Multiple-effect softening and lubricating agent for textile fabrics as well as preparation method and use thereof

A technology of softening agent and auxiliaries, applied in the field of fabric treatment and textile, can solve the problems of affecting the smoothness, extensibility and elasticity of fibers, unable to be scrapped, aggravating the damage of fabrics or textiles, etc., and achieve the prospect of large industrialization and market value. Wide range of health-protecting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

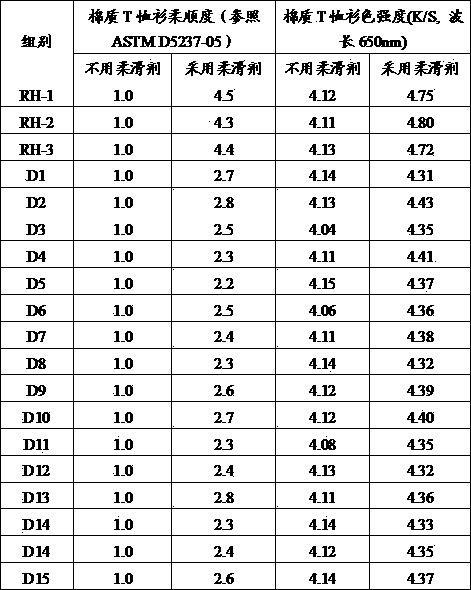

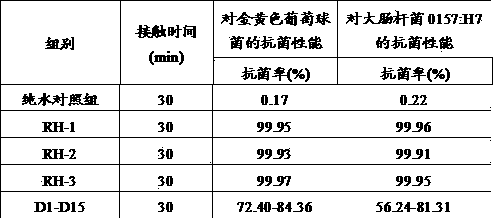

Examples

Embodiment 1

[0037] (1) Weigh 10 g bistallow ethyl ethyl hydroxyethyl methyl ammonium methyl sulfate, 3 g double polyethylene polydimethylsiloxane, 8 g glyceryl monostearate, 2 g epoxy Chloropropane and 12 g of polyethylene glycol 2000 were mixed evenly at room temperature, then heated to 35°C in a water bath at a rate of 2°C / min and stirred for 10 min, and then heated to 45°C at a rate of 2°C / min. Stir at ℃ for 20 minutes, and finally react at 60℃ with a heating rate of 2℃ / min and keep warm for 60 minutes to obtain an intermediate mixture;

[0038](2) Add 5 g trehalose, 0.5 g zinc pyrithione, 0.3 g nano-silica, 0.3 g nano-silver, 6 g sodium hydroxycellulose and 10 g pentaerythritol triacrylate to the intermediate mixture, and then add 2 Slowly cool down to 30°C at a cooling rate of °C / min, stir for 2 h, continue to add 2 g sorbitol, 2 g glycerin, 2 g rhamnosyl ester, 3 g copper abietate, 3 g resveratrol triphosphate Trisodium and 65 g of water were naturally cooled to room temperature an...

Embodiment 2

[0040] (1) Weigh 15 g bistallow ethyl ethyl hydroxyethyl methyl ammonium methyl sulfate, 5 g double polyethylene polydimethylsiloxane, 5 g glyceryl monostearate, 3 g epoxy Chloropropane and 15 g polyethylene glycol 2000 were mixed evenly at room temperature, then heated to 40°C in a water bath at a heating rate of 3°C / min and stirred for 5 min, and then heated to 50°C at a heating rate of 3°C / min Stir at ℃ for 10 min, and finally raise the temperature to 80 °C at a heating rate of 3 °C / min and keep the temperature for 40 min to obtain an intermediate mixture;

[0041] (2) Add 1 g trehalose, 1.5 g zinc pyrithione, 0.4 g nano-silica, 0.4 g nano-silver, 10 g sodium hydroxycellulose and 5 g pentaerythritol triacrylate to the intermediate mixture, and then add 3 g Slowly cool down to 40°C at a cooling rate of °C / min, stir for 1.5 h, and continue to add 1 g sorbitol, 1 g glycerin, 1 g rhamnolate, 4 g copper abietate, and 4 g resveratrol triphosphate Trisodium and 70 g of water were...

Embodiment 3

[0043] (1) Weigh 12 g bistallow ethyl ethyl hydroxyethyl methyl ammonium methyl sulfate, 2 g double polyethylene polydimethylsiloxane, 10 g glyceryl monostearate, 1.5 g epoxy Chloropropane and 10 g of polyethylene glycol 2000 were mixed evenly at room temperature, then heated to 37°C in a water bath at a heating rate of 2°C / min and stirred for 8 min, and then heated to 48°C at a heating rate of 2°C / min. Stir at ℃ for 15 minutes, and finally raise the temperature to 70℃ at a heating rate of 2℃ / min and keep it warm for 50 minutes to obtain an intermediate mixture;

[0044] (2) Add 3 g trehalose, 2.5 g pyrithione zinc, 0.5 g nano-silica, 0.5 g nano-silver, 5 g sodium hydroxycellulose and 7 g pentaerythritol triacrylate to the intermediate mixture, and then add 2 g Slowly cool down to 35°C at a cooling rate of °C / min, stir for 2 h, continue to add 2.5 g sorbitol, 2.5 g glycerin, 2.5 g rhamnolate, 2 g copper abietate, 2 g resveratrol triphosphate Trisodium and 65 g of water were n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com