Method and device for preventing slip of work piece

A workpiece and anti-slip technology, which is applied in the control of workpiece feed movement, machine tools designed for grinding workpiece rotating surfaces, grinding workpiece supports, etc., can solve the problems of undetectable abnormal rotation, etc., and achieve anti-slip and high-precision measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

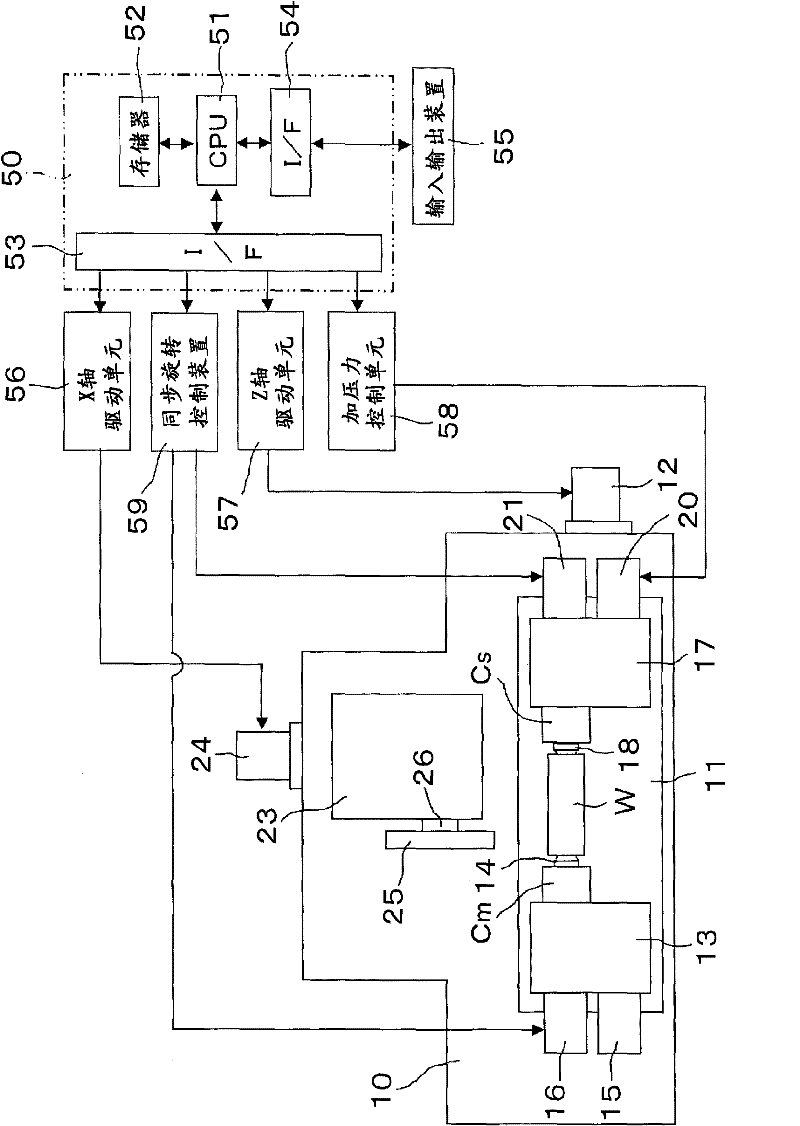

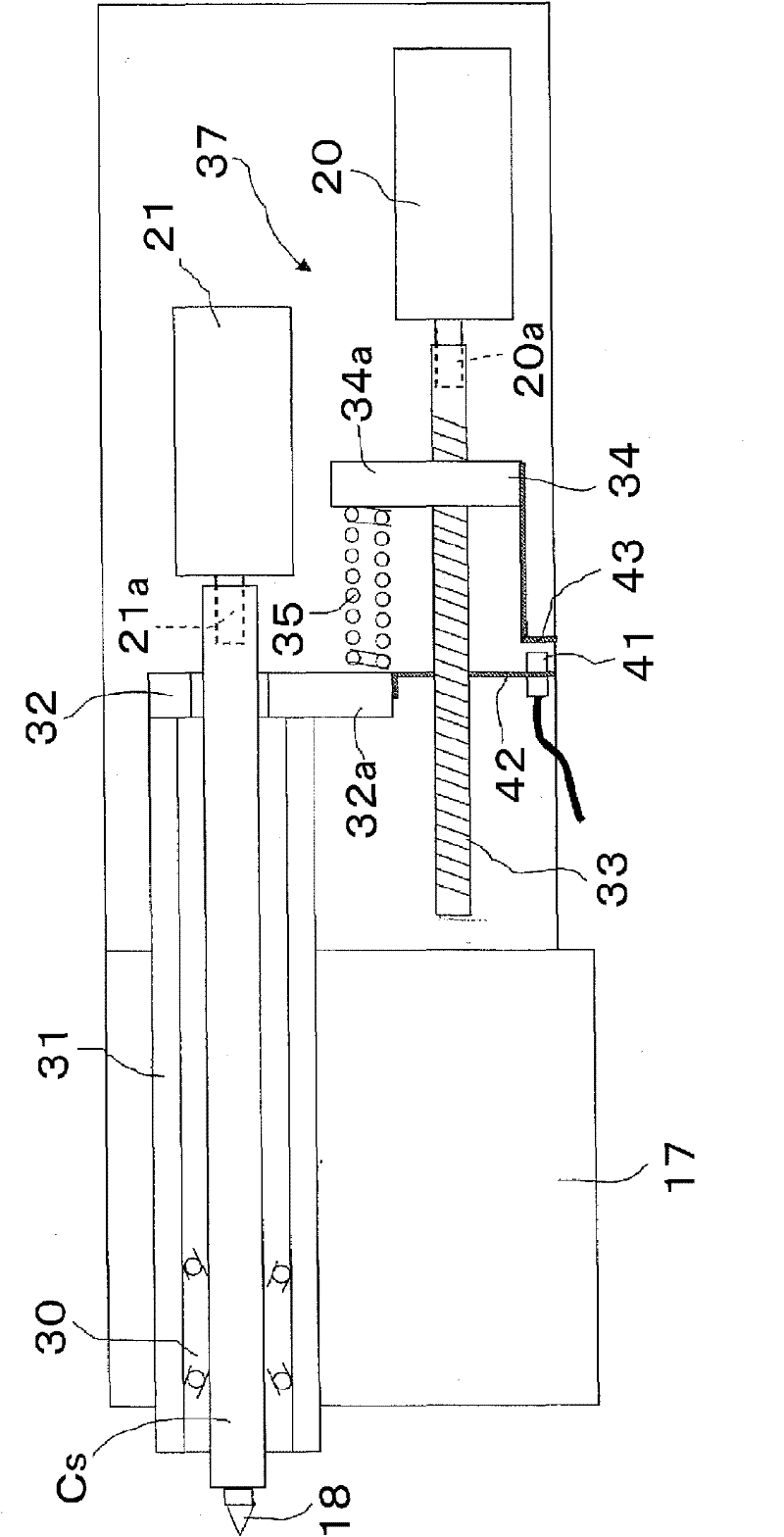

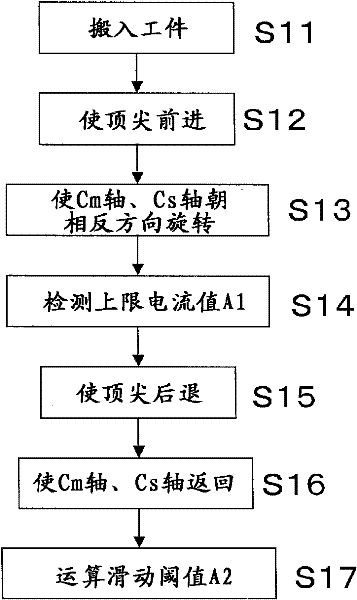

[0049] Embodiments of the present invention will be described below based on the drawings. like figure 1 As shown, on the bed 10 of the grinding machine, the workbench 11 is guided and supported by the Z-axis servo motor 12 and can move along the Z-axis direction ( figure 1 left and right directions) to move. The table 11 is provided with a headstock 13 rotatably supporting the main spindle Cm, and a center 14 supporting one end of the workpiece W is attached to the end of the main spindle Cm. The main spindle Cm is formed to move forward and backward by a predetermined amount in the axial direction by the forward and backward drive device 15 , and is driven to rotate by the main servo motor 16 .

[0050] On the table 11, a tailstock 17 is provided at a position opposite to the headstock 13. On the tailstock 17, the driven spindle Cs is supported coaxially with the driving spindle Cm so that the driven spindle Cs The main shaft Cs is rotatable, and a center 18 supporting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com