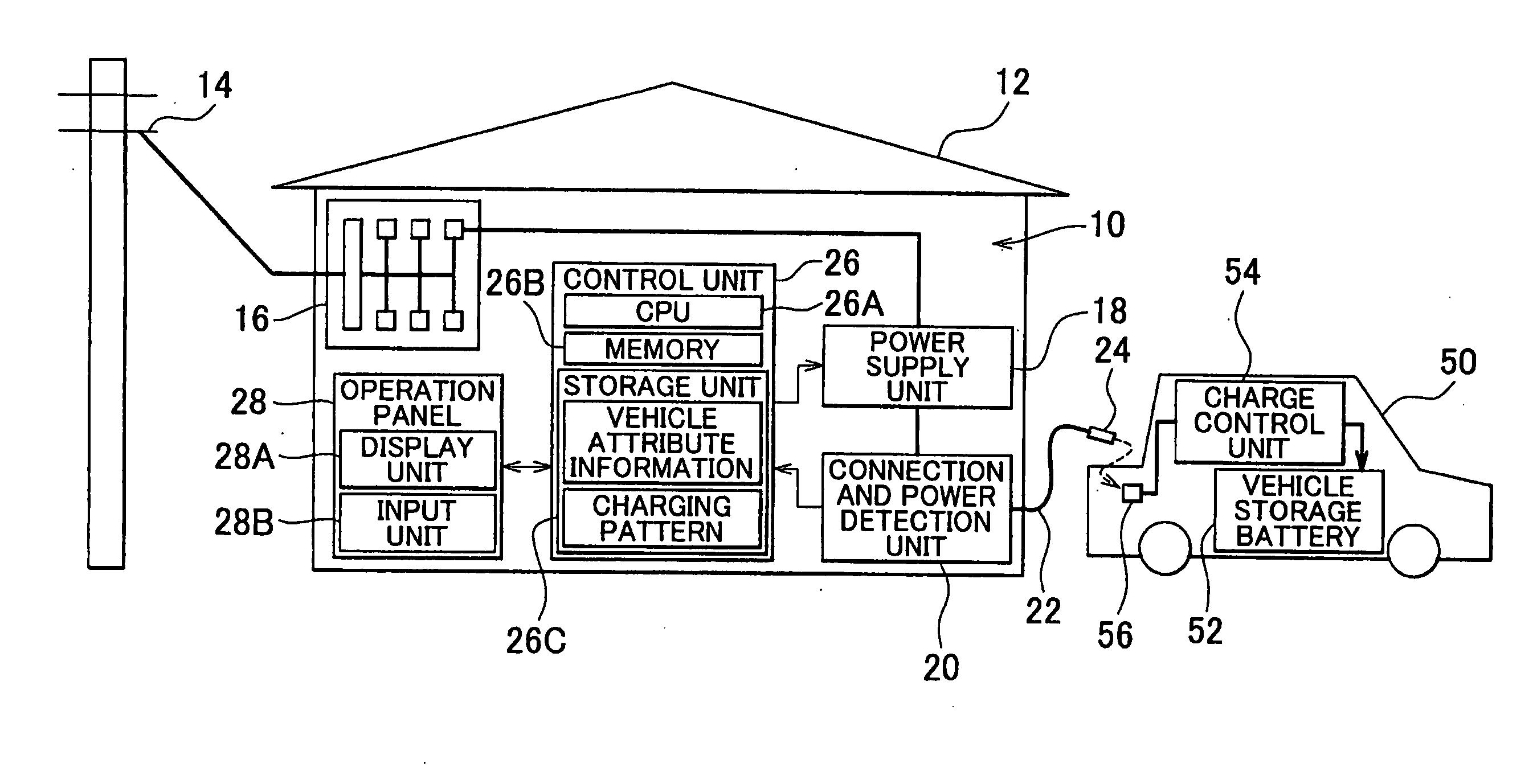

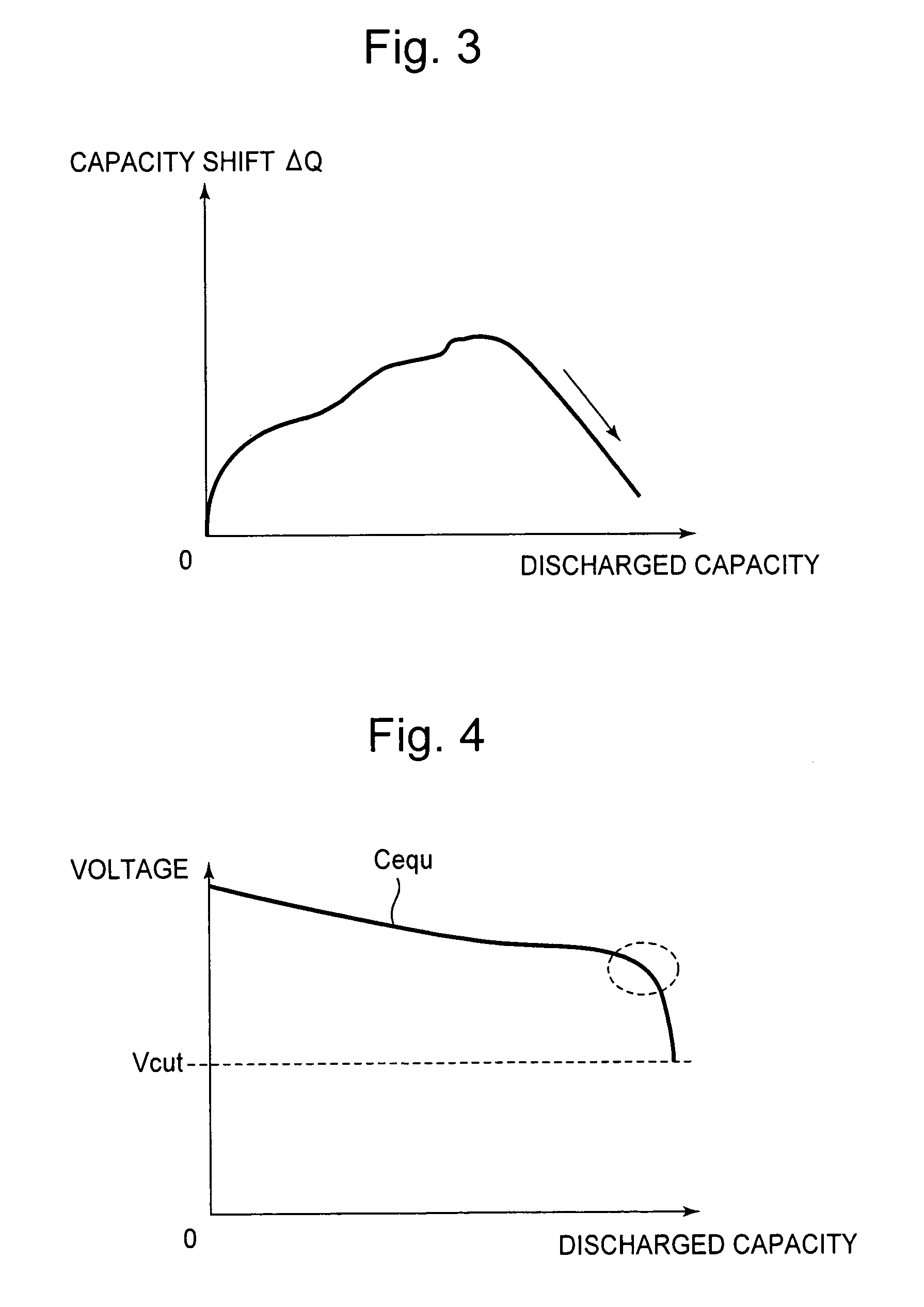

A battery calculating method, apparatus, and program are provided. The battery capacity calculating method and apparatus can very accurately calculate a residual capacity of a secondary battery especially in the last stage of discharging independently of environmental conditions such as a temperature or a deteriorated state. the battery capacity calculating apparatus is equipped with a voltage measuring circuit which measures the terminal voltage (Vmea) of a battery at the time of discharging, a current measuring circuit which measures the current value (I) of the battery at the time of discharging, and a control circuit which calculates a residual capacity and / or residual power. The operation unit in the control circuit calculates a discharged capacity (Qmea) and an apparent discharged capacity (Qocv) based on a terminal voltage (Vmea) and a current value (I) measured by the voltage measuring circuit and the current measuring circuit, respectively, estimates a discharge curve (Cpre) in the future including the last stage of discharging based on a capacity shift (ΔQ) being the difference between the discharged capacity (Qmea) and the apparent discharged capacity (Qocv) during discharging, and calculates the residual capacity and / or the residual power of the battery based on the estimated discharge curve (Cpre).

Owner:MURATA MFG CO LTD

Charging device and charging method

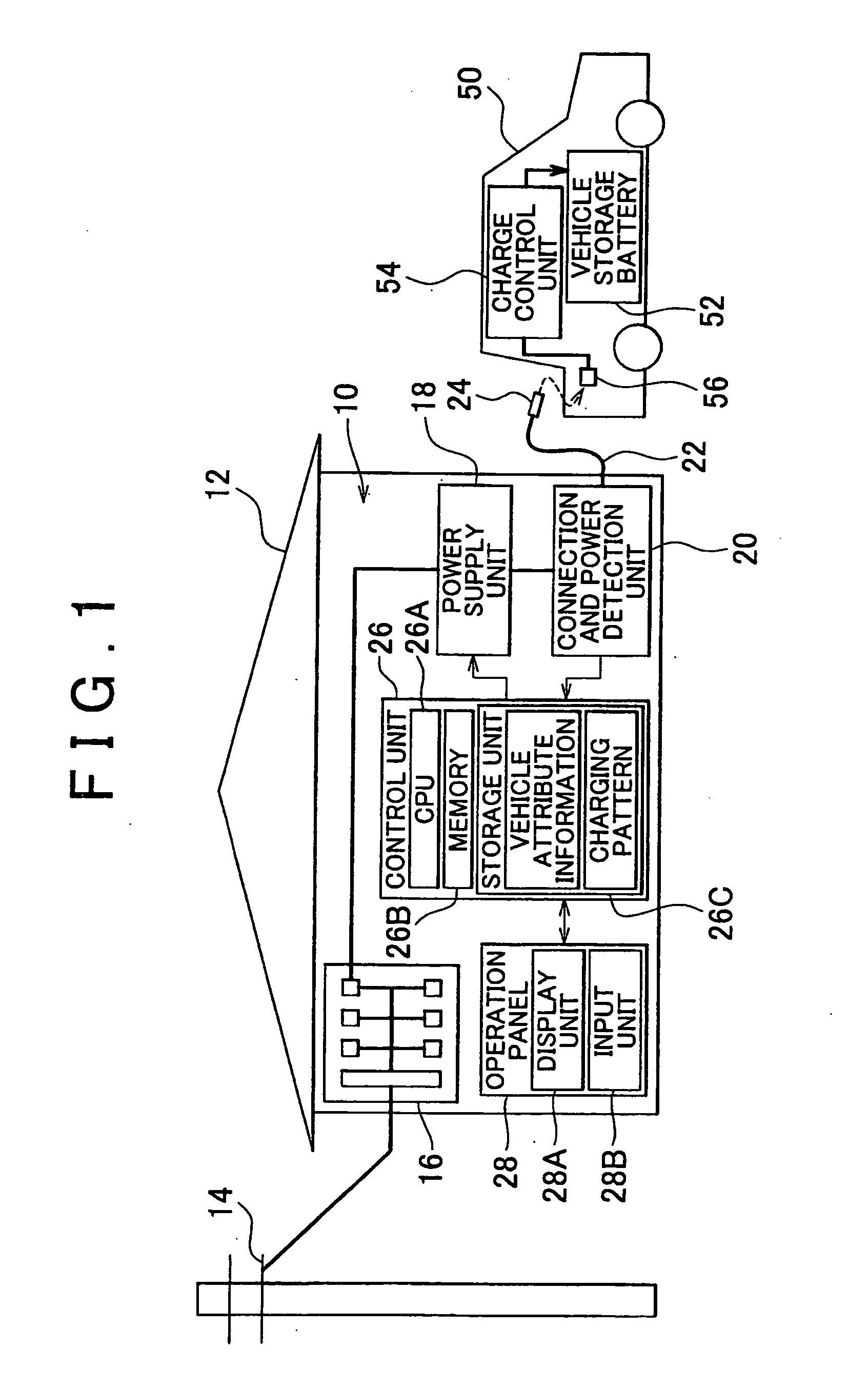

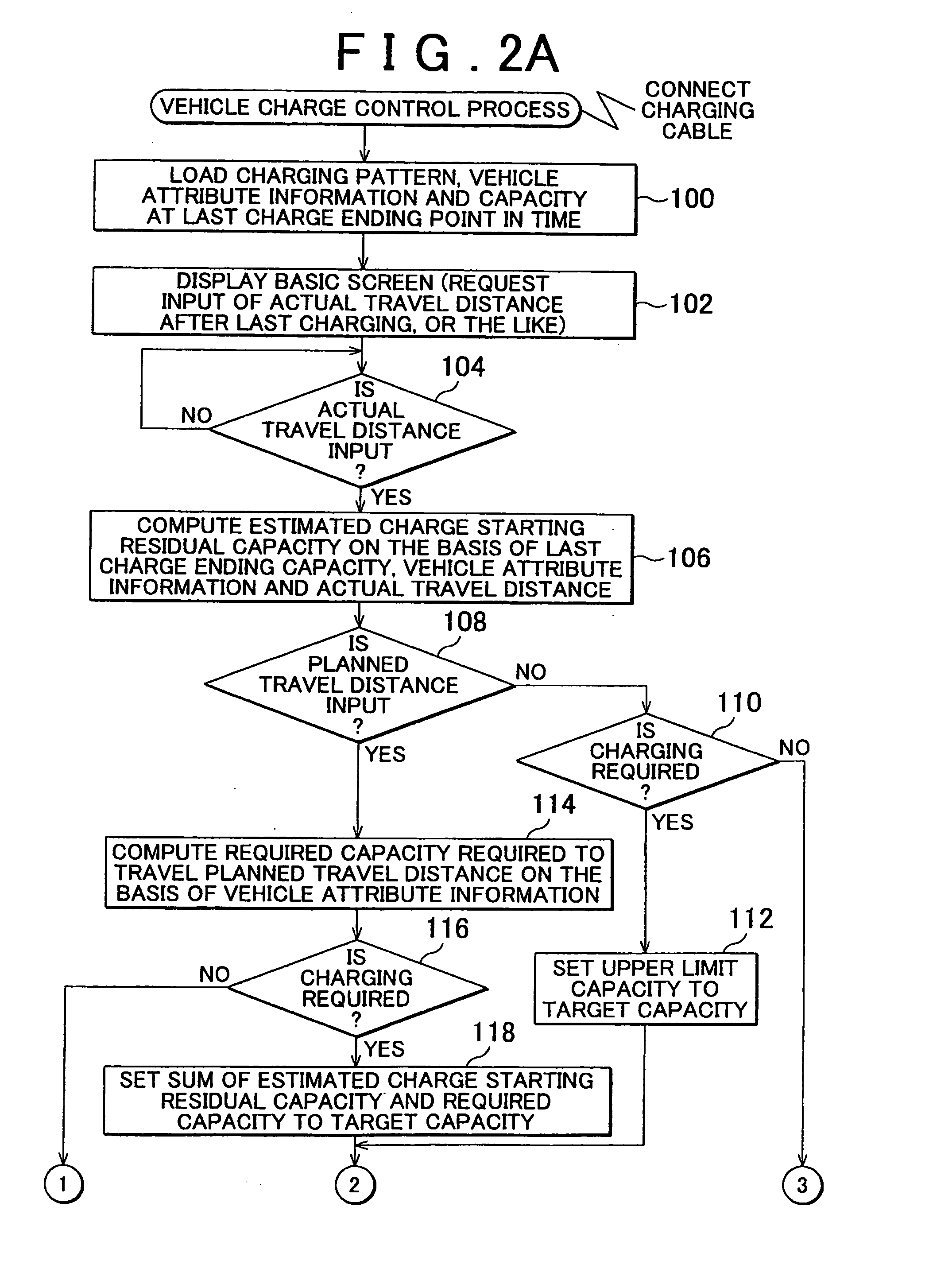

InactiveUS20120293122A1Reduce electric powerAccurate capacityBatteries circuit arrangementsCharging stationsCharge currentUser input

A user inputs a travel distance after last charging of a storage battery of a vehicle into an input field. A capacity of the storage battery at a current charge starting point in time is estimated from a capacity of the storage battery at a last charge ending point in time stored at the last charging and the input travel distance. The estimated capacity of the storage battery is displayed in a display field. During charging of the storage battery, detecting charge current and voltage to estimate a current capacity of the storage battery during charging, a remaining charging period of time and a distance-to-empty by the current capacity and displaying the estimated current capacity, remaining charging period of time and distance-to-empty in display fields are repeated.

Owner:TOYOTA JIDOSHA KK +1

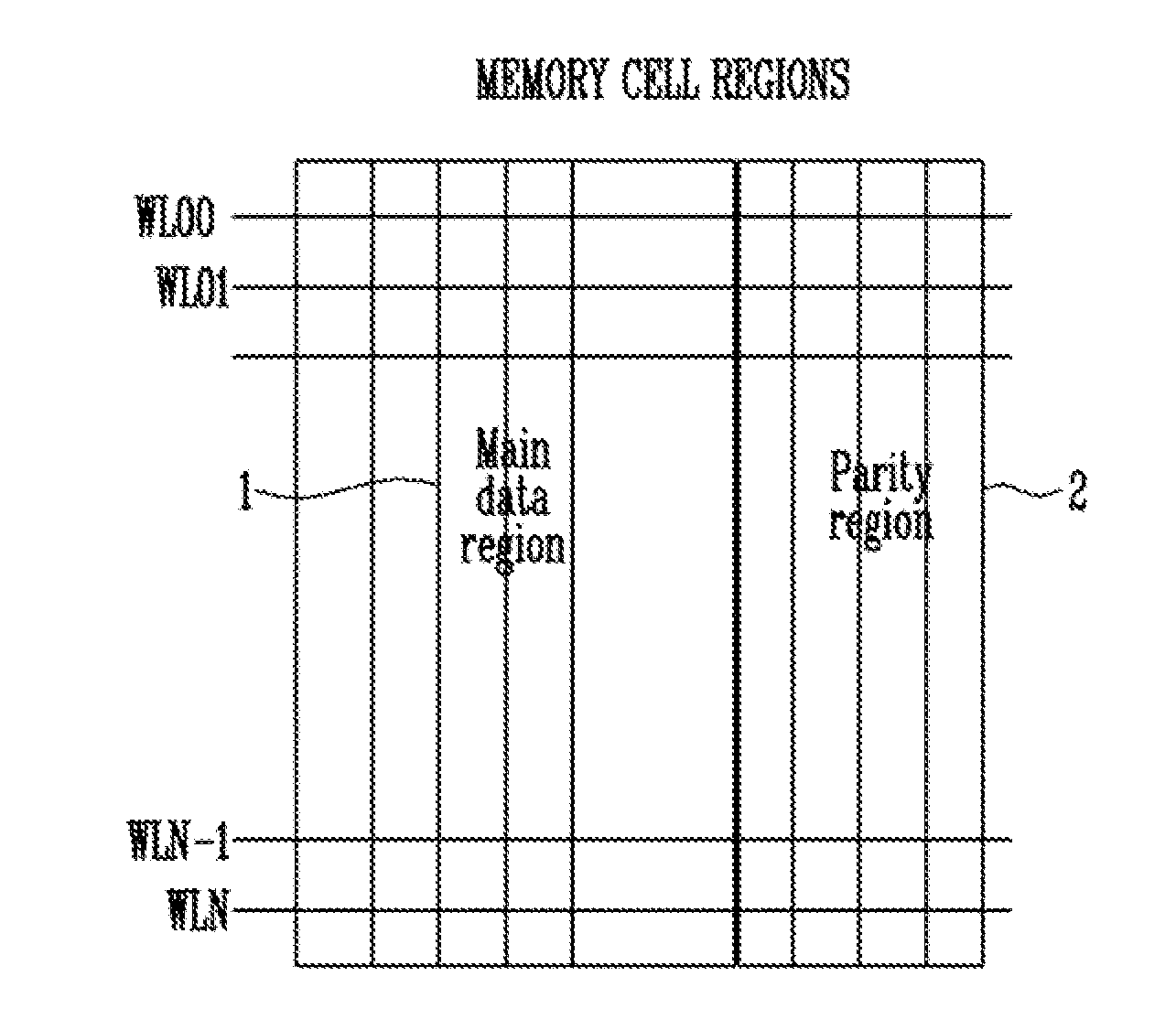

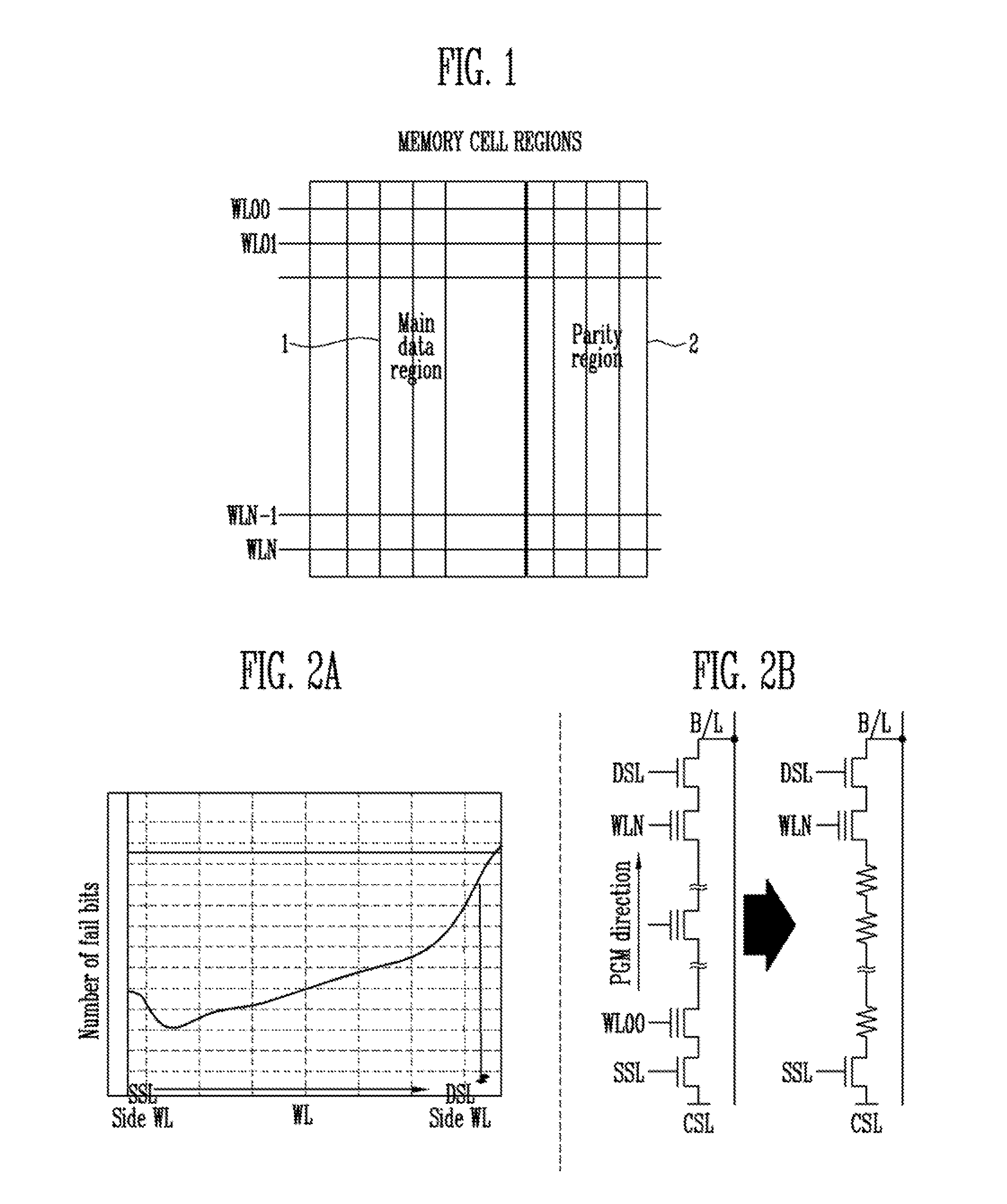

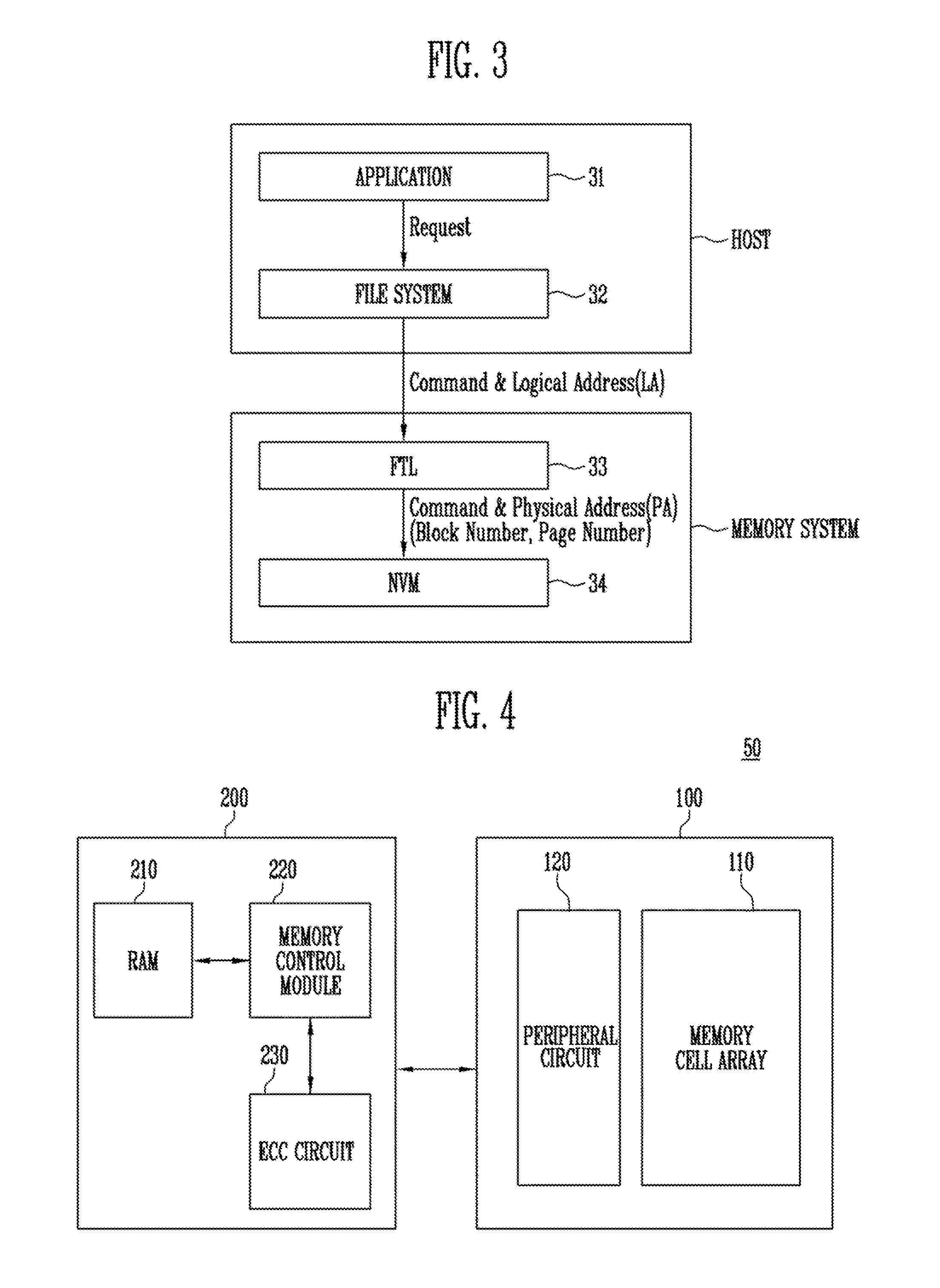

Memory device with different parity regions

ActiveUS20170004037A1Increase capacityImprove reliabilityInput/output to record carriersStatic storageComputer moduleOperation mode

The present disclosure memory includes a controller for a semiconductor memory device, the device including a memory cell array including a plurality of pages. The controller includes a memory control module suitable for translating a logical address for data provided from a host to a physical address representing one of the plurality of pages, and determining one of a plurality of operation modes based on the physical address and pre-stored parity-related information. The controller further includes and an error correction code circuit suitable for generating parity-data for the data provided from the host according to the determined operation mode.

