Glue injection and injection molding method for inductors

A technology for inductive components and glue injection, applied in the direction of coating, etc., can solve problems such as constraints, low inductance, and increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

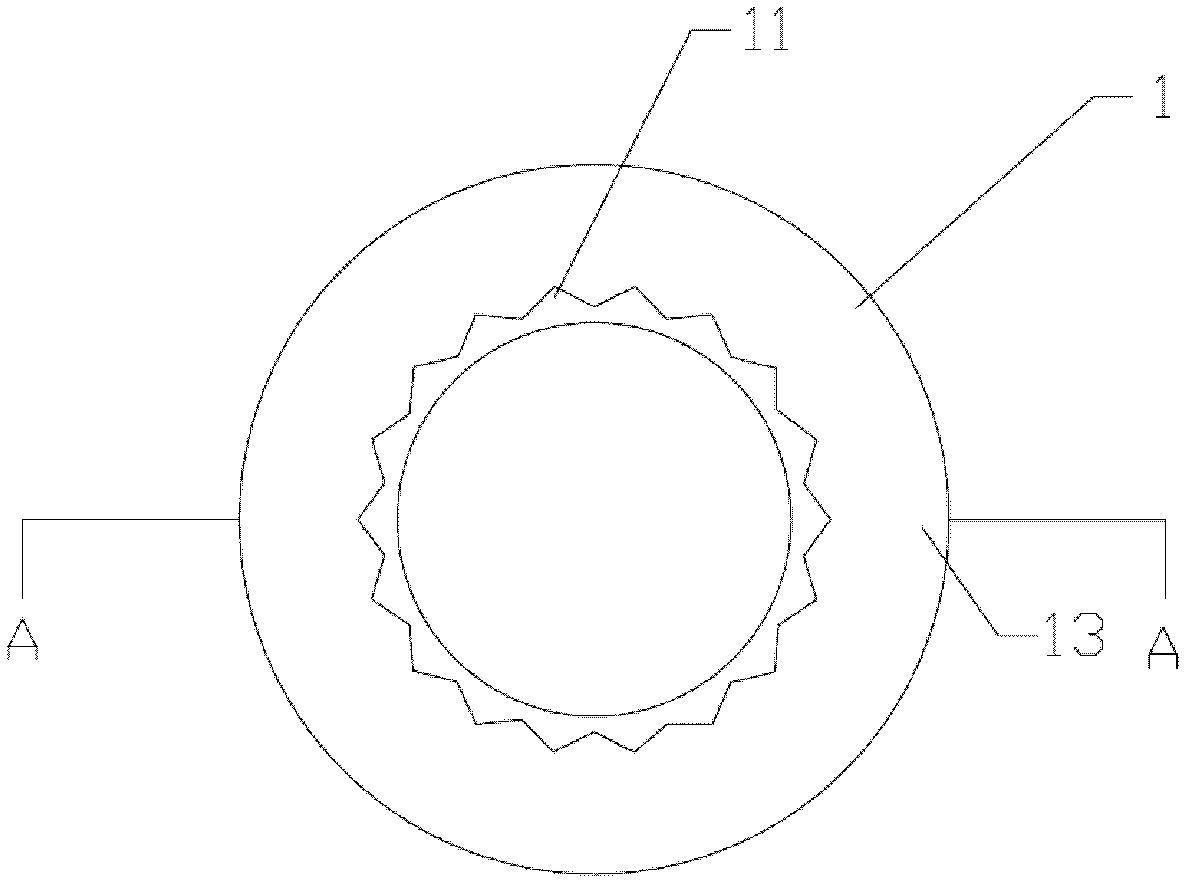

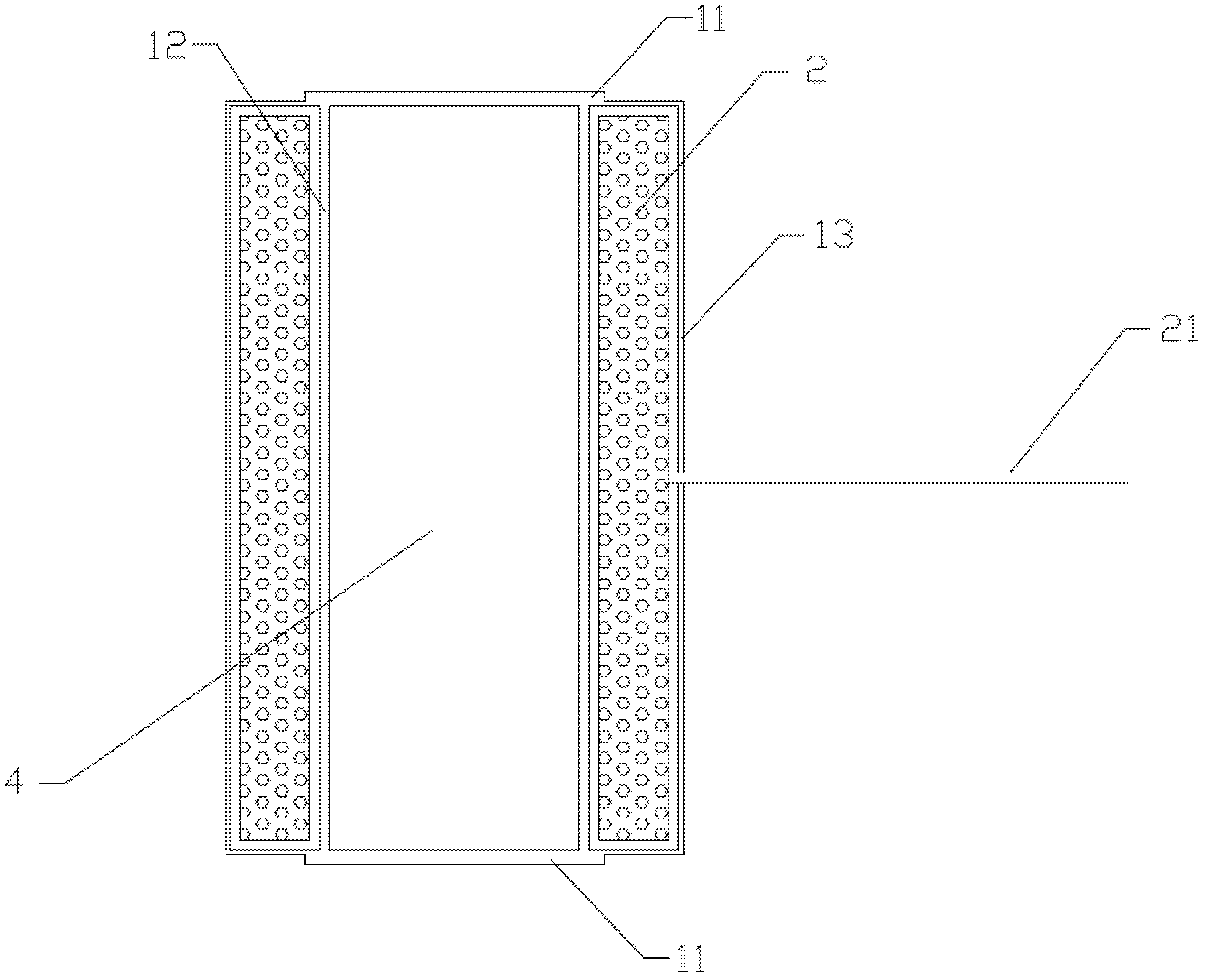

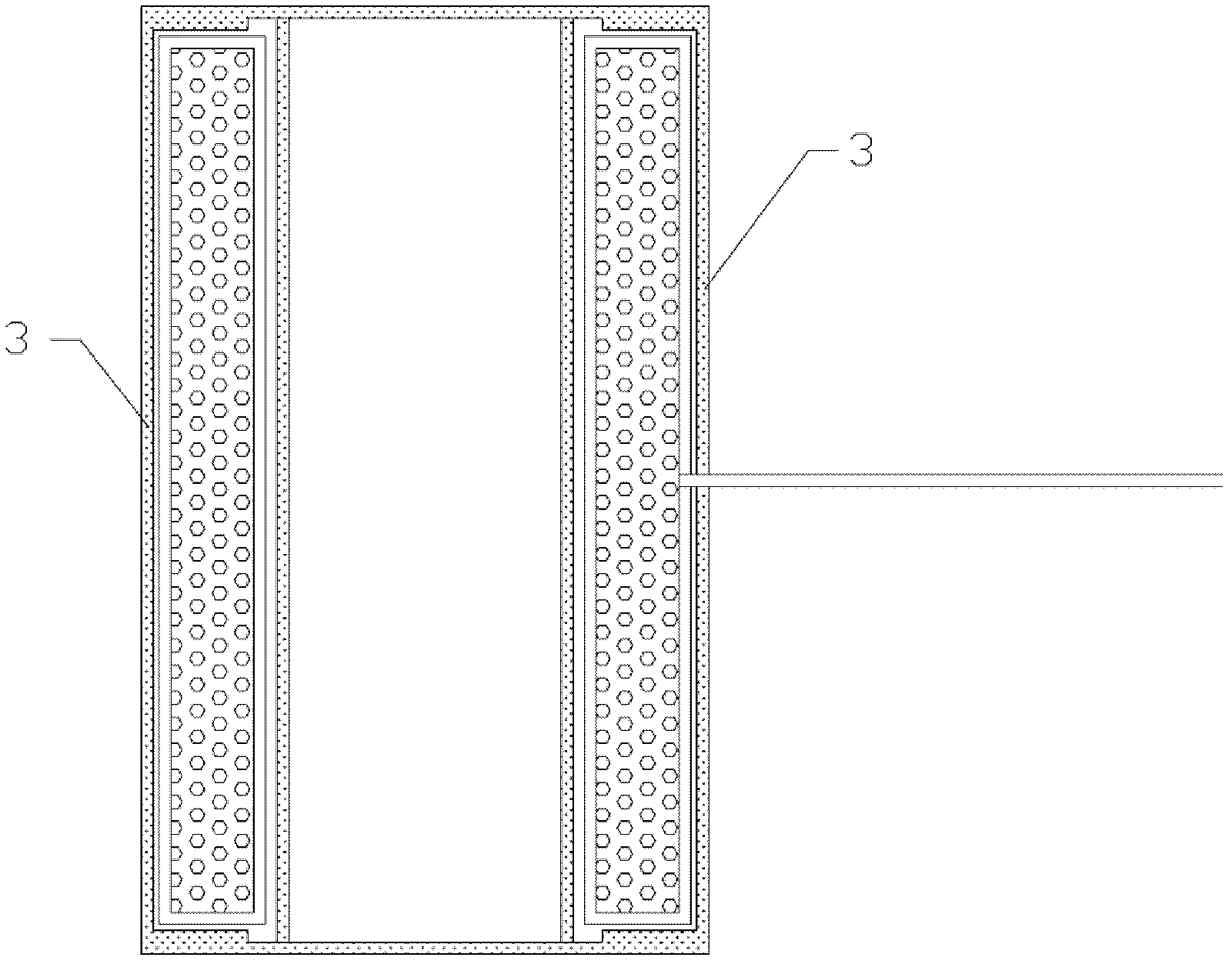

[0025] Such as figure 1 , figure 2 with image 3 As shown, the injection and injection molding method of the inductance element in this embodiment includes the inner layer injection of the first stage and the outer layer injection molding of the second stage:

[0026] The inner layer glue injection is to install a steel mold in a vertical low-pressure glue injection machine, place the inductance element 2 with an iron cover in the steel mold, and put the inductance coil lead-out line 21 of the inductance element 2 into the mold channel And lead out of the steel mold, operate the vertical low-pressure glue injection machine to cover the mold, inject the hot melt adhesive OM646 under the pressure of 5-40bar, and fill the steel mold, and inject a layer of glue on the outer circumference of the inductance element and the through hole 4 , thereby forming the adhesive layer 1, the adhesive layer 1 includes the peripheral adhesive 13 and the annular adhesive 12 adapted to the shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com