High-temperature sterilizer and sterilizing method adopting high-temperature sterilizer

A technology of high-temperature sterilizers and sterilizing tanks, which is applied to sanitary equipment for toilets, water supply devices, heating, etc., can solve the problems of inaccurate control of sterilization temperature and damage to sterilized items, and avoid packaging rupture, The effect of short cooling time and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

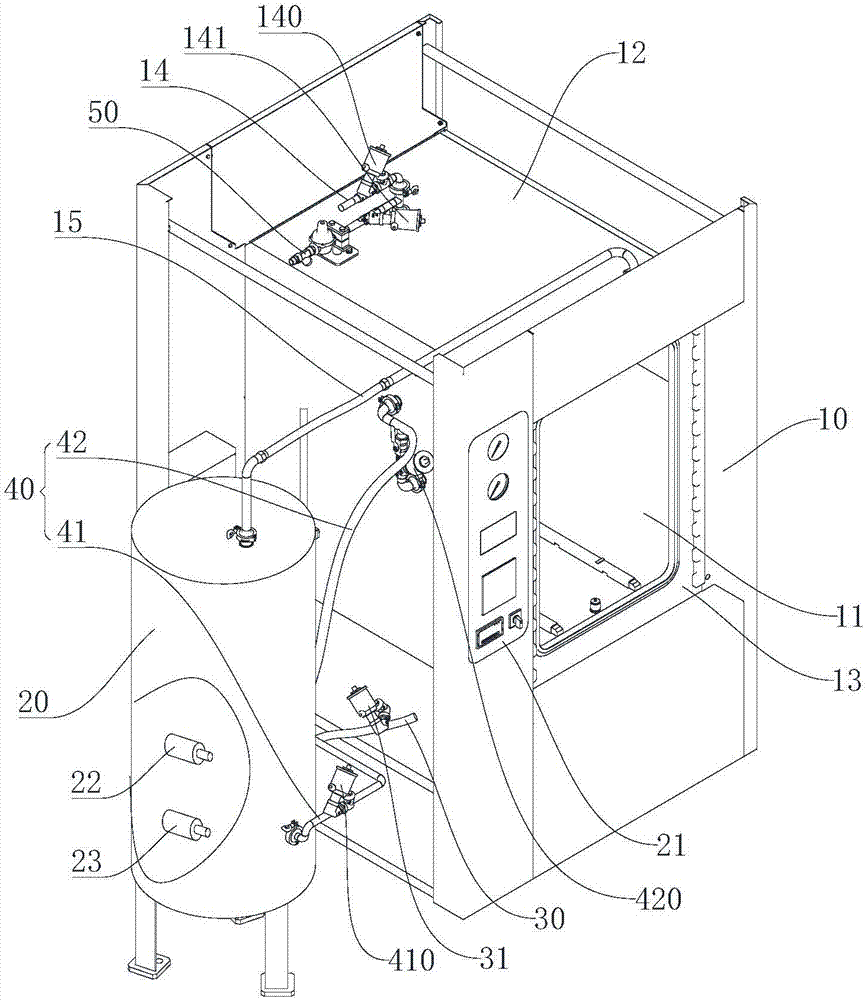

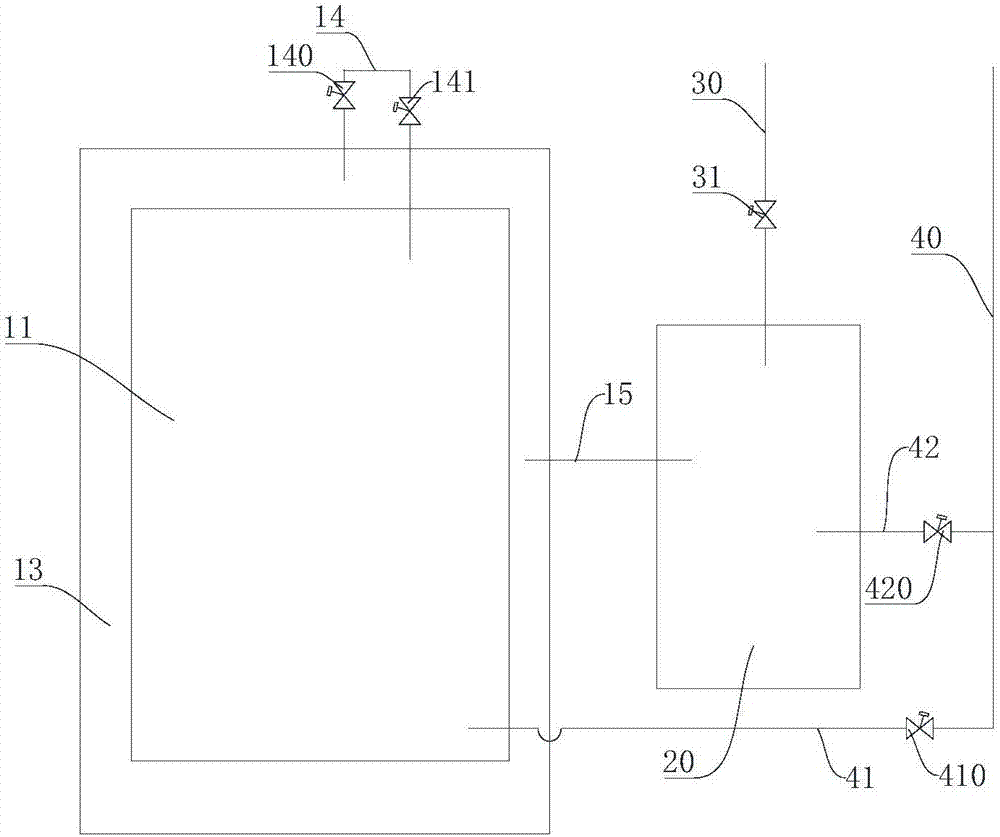

[0037] Please refer to figure 1 with figure 2 As shown, embodiment 1 of the present invention provides a kind of high-temperature sterilizer, comprises sterilization tank 10, mixing tank 20, steam pipeline 30, compressed gas pipeline 40 and water inlet pipeline 50, and sterilized article can be put into sterilizer Sterilization is carried out in the bacteria tank 10, and the function of the mixing tank 20 is to pre-condition the steam, which can fully mix the steam and the compressed gas to make the mixing more uniform and the temperature fluctuation smaller. The steam line 30 is used to add steam to the mixing tank 20, the compressed gas line 40 is used to add compressed gas to the mixing tank 20 and the sterilization tank 10, and the water inlet line 50 is used to supply the steam to the sterilization tank 10 after the sterilization is completed. Water is added to reduce the temperature.