Owner:SK HYNIX INC

Nano-calorimeter device and associated methods of fabrication and use

InactiveUS6988826B2Reduce capacityReduce conductivityMaterial heat developmentNanosensorsEngineeringThermal contact

Owner:GENERAL ELECTRIC CO

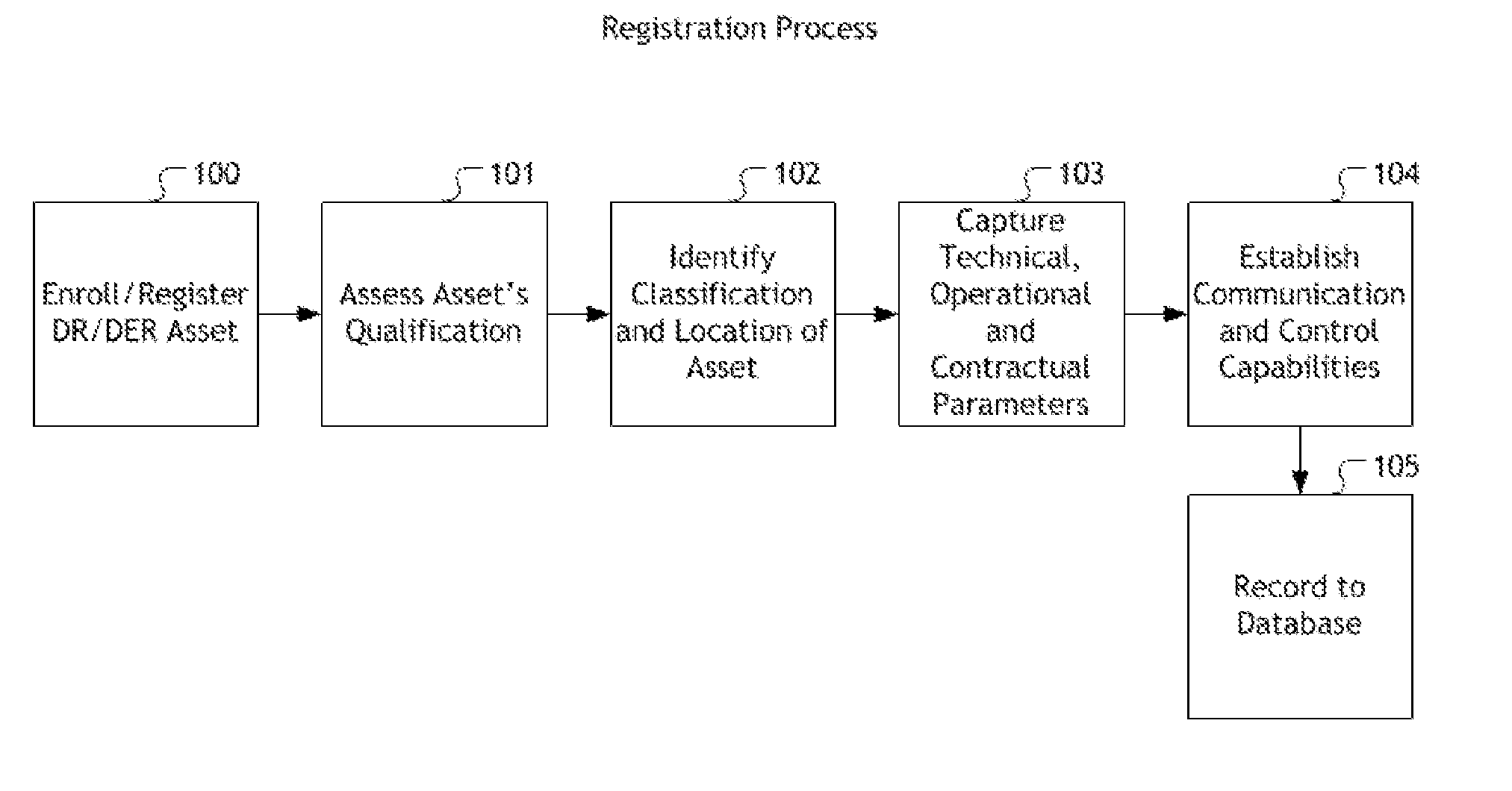

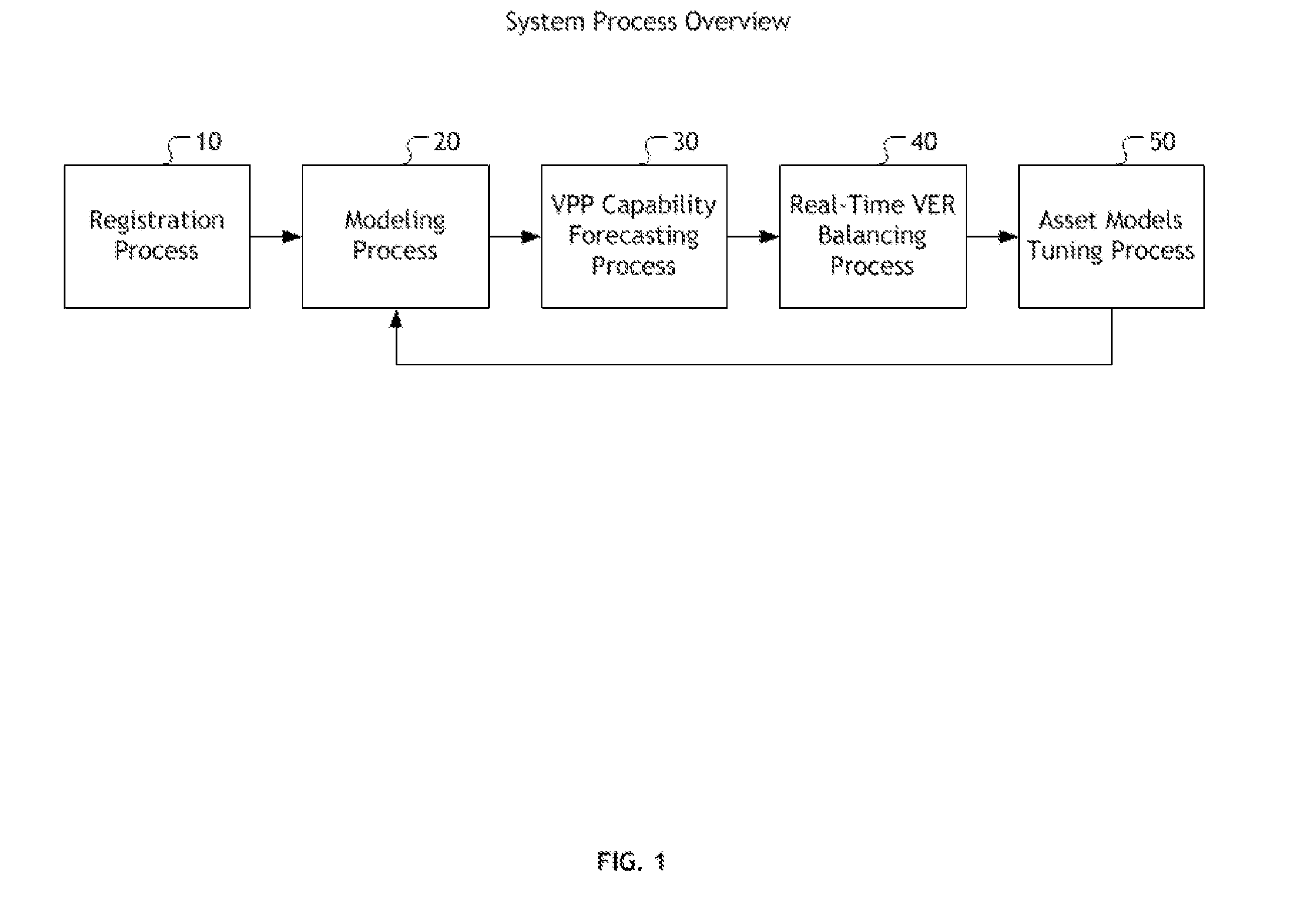

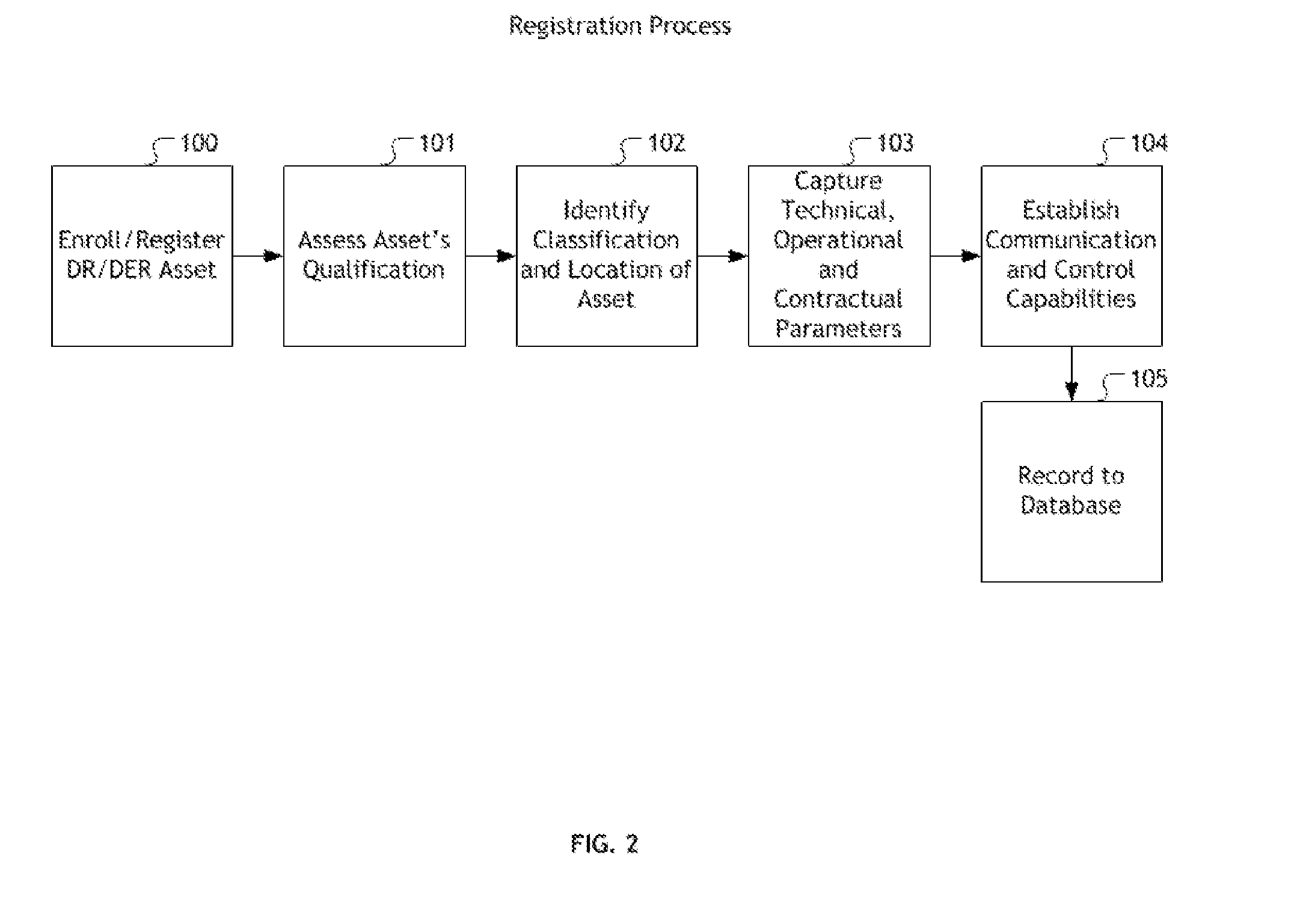

Use of Demand Response (DR) and Distributed Energy Resources (DER) to mitigate the impact of Variable Energy Resources (VER) in Power System Operation

ActiveUS20140277808A1Reduce impactAccurately capabilityProgramme controlMechanical power/torque controlEnergy balancedEngineering

A system and process / method of modeling demand-response (DR) and distributed-energy resource (DER) assets is provided, facilitating the aggregation of said assets in virtual power plants (VPPs), and using VPPs to provide energy balancing services needed to minimize the impact of Variable Energy Resources (VER) on power system. The method accurately accounts for assets by qualifying assets based on various parameters and by forecasting the capabilities of the resulting VPPs for provision of balancing services. Asset performance factors that may affect the aggregated VPP's capabilities are monitored and recalculated when necessary. Near-term forecasted VPP capability is compared to near-term forecasted imbalances in the electric-power-supply system, and the VPP is dispatched to minimize the system imbalances. The dispatch signal is disaggregated to control commands to individual assets. This process provides a reliable and cost effective approach to support higher penetrations of renewable generation in the electric power system.

Owner:OPEN ACCESS TECH INT

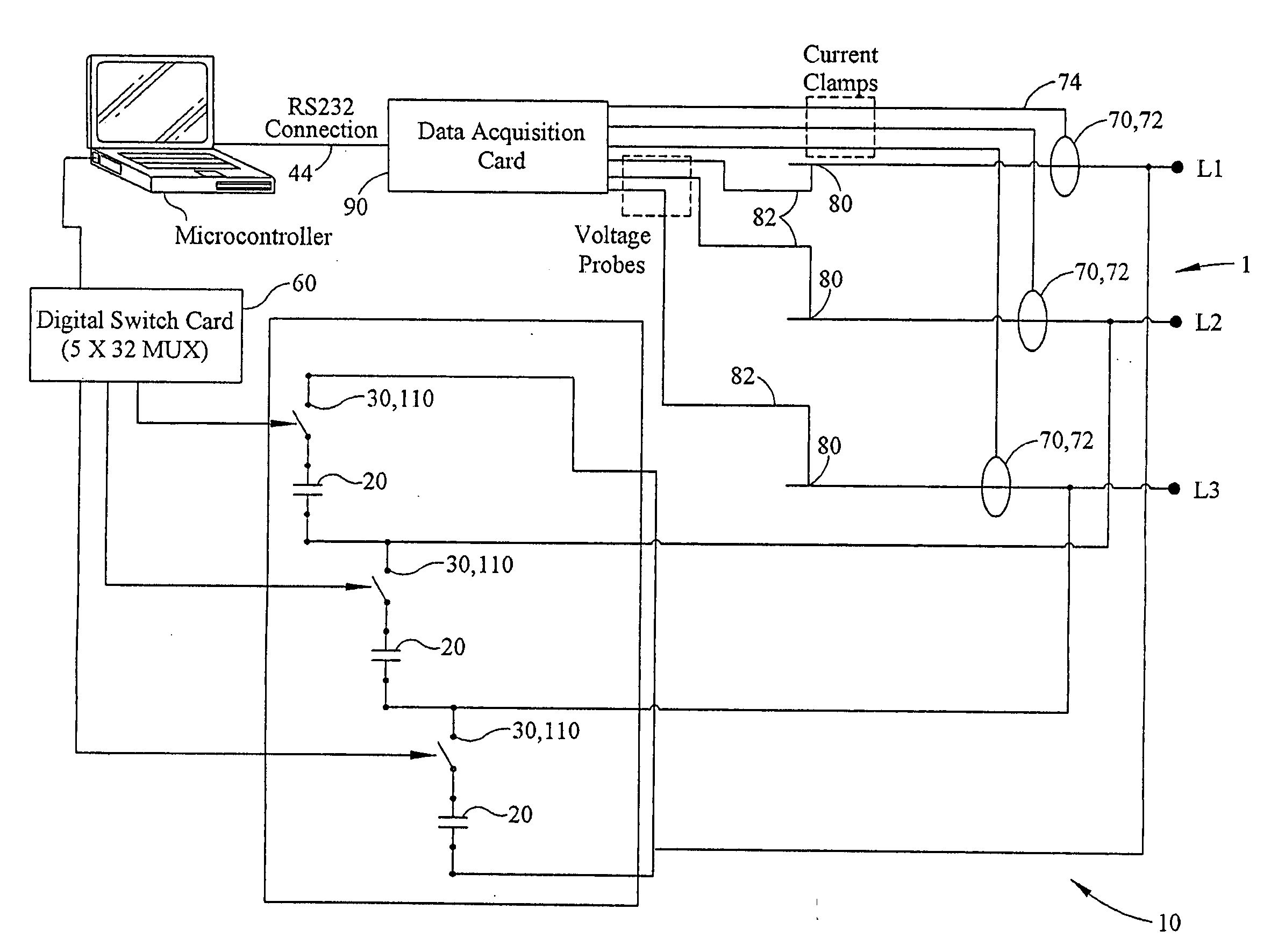

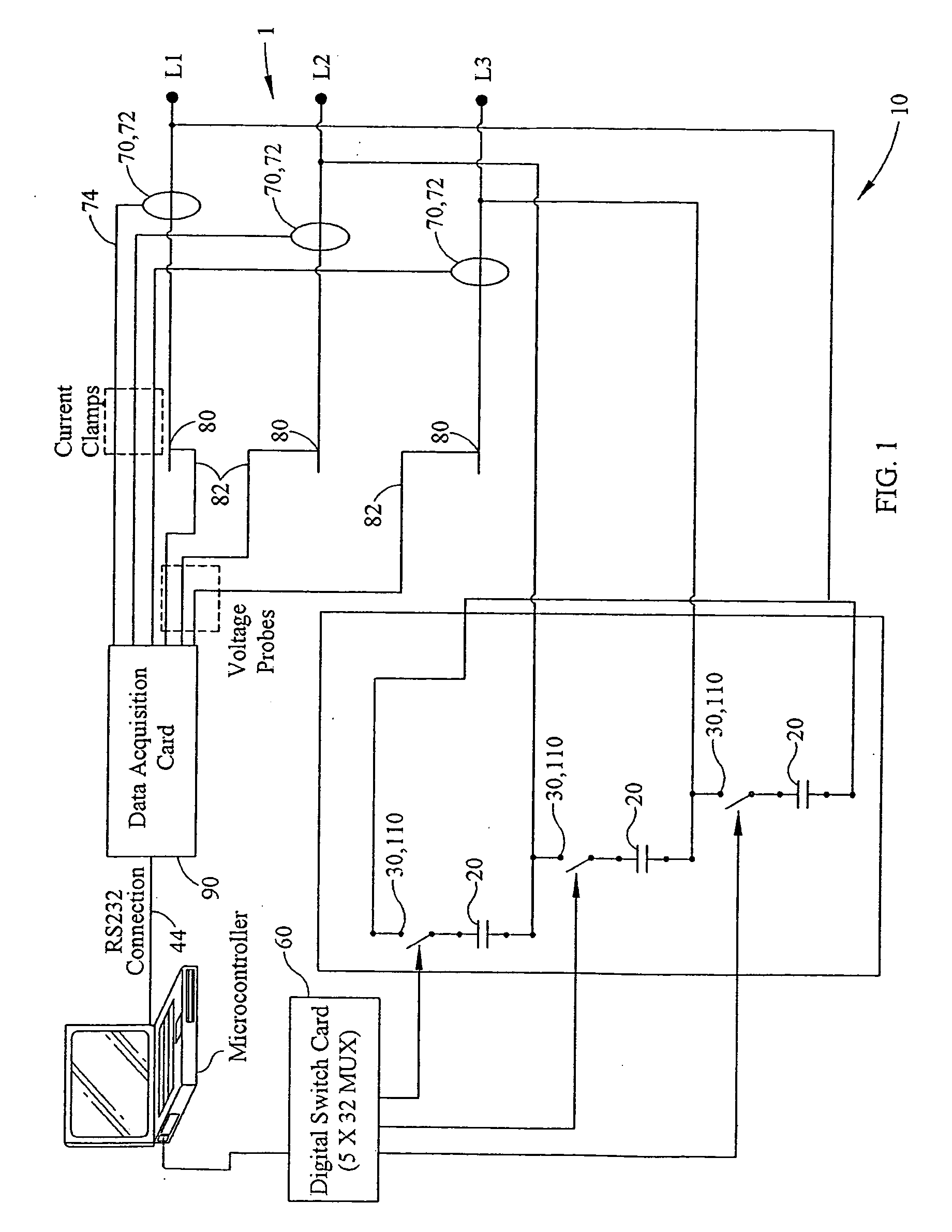

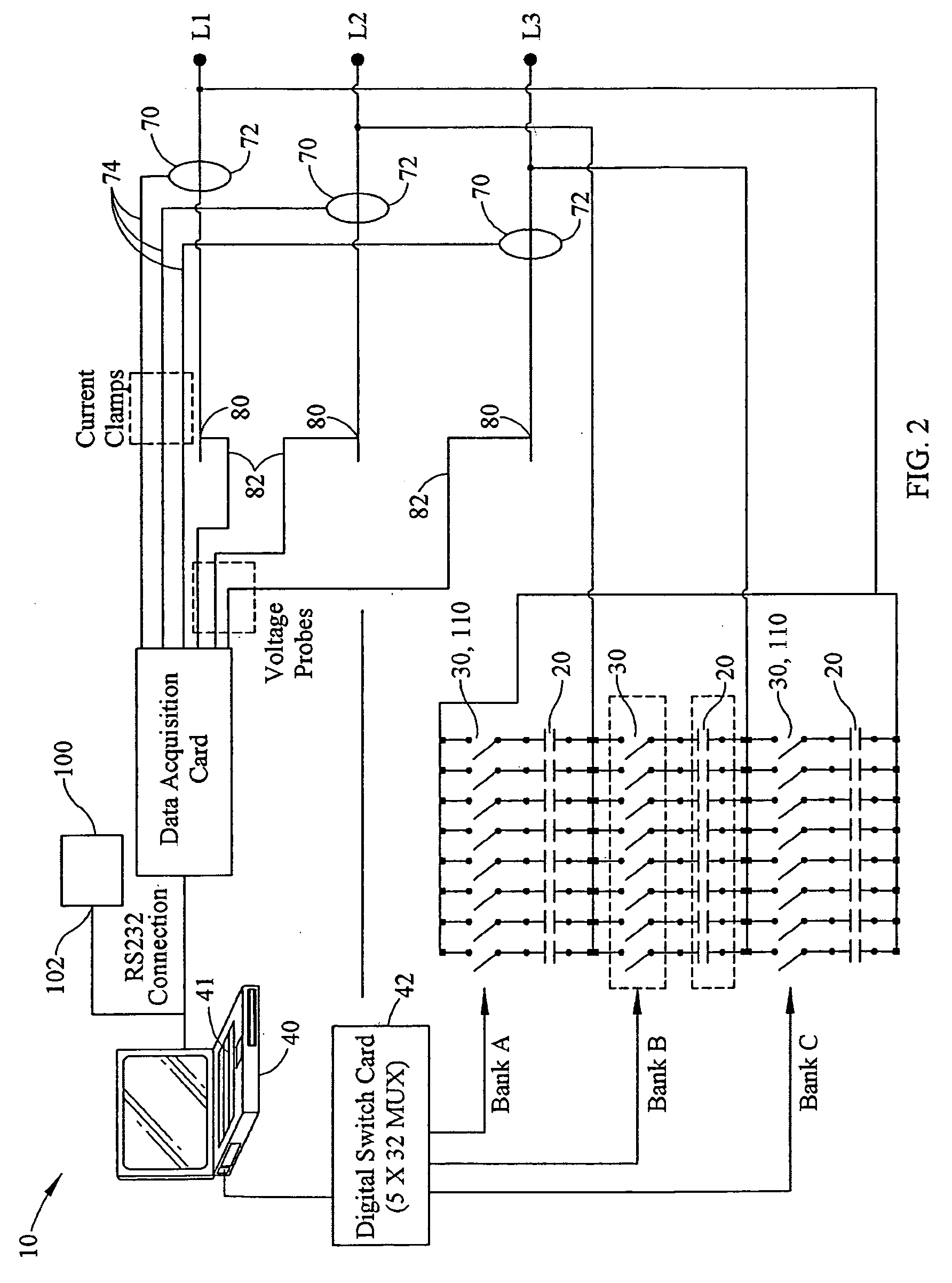

Power Factor Correction Analysis System and Method

InactiveUS20060250117A1Reduce amountQuickly and easily determining the requisite capacitance for power factor correctionReactive power compensationElectric variable regulationMicrocontrollerCapacitance

An apparatus for determining the necessary capacitance required to correct power factor in an electrical power system comprises a plurality of capacitors having predetermined capacitances connected in series with a plurality of switching devices, said capacitances and switching devices connected between the line voltages of said power system to correct power factor. A means for determining power factor in said power system may include a power factor meter or a plurality of current transmitters and voltage probes used to provide data to a microcontroller to calculate power factor.

