Precharge control circuit and control method for high-voltage system of hybrid electric vehicle

A hybrid vehicle and high-voltage system technology, applied in electric vehicles, electrical devices, vehicle components, etc., can solve problems such as vehicle damage or injury, potential safety hazards, electric shock, etc., to improve the safety of use, save production costs, guarantee The effect of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

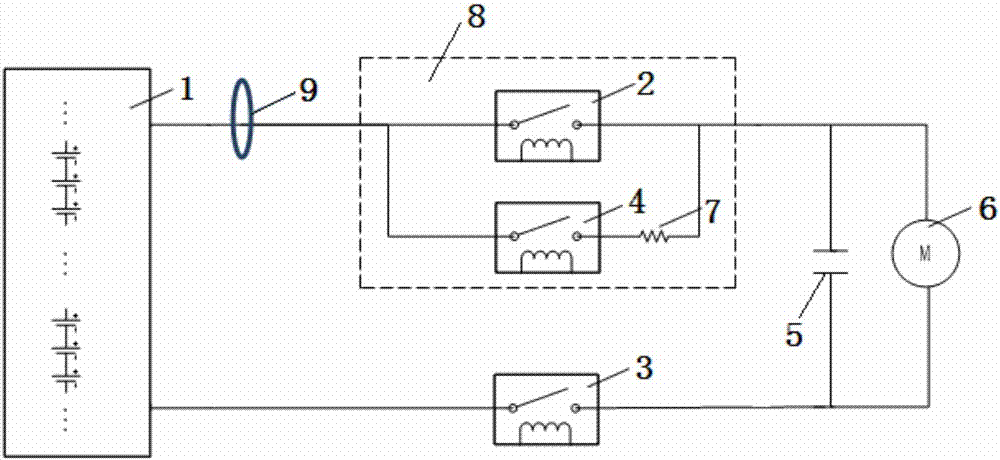

[0018] A pre-charge control circuit for a high-voltage system of a hybrid electric vehicle, such as figure 1 As shown, it includes the power battery pack 1, the main positive relay 2, the main negative relay 3, the pre-charging relay 4, the capacitor 5 and the motor 6, and one end of the main positive relay 2 and the main negative relay 3 is respectively connected to the positive end of the power battery pack 1 , the negative terminal, the other end of the main positive relay 2 and the main negative relay 3 are connected to the motor 6, the capacitor 4 is connected to both ends of the motor 6 in parallel, and the pre-charging relay 4 is connected in series with the pre-charging resistor 7 and then connected to the main positive relay 2 A parallel circuit 8 is formed at both ends, and a shunt 9 is provided between the parallel circuit 8 and the positive terminal of the power battery pack 1 .

Embodiment 2

[0020] A kind of precharge control method of hybrid electric vehicle high voltage system, according to the precharge control circuit of hybrid electric vehicle high voltage system as described in embodiment 1, carry out according to the following steps,

[0021] Ⅰ After the weak current is connected to the high-voltage system, the BMS controls and closes the main negative relay, and the BMS collects the current value of the shunt at this time and uses it as the initial value of the current I 0 , and then execute step II;

[0022] Ⅱ BMS controls the closed pre-charging relay to pre-charge the capacitor, and the BMS collects the current value I of the shunt every 2ms n , calculate the current slope value L of the shunt in turn according to the formula (a) n and the current slope value of the shunt L n Stored in a data buffer of the BMS in turn, the data buffer is a queue structure, and its update method is first-in-first-out. If the high-voltage system meets the following thre...

Embodiment 3

[0026] A pre-charging control method for a high-voltage system of a hybrid electric vehicle, the steps of which are similar to the pre-charging control method for the high-voltage system of a hybrid electric vehicle in Embodiment 2, the difference being that in step II, the BMS collects the current of the shunt The value interval time T is 800μs, and the condition (1) is that the BMS detects that the current slope values of the shunt for the last 30 consecutive times are all distributed in the range of -0.2 ~ 0.1mA / ms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com