Bio-based high gloss vegan leather and manufacturing method thereof

A manufacturing method and high gloss technology, applied in pulp beating method, paper making, calender and other directions, can solve the problems of high gloss, surface smoothness of vegan leather, gloss not as good as genuine leather, inability to make texture, etc. To achieve the effect of simple preparation process, improved gloss and smoothness, and tight integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

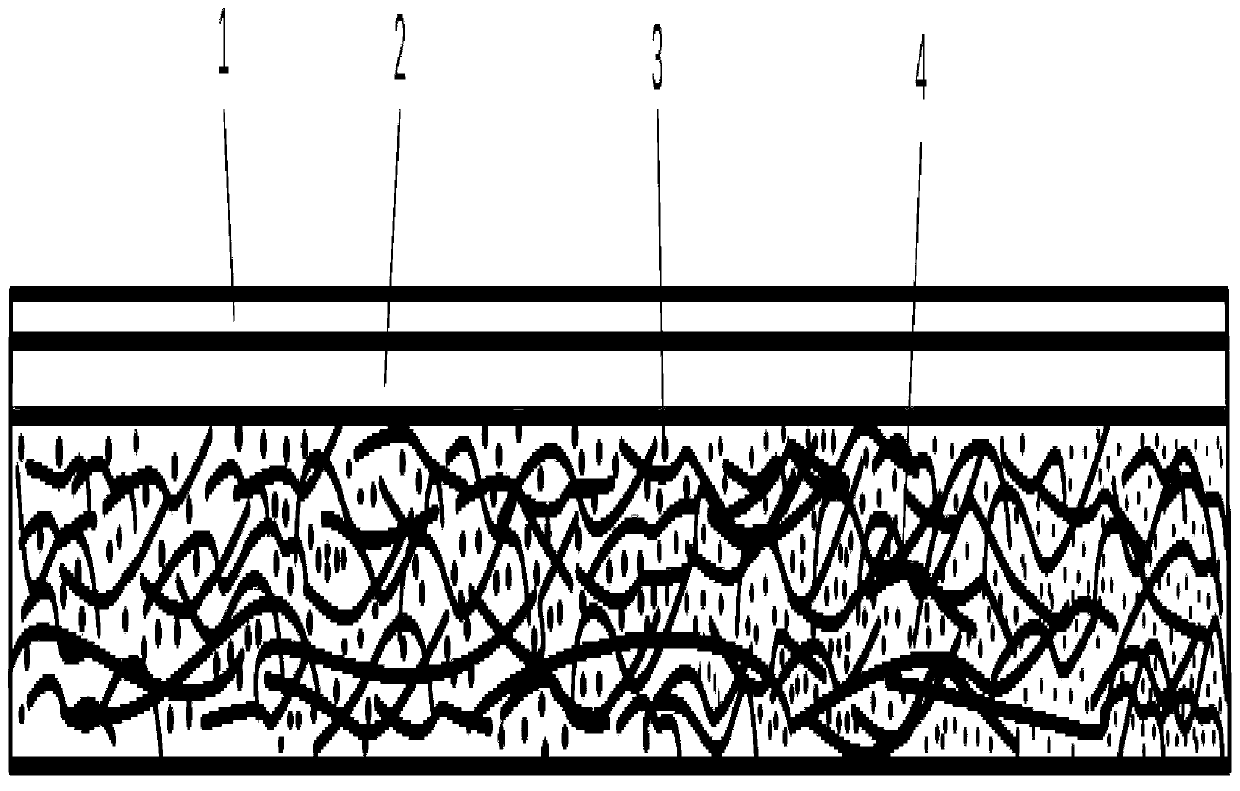

Image

Examples

Embodiment 1

[0032] A method for manufacturing bio-based high-gloss vegan leather, comprising the following steps:

[0033] (1) Select coniferous wood pulp to be beaten by disc grinding until its beating degree is 30 ° SR, then transported to the headbox, and then sent to the wire section of the paper machine for dehydration and molding through the headbox to obtain vegan leather sheets, quantitatively 150 g / m 2 , pressed after dehydration, the pressing pressure is 500KN / m, dried in the dryer after pressing, the drying temperature is 70°C, and the vegan leather base is obtained after drying;

[0034] (2) Transport the vegan leather base described in step (1) to a sizing machine for sizing, select polylactic acid as the sizing agent, and the sizing amount is 100g / m 2 , after drying with hot air at 60°C, perform the first polishing treatment, the pressure of the polishing roller in the first polishing treatment is 30KN / m, and the rolling speed of the polishing roller in the first polishing ...

Embodiment 2

[0037] A method for manufacturing bio-based high-gloss vegan leather, comprising the following steps:

[0038] (1) Select the coniferous wood pulp and beat it through disc grinding until its beating degree is 60 ° SR, then transport it to the headbox, and then spray it to the wire part of the paper machine for dehydration and forming to obtain vegan leather sheets, quantitatively 450 g / m 2 , pressed after dehydration, the pressing pressure is 800KN / m, dried in the dryer after pressing, the drying temperature is 120°C, and the vegan leather base is obtained after drying;

[0039] (2) Transport the vegan leather base described in step (1) to a sizing machine for sizing, select alkyd resin as the sizing agent, and the sizing amount is 200g / m 2 , after drying with hot air at 80°C, perform the first polishing treatment, the polishing roller pressure of the first polishing treatment is 40KN / m, and the polishing roller speed of the first polishing treatment is 350r / min; then transpo...

Embodiment 3

[0042] A method for manufacturing bio-based high-gloss vegan leather, comprising the following steps:

[0043] (1) Select coniferous wood pulp to be beaten by disc grinding until its beating degree is 45°SR, then transported to the headbox, and then sent to the wire section of the paper machine for dehydration and forming through the headbox to obtain vegan leather sheets, quantitatively 300 g / m 2 , pressed after dehydration, the pressing pressure is 650KN / m, after pressing, the dryer is dried at a drying temperature of 95°C, and the vegan leather base is obtained after drying;

[0044] (2) Transport the vegan leather substrate described in step (1) to a sizing machine for sizing, and select polyhydroxy fatty acid ester as the sizing agent, and the sizing amount is 150g / m 2 After drying with hot air at 70°C, perform the first polishing treatment, the pressure of the polishing roller for the first polishing treatment is 50KN / m, and the rolling speed of the polishing roller for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com