Owner:TITON ENERGY

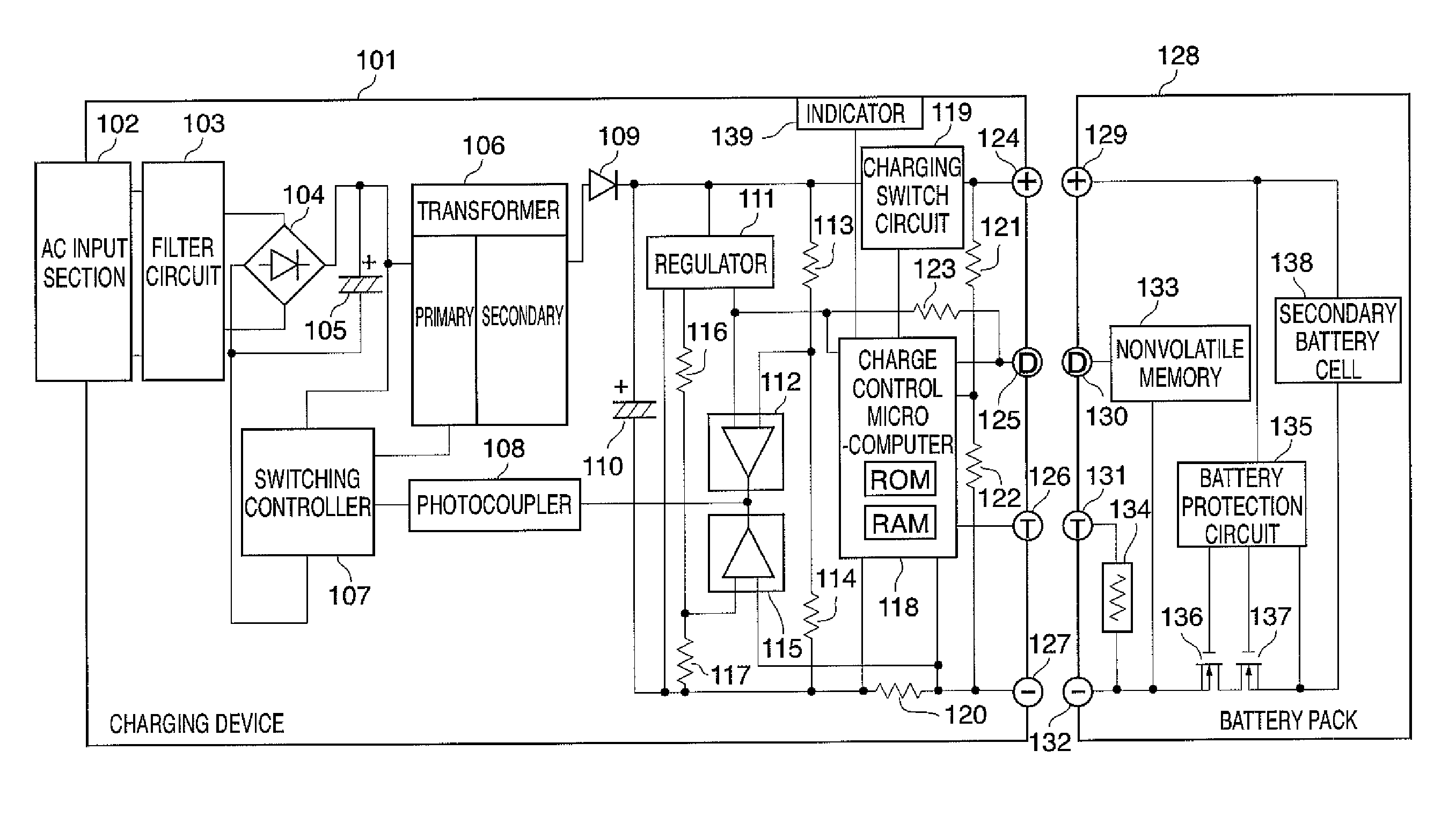

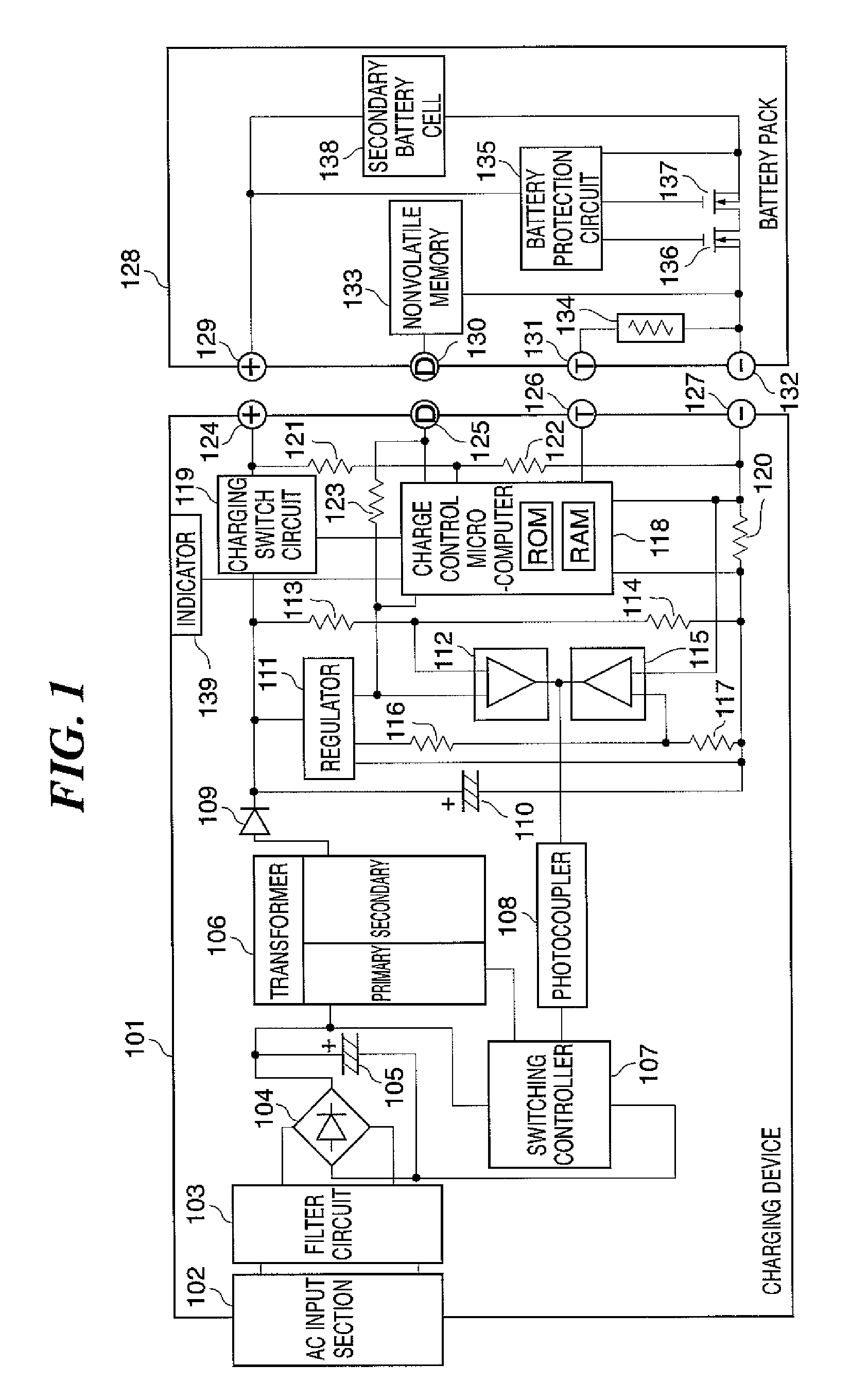

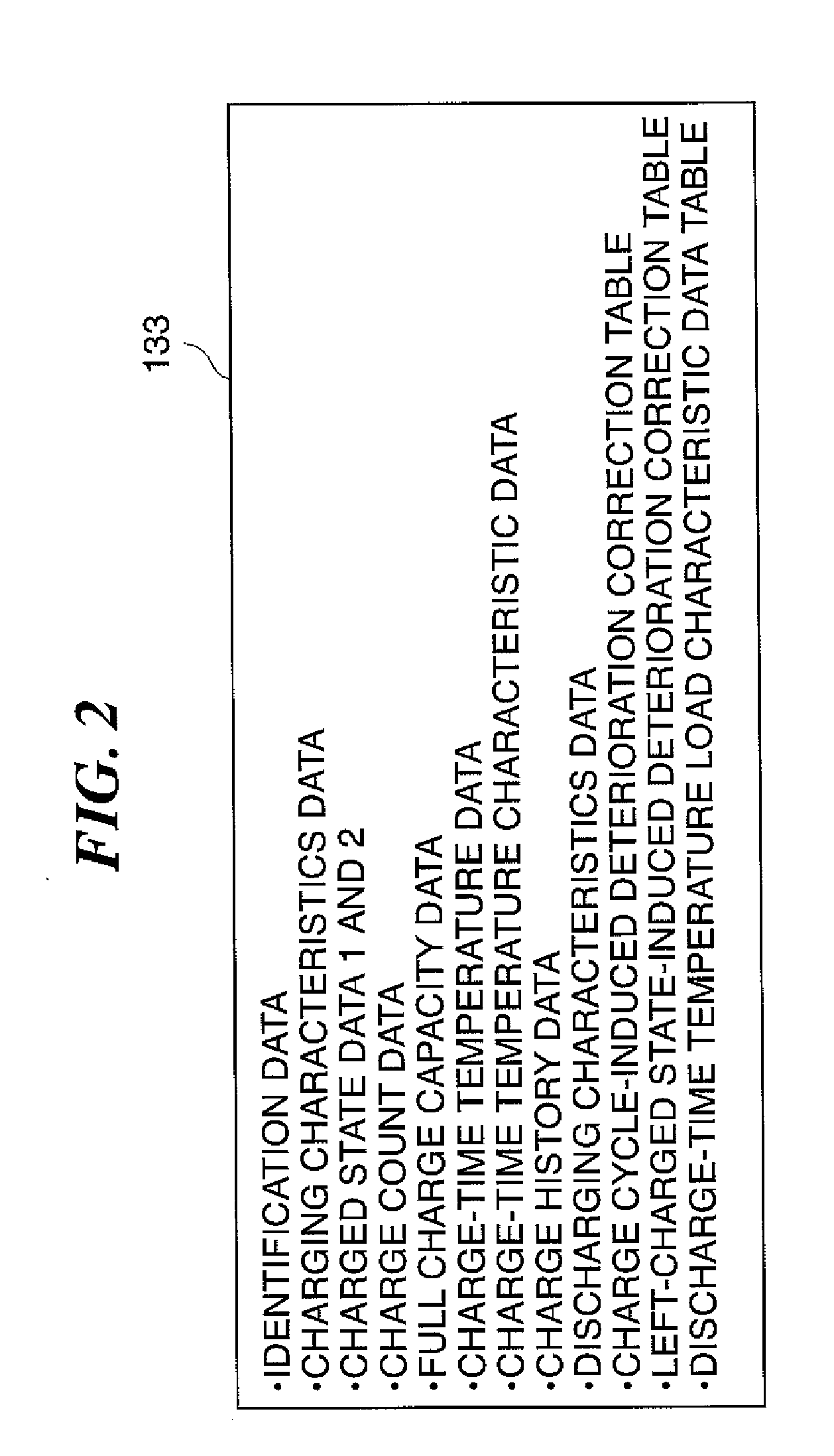

Battery pack, charging device, and electronic device

InactiveUS20080290833A1Accurate capacityGuaranteed true stateCircuit monitoring/indicationDifferent batteries chargingMicrocomputerCharge current

A charging device which enables the charged state and remaining capacity of the battery pack to be accurately grasped. In the charging device on which a battery pack including a nonvolatile memory and a secondary battery cell is mounted, a charge control microcomputer measures a charging current supplied to and a charging voltage applied to the battery pack. Charged state data indicative of the charged state of the battery pack is determined based on at least one of the measured charging current and the measured charging voltage. The charge control microcomputer writes the determined charged state data in the memory of the battery pack.

Owner:CANON KK

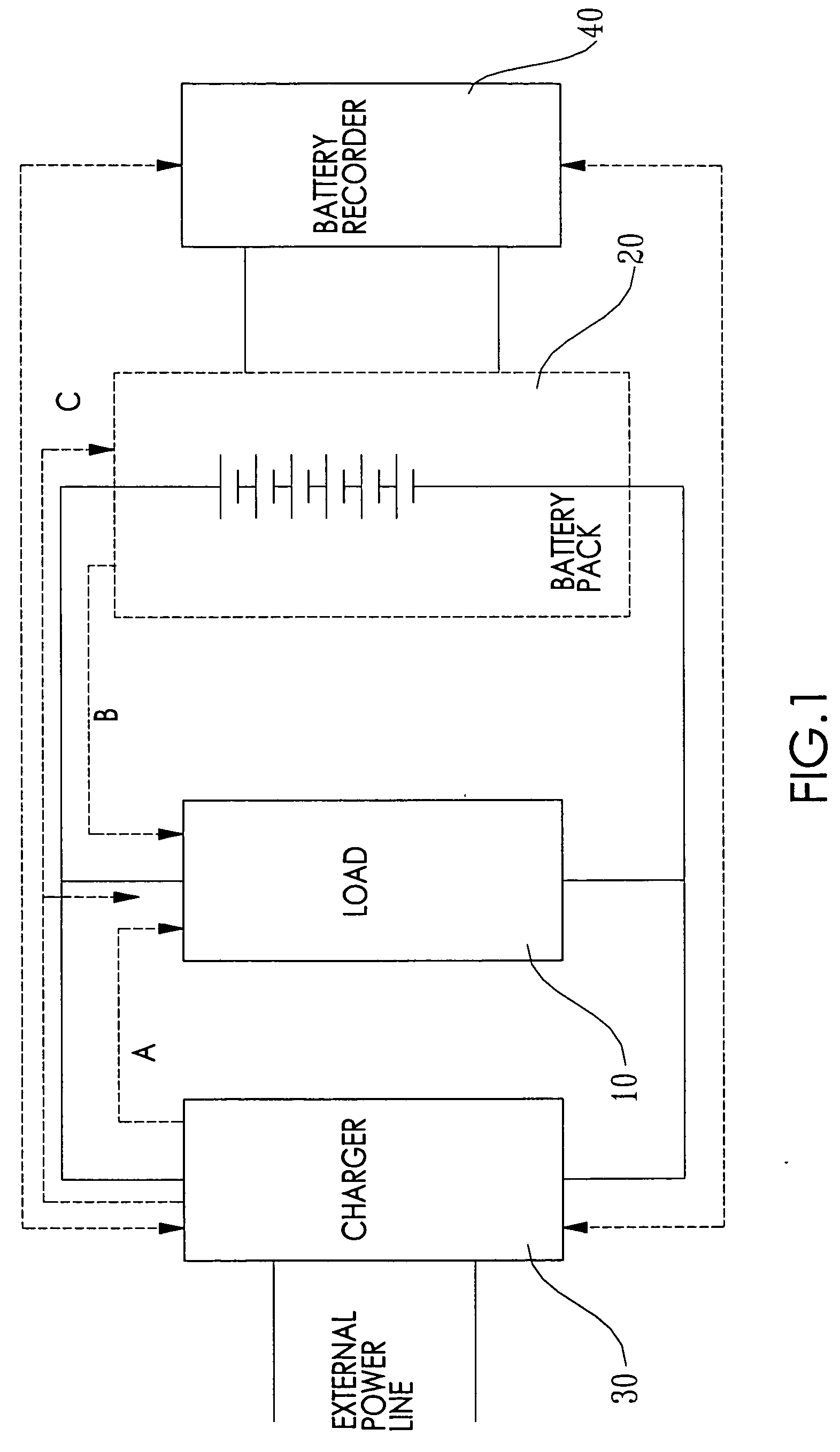

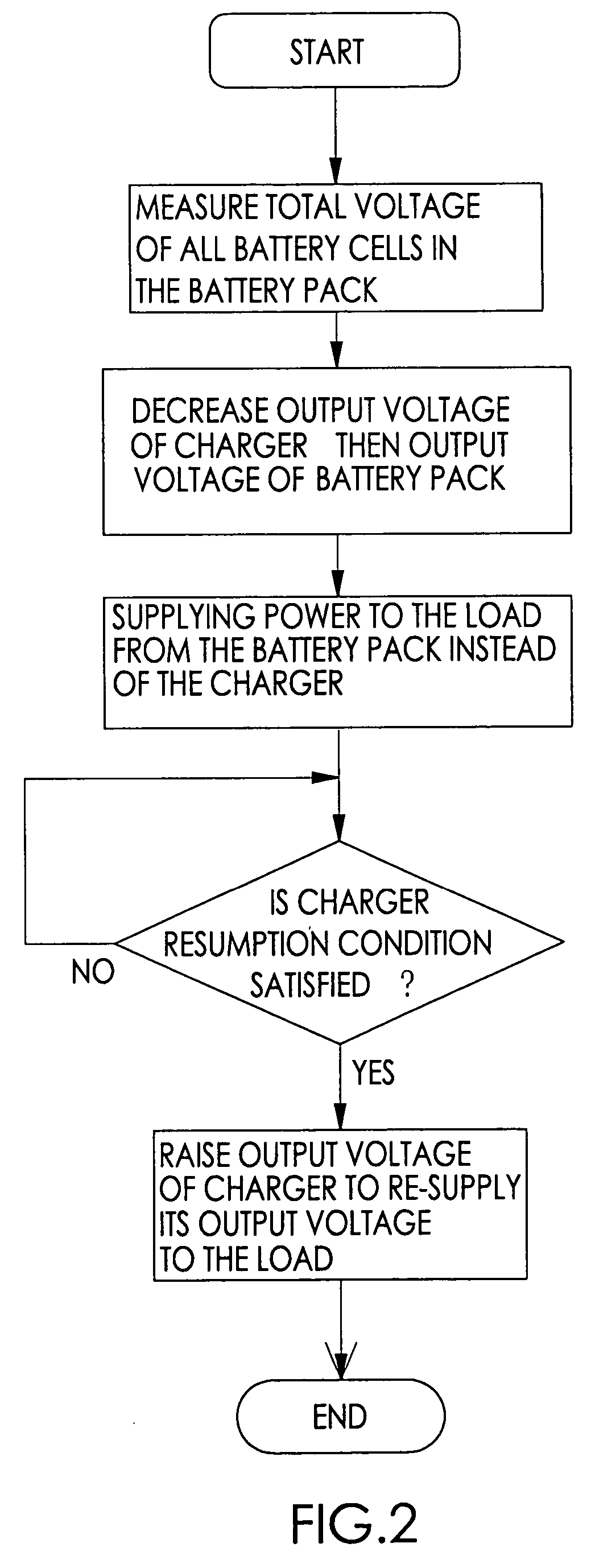

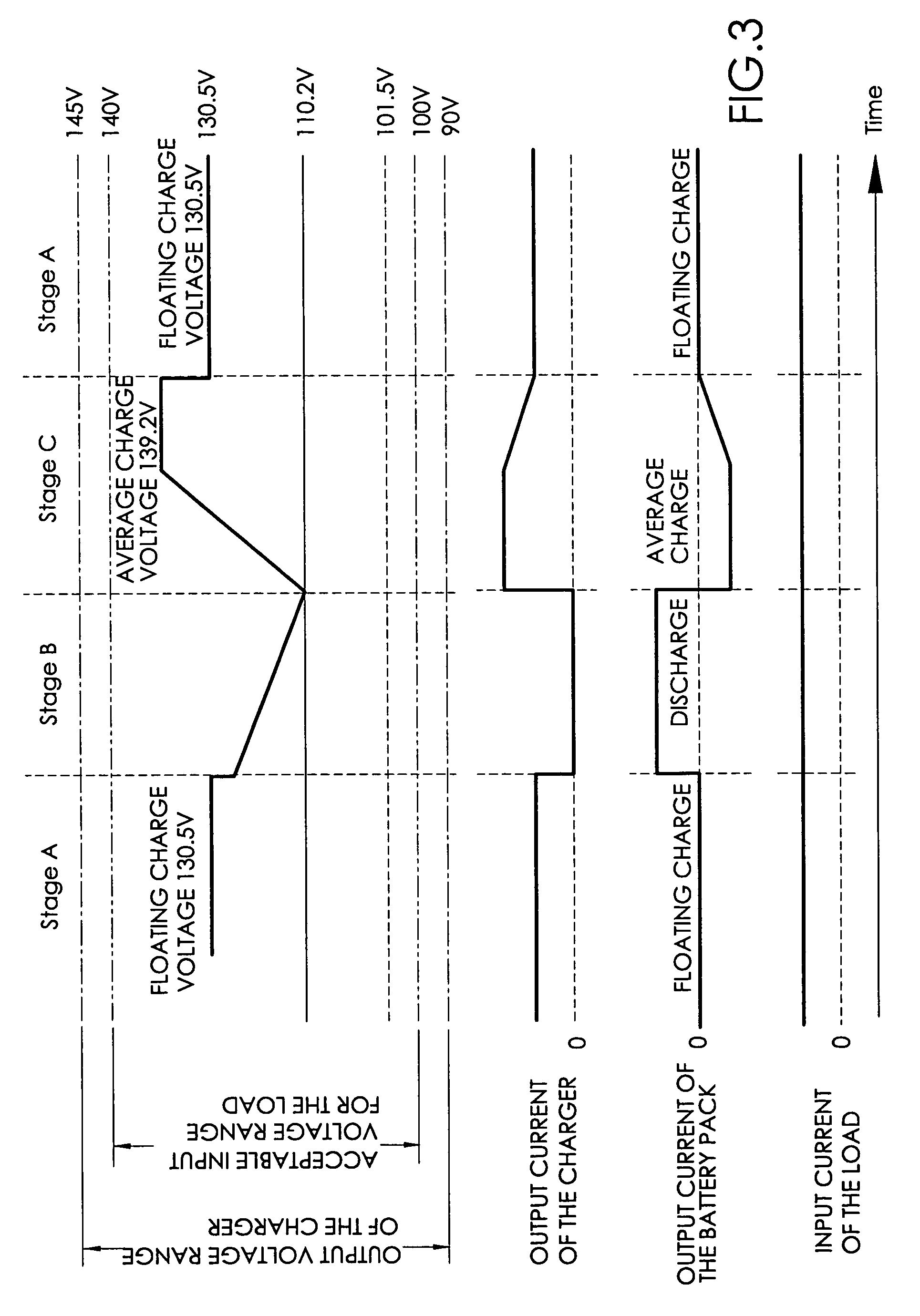

Method of testing a battery pack by purposeful charge/discharge operations

InactiveUS20050156603A1Convenient recordingAccurate capacityCircuit monitoring/indicationDifferent batteries chargingTest batteryEngineering

A method of testing a battery pack, wherein a load is connected to a charger and the battery pack, and receives power supply from either the external charger or the battery pack. When the external power line is normally supplied to the load through the charger, the battery pack is purposely enabled to start its discharge and to supply power to the load. When the output voltage of the battery pack drops below a threshold level or the discharging time exceeds a preset limit, the charger re-supplies its output voltage to the load and to charge the battery pack. By the purposeful charge / discharge operations, characteristic data of the battery pack are collected and recorded for estimation of the battery pack capacity and the remaining service life.

Owner:HANDSUN ELECTRONICS ENTERPRISE +2

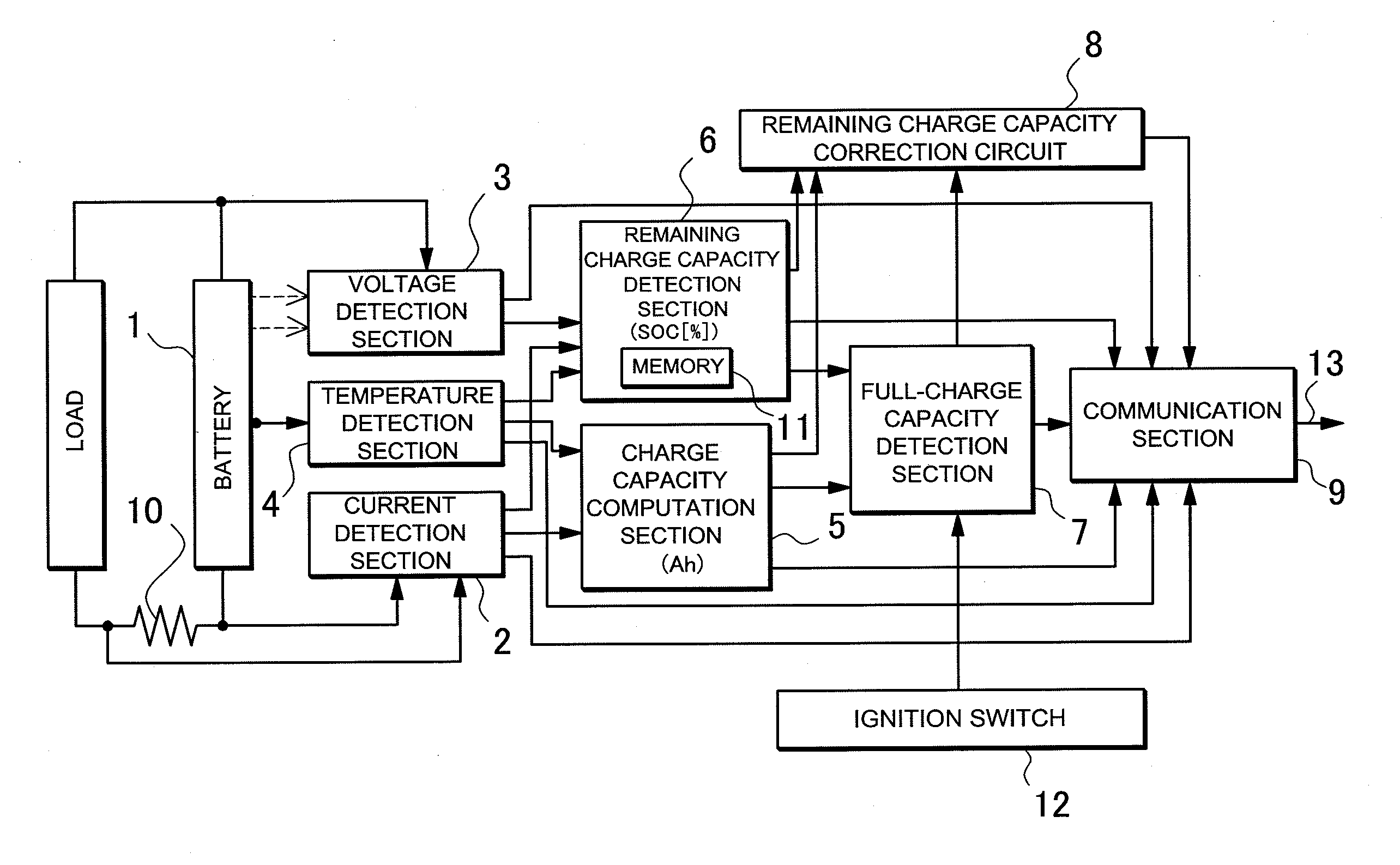

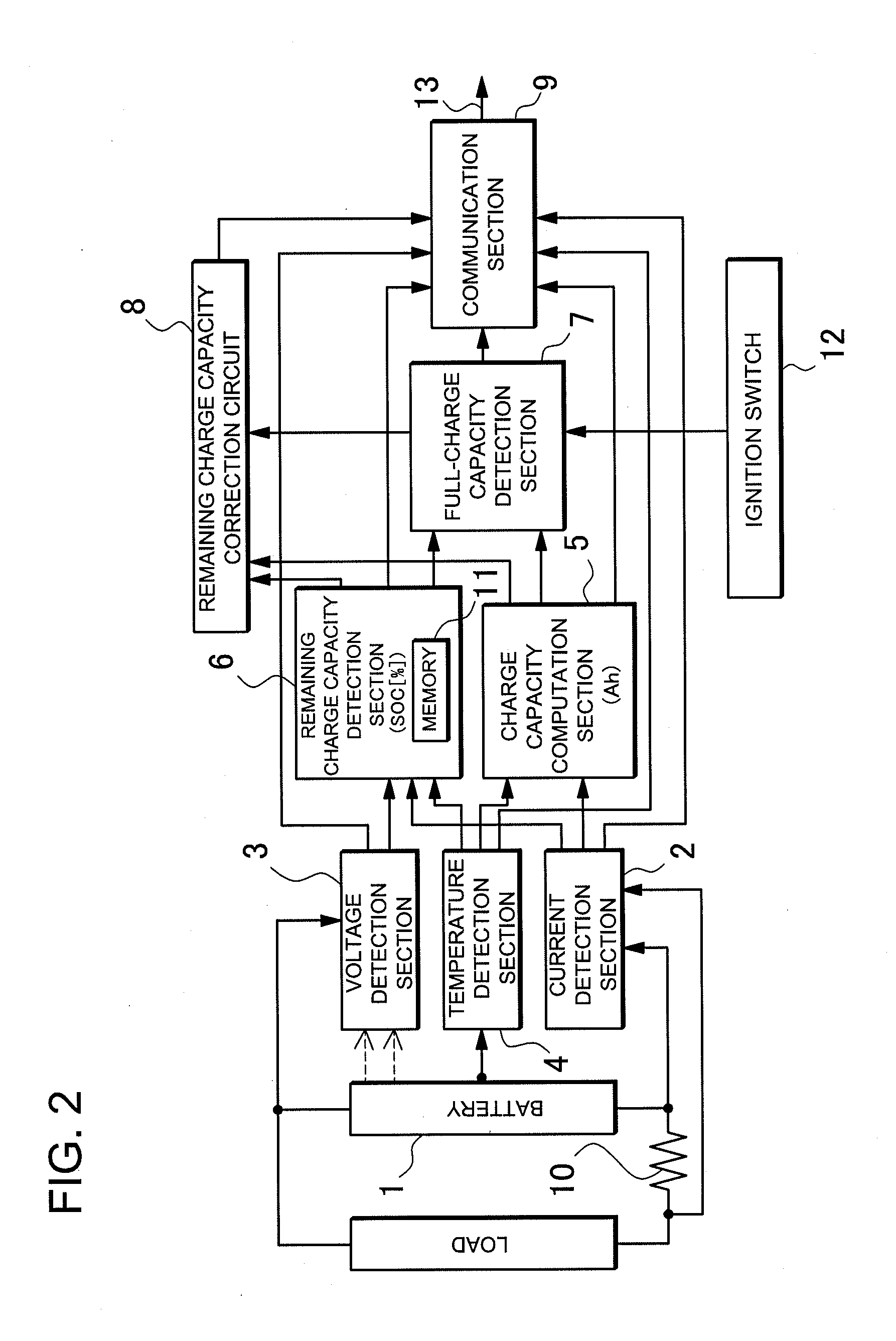

Method of detecting battery full-charge capacity

InactiveUS20130311119A1Accurate detectionAccurate capacityElectrical testingSecondary cells charging/dischargingPhysical chemistryHemt circuits

A method including a remaining charge capacity determination step to determine a first remaining charge capacity from the first open circuit voltage and a second remaining charge capacity from the second open circuit voltage, a change in remaining charge capacity computation step to compute the change in remaining charge capacity from the difference between the first remaining charge capacity and the second remaining charge capacity, and a full-charge capacity computation step to compute the battery full-charge capacity from the change in remaining charge capacity and the change in charge capacity. The method computes battery full-charge capacity from the change in charge capacity and the change in remaining charge capacity when at least one of the values, namely the change in charge capacity, the change in remaining charge capacity, and the difference between the first open circuit voltage and the second open circuit voltage, is greater than a preset value.

