PE blown film for liquid packaging and preparation method thereof

A technology for blown film and packaging, which is applied in the field of PE blown film for liquid packaging and its preparation. It can solve the problems of high packaging cost and transportation cost, low dart impact performance, and weak right-angle tear strength. Rapid antistatic effect, lower coefficient of friction, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

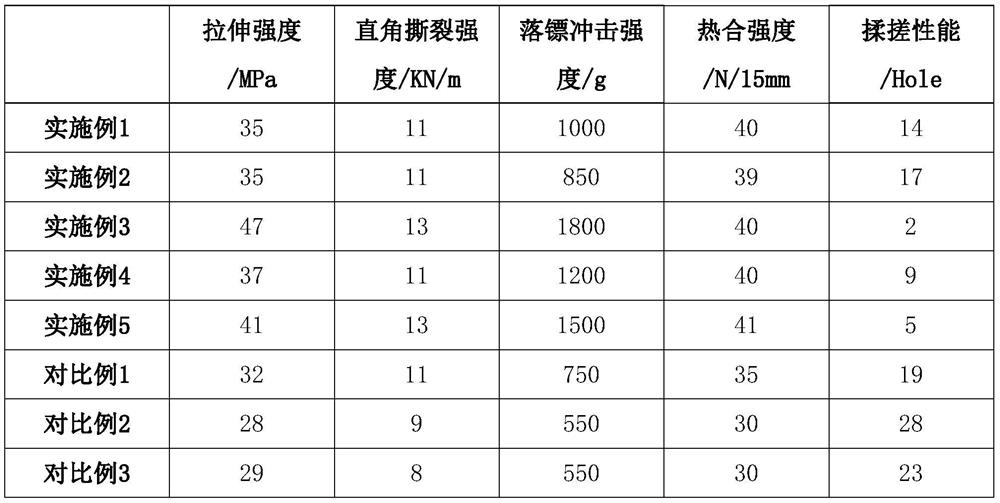

Examples

Embodiment 1

[0037] The PE blown film for liquid packaging in this embodiment is made of the following raw materials: metallocene polyethylene MPE-5400G 70kg, linear low density polyethylene LLDPE-LL0209AA 20kg, low density polyethylene LDPE-2100TN00 10kg , erucamide 0.5kg, phosphate ester 0.6kg.

[0038] A kind of preparation method of PE blown film for liquid packaging of the present embodiment comprises the following steps:

[0039] S1. Put 25kg of metallocene polyethylene, 5kg of linear low density polyethylene, 0.25kg of erucamide, and 0.3kg of phosphate into the inner and outer layer mixers of the 3-layer co-extrusion blown film equipment, and mix and stir for 30 minutes , and then obtain uniformly mixed particles;

[0040] S2. Put 20kg of metallocene polyethylene, 10kg of linear low-density polyethylene, and 10kg of low-density polyethylene in the middle layer mixer of the 3-layer co-extrusion blown film equipment, mix and stir for 30 minutes, and then obtain uniformly mixed partic...

Embodiment 2

[0044] The PE blown film for liquid packaging in this embodiment is made of the following raw materials: metallocene polyethylene MPE-5400G is 50 kg, linear low density polyethylene LLDPE-LL0209AA is 25 kg, and low density polyethylene LDPE-2100TN00 is 25 kg , erucamide 0.6kg, phosphate ester 0.6kg.

[0045] A preparation method of a PE blown film for liquid packaging provided in this embodiment comprises the following steps:

[0046] S1. Put 25kg of metallocene polyethylene, 5kg of linear low density polyethylene, 0.3kg of erucamide, and 0.3kg of phosphate into the inner and outer layer mixers of the 3-layer co-extrusion blown film equipment, and mix and stir for 30 minutes , and then obtain uniformly mixed particles;

[0047] S2, 15kg of linear low density polyethylene and 25kg of low density polyethylene are respectively placed in the middle layer mixer of the 3-layer co-extrusion blown film equipment, mixed and stirred for 30 minutes, and then uniformly mixed particles ar...

Embodiment 3

[0051] The PE blown film for liquid packaging of this embodiment is made of the following raw materials: metallocene polyethylene MPE-8656 counts 80 kg, linear low density polyethylene LLDPE-LL0209AA counts 10 kg, low density polyethylene LDPE-2100TN00 counts 10 kg , erucamide 0.3kg, phosphate ester 0.4kg.

[0052] A preparation method of a PE blown film for liquid packaging provided in this embodiment comprises the following steps:

[0053] S1, specifically including the following steps:

[0054] S11, respectively place 20kg of metallocene polyethylene, 0.15kg of erucamide, and 0.2kg of phosphoric acid ester in the inner and outer layer mixers of the 5-layer co-extrusion blown film equipment, mix and stir for 30 minutes, and then obtain a uniform mixture particles;

[0055] S12, respectively place 20kg of metallocene polyethylene in the second inner and second outer layer mixers of the 5-layer co-extrusion blown film equipment, mix and stir for 30 minutes, and then obtain u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com