Upstream pumping machinery sealing ring with multiple stages of helical grooves

A mechanical seal and spiral groove technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of limited bearing capacity or ability to maintain non-contact, end face wear and service life, poor start-stop effect, etc., to ensure The effect of long-term stable operation, reducing the degree of friction and wear, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

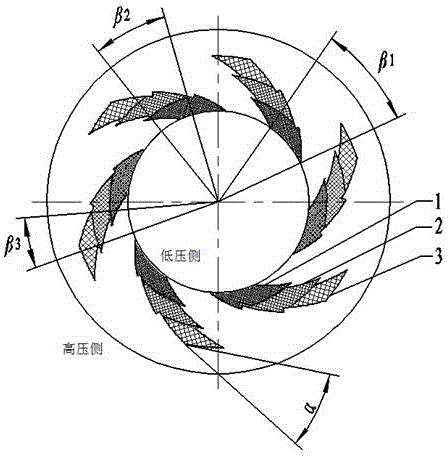

[0022] Such as Figure 1-3 As shown, an upstream pumping mechanical seal ring with three-stage spiral grooves, the outer diameter side of the end face of the seal ring is the high-pressure side, the inner diameter side is the low-pressure side, and there are six three-point grooves evenly distributed along the circumference of the end face on the end face of the seal ring. The first-stage spiral groove, the third-stage spiral groove opens on the low-pressure side of the end face, and the ungrooved area on the end face of the sealing ring forms a sealing dam;

[0023] Each of the three-stage spiral grooves is composed of logarithmic helices with equal helix angles, and the helix angle α is 15°;

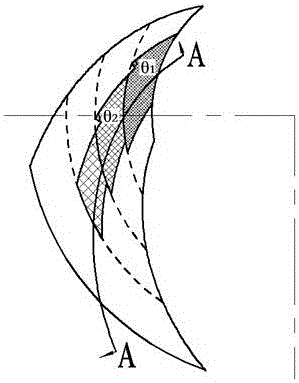

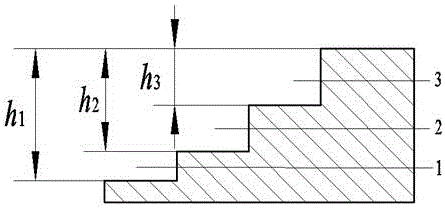

[0024] The circumferential width of the three-stage spiral groove decreases step by step from the low-pressure side to the high-pressure side, forming a convergence gap; the junction of the first-stage spiral groove 1 and the second-stage spiral groove 2 faces the side of the high-pre...

Embodiment 2

[0030] An upstream pumping mechanical seal ring with multi-stage spiral grooves. The outer diameter side of the end face of the seal ring is the high-pressure side, and the inner diameter side is the low-pressure side. There are 10 four-stage spiral grooves evenly distributed along the circumference of the end face on the end face of the seal ring. , the four-stage spiral groove opens on the low-pressure side of the end face, and the ungrooved area on the end face of the seal ring forms a seal dam;

[0031] Each level of helical grooves in the four-stage helical grooves is composed of logarithmic helixes with equal helix angles, and the helix angle is -15 °, that is, the helix direction of the logarithmic helix is opposite to that of embodiment 1;

[0032] The circumferential width of the four-stage spiral groove gradually decreases from the low-pressure side to the high-pressure side to form a convergence gap; the junction of the first-stage spiral groove and the second-stag...

Embodiment 3

[0038] An upstream pumping mechanical seal ring with multi-stage spiral grooves. The outer diameter side of the end face of the seal ring is the high-pressure side, and the inner diameter side is the low-pressure side. There are 15 eight-stage spiral grooves evenly distributed along the circumference of the end face on the end face of the seal ring. , the eight-stage spiral groove opens on the low-pressure side of the end face, and the ungrooved area on the end face of the seal ring forms a seal dam;

[0039] Each of the eight-stage spiral grooves is composed of logarithmic helixes with equal helix angles, and the helix angle is -15 °, that is, the helix direction of the logarithmic helix is opposite to that of Embodiment 1;

[0040] The circumferential width of the eight-stage spiral groove gradually decreases from the low-pressure side to the high-pressure side, forming a convergence gap; the junction of the first-stage spiral groove and the second-stage spiral groove faces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com