Tear-resistant polyethylene film, composite membrane and preparation method thereof

A polyethylene film and tear-resistant technology, which is applied in the field of film materials, can solve the problems that the tear resistance cannot meet the packaging requirements, and achieve the effects of extending product shelf life, improving composite strength, and excellent moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

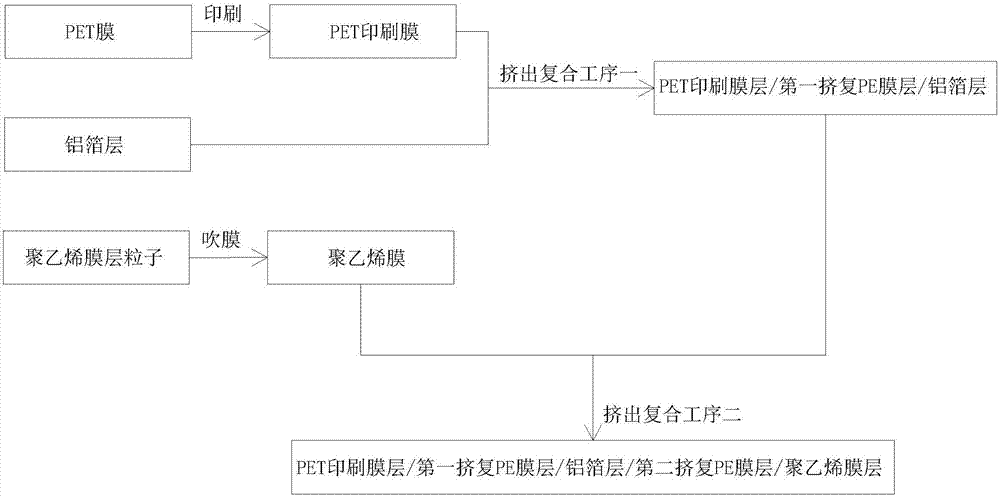

Method used

Image

Examples

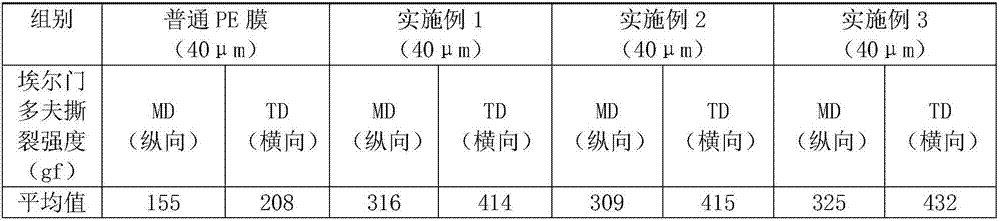

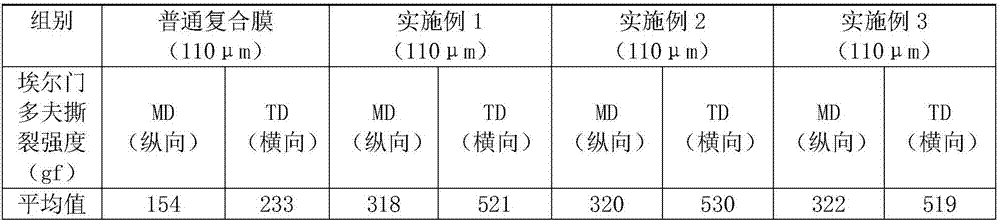

Embodiment 1

[0033] The composite film for high-resistance, moisture-resistant and tear-resistant powder packaging of the present invention is composed of a PET printing film layer, a first extruded PE film layer, an aluminum foil layer, a second extruded PE film layer and a polyethylene film laminated sequentially along the thickness direction of the film layer. layer composition;

[0034] The polyethylene film layer is made of polyethylene film, including a corona layer, an intermediate layer and a heat-sealing layer, and the corona layer and the intermediate layer are respectively composed of the first metallocene PE, eight Composed of carbon LLDPE and processing aids, the heat-sealing layer is composed of the first metallocene PE, the second metallocene PE, silicone, slippery agent and opening agent with a mass ratio of 45:20:1.9:2.3:1.5;

[0035] The extruded PE film layer includes a first adhesive layer bonded to the aluminum foil layer and a second adhesive layer bonded to the PET p...

Embodiment 2

[0039] The composite film for high-resistance, moisture-resistant and tear-resistant powder packaging of the present invention is composed of a PET printing film layer, a first extruded PE film layer, an aluminum foil layer, a second extruded PE film layer and a polyethylene film laminated sequentially along the thickness direction of the film layer. layer composition;

[0040] The polyethylene film layer is made of polyethylene film, including a corona layer, an intermediate layer and a heat-sealing layer, and the corona layer and the intermediate layer are respectively composed of the first metallocene PE, eight Composed of carbon LLDPE and processing aids, the heat-sealing layer is composed of the first metallocene PE, the second metallocene PE, silicone, slippery agent and anti-blocking agent with a mass ratio of 55:30:2.3:2.7:1.9;

[0041] The extruded PE film layer includes a first adhesive layer bonded to the aluminum foil layer and a second adhesive layer bonded to the...

Embodiment 3

[0045] The composite film for high-resistance, moisture-resistant and tear-resistant powder packaging of the present invention is composed of a PET printing film layer, a first extruded PE film layer, an aluminum foil layer, a second extruded PE film layer and a polyethylene film laminated sequentially along the thickness direction of the film layer. layer composition;

[0046] The polyethylene film layer is made of polyethylene film, including a corona layer, an intermediate layer and a heat-sealing layer, and the corona layer and the intermediate layer are respectively composed of the first metallocene PE, eight Composed of carbon LLDPE and processing aids, the heat-sealing layer is composed of the first metallocene PE, the second metallocene PE, silicone, slippery agent and opening agent with a mass ratio of 50:25:2.1:2.5:1.7;

[0047] The extruded PE film layer includes a first adhesive layer bonded to the aluminum foil layer and a second adhesive layer bonded to the PET p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com