Owner:SANYO ELECTRIC CO LTD

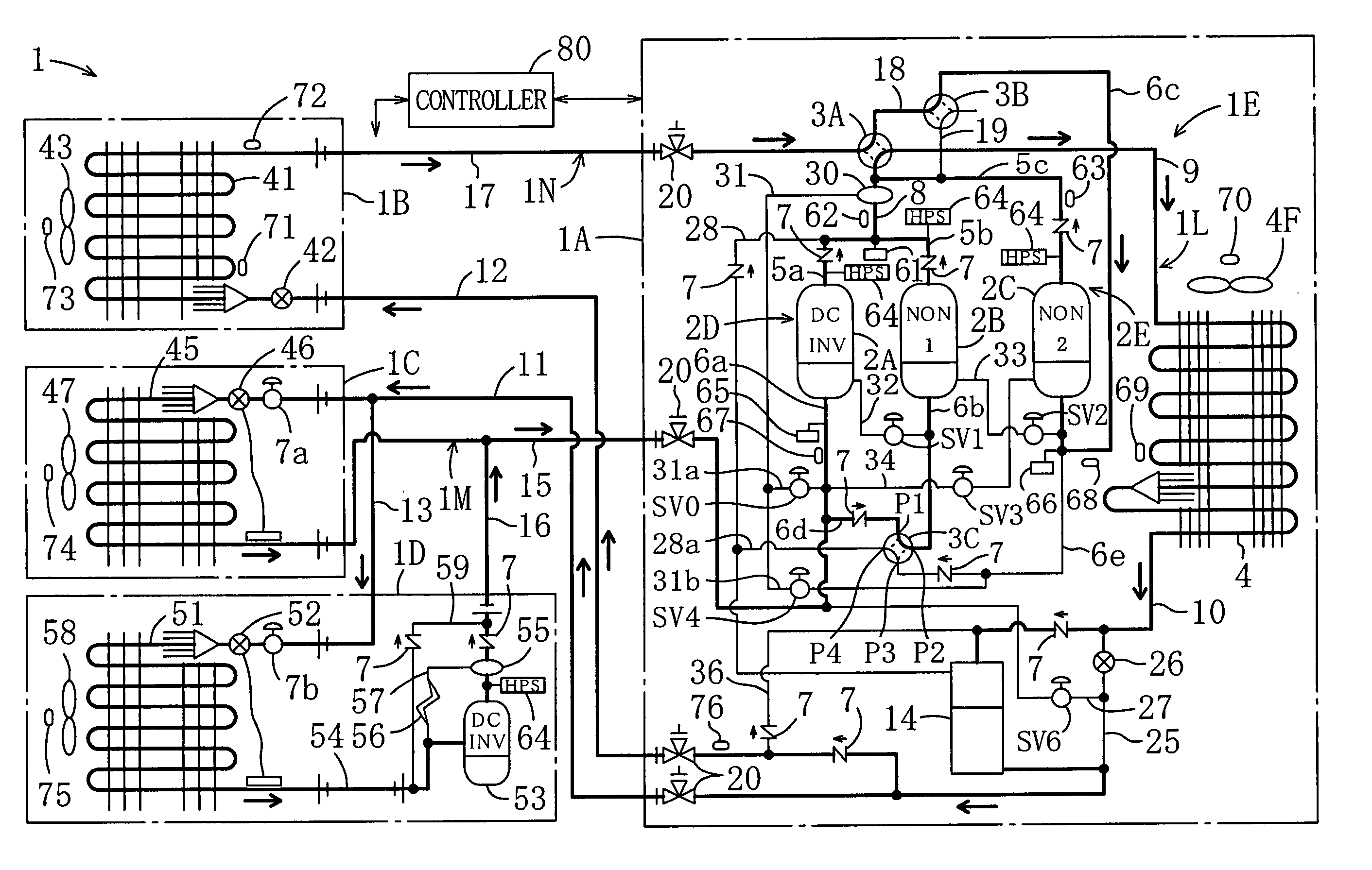

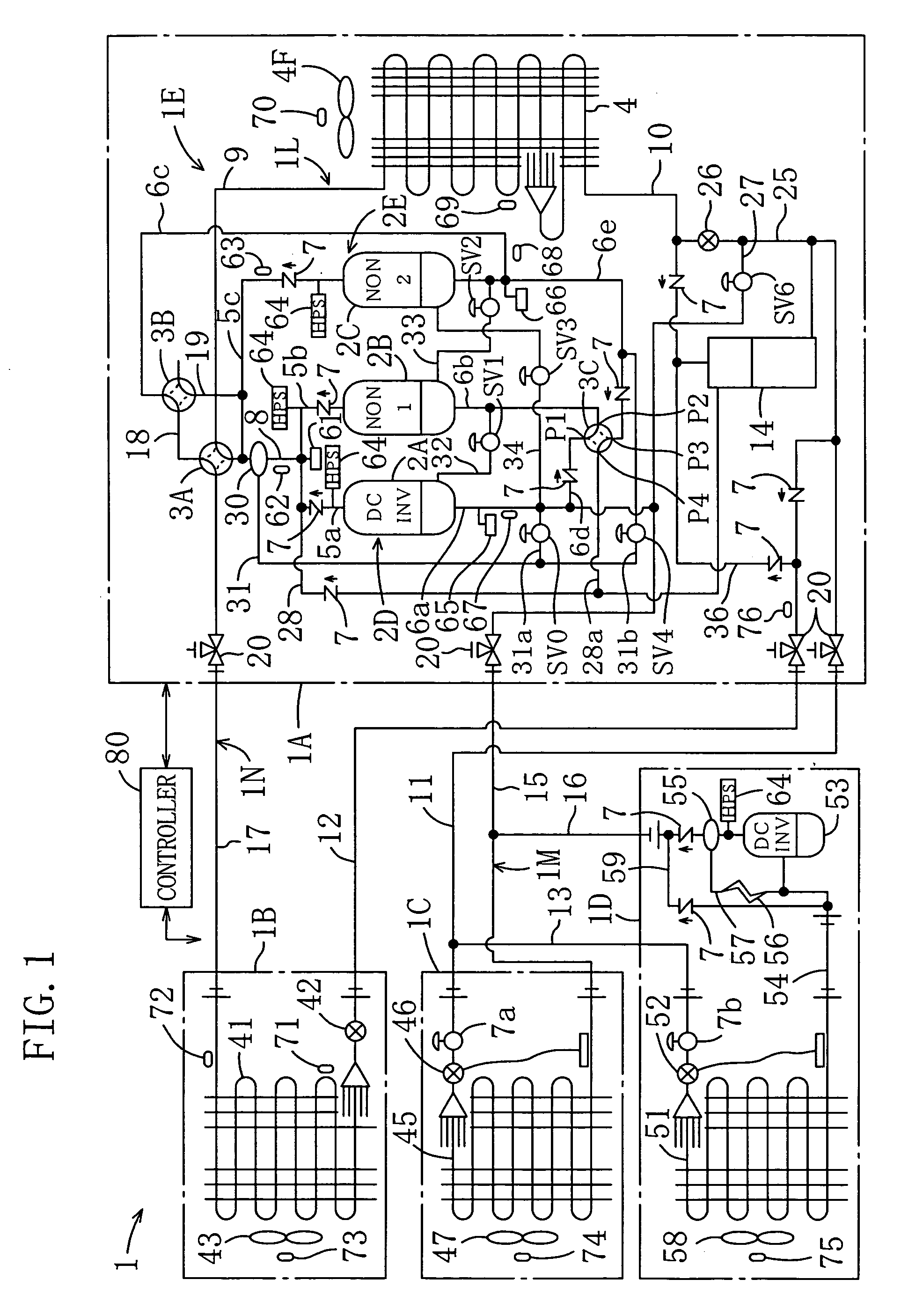

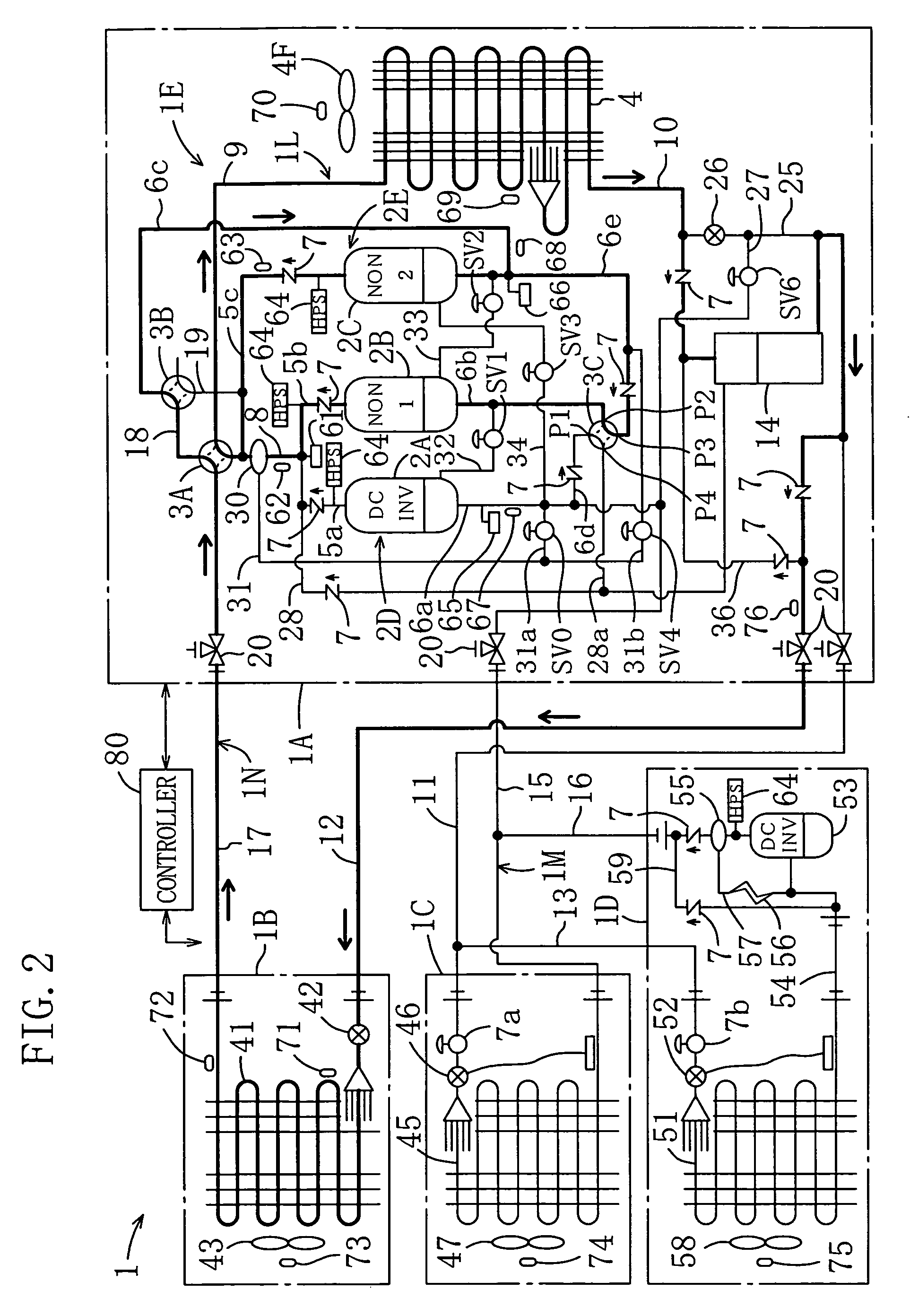

Regfrigerating device

InactiveUS20040112082A1Improve COPEasy to operateCompression machines with non-reversible cycleCompression machines with several evaporatorsEngineeringHeat exchanger

A refrigerating apparatus including three compressors (2A, 2B, 2C) and application side heat exchangers (41) (45, 51) for two channels is formed so that a first compressor (2A) is used only for the application side heat exchangers (45, 51) in a first channel of a circuit, a third compressor (2C) is used only for the application side heat exchanger (41) in a second channel of the circuit, and a second compressor (2B) is used in a switchable manner between the application side heat exchangers (45, 51) in the first channel of the circuit and the application side heat exchanger (41) in the second channel of the circuit. Thus, not only the pipe arrangement at suction side is simplified, but also operation control is streamlined.

Owner:DAIKIN IND LTD

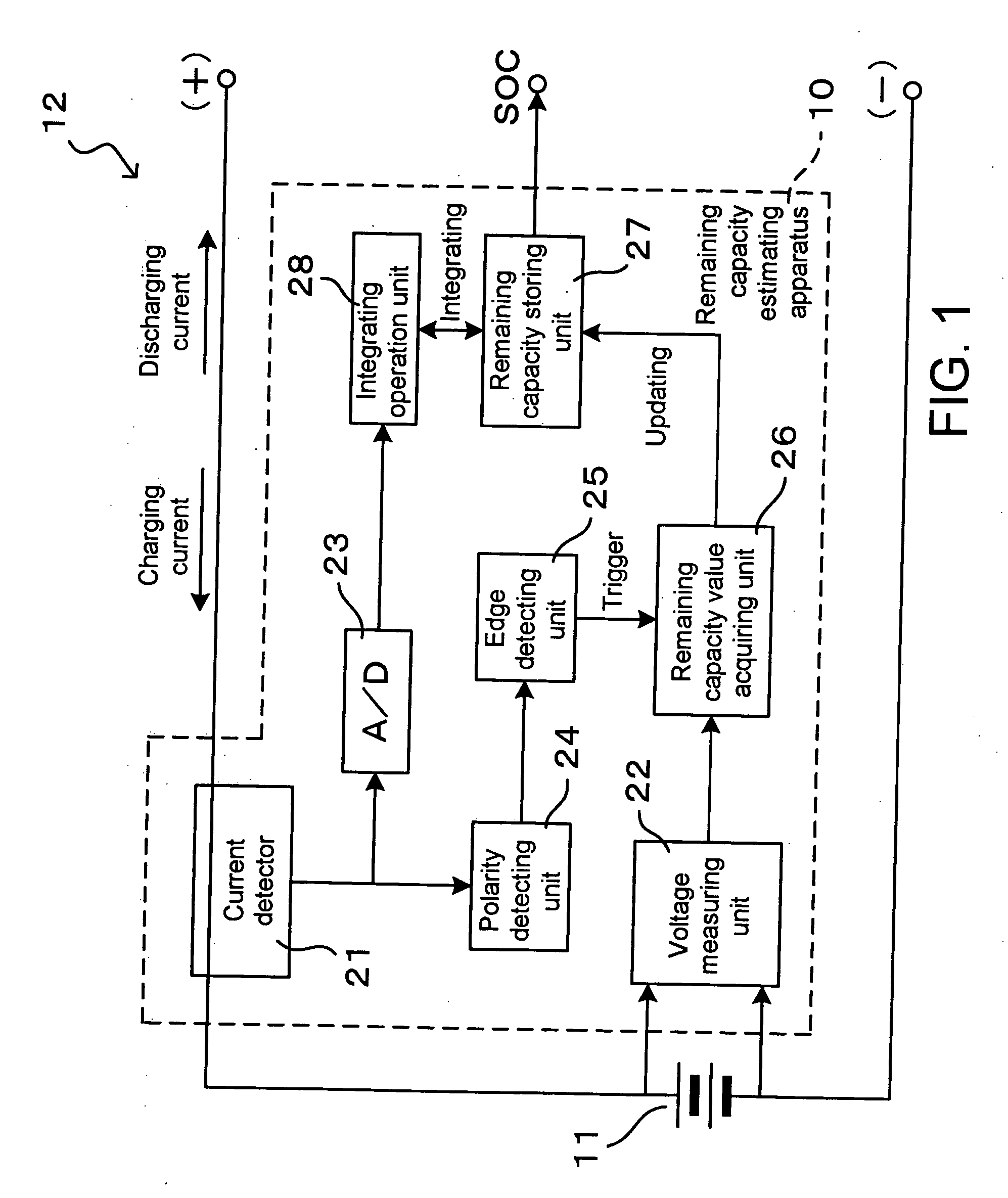

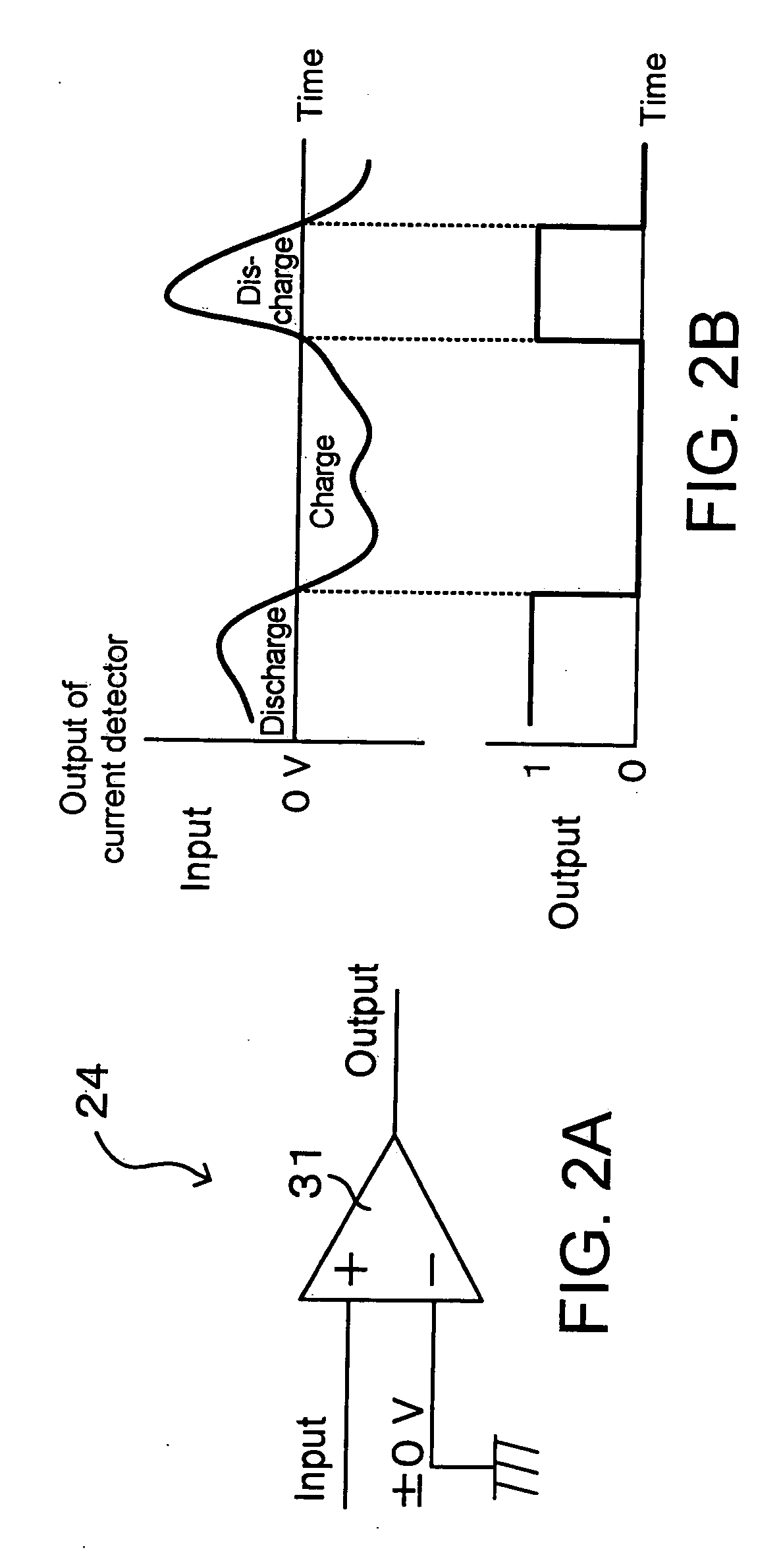

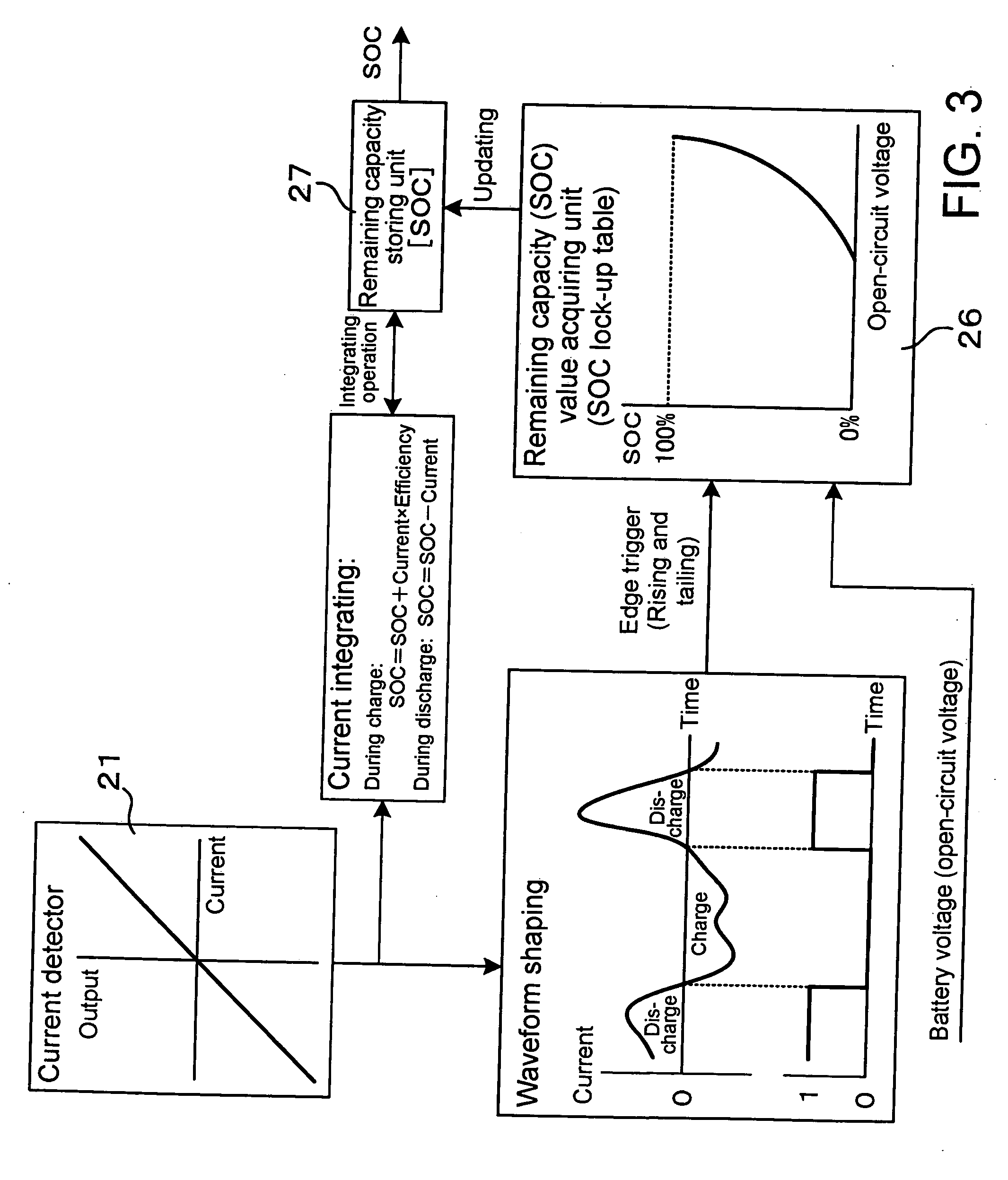

Method and apparatus for estimating remaining capacity of electric storage

InactiveUS20070170892A1Accurate estimateSmall amount of operationBatteries circuit arrangementsElectrical testingLithiumCapacity value

A method for determining a remaining capacity of an electric storage such as a lithium ion secondary battery which is mounted on a hybrid electric automobile or the like accurately at an arbitrary time interval includes the steps of: monitoring a charging / discharging current of the secondary battery and calculating a first remaining capacity value continuously by executing an integrating operation based on the charging / discharging current; and detecting a switching timing between charge and discharge of the secondary battery, regarding with the timing that is detected, a terminal voltage of the secondary battery at the detected timing as an open-circuit voltage to obtain a second remaining capacity value based on the open-circuit voltage, and updating the first remaining capacity-value with the second remaining capacity value.

Owner:NEC LAMILION ENERGY +1

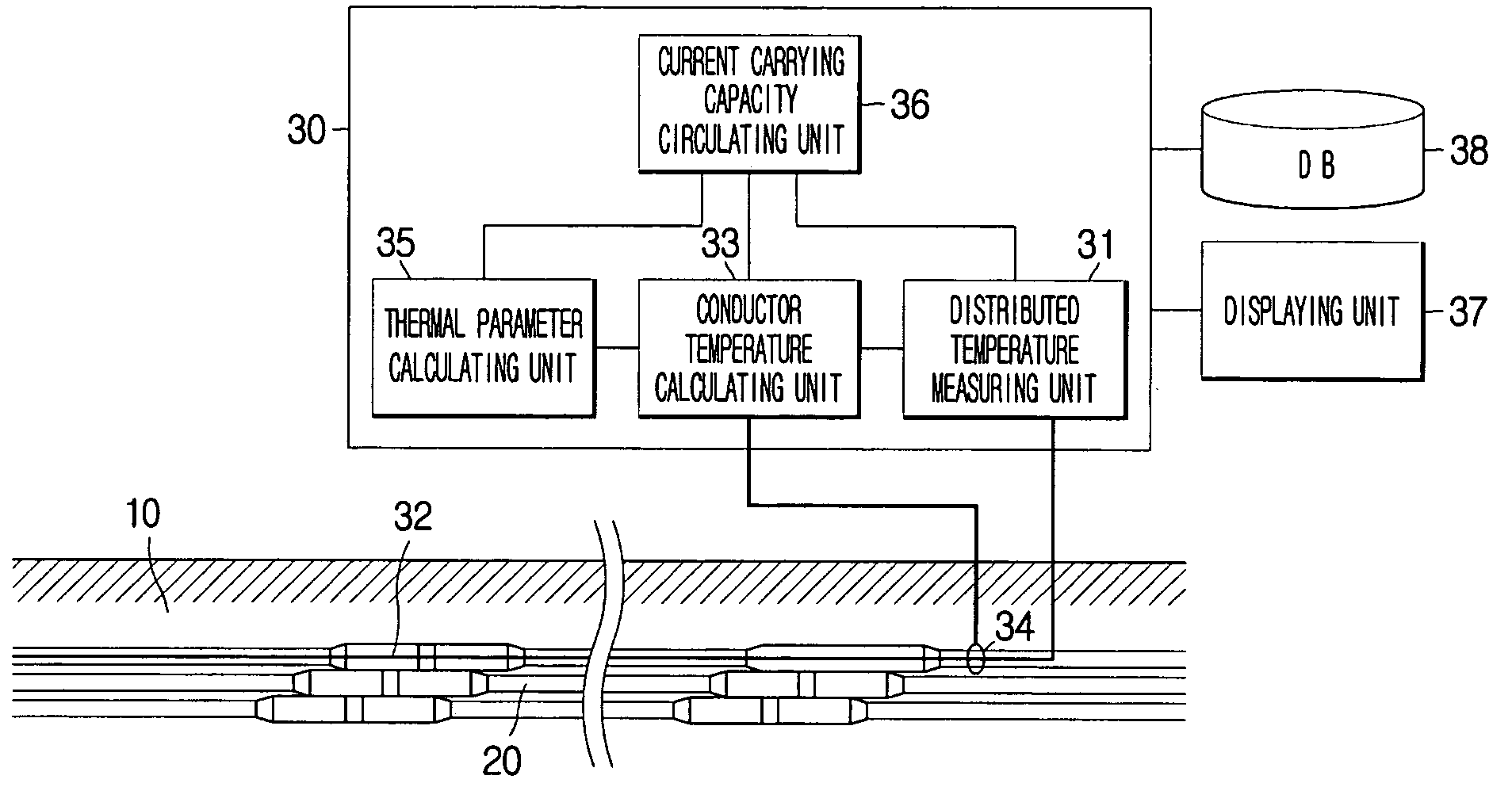

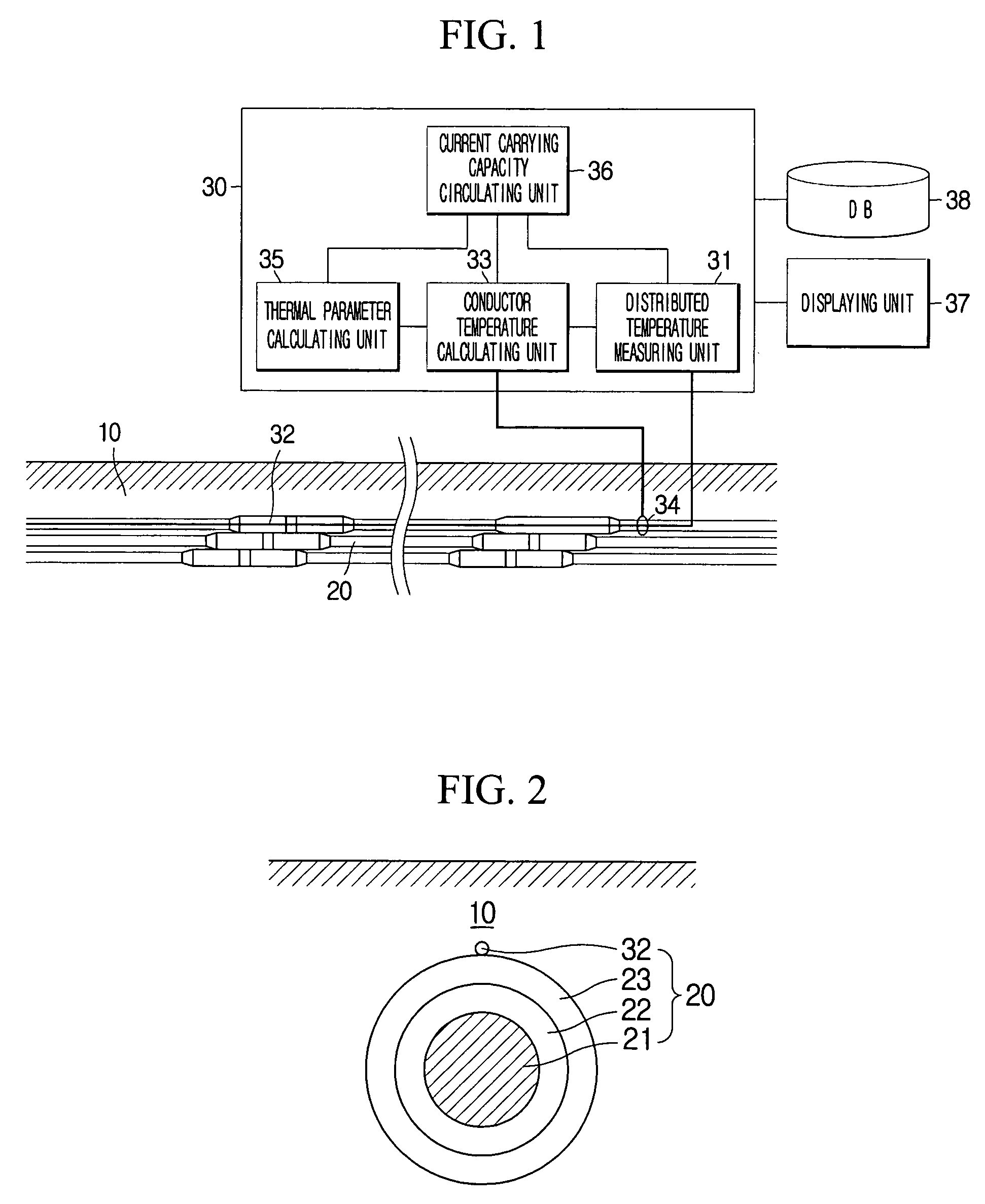

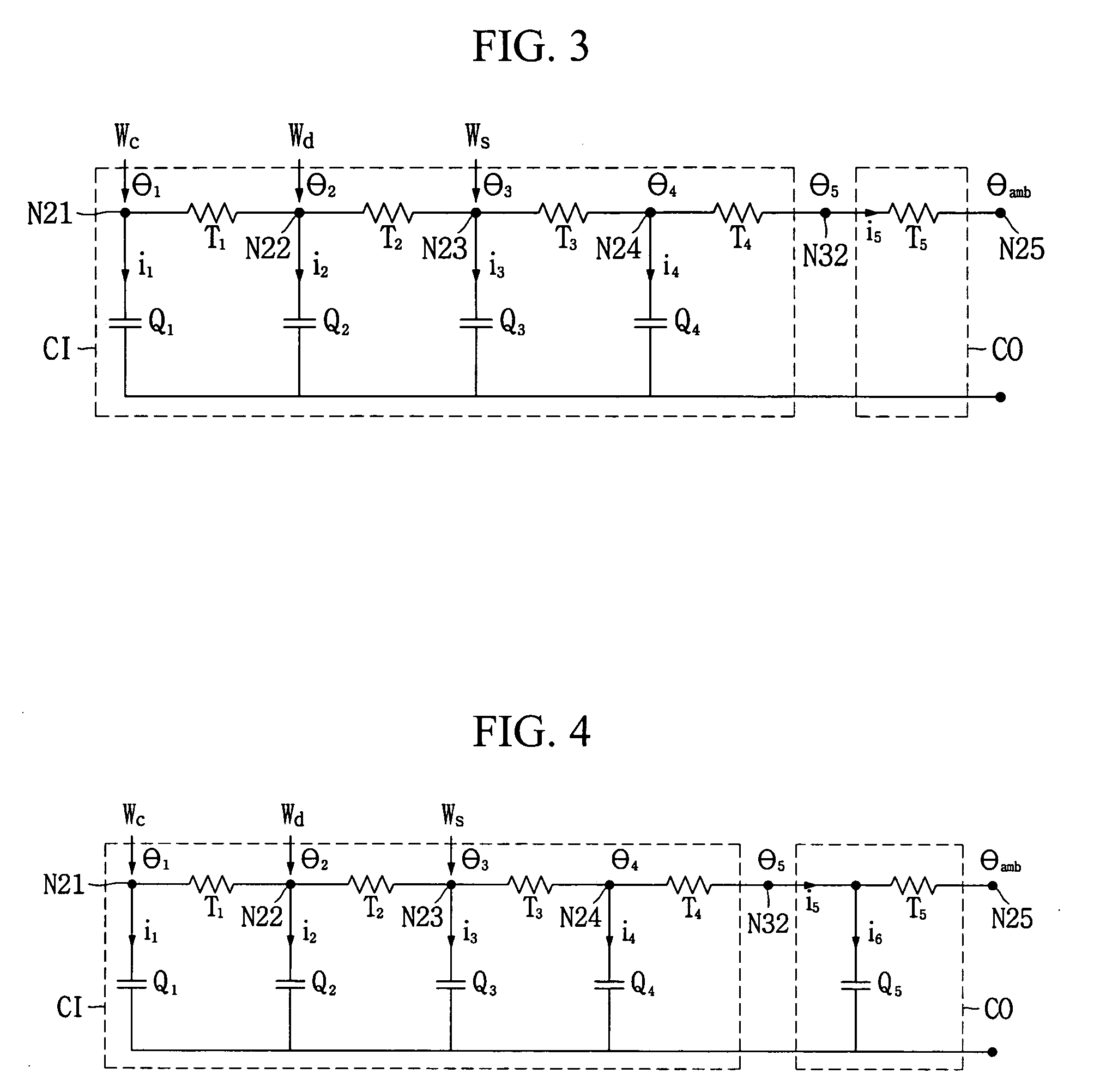

Apparatus and method for analysis of electric power transmission link status having function of real-time evaluating thermal parameters outside the link

InactiveUS20050125174A1Preventing a critical accidentAccurate capacityData processing applicationsResistance/reactance/impedenceElectric power transmissionHeat flow

Apparatus and method for real-time analysis of an electric power transmission link status direct buried or installed in a duct or a tunnel are described. The method includes: real-time measuring a surface distributed temperature of the link by using a distributed temperature sensor installed along a longitudinal direction of the link; calculating a conductor temperature of the link on the basis of the surface distributed temperature and an electric current flowing through the link; calculating a heat flow emitted out of the link on the basis of the surface distributed temperature and the conductor temperature; and real-time calculating a thermal parameter of an environment around the link on the basis of the heat flow. Thus, it is possible to calculate operating conditions of the link more accurately and improve safety of electric power transmission by real-time calculating the thermal parameter of the environment around the link.

