Brake control device for elevator

A technology for brake control and elevators, which is applied to brake actuators, transportation and packaging, elevators, etc., and can solve problems such as joint deterioration, passenger discomfort, and high costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0039] First, a first embodiment of the present invention will be described.

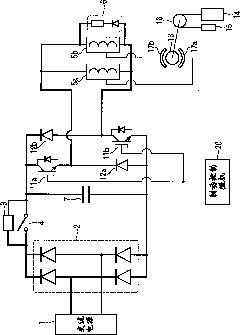

[0040] figure 1 It is a figure which shows the example of the circuit structure of the brake control apparatus of the elevator which concerns on one Embodiment of this invention.

[0041] exist figure 1 In the shown brake control device, the AC power supplied from the AC power supply 1 is full-wave rectified into DC power by the rectifier circuit 2 , and the pulsation of the DC power is smoothed by the smoothing capacitor 7 .

[0042] Such as figure 1As shown, the brake control device is provided with a brake control microcomputer 20 that is a brake control unit that applies predetermined voltages to various elements or opens and closes various switches.

[0043] In addition, a parallel circuit of a limiting resistor 3 and a DC switch 4 is provided between a high potential point on the output side of the rectifier circuit 2 and a high potential point of the smoothing capacitor 7 . This circui...

no. 2 approach

[0063] Next, a second embodiment of the present invention will be described. In addition, the structures of the brake control devices of the following embodiments are the same as figure 1 The ones shown are basically the same, and therefore descriptions of the same parts are omitted.

[0064] Figure 4 It is a figure which shows the example of the circuit structure of the brake control apparatus of the elevator in the 2nd Embodiment of this invention.

[0065] Such as Figure 4 As shown, in the second embodiment of the present invention, compared with the first embodiment, a voltage detector 23a for detecting the voltage across the diode 12a is further provided. Moreover, the voltage detector 23b which detects the voltage of both ends of the diode 12b is provided further. In addition, an AC switch 24 for disconnecting the AC power supply 1 is provided.

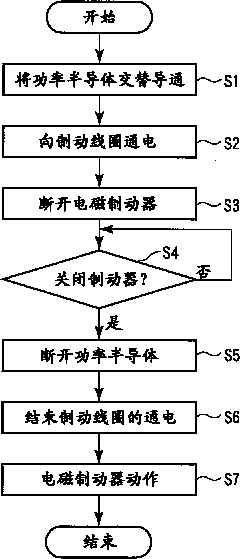

[0066] Figure 5 It is a flowchart showing an example of the operation of the braking control device of the elevator ...

no. 3 approach

[0075] Next, a third embodiment of the present invention will be described.

[0076] Figure 6 It is a figure which shows the example of the circuit structure of the brake control apparatus of the elevator in the 3rd Embodiment of this invention.

[0077] Such as Figure 6As shown, in the third embodiment of the present invention, compared with the second embodiment, a current detector for detecting the current supplied to the brake coils 5a, 5b is provided between the brake coil 5a and the switching element 11b. 25.

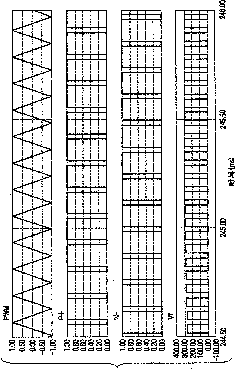

[0078] The brake control microcomputer 20 is different from the operations described in the first and second embodiments. In the PWM control, the switching elements 11a and 11b are controlled to be on and off so that when the current detector 25 detects There is no deviation between the value and the target value, which is the current supplied to the brake coils 5a, 5b in PWM control.

[0079] Generally, the voltage value based on the AC power supply 1 fluct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com