Multi-stage modified thermoplastic starch master batch and application thereof in preparation of starch-based biodegradable film

A thermoplastic starch and biodegradable resin technology, applied in the field of starch-based biodegradable films, can solve problems such as poor compatibility, impact on mechanical properties and film blowing efficiency, and poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0052] The preparation method of thermoplastic starch masterbatch, its step comprises:

[0053] (1) Take 100 parts of starch, adjust the starch to a water content of 22%, add 3 parts of oxidized starch and 4 parts of hydroxypropyl starch, and carry out the first high-speed stirring at room temperature;

[0054] (2) Raise the temperature to 50-70°C, add a part of additives, and carry out the second high-speed stirring;

[0055] (3) Heat up to 75-95°C, add the remaining additives, and perform the third high-speed stirring;

[0056] (4) Add the biodegradable resin for the masterbatch, and carry out the fourth high-speed stirring;

[0057] (5) stop stirring, heat preservation treatment;

[0058] (6) The starch after heat preservation is melted and extruded to make thermoplastic starch masterbatch.

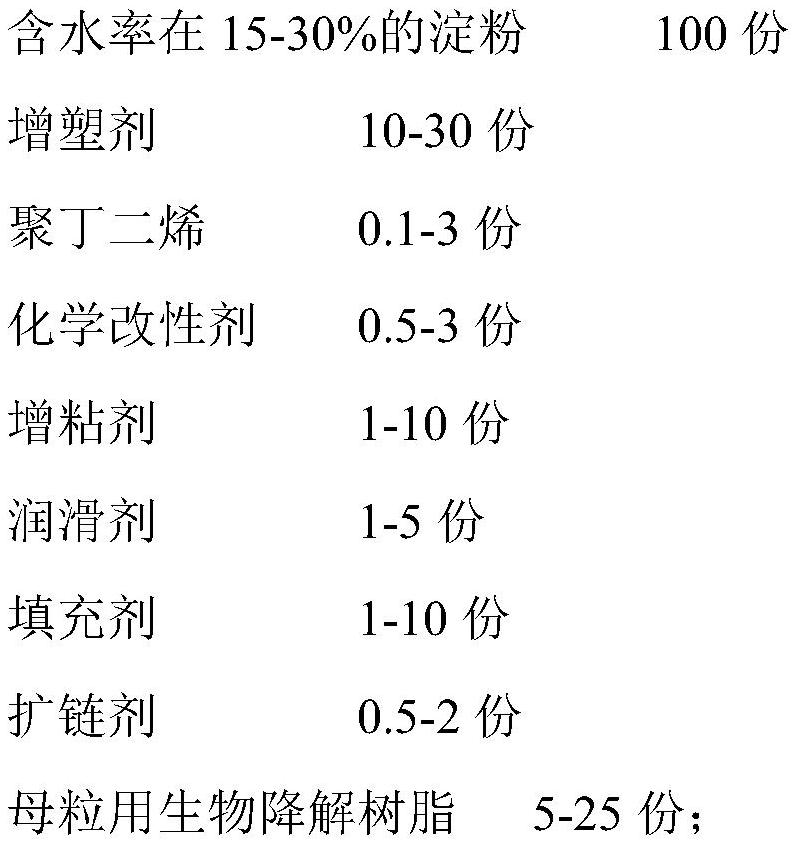

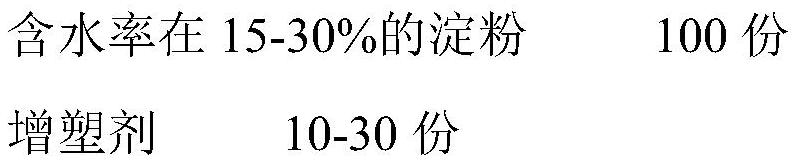

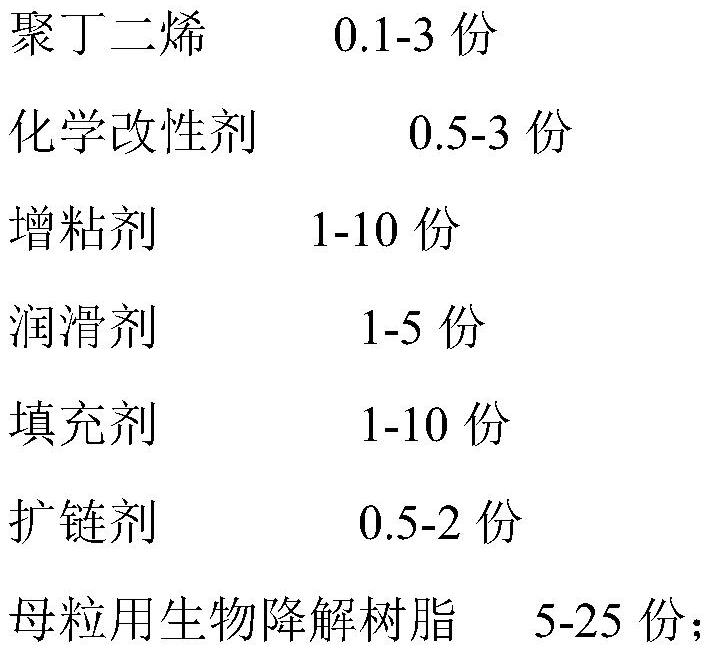

[0059] Wherein the list of ingredients is as shown in Table 1, all in Table 1 are parts by weight, and the process parameters of each step are as shown in Table 2.

[0060] Wherein...

Embodiment 9-16

[0069] The thermoplastic starch masterbatches obtained in Examples 1-8 were respectively made into starch-based biodegradable films. The steps were: blending 60 parts of thermoplastic starch masterbatches with 25 parts of PBSA and 20 parts of PBAT, and the film blowing temperature was 165°C. The inflation ratio is 4:1, and the starch-based biodegradable film is prepared by blow molding. The PBSA used therein is consistent with the PBSA added in the thermoplastic starch masterbatch.

[0070] The prepared starch-based biodegradable film was tested, and the test results are shown in Table 3. Test method: GB / T1040.3-2006.

[0071] The detection result of table 3 embodiment 9-16

[0072]

Embodiment 17-22

[0074] The preparation method of thermoplastic starch masterbatch, its step comprises:

[0075] (1) Take 100 parts of starch and partially modified starch, adjust the starch to a water content of 15-30%, and carry out the first high-speed stirring at room temperature, with a rotating speed of 900 rpm for 4 minutes;

[0076] (2) Heat up to 60°C, add 13 parts of glycerin, 2.6 parts of sorbitol, 1 part of hydroxyl-terminated polybutadiene, 1 part of epoxidized polybutadiene, 0.8 parts of maleic anhydride, 0.5 parts of citric acid, methyl 0.8 part of glycidyl acrylate, carry out the second high-speed stirring, the rotating speed is 1200 rev / min, and the time is 15 minutes;

[0077] (3) Heat up to 85°C, add 4 parts of polyvinyl acetate, 2 parts of ethylene-ethyl acrylate copolymer, 3 parts of calcium stearate, 3 parts of talcum powder, 3 parts of calcium carbonate, and 1.2 parts of isocyanate chain extender , carry out the third high-speed stirring, the rotating speed is 1000 rpm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com