Owner:LG CABLE LTD (KR)

Battery capacity calculating method, battery capacity calculating apparatus and battery capacity calculating program

InactiveUS7078907B2Extend battery lifeAccurate capacityBatteries circuit arrangementsMaterial analysis by electric/magnetic meansTerminal voltageEngineering

Owner:MURATA MFG CO LTD

Heat-shrinkable polystyrene based resin film roll and method for production thereof, and heat-shrinkable label

InactiveUS20050019514A1Less dispersionReducing raw materialWrappers shrinkageLayered productsShrinkage ratePolystyrene

A film roll comprising a heat-shrinkable polystyrene based resin film wound into a roll, characterized in that, each of the samples taken out from the roll exhibits, in a heat shrinkage test under the condition of the immersion in a hot water at 85° C. for 10 sec, a heat shrinkage rate in the main shrinking direction of within ±5% relative to an average rate of the total samples; a heat-shrinkable polystyrene based resin film taken from the roll; a heat-shrinkable label comprising the film; a method for producing the heat-shrinkable polystyrene based resin film roll which comprises using raw material chips having a specific form, or using a hopper having a specific shape for feeding raw material chips to an extruder, or limiting the variation of the surface temperature of a film in a specific production step to a specific range.

Owner:TOYOBO CO LTD

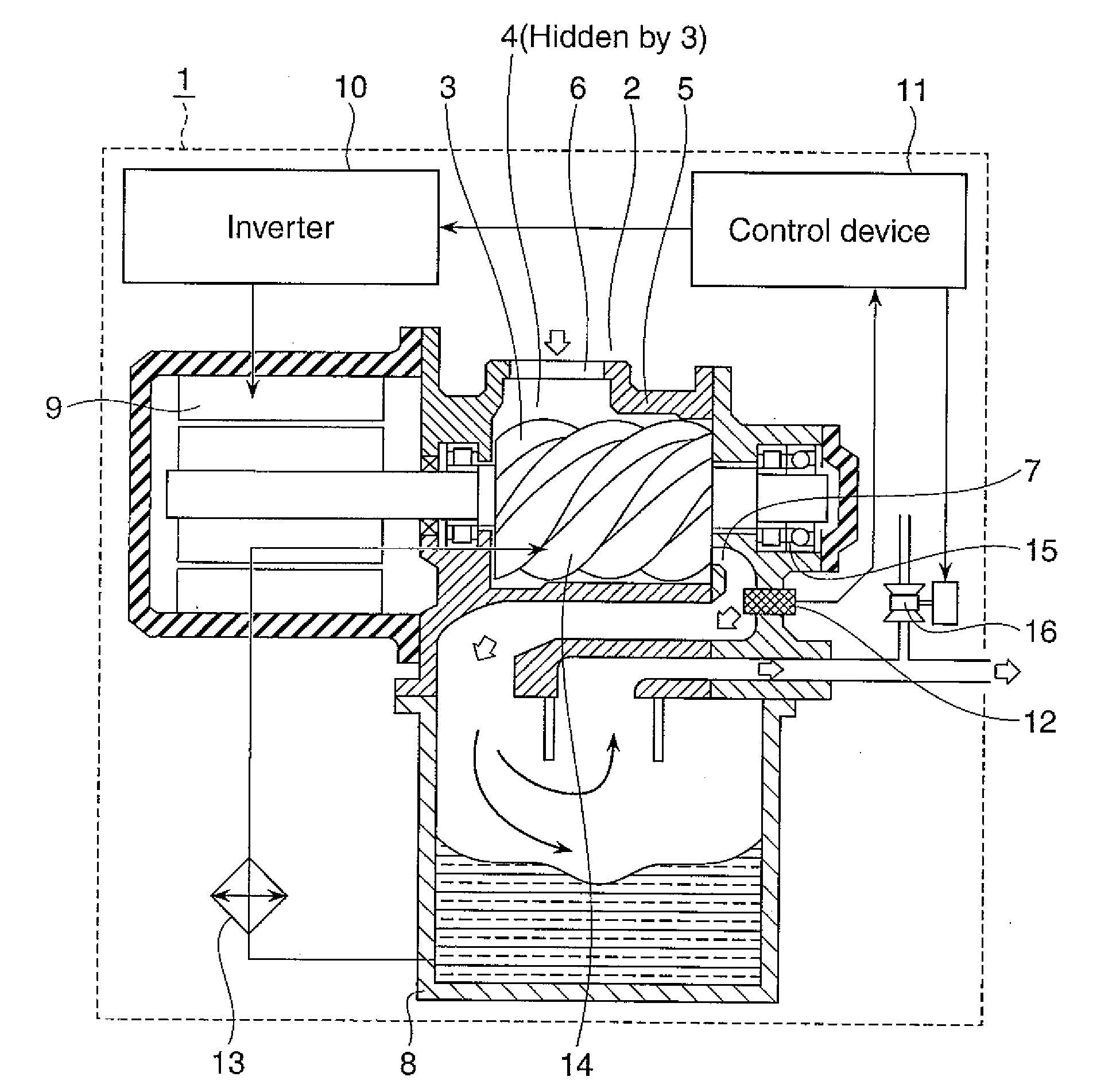

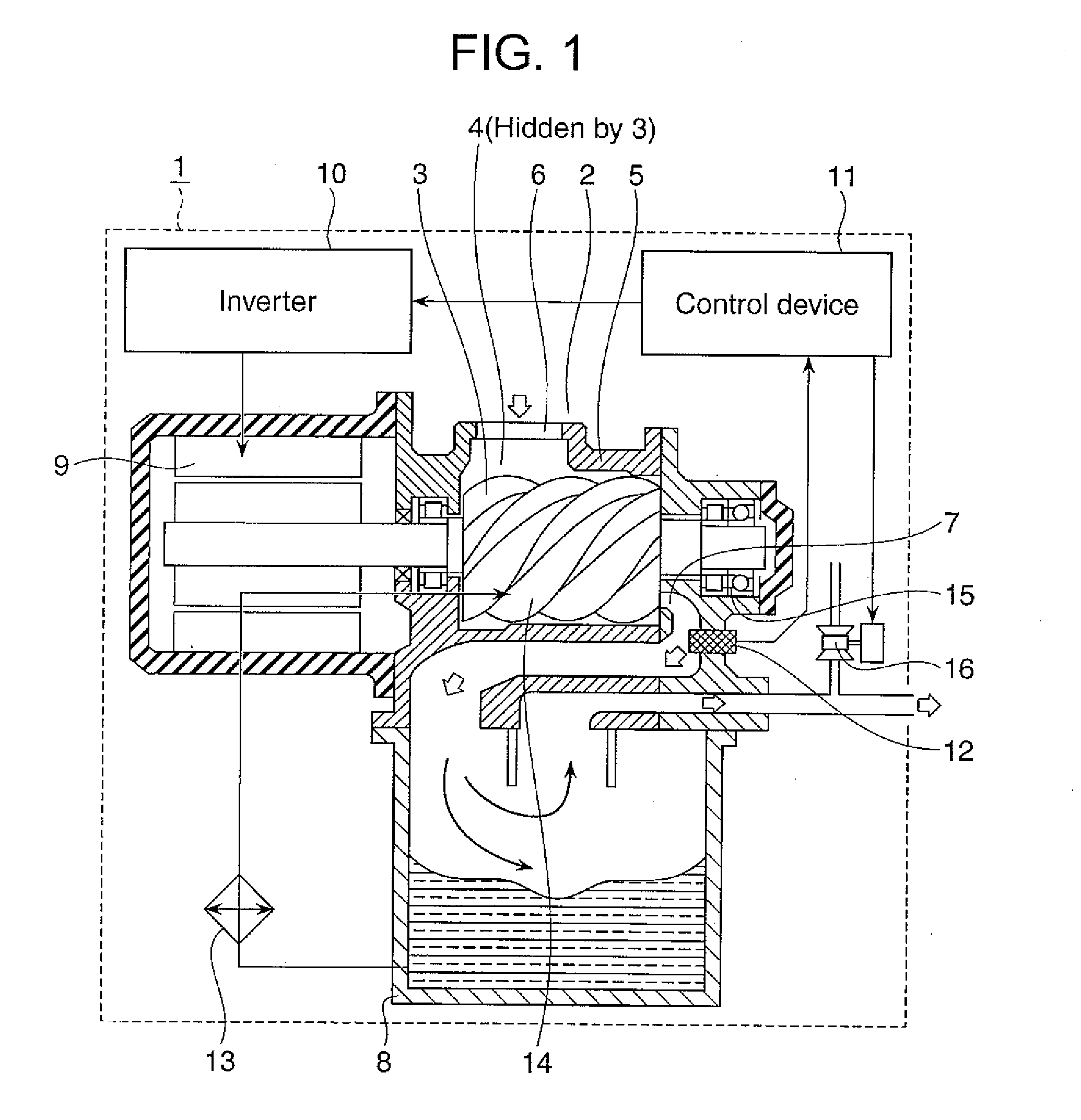

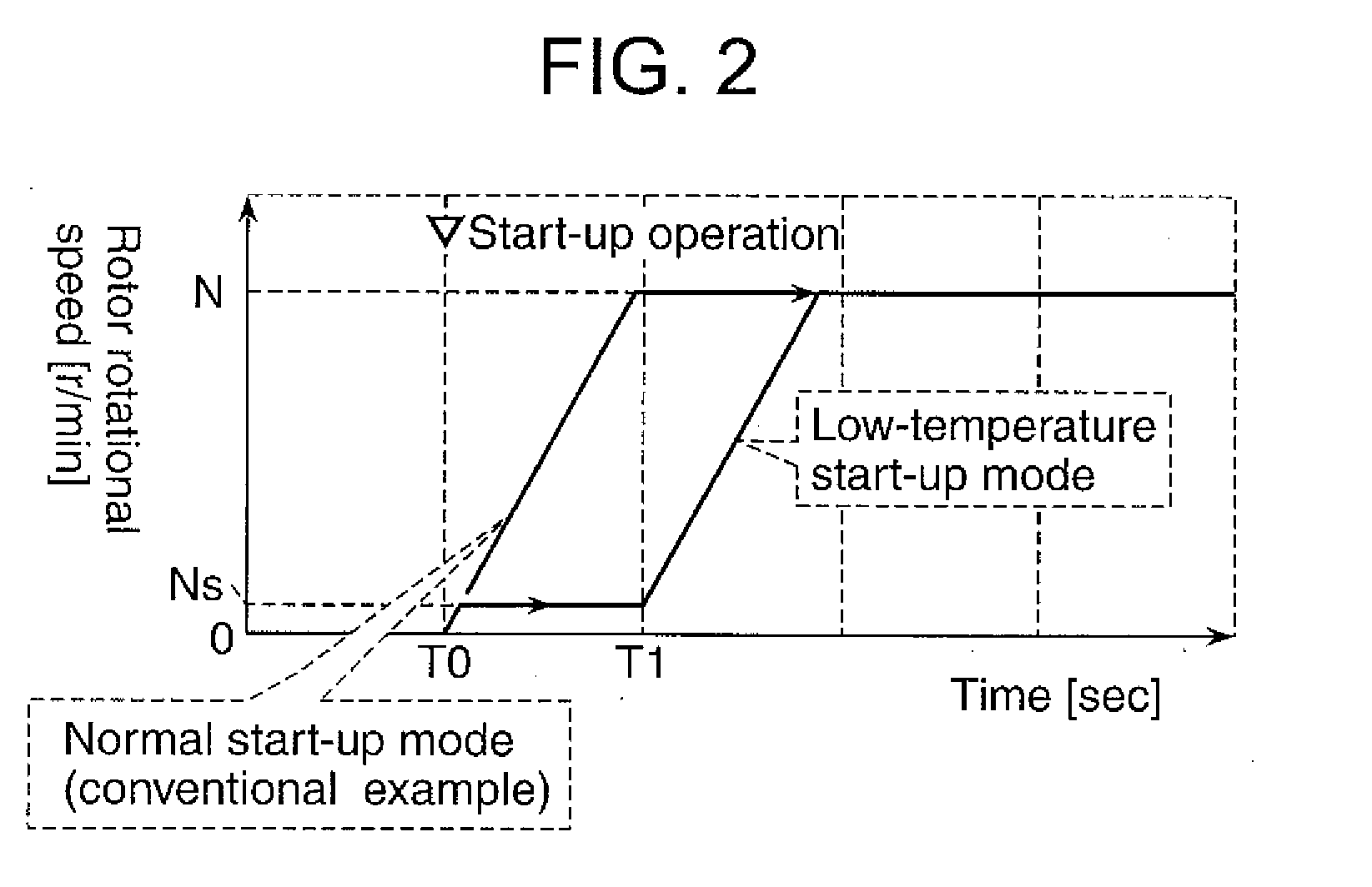

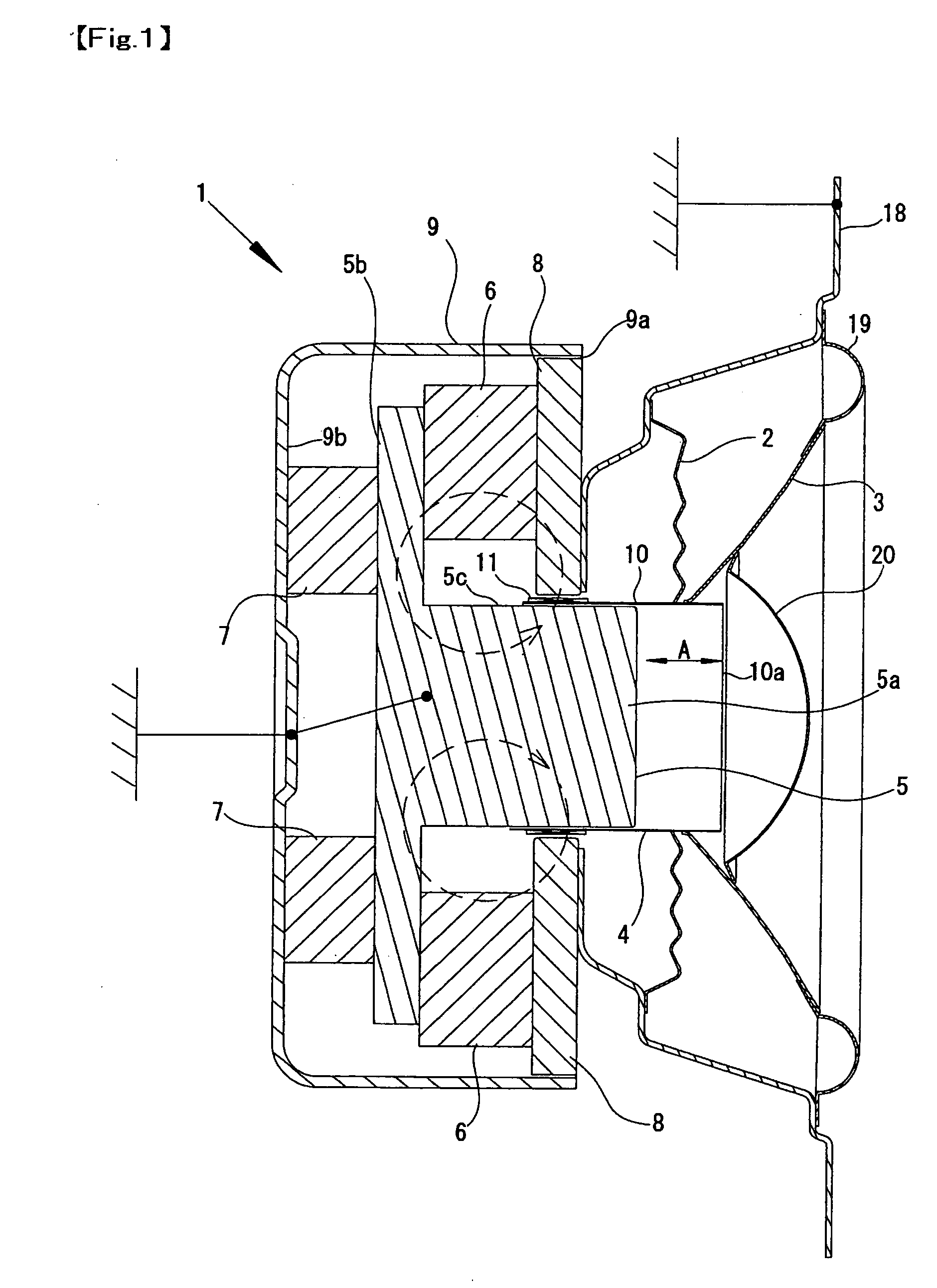

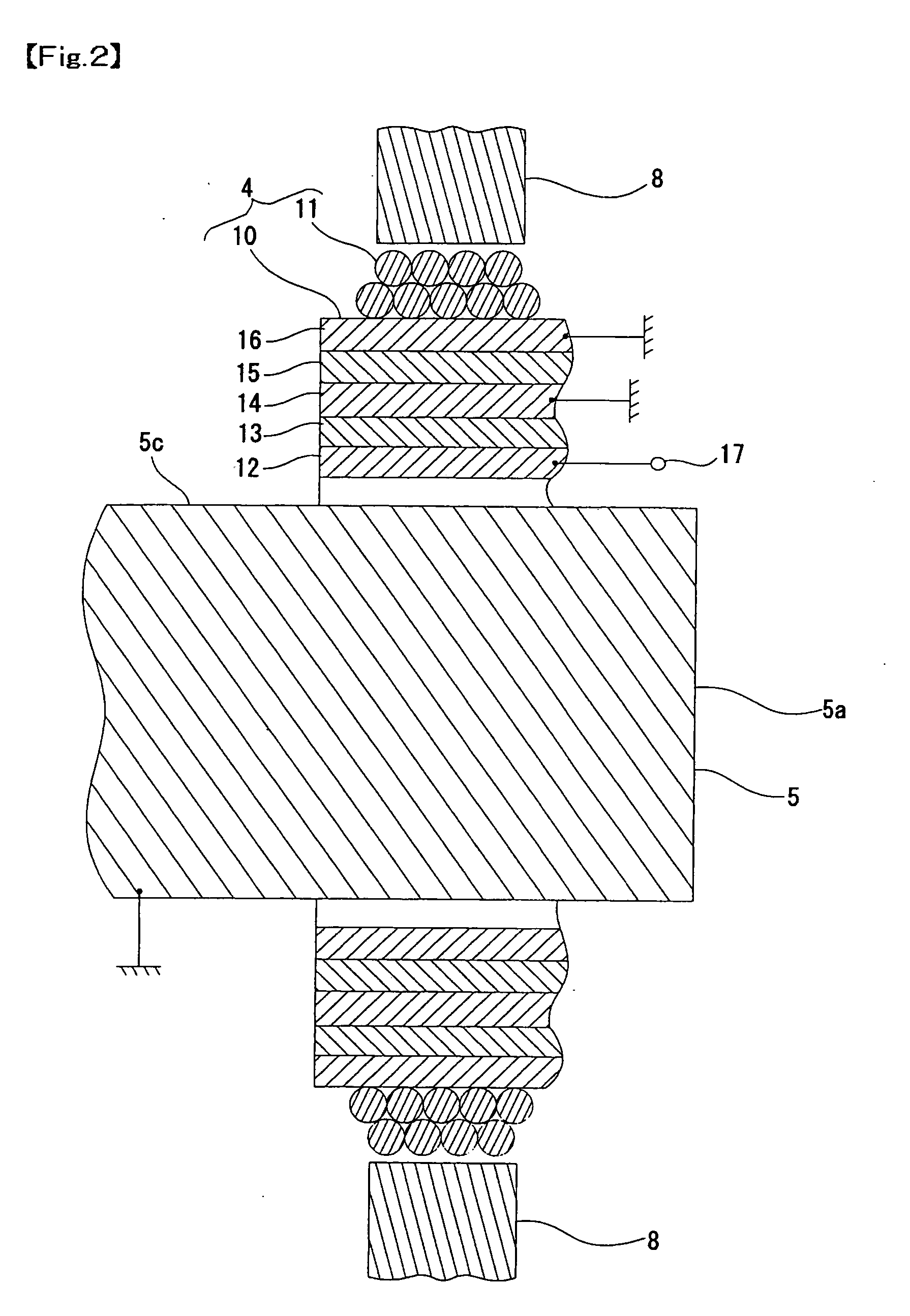

Oil-flooded screw compressor, motor drive system, and motor control device

ActiveUS20100028165A1Smooth startReduce weightDC motor speed/torque controlEmergency protective circuit arrangementsMotor driveMotor control

When an oil-flooded screw compressor is started up in a cold environment after a long halt, start-up torque increases due to the increased viscosity of the oil that has long stayed inside the working chambers of the compressor. This has necessitated drive means with a larger capacity than that required for normal operation.An oil-flooded screw compressor according to the invention comprises: a casing; a pair of rotors each having screw-thread-shaped groove and being housed in the casing; an electric motor for rotationally driving the pair of rotors; a control device for controlling the electric motor; an oil feeding mechanism for feeding oil into working chambers formed by being enclosed by the casing and the pair of rotors in which teeth thereof are meshed to each other; and an oil separating mechanism for separating the oil from compressed gas discharged from the working chambers. The oil-flooded screw compressor drives the pair of rotors at a rotational speed which is low enough not to increase torque for a short amount of time after start-up and accelerates the pair of rotors up to a normal-operation rotational speed after oil discharge. Alternatively, the oil-flooded screw compressor rotates the pair of rotors for a short amount of time after the remaining compressed gas is discharged after a halt, thereby allowing the oil accumulated inside the working chambers to be discharged and ensuring smooth start-up after the halt.

