Sterilizing method and device for jam and fruit juice which are heated directly by steam and cooled by flash evaporation

A steam and flash evaporation technology, applied in the field of food processing, can solve the problems of poor product taste and uncontrollable heating time, achieve good sensory characteristics and quality characteristics, ensure food hygiene and safety, and improve the effect of output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below by means of examples, and the present invention is not limited to the scope of the examples.

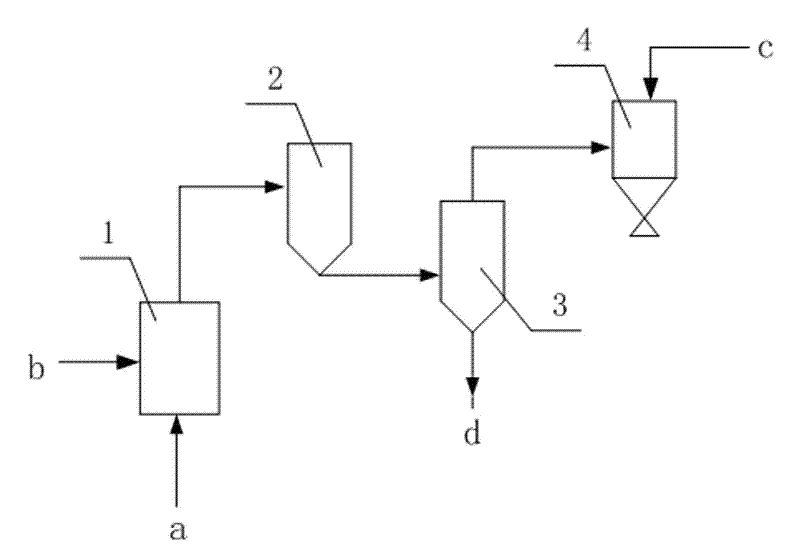

[0039] Such as figure 1 Shown, a kind of steam direct heating and flash cooling jam, fruit juice sterilizing device, it comprises sequentially connected steam injection heater 1, holding tank 2, flash cooler 3 and steam jet vacuum pump 4, on the holding tank 2 A liquid level control device is provided for adjusting the liquid level of the material in the holding tank 2 to control the heat preservation time of the material.

[0040] A kind of steam direct heating and the ketchup sterilization method of flash cooling, it comprises the following steps:

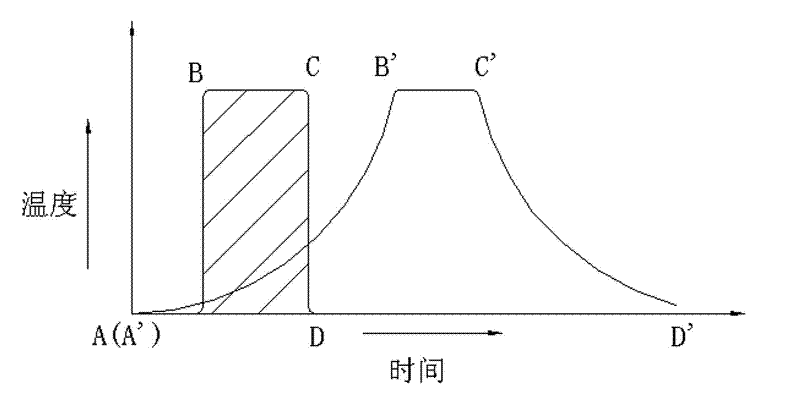

[0041] Step 1), tomato paste raw material is sent into steam injection heater 1 through port a, steam is sent into steam injection heater 1 through port b, tomato paste raw material and steam are directly mixed in steam injection heater 1, through Mix two media with differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com