[0038]Specifically, the sterilization tank 10 includes an inner chamber 11 and an o...

Embodiment 2

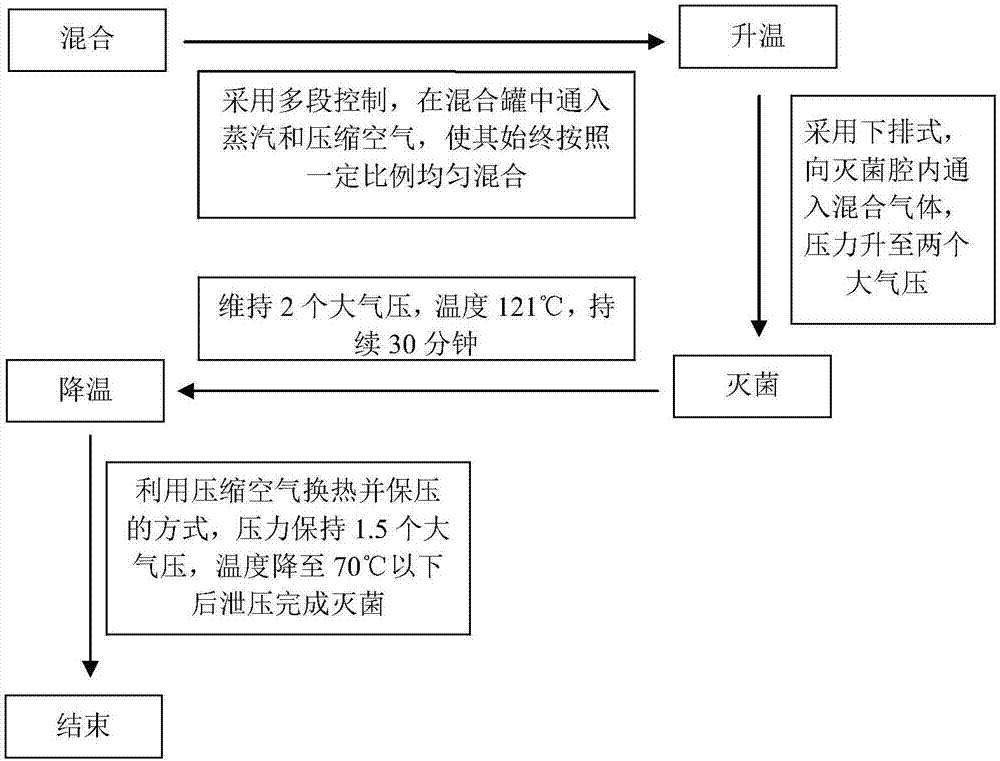

[0044] Please refer to image 3 As shown, Embodiment 2 of the present invention provides a method for sterilizing using the high-temperature sterilizer in Embodiment 1. This method is realized in this way: the mixing of steam and compressed air is carried out in a separate mixing tank, Adopt the method of segmental control of pressure and temperature, divide 0 ~ 220kPa into seven control segments, and can also be divided into other numbers of multiple control segments, each segment corresponds to a temperature value, and the control temperature and control pressure parameters of the control segment are input in advance PLC controller for subsequent automatic control. Below this temperature, the PLC controller opens the first steam inlet valve to let in steam, and above this temperature, the PLC controller opens the second inlet valve to let in compressed air, so that the steam and compressed air are always mixed in the same proportion, and the mixed gas is fully After mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com