Owner:HITACHI IND EQUIP SYST CO LTD

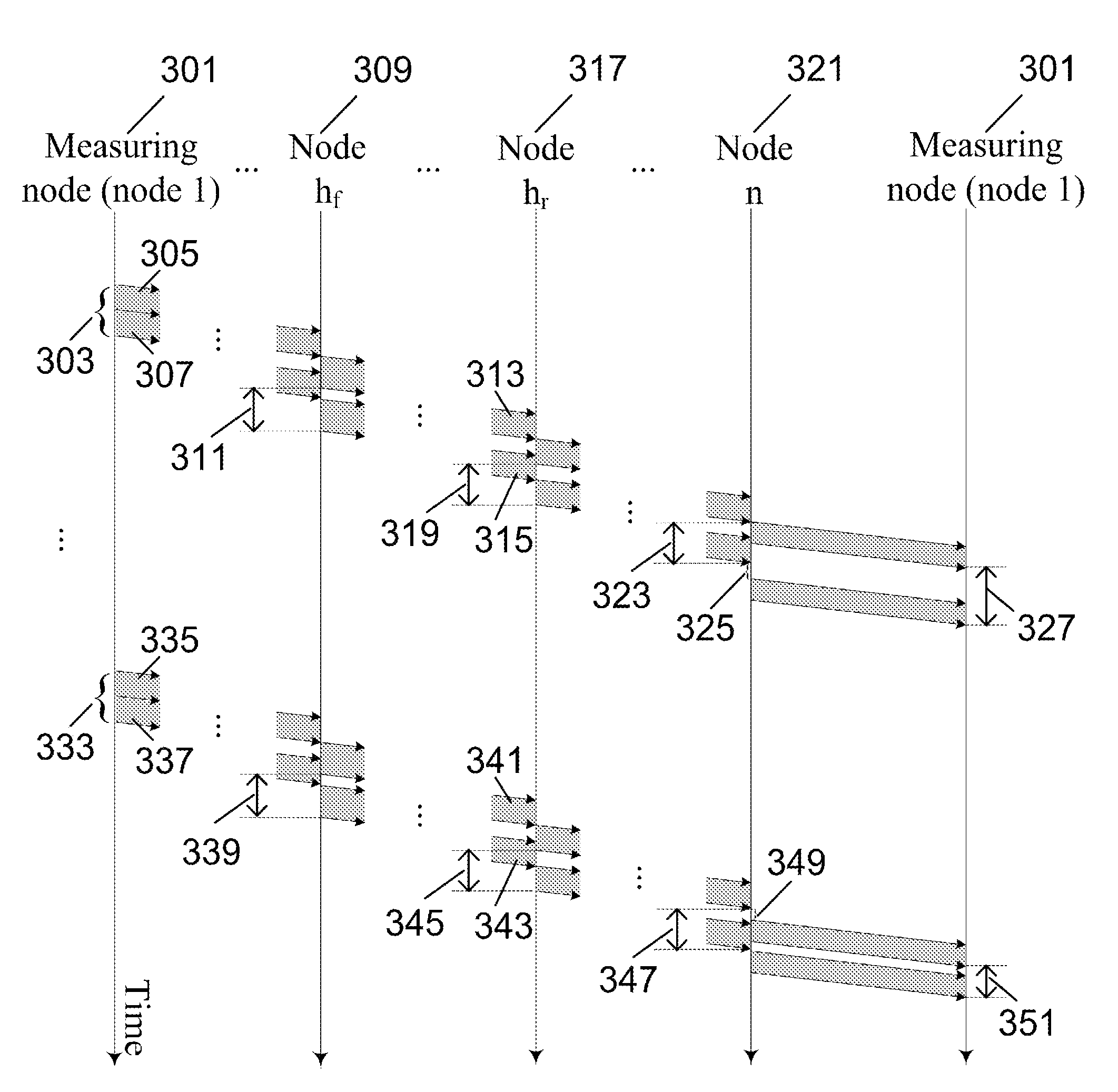

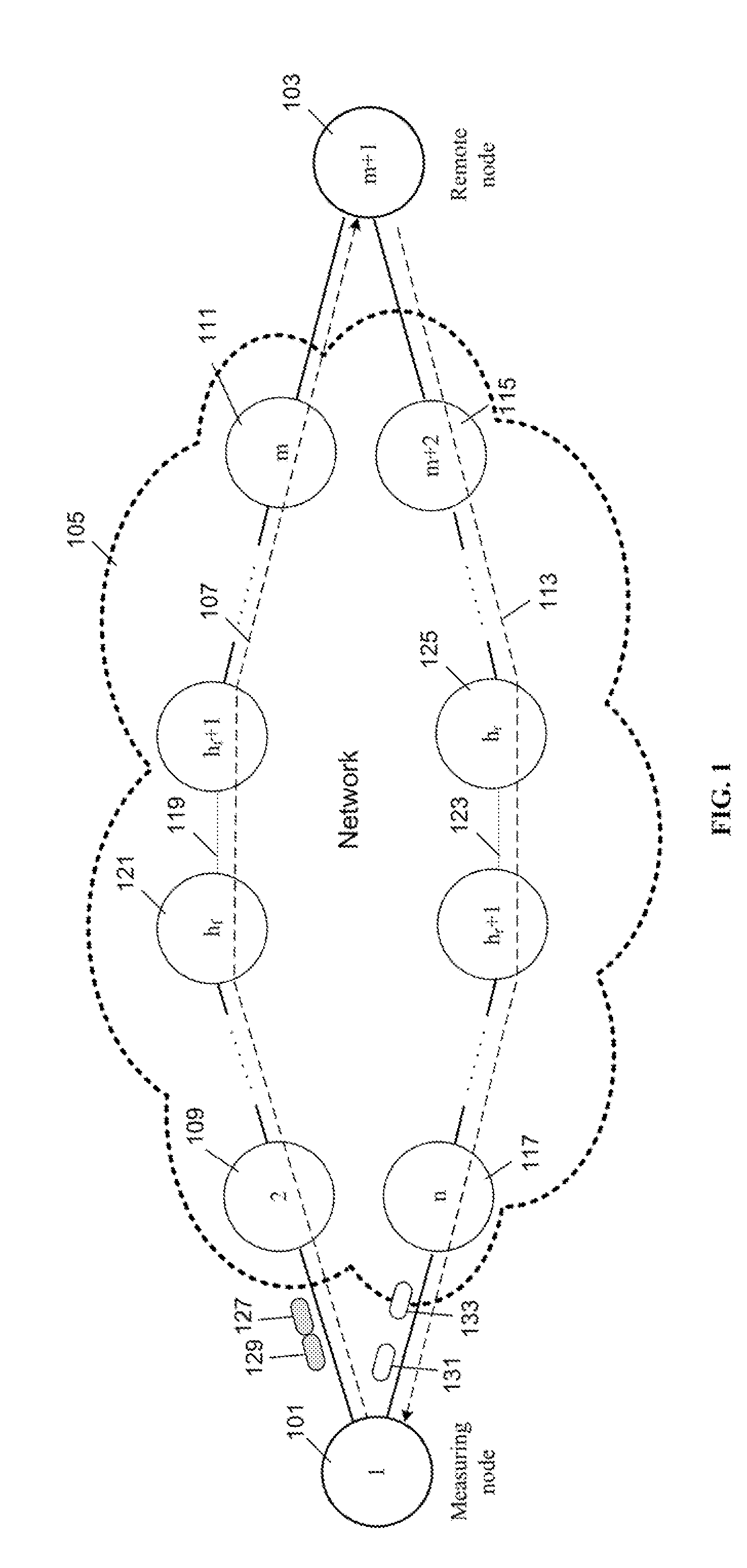

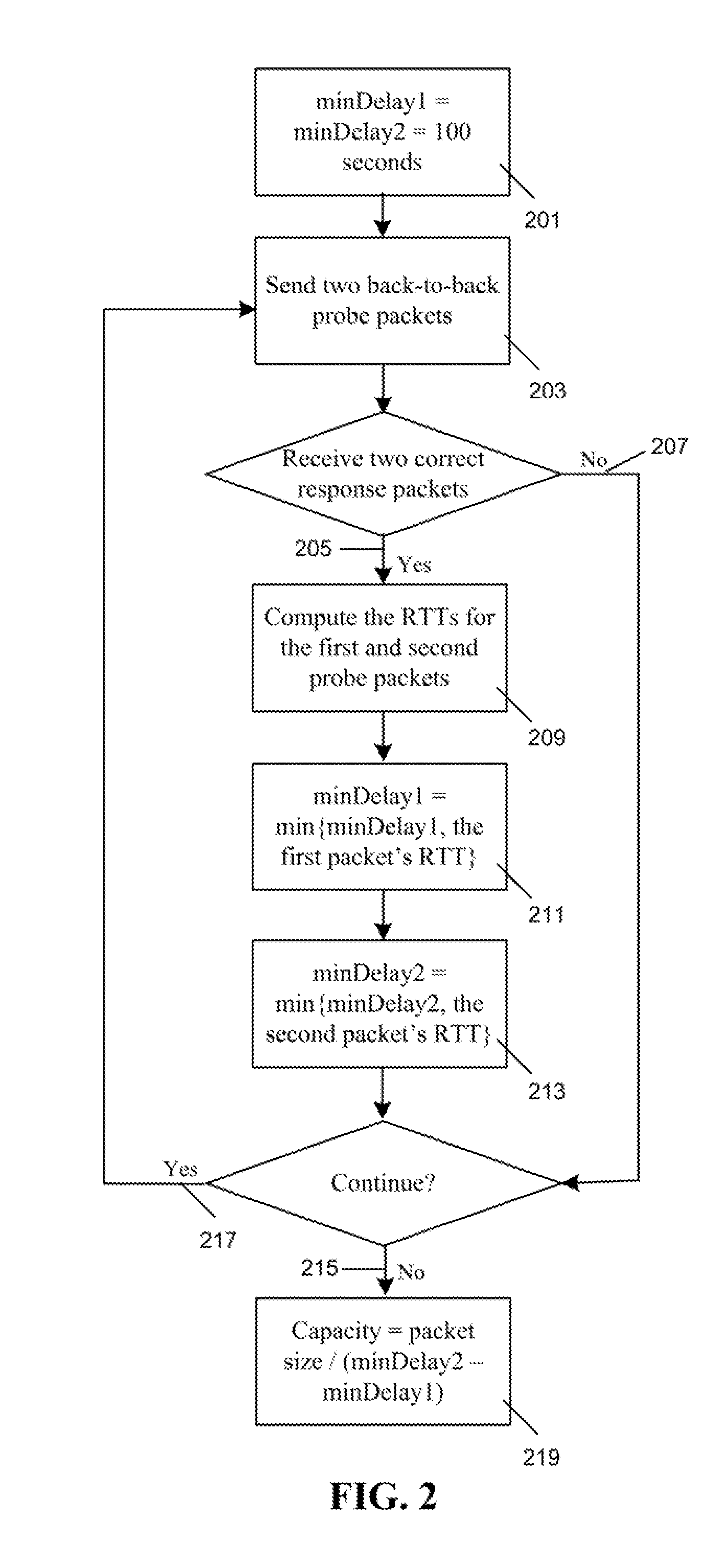

Method for measurment of network path capacity with minimum delay difference

ActiveUS20110128864A1Less storageAvoid excessive computationError preventionTransmission systemsReal-time computing

A method for achieving fast and efficient measurement of path capacity of a communication network. The method includes the following steps: (a) transmitting a number of probes from a local endpoint to a remote endpoint over a network path and each probe contains at least two outgoing packets and each probe can elicit at least two response packets from the remote endpoint; (b) determining a first minDelay by measuring RTT between the time sending the first probe packet and the time receiving the first response packet; (c) determining a second minDelay by measuring RTT between the time sending the second probe packet and the time receiving the second response packet; and (d) determining a minimum delay difference by subtracting said first minDelay from said second minDelay. The minimum delay difference divided by packet size can be used as a measurement of the network path capacity.

Owner:THE HONG KONG POLYTECHNIC UNIV

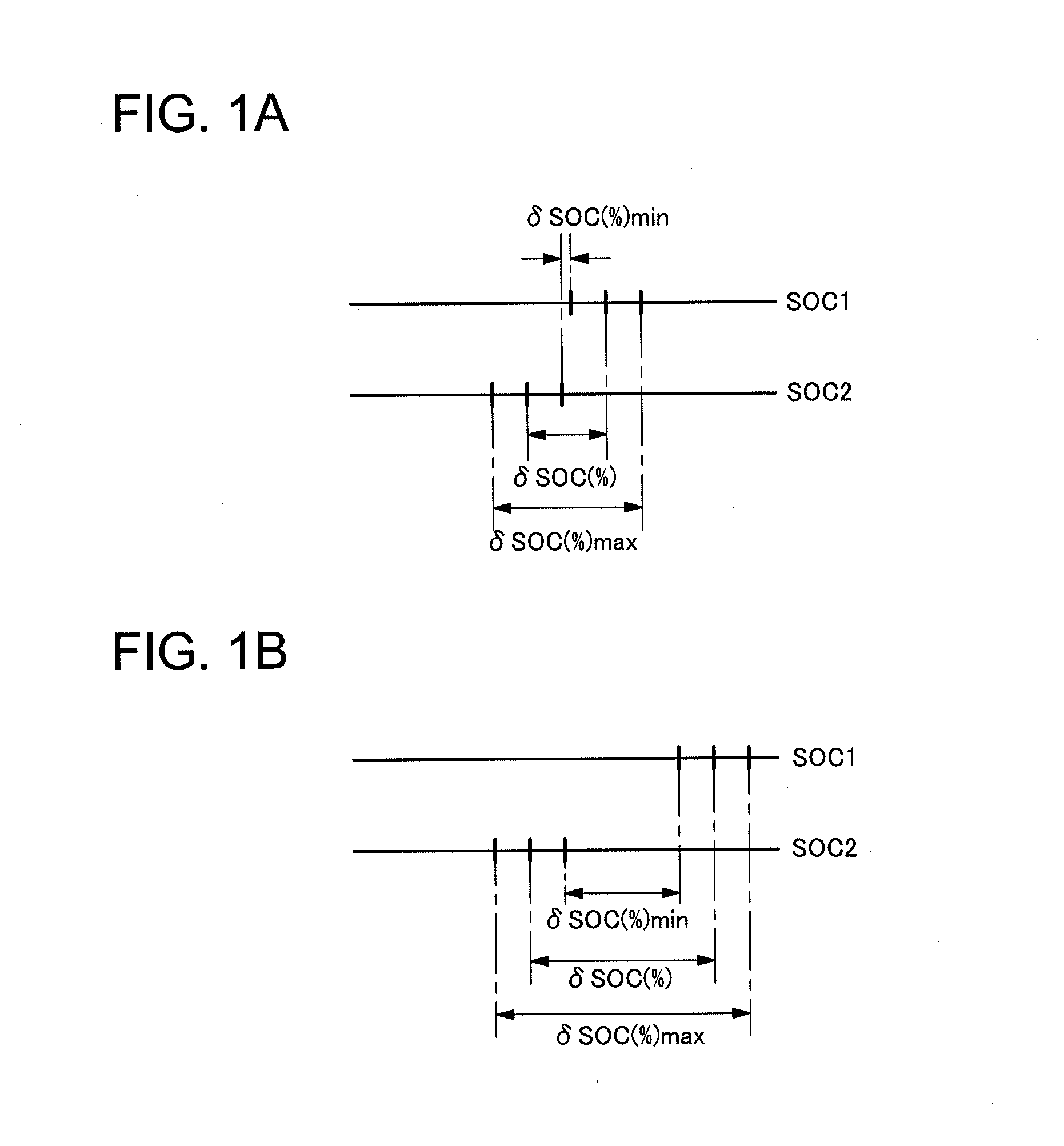

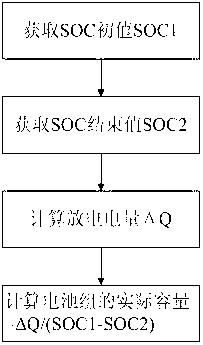

Calculation method of battery pack actual capacity

The invention discloses a calculation method of a battery pack actual capacity. The calculation method includes the following steps: (1) acquiring the value of the stress optical coefficient (SOC) SOC1 as an initial value when the battery pack just enters a working state. (2) acquiring the value of the stress optical coefficient (SOC) SOC2 as an end value when the battery pack stops working for a long time or enters the working state for the second time.(3) calculating the discharge capacity delta Qin the time quantum between SOC1and SOC 2. (4) calculating the actual capacity of the battery pack= delta Q / (SOC1-SOC2). If delta Q is less than a preset threshold value, then the currently detected data is deleted and the detection is carried out again. The preset threshold value is regulated according to the size of the different battery pack capacity. The calculation method of the battery pack actual capacity has the advantages that the calculation is simple; the realization of the calculation is simple, the actual capacity of the battery pack can be exactly calculated. The initial value and the end value of the calculation all chooses the value of the battery pack after standing so that the calculation can be exact and the calculation value is more close to the true value.

Owner:HUIZHOU EPOWER ELECTRONICS

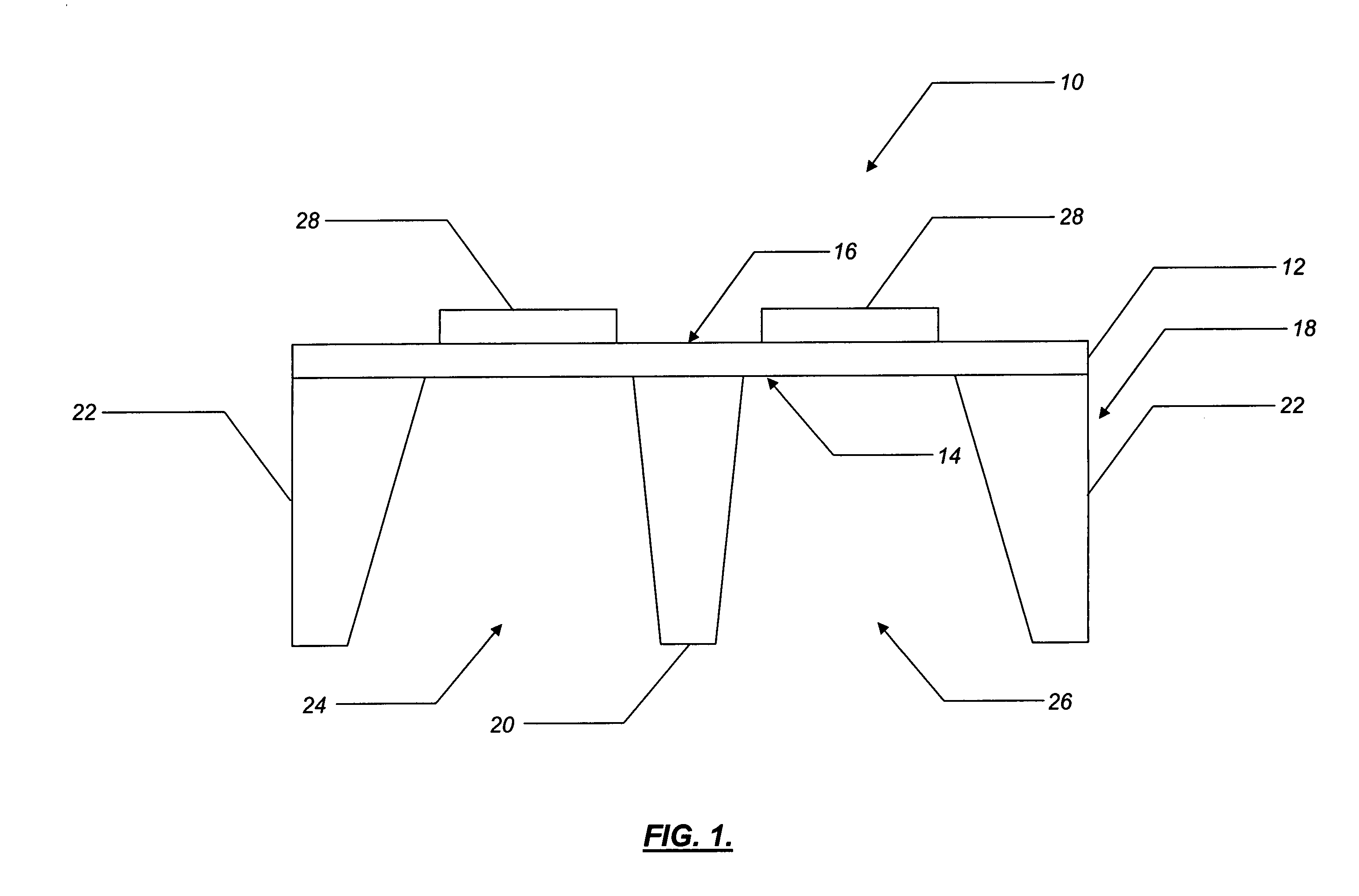

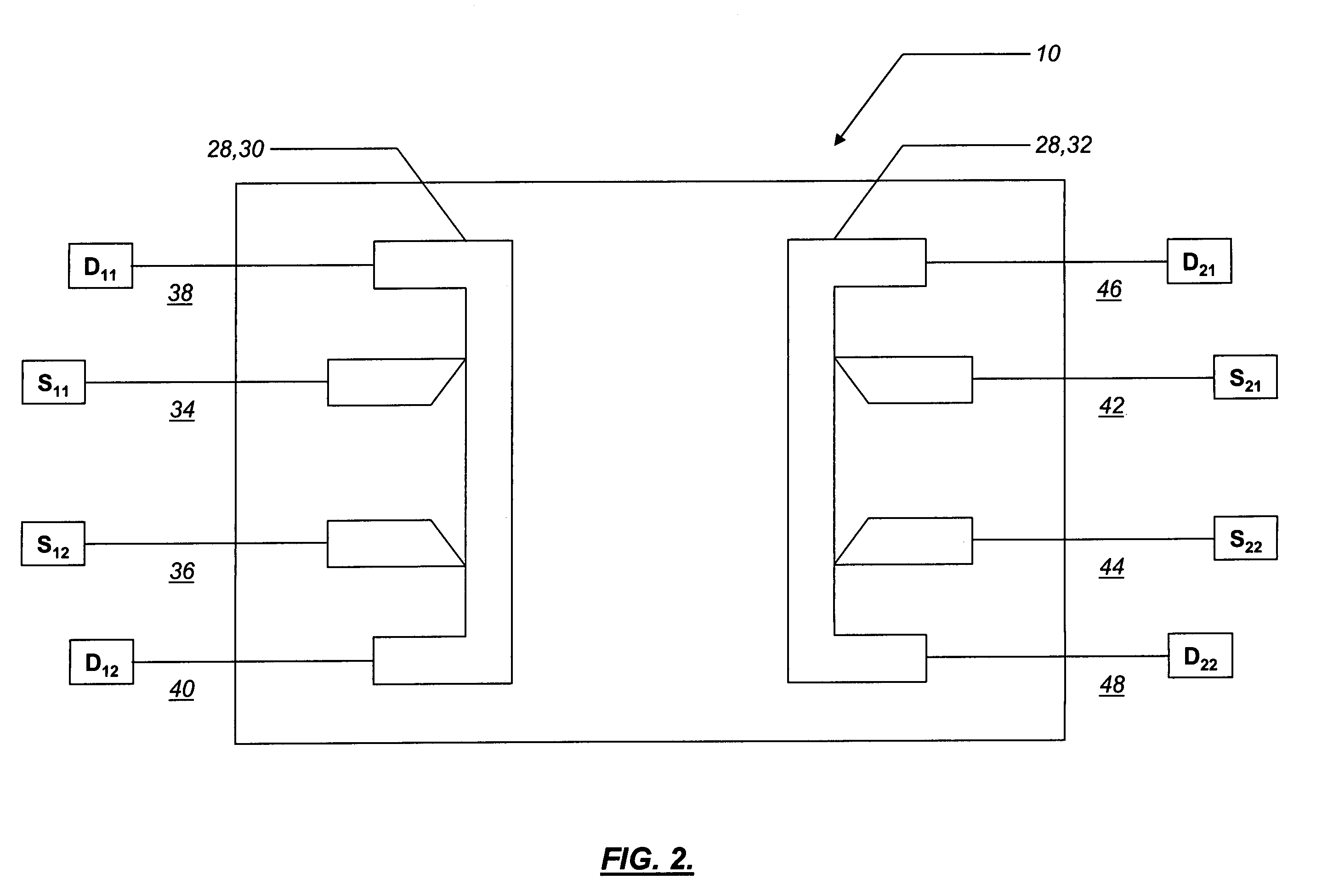

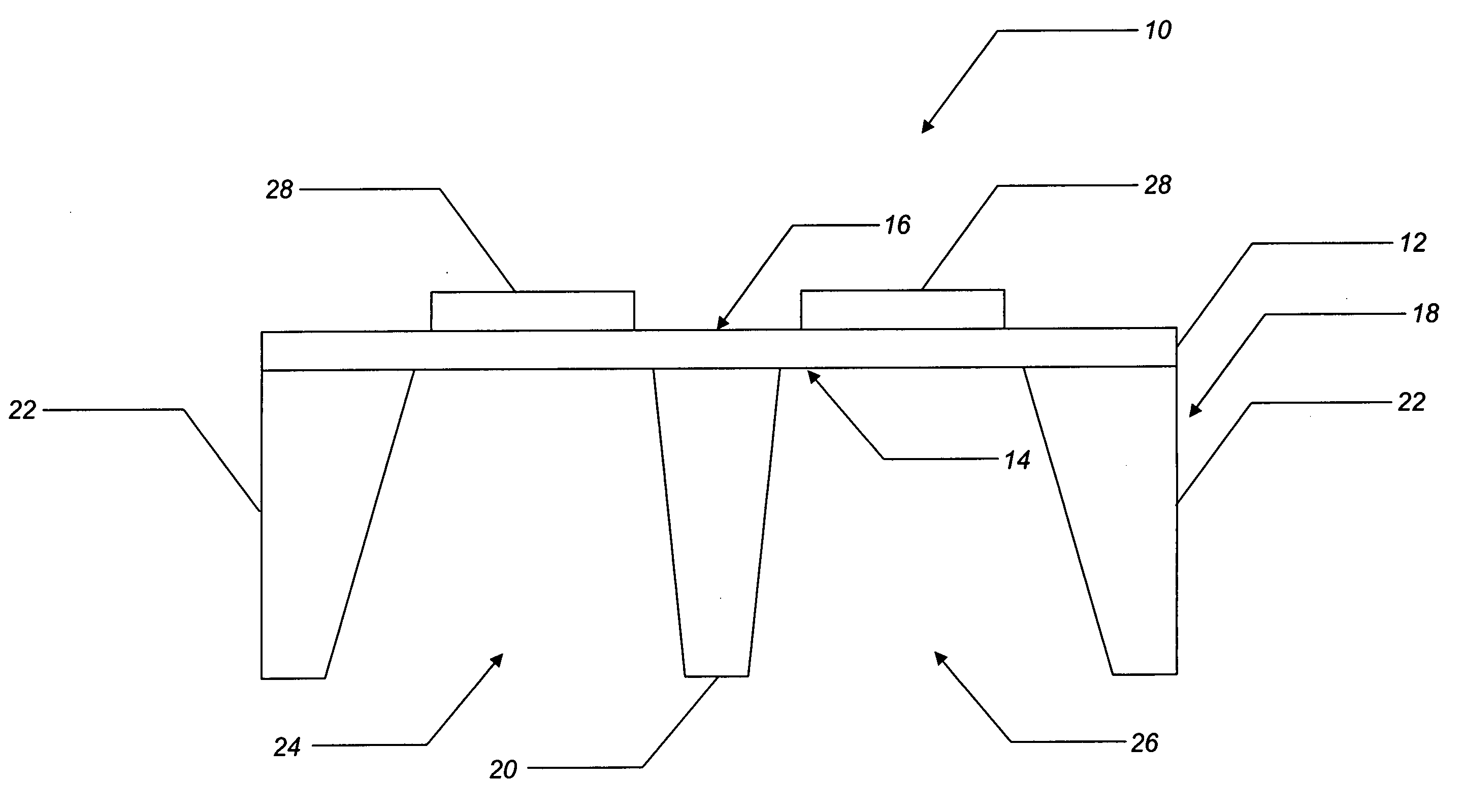

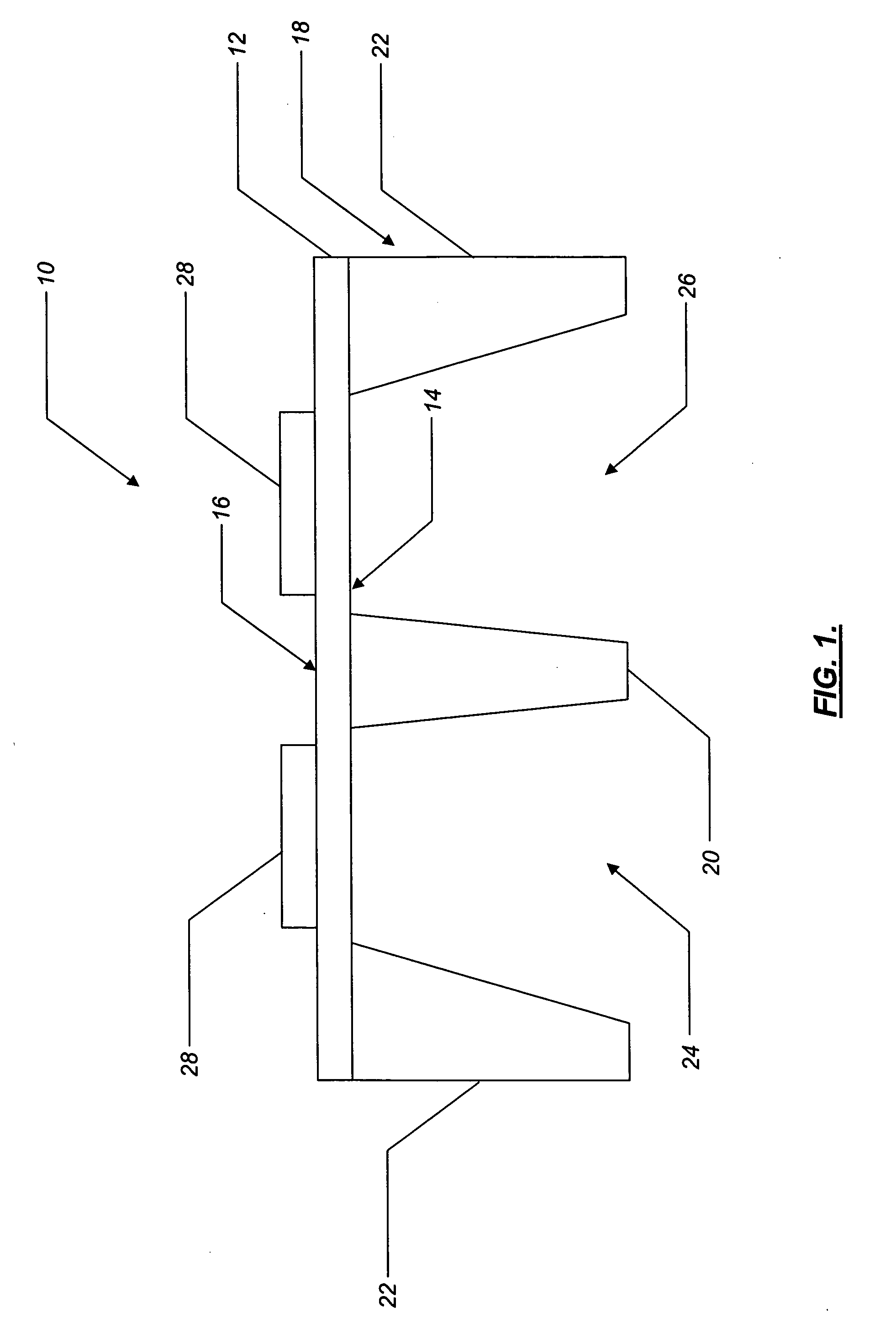

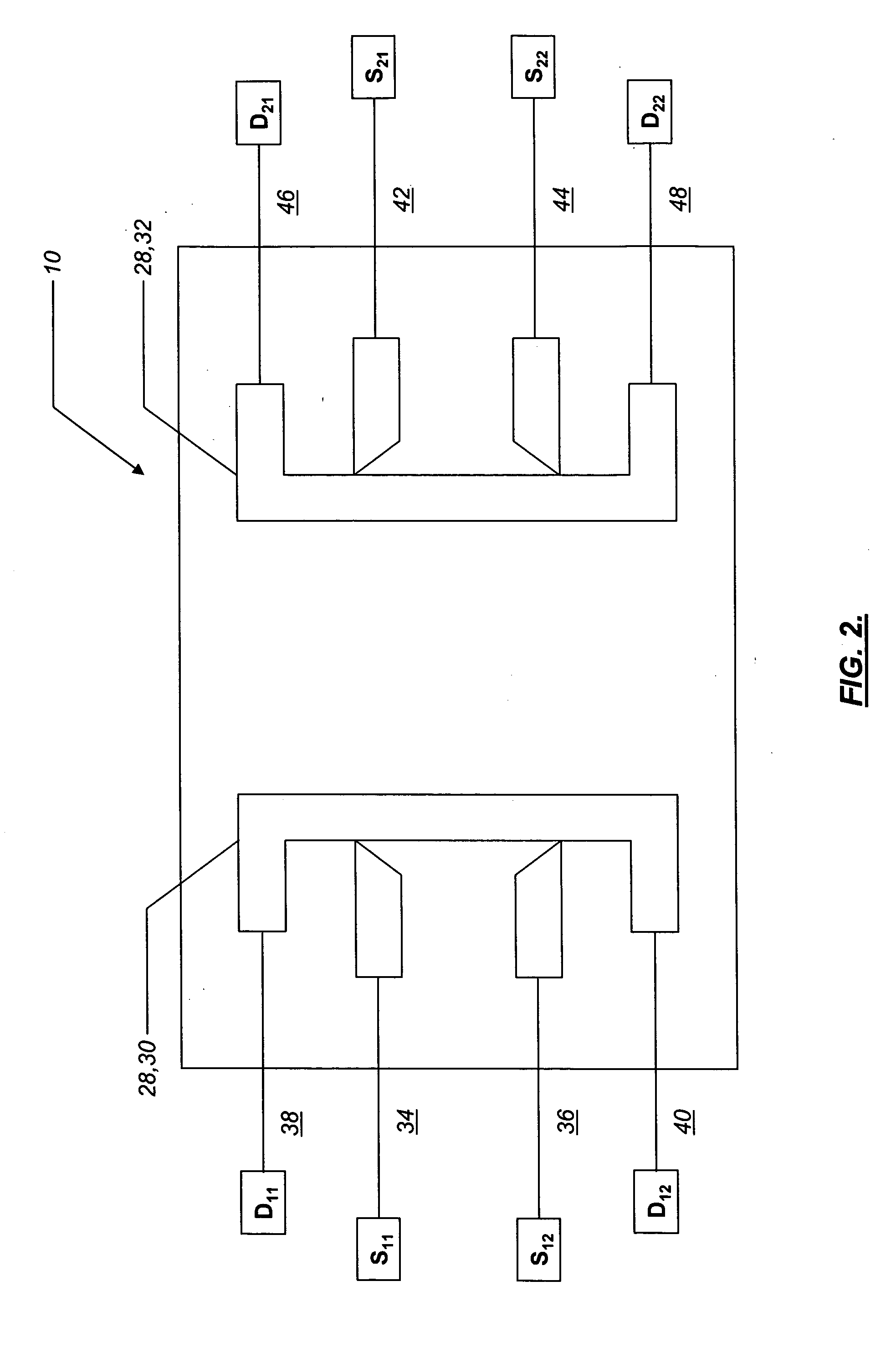

Nano-calorimeter device and associated methods of fabrication and use

InactiveUS20050254547A1Low thermal conductivity and heat capacityAdequate temperature controlMaterial heat developmentNanosensorsNanometreMembrane configuration

The present invention provides a nano-calorimeter device operable for measuring and characterizing the thermodynamic and other physical properties of materials that are confined to essentially nano-scale dimensions. The nano-calorimeter device including a thin film membrane having a first surface and a second surface. The nano-calorimeter device also including a frame structure disposed adjacent to and in thermal contact with the first surface of the thin film membrane, the frame structure defining a plurality of hollow cells adjacent to and in thermal contact with the first surface of the thin film membrane. The nano-calorimeter device further including one or more micro-heating elements disposed adjacent to and in thermal contact with the second surface of the thin film membrane, the location of the one or more micro-heating elements disposed adjacent to the second surface of the thin film membrane substantially corresponding to the location of the plurality of hollow cells defined adjacent to the first surface of the thin film membrane.

