Method of inspecting defect for electroluminescence display apparatus, repairing method and manufacturing method

An electroluminescence display and manufacturing method technology, applied in electroluminescence light sources, electric light sources, measuring devices, etc., can solve problems such as inspection methods that have not yet been established, and achieve the effects of easy automatic defect determination and improved correction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, the best mode of carrying out this invention (hereinafter referred to as "embodiment") will be described with reference to the drawings.

[0046] [check principle]

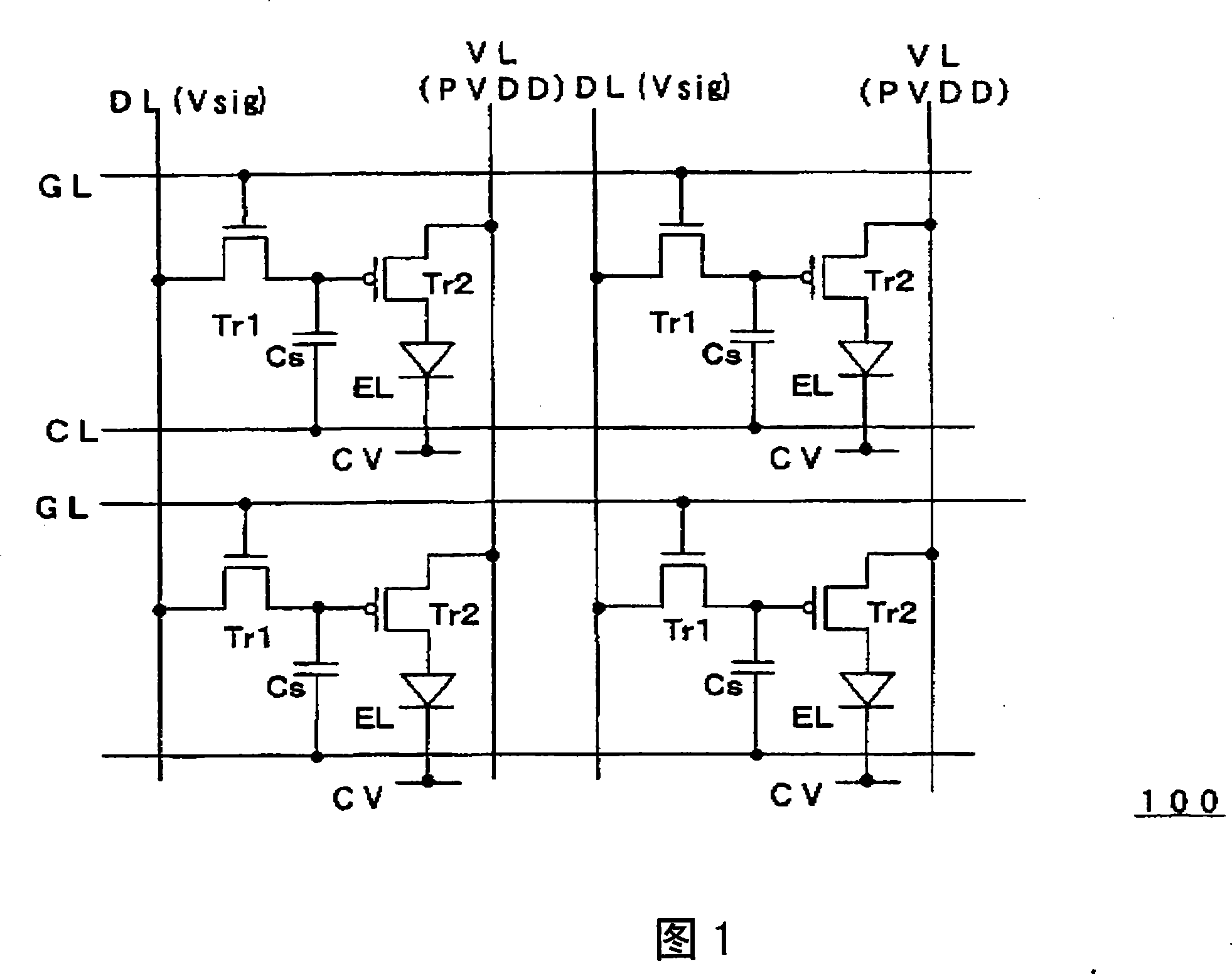

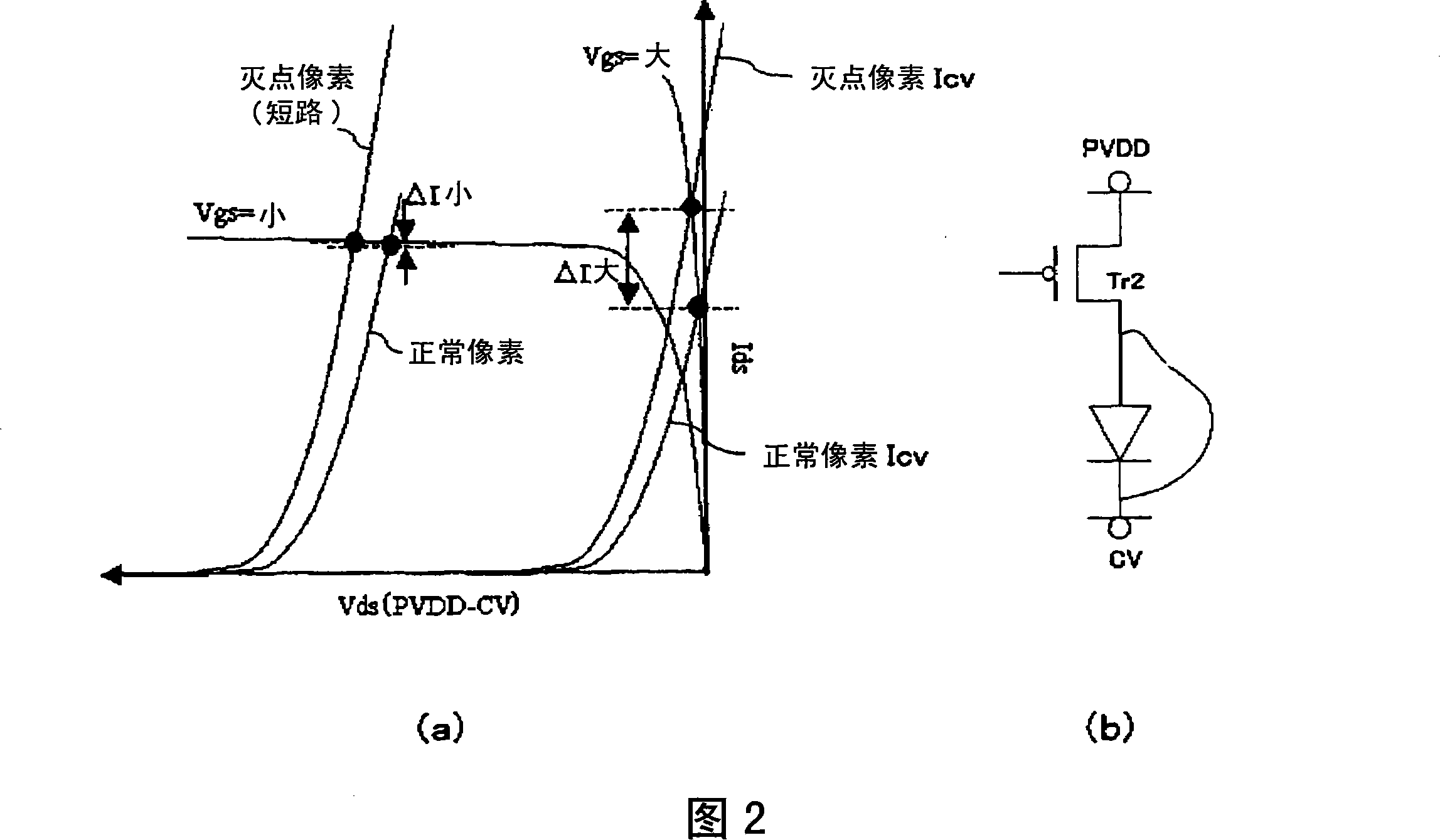

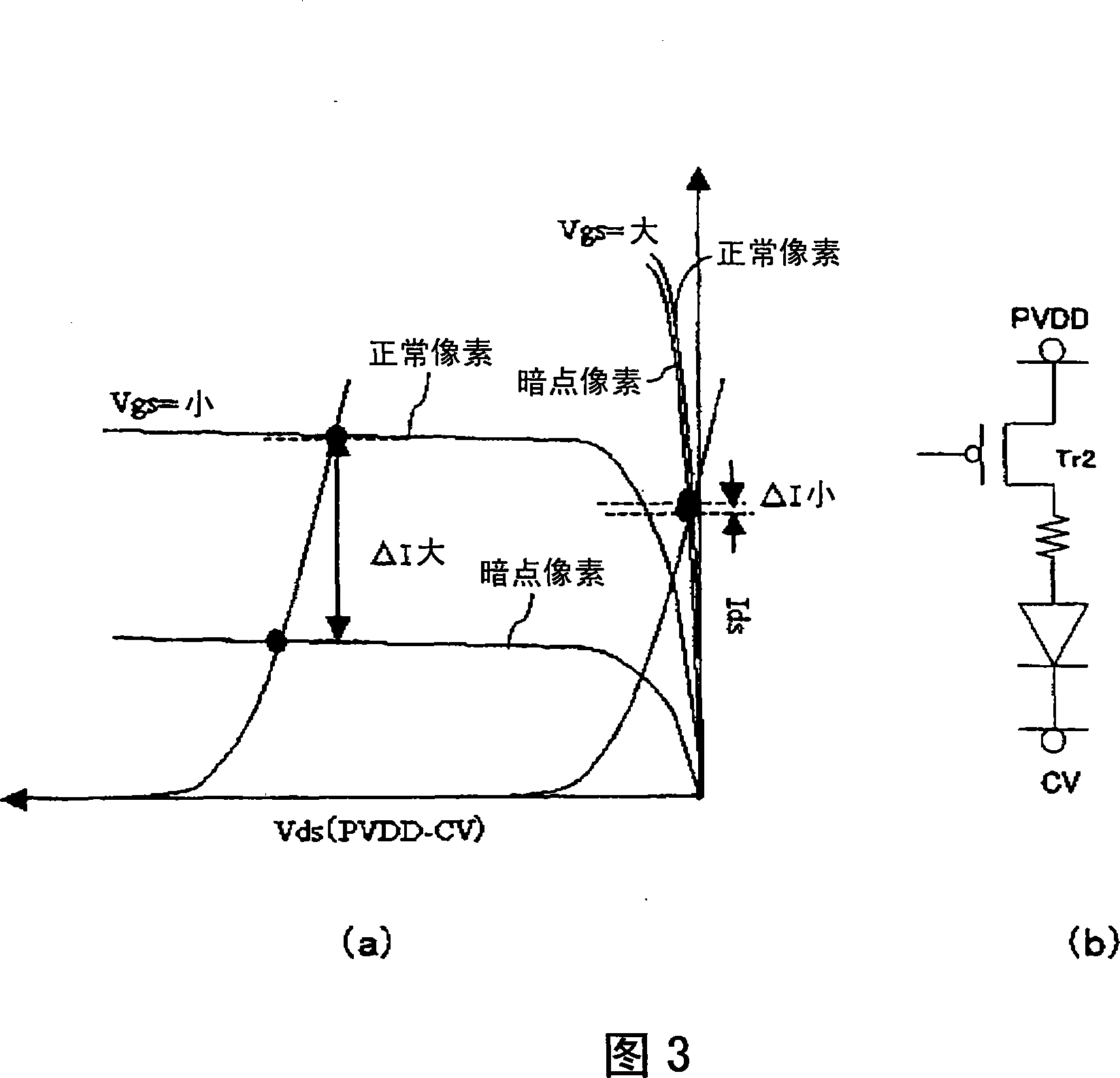

[0047] In the present embodiment, the display device is specifically an active matrix organic EL display device, and a display unit including a plurality of pixels is formed on the EL panel 100 . FIG. 1 is a diagram showing an equivalent circuit configuration of an active matrix display device in this embodiment, and FIGS. 2 and 3 show the principle of defect inspection for each pixel of the EL display device used in this embodiment. In the display portion of the EL panel 100, a plurality of pixels are arranged in a matrix, and in the horizontal scanning direction (row direction) of the matrix, selection lines GL for sequentially outputting selection signals are formed, and in the vertical scanning direction (column direction), A data line DL for outputting a data signal and a power line VL fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com