Unmanned analysis experiment lab system and its usage method

A laboratory and cooling system technology, applied in the field of industrial analysis, can solve the problems of high probability of sample cooling cracks, difficult to meet the analysis equipment, slow analysis speed, etc., to achieve long equipment maintenance intervals, save system operation time, cooling short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

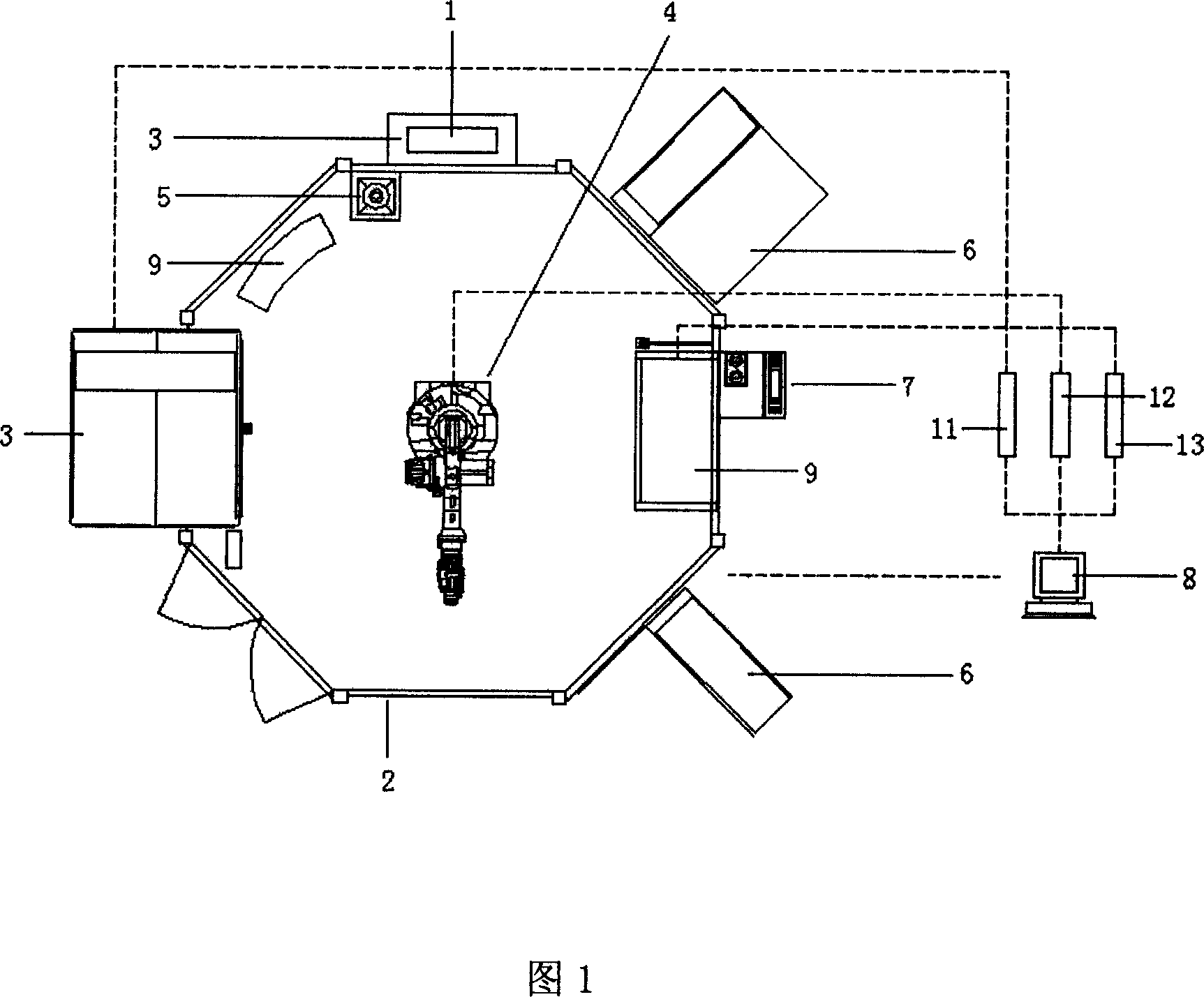

[0013] The unmanned analysis laboratory described in Fig. 1 includes a code input system 1, a safety device 2, a sample cooling and processing device 3, a sample transmission system 4, a defect detection system 5, a spectrum analyzer 6, and a sample code printing system 7 , Laboratory center computer 8, auxiliary system 9.

[0014] The code input system 1 means that the code input terminal is installed on the side of the sample input door of the pneumatic sample sending station, the operator inputs the sample code, the code is transmitted to the central computer through the RS232 interface, and the specific sample code is programmed on site. The central computer distinguishes the sample type according to the sample code and sends a control signal to instruct the sample grinding machine to use which processing program to process the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com