Owner:GENERAL ELECTRIC CO

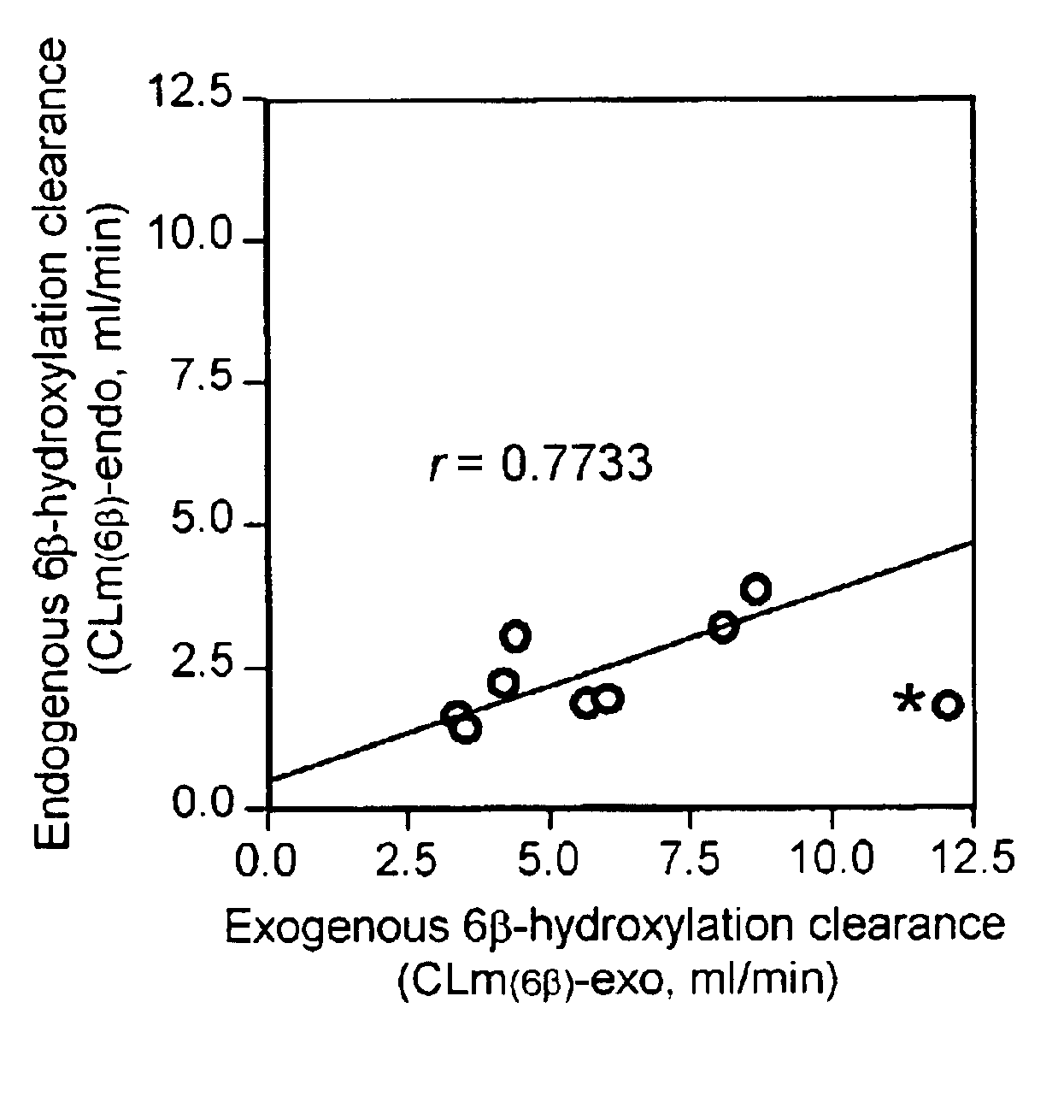

In vivo phenotyping for human cytochrome P450 3A activity

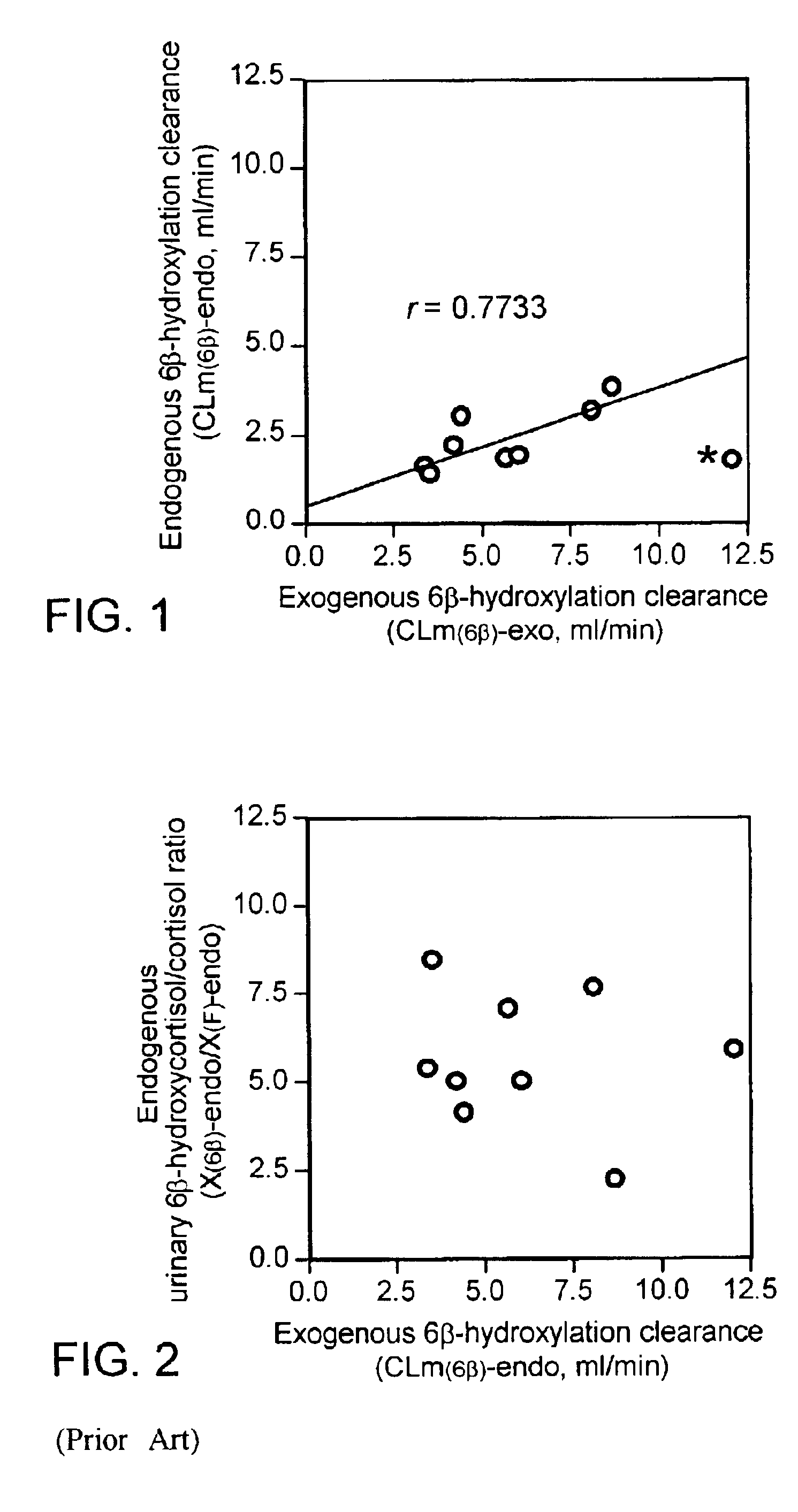

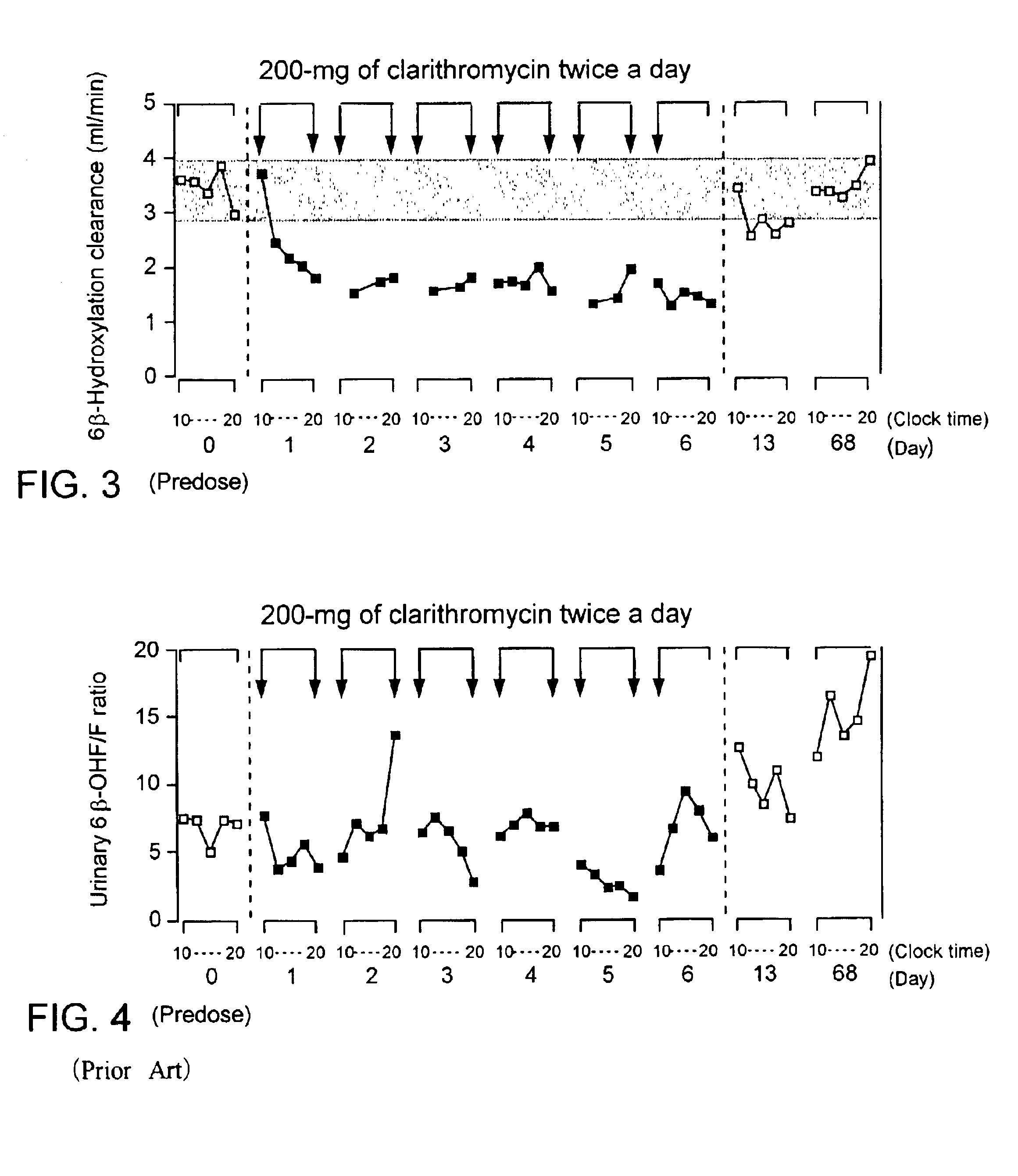

InactiveUS6905839B2Accurate capacityFunctions is unclearCompounds screening/testingMicrobiological testing/measurementUrine productionHaematological sample

In a method for evaluating in vivo human cytochrome P450 3A (CYP3A), at least a 2-hour urine collection and one blood sample are obtained. Endogenous cortisol in plasma and 6β-hydroxycortisol in urine are measured. Metabolic clearance specific for the 6β-hydroxylation of cortisol is then expressed as the amount of urinary excreted 6β-hydroxycortisol divided by the area under the concentration-time curve of cortisol, being a safe and reliable index for CYP3A phenotyping to assess in vivo CYP3A activity in humans.

Owner:FURUTA TAKASHI

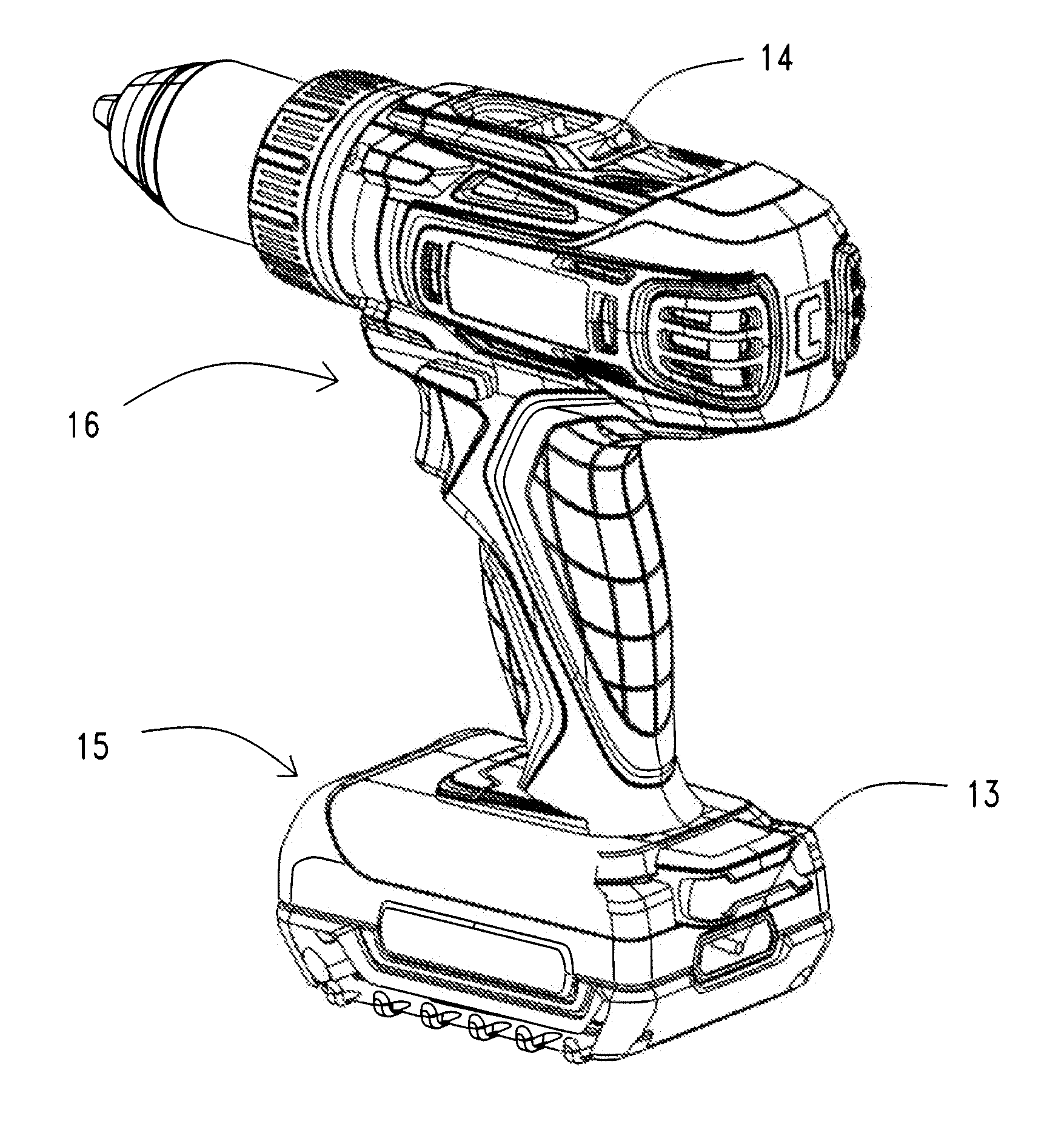

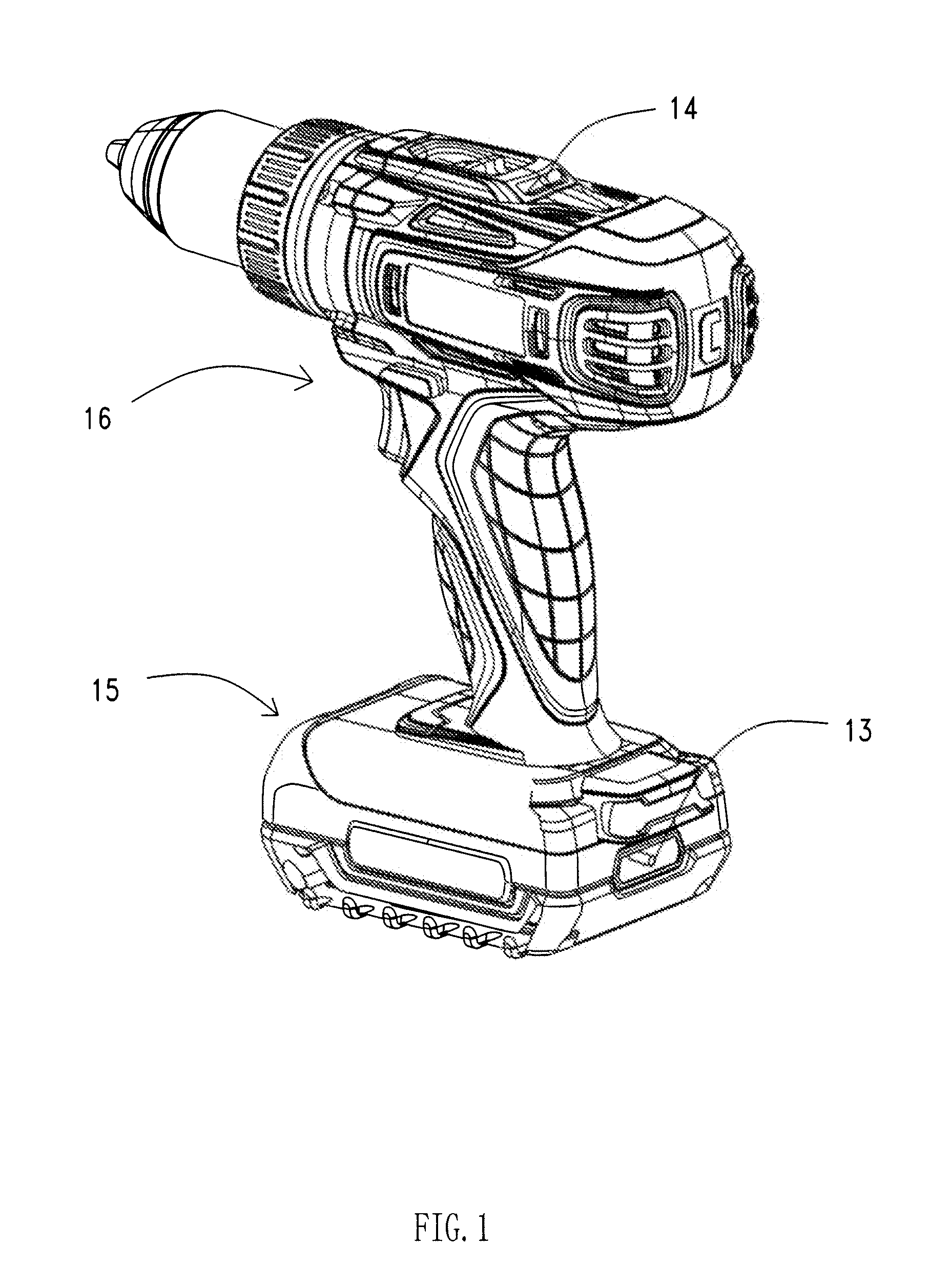

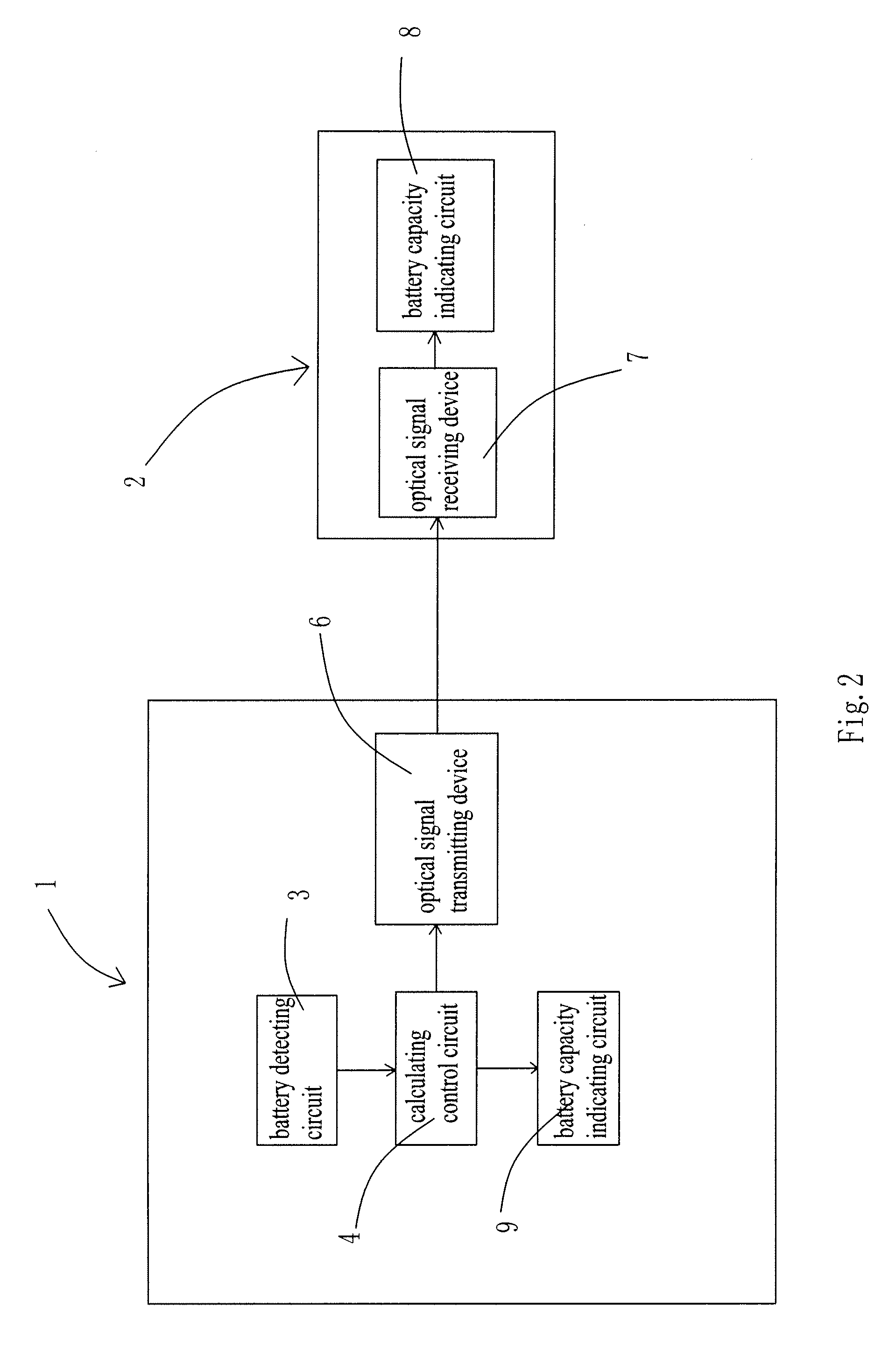

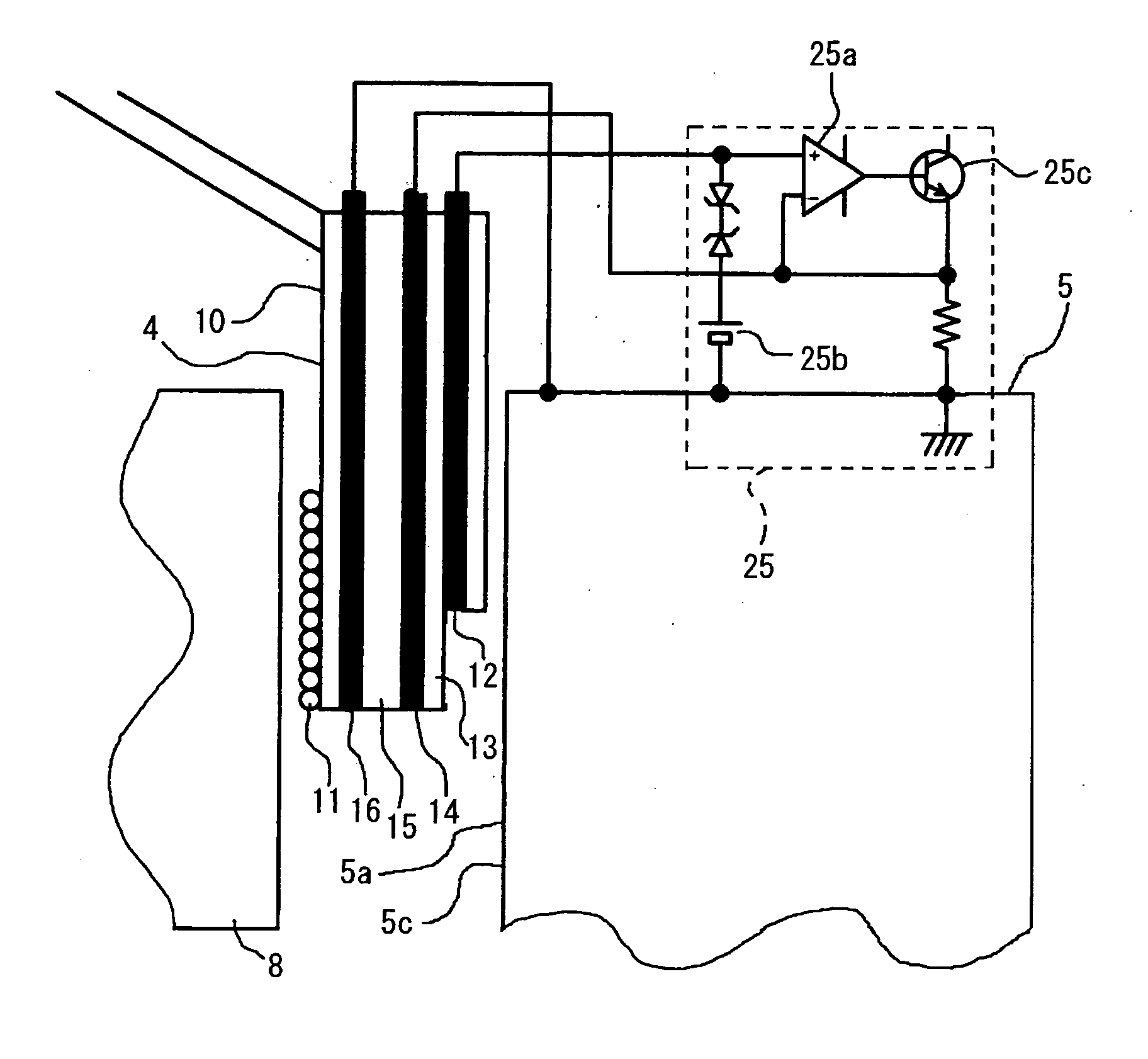

Control circuit and method for manipulating a power tool

ActiveUS20110304287A1Accurate capacityAccurate displaySingle motor speed/torque controlSecondary cellsElectricityElectrical battery

The present application discloses a control circuit for a power tool and a method for manipulating the power tool. The control circuit has a detection circuit for battery packs, a calculating control circuit, a battery capacity indicating circuit for indicating the calculation result of the battery capacity, and a current measure and calculating circuit for measuring the current flowing through motors. The calculation result further includes the voltages consumed by the battery pack internally and the discharge loop. The method for manipulating the power tool includes pressing the switch to electrically connect the motor and the battery pack, measuring the parameters of the battery pack and allowing the motor to operate or not according the measured parameters. Further, after the motor is in operation, the battery capacity is calculated and the results are displayed.

Owner:CHERVON HK LTD WANCHAI

Speaker

InactiveUS20060285704A1Improve electrostatic capacityImprove shielding effectTransducer circuit dampingTransducer casings/cabinets/supportsCapacitanceElectrical conductor

A speaker may include a center pole and a voice coil bobbin having a bobbin that may include nonmagnetic and electric conductor layers and insulator layers disposed between the electric conductor layers. An electrostatic capacity, which is formed between the center pole and the voice coil bobbin, is detected and outputted as an electrical signal.

