AC pulse arc welding control method

A technology of arc welding and control method, which is applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of arc disappearance, welding status instability, electrode reduction, etc., and achieve the purpose of suppressing arc disappearance, reducing sputtering, reducing The effect of small splashes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

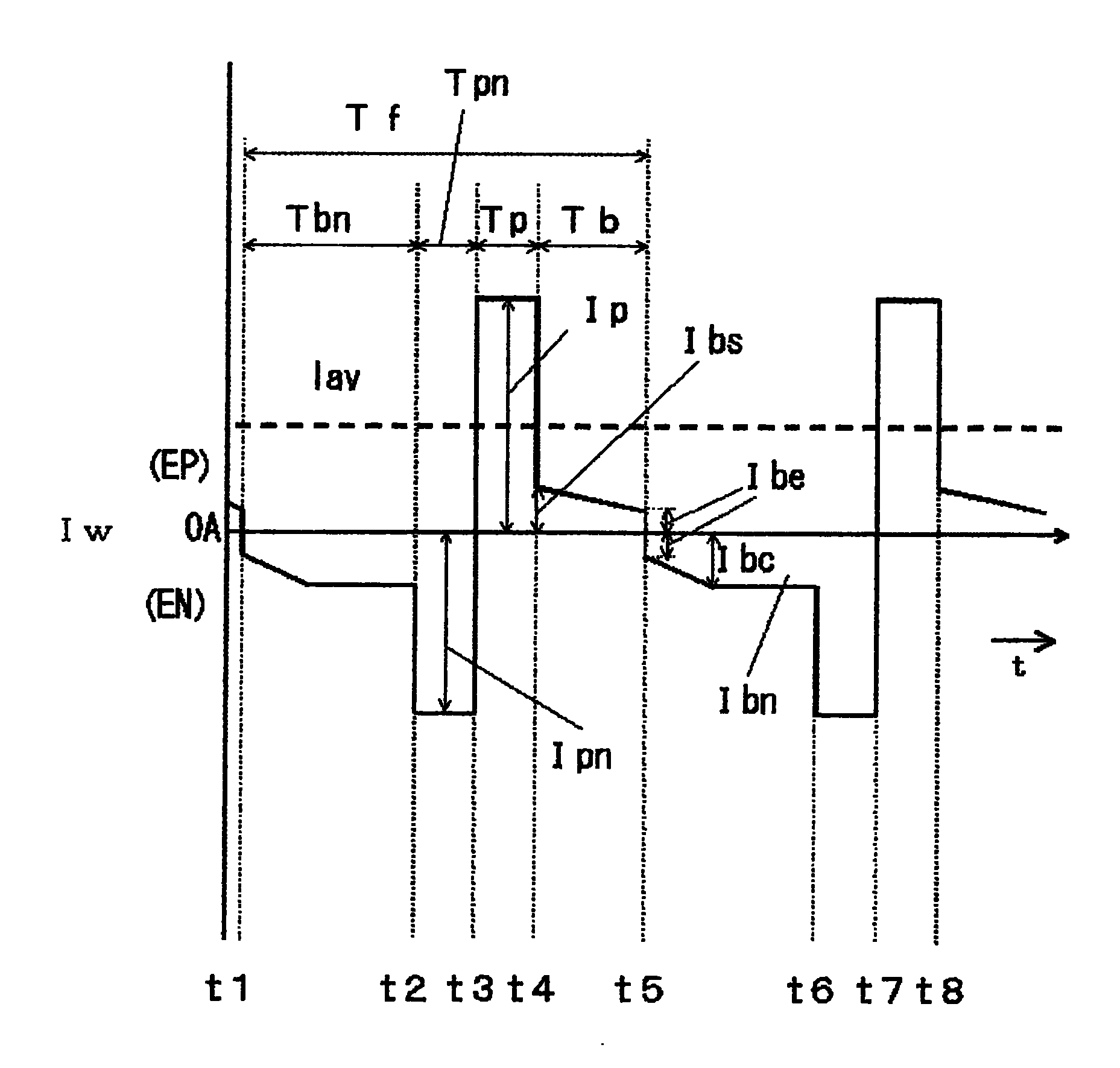

[0107] figure 1 It is a waveform diagram showing the welding current Iw of the AC pulse arc welding control method according to Embodiment 1 of the present invention. exist figure 1 In , starting from 0A, the upper side represents the positive polarity of the electrode EP, and the lower side represents the negative polarity of the electrode EN. figure 1 This indicates that the electrode negative polarity current ratio is set larger than the normal range (about 0 to 30%). exist figure 1 In this method, in order to prevent arc extinction at the time of polarity switching, a high voltage is applied between the welding wire and the base metal for a short period of time at the time of polarity switching. figure 1 with the above Figure 4 Correspondingly, and are the same except for the operation of the electrode positive polarity base period Tb and the electrode negative polarity base period Tbn, so the description thereof is omitted. Below, refer to figure 1 Be explained....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com