Owner:CHEMTRON RES

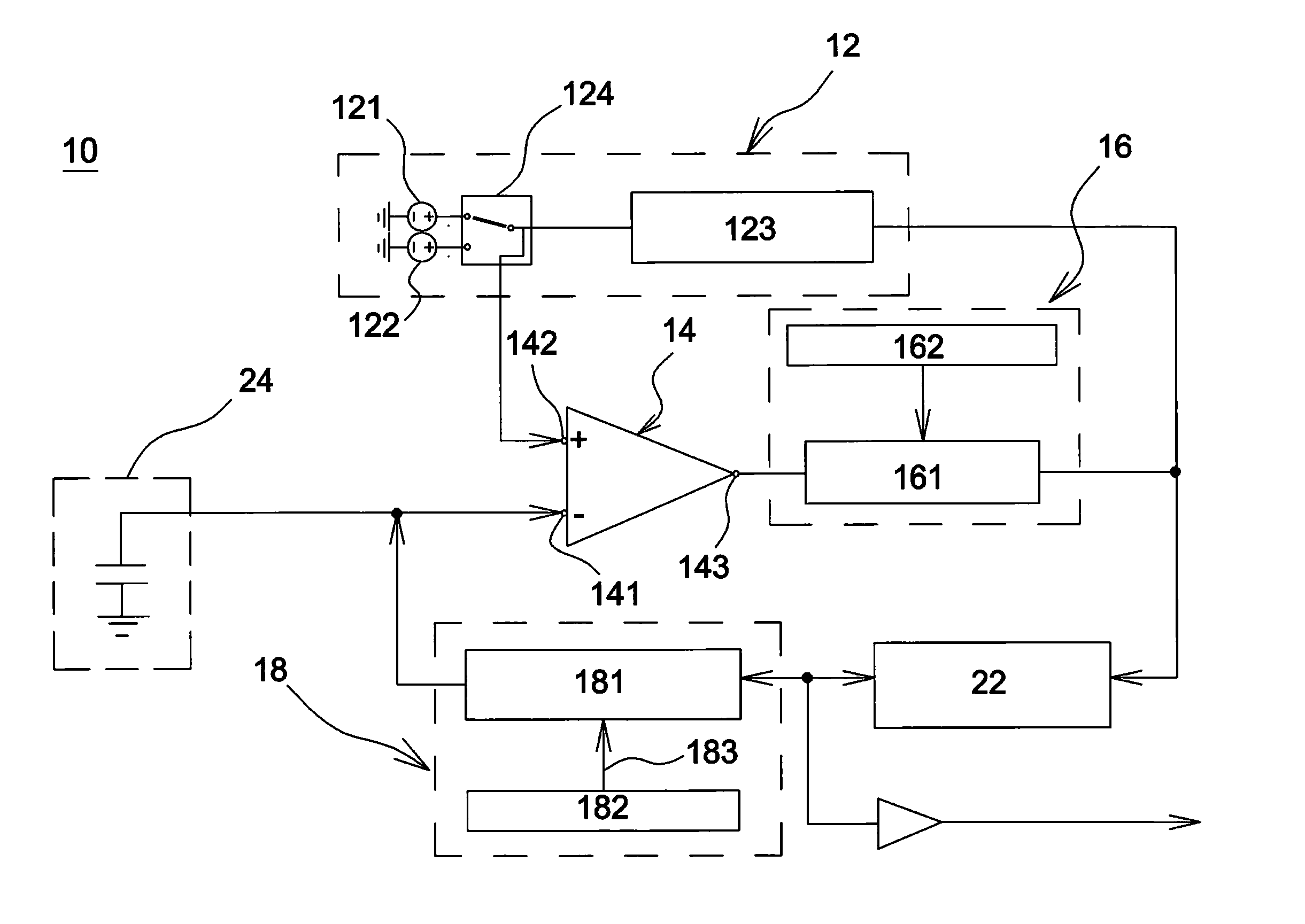

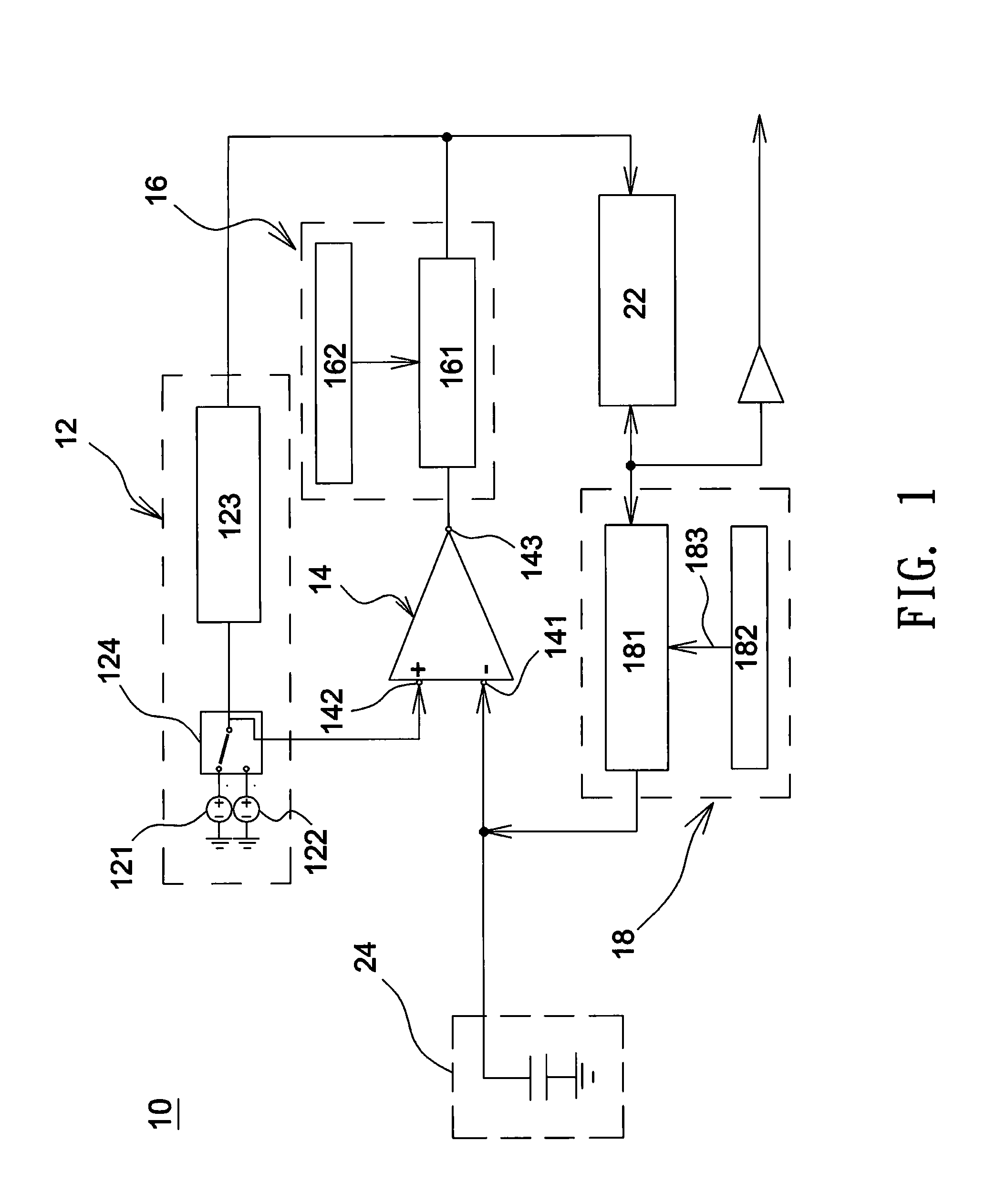

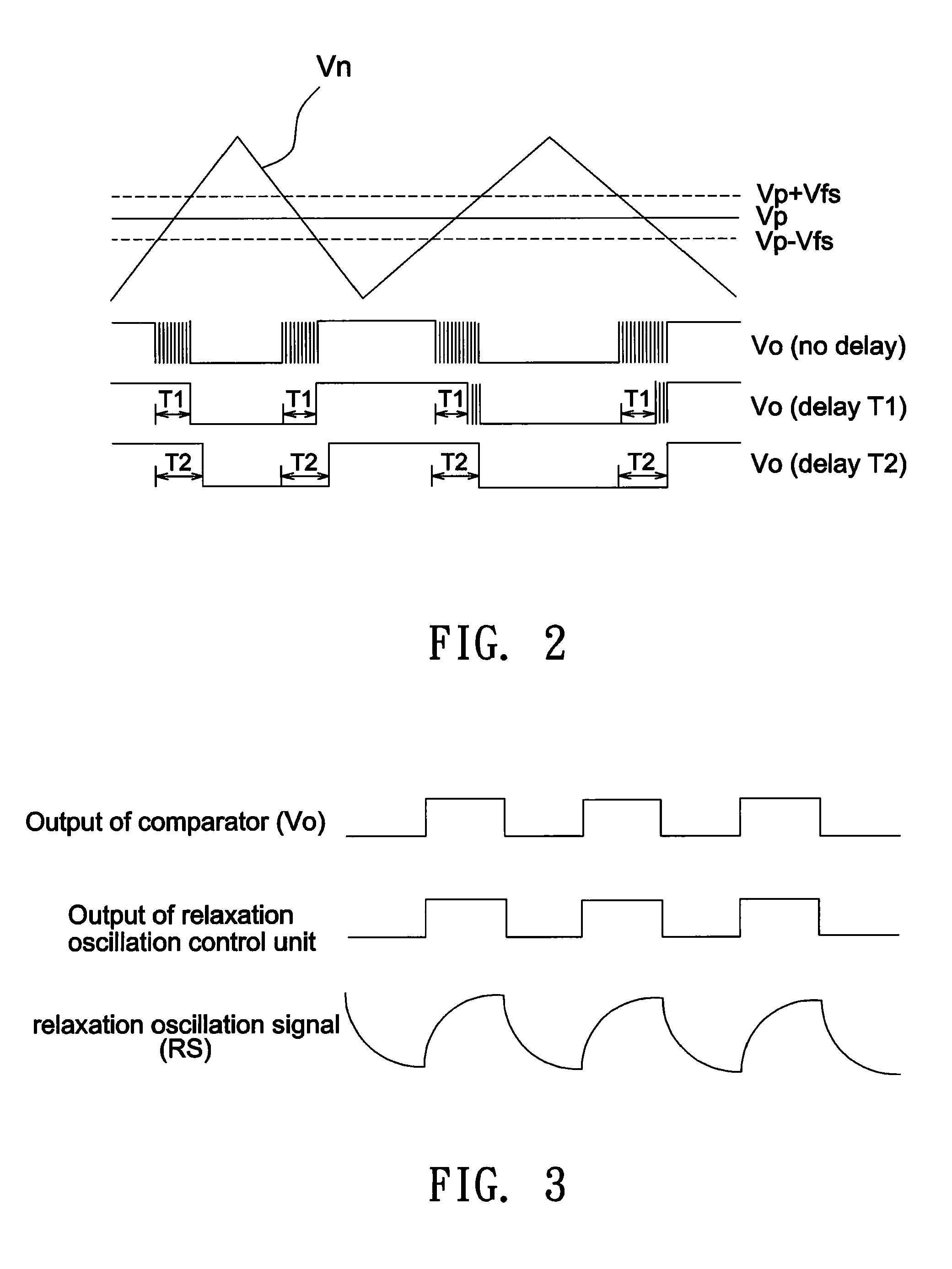

Capacitive touch circuit

InactiveUS20110011717A1Reduce manufacturing costSimple structureElectronic switchingVideo gamesElectricityVoltage reference

A capacitive touch circuit includes a single comparator, a reference voltage control unit, a resistance adjusting unit, a delay unit, and a relaxation oscillation control unit. The comparator has a first input terminal, a second input terminal, and an output terminal. The reference voltage control unit is electrically connected to the second input terminal and includes a high level voltage source, a low level voltage source, and a voltage switching controller. The voltage switching controller electrically connects either the high level voltage source or the low level voltage source to the second input terminal of the single comparator according to an output signal of the single comparator. The relaxation oscillation control unit is electrically connected to the resistance adjusting unit, the delay unit, and the reference voltage control unit. The relaxation oscillation control unit outputs a relaxation oscillation signal, and the frequency of the relaxation oscillation signal varies according to the resistance set by the resistance adjusting unit.

Owner:SONIX TECH

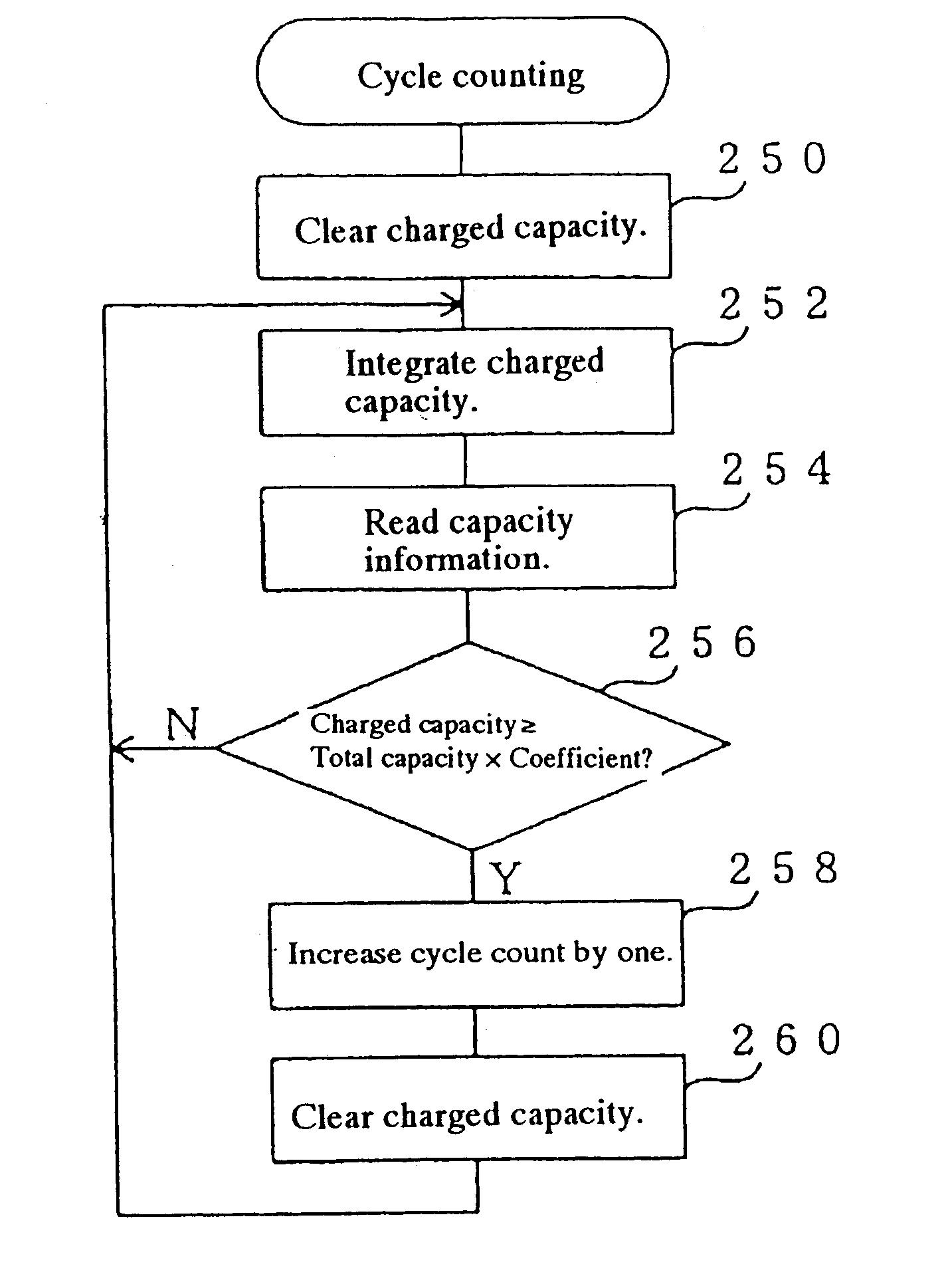

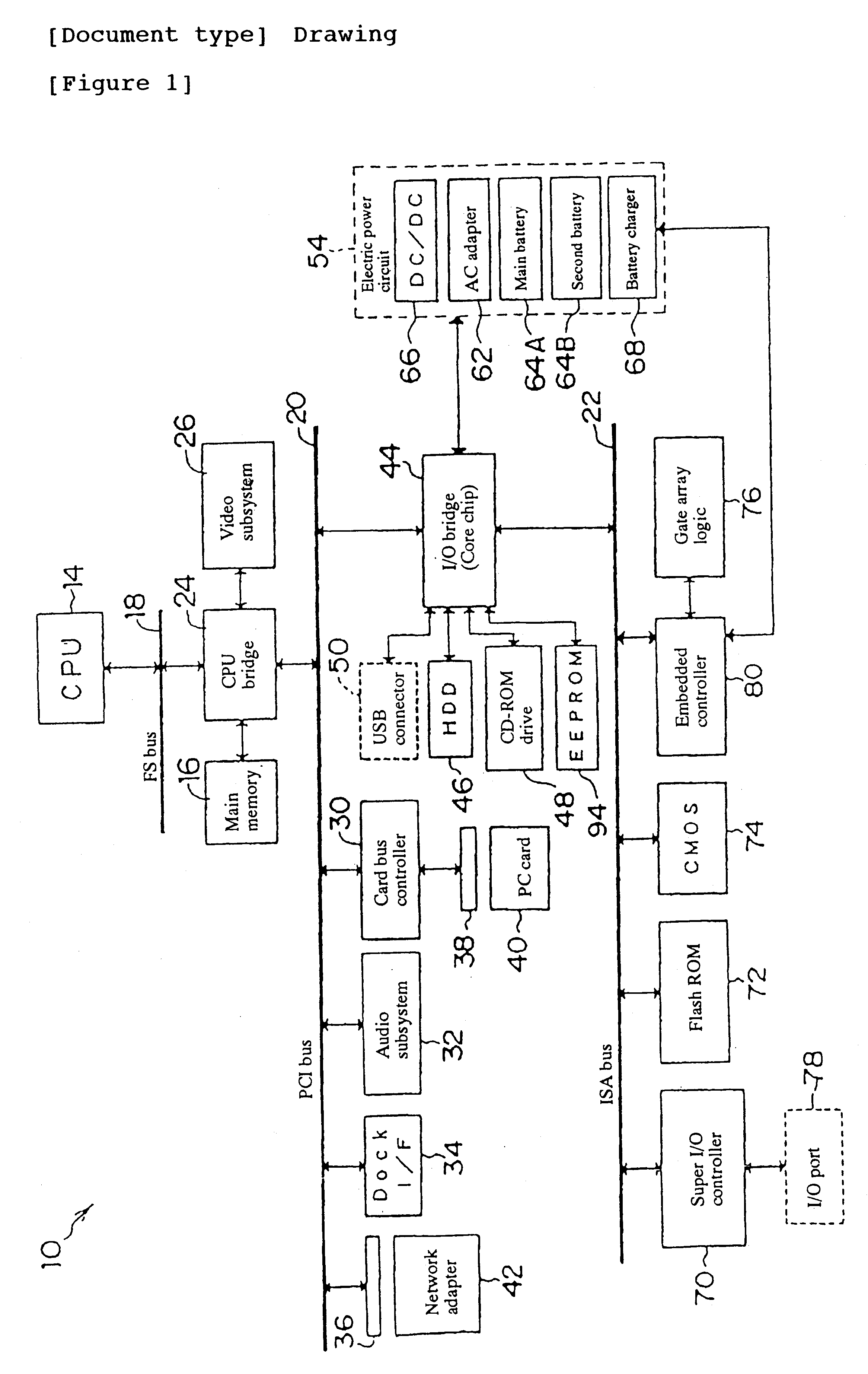

Electronic power unit with a battery and a compensator for calculating the actual charge capacity of the battery

InactiveUS6910143B2Accurate compensationAccurate capacityBatteries circuit arrangementsVolume/mass flow measurementBattery chargeElectrical battery

A main battery used as an electric power unit for a computer is provided with a memory that stores capacity information denoting the total capacity of a battery and compensation information representing the total capacity of the battery as a function of a battery charging cycle count. A CPU detects a cycle count of the battery according to an integrated charged capacity of the battery, thereby obtaining the total capacity with respect to this cycle count from the compensation information so as to compensate the capacity information according to the obtained total capacity.

Owner:LENOVO PC INT

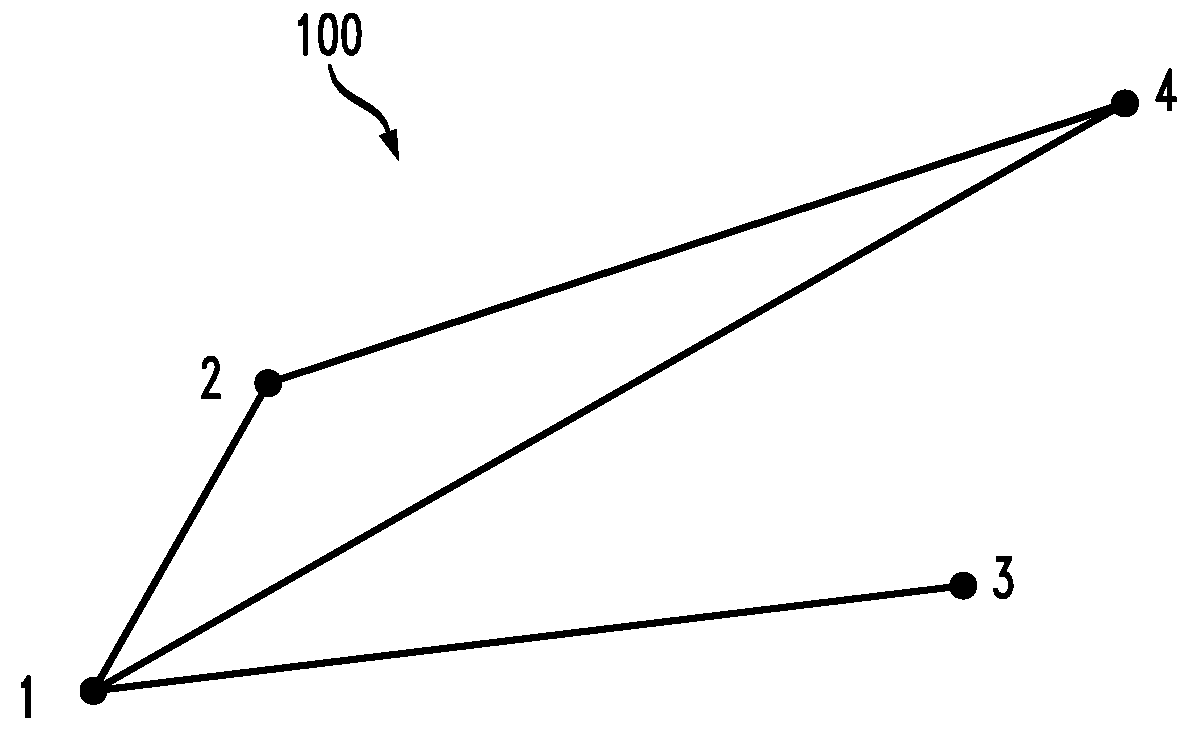

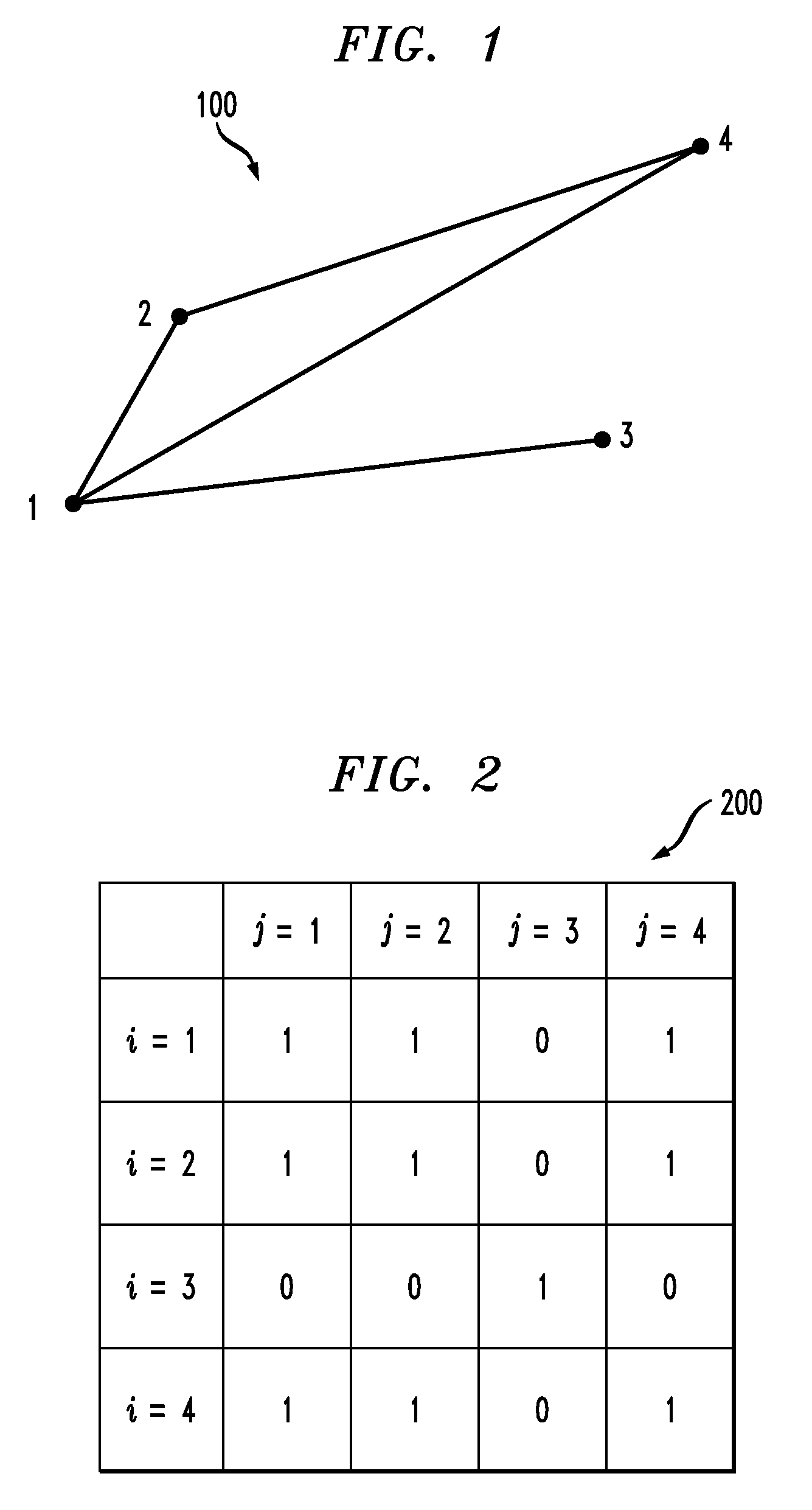

Method to predict edges in a non-cumulative graph

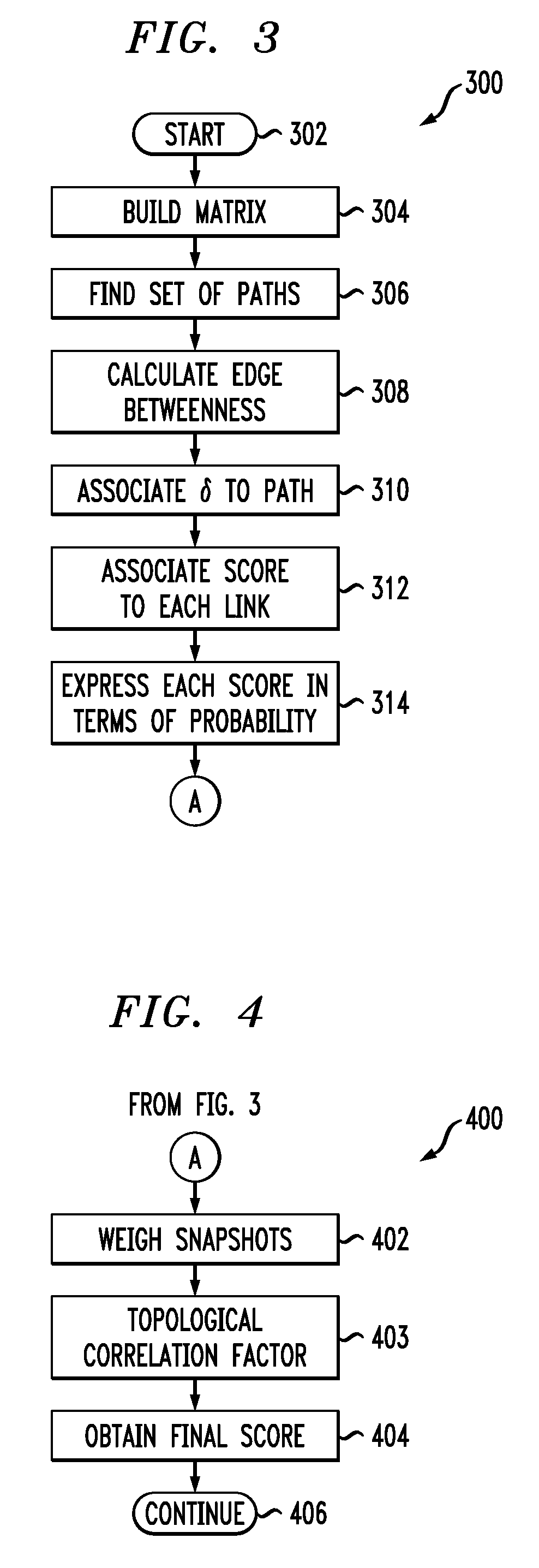

InactiveUS20090141028A1Accurate capacityDrawing from basic elementsAnalogue computers for electric apparatusAlgorithmComputer science

To predict edges in a non-cumulative graph, based on a sequence of non-cumulative previous occurrences of the graph, the sequence of non-cumulative previous occurrences of the graph is obtained, and topological properties of each of the previous occurrences of the graph are extracted. Topological similarities between each of the previous occurrences of the graph are computed based on the topological properties. The edges of the graph are predicted by computing a score for each possible edge of the graph, based upon the topological similarities.

Owner:AIRBNB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com